Академический Документы

Профессиональный Документы

Культура Документы

3 Phase Sizing

Загружено:

c_nghiaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3 Phase Sizing

Загружено:

c_nghiaАвторское право:

Доступные форматы

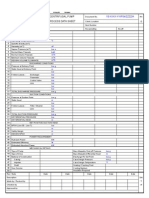

Project Name

PO No

Unit Code

Discipline

Doc. Type

Seria N

Rev

P

Revision

CALCULATION NOTE

Page

Date

Originator

NTN

1 of 2

Checked By

SEPARATOR THREE PHASE WITH BOOT

Approved by

1

INPUT

OUTPUT

2

3 Feed

4

5

6

7

8

9

10

Flow (kg/hr)

Density (kg/m3)

Viscocity (cP)

Droplet size ( )

Droplet size ( )

Droplet size ( )

Gas

Oil

Water

0.6

3.57

0.01

102125.00

646.3

0.27

150

150

3000

1000

1.79

Oil in Gas

Oil in Water

Water in Oil

2

11 v2 max for inlet nozzle (kg/m.s )

2

12 v2 max for gas outlet nozzle (kg/m.s )

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Max velocity in Oil outlet (m/s)

Max velocity in Water outlet (m/s)

K value (m/s) per GPSA

Mixture Density

SETTLING VELOCITY CRITERIA

Max. Allowable Gas Velocity (m/s)

Gas Velocity (m/s)

Oil droplet velocity (m/s) - Gravity settling method

Oil from Gas

Water from Oil

Oil from Water

DROPLET FALL TIME

Oil in Gas

(Top-Liquid)

Water in Oil

(NIL to Btm of Shell)

Oil in Water

(NIL to Btm of Boot)

Length/Diameter

2.5

Boot Dia./Shelle Diameter

0.2

Boot Hieght./Boot Diameter

2.8

105126 kg/hr

3

161.18 Am /hr

35 Qmix =

36

37 D > =

193.88

38 horizontal pipe nozzle

39

40

41

42

2550

Specified

Actual

mins

60

(mins)

3210.1

Shell

HLL - HLSD

NLL - HLL

2

2

2.38

4.98

OK!

OK!

1500

NLL -LLL

7.34

OK!

3750

1

1

0.108

652.21

LLL - LLSD

LSD to Outlet

Oil Resistent Time at NLL

2

1

6

2.23

1.19

10.76

OK!

OK!

OK!

Boot

HIL - HILSD

1

NIL - HIL

2.5

NIL - LIL

2.5

LIL - LILSD

1

LILSD to Outlet

1

Oil Resistent time (NIL of boot to Btm of Shell)

Water Resistent time ( Btm to NIL)

1.45 m/s

4E-06 m/s

0.33

m/s

0.012

m/s

0.0024 m/s

0.0329 min

1.0665 min

11.737 min

Wg =

Qg

7500

3000

mm

0.6

0.168067227

kg/h

Am3/h

mm

GAS

I.D =

**Warning**

OK!

OK!

OK!

OK!

OK!

1.03

7.19

7.81

3.48

1.33

10.76

12.61

OK!

OK!

OK!

OK

**Warning**

150

LENGTH T/T =

Wmix

Resistent Times

HLSD

HLL

NLL

LLL

LLSD

Height

2350

2050

1500

650

300

Gas volume

HLL to HLSD

NLL to HLL

LLL to NLL

LLSD to LLL

Btm to LLSD

Volume (m3)

8.99

6.26

13.11

19.33

5.87

3.12

OIL

43

44

45

46

47

48

Boot Height

600

Volume (m3

HILSD

1480

HIL toHILSD

0.05

W oil =

102125.00

kg/hr

50

HIL

1380

NIL to HIL

0.36

Qoil =

158

m3/hr

51

52

53

54

55

NIL

LIL

LILSD

940

500

200

LIL to NIL

LILSD to LIL

Btm LILSD

0.39

0.17

0.07

49

1680

mm

WATER

56

57

W water

3000 kg/hr

58

Qwater

3 m3/hr

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

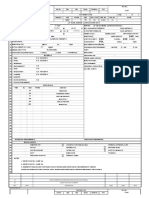

CALCULATION

K factor:

Maximum allowable Vel.

Gas Velocity

0.108

1.45

4E-06

m/s

m/s

m/s

OK

Oil in Gas (Gravity Setting law method)

Water in oil (Gravity Setting law Method)

Settling Velocity

Method for application

Settling Velocity

Method for application

Method

Stoke's Law

Intermediate

Newton's Law

0.33

Intermediate

Kcr

0.025

0.334

18.13

Vt (m/s)

0.78

0.33

0.89

Maximum Dp m

54

719

39021

Vt (m/s)

0.0024

0.01

0.05

Maximum Dp

369

4925

267349

Oil in Water (Gravity Setting law Method)

Settling Velocity

Method for application

Method

Stoke's Law

Intermediate

Newton's Law

0.0024

Stoke's Law

Kcr

0.025

0.334

18.13

Method

Stoke's Law

Intermediate

Newton's Law

Kcr

0.025

0.334

18.13

0.012

Intermediate

Vt (m/s)

0.02

0.01

0.05

Maximum Dp

104

1396

75756

Project Name

PO No

Unit Code

Discipline

Doc. Type

Seria N

Rev

P

CALCULATION NOTE

SEPARATOR THREE PHASE WITH WEIR

Ze

Revision

Date

Originator

Checked By

Approved by

Page

f(Ze)

1 0.01

0.004672

2 0.02

0.007250

3 0.03

0.010368

4 0.04

0.014014

5 0.05

0.018176

6 0.06

0.022842

7 0.07

0.028000

b

L

b

8 0.08

0.033638

9 0.09

0.039744

10 0.10

0.046306

11 0.11

0.053312

12 0.12

0.060750

D

13 0.13

0.068608

14 0.14

0.076874

15 0.15

0.085536

H1

16 0.16

0.094582

17 0.17

0.104000

18 0.18

0.113778

19 0.19

0.123904

20 0.20

0.134366

TOTAL VOLUME = Volume in 2 heads + Volume in cylinder

21 0.21

0.145152

= 1 / 6 p K D3 +1 / 4 p D2 L

22 0.22

0.156250

K = 2b / D

Ze = H1 / D

Zc = H1 / D

23 0.23

0.167684

PARTIAL VOLUME = (1 / 6 p K D3) * f(Ze) + (1 / 4 p D2 L) * f(Zc)

24 0.24

0.179334

f(Ze) = Ellipsoidal Coefficient

25 0.25

0.191296

f(Zc) = Horizontal cylinder coefficient.

26 0.26

0.203522

For elliptical heads, b = 0.25 * D and K = 0.5

27 0.27

0.216000

28 0.28

0.228718

29 0.29

0.241664

30 0.30

0.254826

31 0.31

0.268192

32 0.32

0.281750

33 0.33

0.295488

34 0.34

0.309394

35 0.35

0.323456

Ze

f(ze)

End

Volume (m3)

36 0.36

0.337662

=H1 /D

=H1 /D

37 0.37

0.352000

38 0.38

0.366458

39 0.39

0.381024

TOTAL Cross Sectional Area

1.00

1

3.53

40 0.40

0.395686

GAS (Volume to Top)

0.216666667

0.16

0.55

41 0.41

0.410432

HLSD TO TOP

42 0.42

0.425250

43 0.43

0.440128

STORAGE (Volume from Bottom)

44 0.47

0.455054

Horizontal vessel

45 0.48

0.470016

HLSD

0.783333333

0.89

3.13

46 0.49

0.485002

HIL

0.683333333

0.77

2.73

47 0.50

0.500000

NIL

0.5

0.51

1.82

48 0.51

0.514998

LIL

0.216666667

0.16

0.55

49 0.52

0.529984

LILSD

0.1

0.05

0.19

50 0.53

0.544946

Boot Volume

0.88

0.97

0.60

51 0.54

0.559872

HILSD

52 0.55

0.574750

HIL

0.82

0.92

0.57

53 0.56

0.589568

NIL

0.56

0.57

0.36

54 0.57

0.604314

LIL

0.30

0.25

0.16

55 0.58

0.618976

LILSD

0.12

0.05

0.03

56 0.59

0.633542

Total volume Boot

1.00

1.00

0.62

57 0.60

0.648000

58 0.61

0.662338

59 0.62

0.676544

60 0.63

0.690606

61 0.64

0.704512

TOTAL Cross Sectional Area of horizontal vessel

Fraction

Chord

Cylinder

62 0.65

0.718250

74.22

of Dia.

Chord

Volume Incrment

Fraction

Area (m2)

partial

63 0.66

0.731808

=H1 /D

(Radian)

(m3)

f(Zc)

Volume (m3) Partial Volume + End

64 0.67

0.745174

GAS (Volume to Top)

Zc

Volume Volume (m3)

65 0.68

0.758336

66 0.69

0.771282

WEIR TO TOP (Left side of weir)

0.22

1.94

0.16

11.85

8.44

8.99

8.99

67 0.70

0.784000

STORAGE (Volume from Bottom)

68 0.71

0.796478

Left side of weir

69 0.72

0.808704

WEIR

0.78

4.35

0.84

62.37

44.57

47.70

6.26

70 0.73

0.820666

HIL

0.68

3.89

0.73

54.04

38.71

41.44

13.11

71 0.74

0.832352

NIL

0.50

3.14

0.50

37.11

26.50

28.32

19.33

72 0.75

0.843750

LIL

0.22

1.94

0.16

11.85

8.44

8.99

5.87

73 0.76

0.854848

LILSD

0.10

1.29

0.06

3.86

2.94

3.12

3.12

74 0.77

0.865634

Boot Volume

0.88

4.87

0.93

3.02

0.44

1.04

0.05

75 0.78

0.876096

HILSD

76 0.79

0.886222

HIL

0.82

4.54

0.88

2.85

0.42

0.99

0.36

77 0.80

0.896000

NIL

0.56

3.38

0.58

1.86

0.27

0.63

0.39

78 0.81

0.905418

LIL

0.23

2.00

0.17

0.56

0.08

0.24

0.17

79 0.82

0.914464

LILSD

0.12

1.41

0.07

0.22

0.03

0.07

0.07

80 0.83

0.923126

Total Volume Boot

1.00

6.28

1.00

3.24

0.48

1.10

1.10

81 0.84

0.931392

Total Cross Section Area Boot

82 0.85

0.939250

3.2374

83 0.86

0.946688

84 0.87

0.953694

85 0.88

0.960256

86 0.89

0.966362

87 0.90

0.972000

88 0.91

0.977158

89 0.92

0.981824

90 0.93

0.985986

91 0.94

0.989632

92 0.95

0.992750

93 0.96

0.995328

94 0.97

0.997354

95 0.98

0.998816

96 0.99

0.999702

97 1.00

1.000000

98

99 NOTED

100 1. Sizing must ensure time for oil in gas at gas nozzle, oil in water at water outlet and water in oil at weir.

101

102

103

104

105

Вам также может понравиться

- Etoos Solid State PS SirДокумент27 страницEtoos Solid State PS SirGyandeep KalitaОценок пока нет

- Jan 98Документ30 страницJan 98c_nghiaОценок пока нет

- Compressor Settle Out PressureДокумент1 страницаCompressor Settle Out PressureAhmed GattoufiОценок пока нет

- Separator DesignДокумент3 страницыSeparator DesignprabhuarunkumarОценок пока нет

- Liquid - Gas Phase SizingДокумент12 страницLiquid - Gas Phase Sizingeke23Оценок пока нет

- Horizontal SeparatorДокумент16 страницHorizontal SeparatorMaryJane Ayisha Sado-Obah100% (1)

- Spreadsheet To Design SeparatorsДокумент21 страницаSpreadsheet To Design SeparatorsreninbabaskiОценок пока нет

- Hydraulic CalculationsДокумент20 страницHydraulic CalculationsJayesh ChandranОценок пока нет

- 3 Phase - Overflow WeirДокумент5 страниц3 Phase - Overflow WeirAnonymous R23prjoKnoОценок пока нет

- AQA GCSE Chemistry AnswersДокумент14 страницAQA GCSE Chemistry AnswersErvin MetushiОценок пока нет

- Poettmann Carpenter BHPДокумент5 страницPoettmann Carpenter BHPcesar_d10% (1)

- Dec 07Документ55 страницDec 07c_nghia100% (1)

- Separator Sizing and DesignДокумент44 страницыSeparator Sizing and DesignKay EenОценок пока нет

- Seperator Sizing Sheet (Ken Arnold)Документ2 страницыSeperator Sizing Sheet (Ken Arnold)Hani KirmaniОценок пока нет

- Solids CalculationsДокумент17 страницSolids Calculationsmohamed4874Оценок пока нет

- Instrument Signal LineДокумент62 страницыInstrument Signal Linedewking198875% (4)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Документ2 страницыMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqОценок пока нет

- Anchor Bolts Design of Headed Anchor BoltsДокумент12 страницAnchor Bolts Design of Headed Anchor BoltsDoug LambОценок пока нет

- 3 PhaseДокумент7 страниц3 PhaseMufleh IdrisОценок пока нет

- Cvts - Tag No. Mpt-tv-4161Документ2 страницыCvts - Tag No. Mpt-tv-4161biswasdipankar05Оценок пока нет

- Sustained Stress Indices (SSI) in The B31.3 2010 EditionДокумент9 страницSustained Stress Indices (SSI) in The B31.3 2010 Editiont_rajith1179100% (2)

- Dec 09Документ55 страницDec 09c_nghia100% (1)

- Sep 02Документ19 страницSep 02c_nghia100% (1)

- Filter Separator Revised Feb 19 2004Документ1 страницаFilter Separator Revised Feb 19 2004motalebyОценок пока нет

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsДокумент20 страницExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnОценок пока нет

- Distillation Theoretical Stages CalculatorДокумент1 557 страницDistillation Theoretical Stages Calculatorgautam_96948069Оценок пока нет

- Aug 09Документ31 страницаAug 09c_nghiaОценок пока нет

- Hydraulics - Summary: Including Cutting Weight & Tool JointДокумент5 страницHydraulics - Summary: Including Cutting Weight & Tool JointAnonymous U5t9NYzhLWОценок пока нет

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Документ12 страницLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiОценок пока нет

- Flare Ko Drum SizingДокумент5 страницFlare Ko Drum SizingSujith Sekar100% (2)

- Jan 10Документ44 страницыJan 10c_nghiaОценок пока нет

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetДокумент1 страницаCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaОценок пока нет

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpДокумент5 страницObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381Оценок пока нет

- Scrubber ManualДокумент41 страницаScrubber ManualRahul Sonkamble100% (1)

- V-102 MP Separator: Outlet NDДокумент2 страницыV-102 MP Separator: Outlet NDToyinОценок пока нет

- Sep 09Документ24 страницыSep 09c_nghia50% (2)

- Dec 09Документ24 страницыDec 09c_nghiaОценок пока нет

- Mar 09Документ30 страницMar 09c_nghia100% (1)

- Separator SizingДокумент26 страницSeparator SizingToyinОценок пока нет

- Horizontal 3 Phase Separator With Boot SizingДокумент16 страницHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- Gas/Liquids Separators - Part 3: Quantifying Separation PerformanceДокумент14 страницGas/Liquids Separators - Part 3: Quantifying Separation PerformanceWendellReeceFrankОценок пока нет

- Process Engineer - PSV SizingДокумент3 страницыProcess Engineer - PSV SizingLaorenciaОценок пока нет

- Tank Pressure During Pump OutДокумент1 страницаTank Pressure During Pump OutRexx MexxОценок пока нет

- Dec 08Документ31 страницаDec 08c_nghia100% (1)

- Power CalculationДокумент4 страницыPower CalculationGunasekaranОценок пока нет

- Flare KOD SizingДокумент4 страницыFlare KOD SizingSaid Ahmed Salem100% (1)

- Fdocuments - in Separator Sizing SpreadsheetДокумент31 страницаFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaОценок пока нет

- PSV D-103Документ24 страницыPSV D-103DIANTOROОценок пока нет

- CalculationДокумент13 страницCalculationajit kumarОценок пока нет

- C06 006 Process Calculation (02V 6010) RevEДокумент6 страницC06 006 Process Calculation (02V 6010) RevEAlphaEcc EngineeringTeamОценок пока нет

- Restriction Orifice Final CalculationДокумент1 страницаRestriction Orifice Final CalculationJasperTanОценок пока нет

- Tube Rupture (Two Phase-Omega Method) PDFДокумент1 страницаTube Rupture (Two Phase-Omega Method) PDFAmin RoisОценок пока нет

- Vertical Separator SizingДокумент8 страницVertical Separator SizingAnonymous yLPPdPwОценок пока нет

- Some Aspects of Metallurgical Assessment of Boiler Tubes-Basic Principles and Case StudiesДокумент10 страницSome Aspects of Metallurgical Assessment of Boiler Tubes-Basic Principles and Case StudiesmsdoharОценок пока нет

- Dec 98Документ25 страницDec 98c_nghia100% (1)

- Thermosyphon Reboiler (Horizontal) GPSAДокумент6 страницThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006Оценок пока нет

- Sep 02Документ44 страницыSep 02c_nghiaОценок пока нет

- ExamSlip - 148865 - 20190401 - 1520 VladДокумент23 страницыExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanОценок пока нет

- Colum Specification SheetДокумент6 страницColum Specification SheetEddy RainОценок пока нет

- Dec 08Документ45 страницDec 08c_nghia100% (1)

- T316Документ5 страницT316ANKIT SHARMA100% (1)

- Vane Mist Eliminator DesignДокумент2 страницыVane Mist Eliminator DesignEng Alf100% (1)

- DJM MBA PCS CA 011 de Butanizer Accumulator REV 1Документ6 страницDJM MBA PCS CA 011 de Butanizer Accumulator REV 1DIANTOROОценок пока нет

- Jul 98Документ38 страницJul 98c_nghia100% (2)

- Validated SheetДокумент12 страницValidated SheetrohitkushОценок пока нет

- Three Phase Horizontal SeparatorДокумент6 страницThree Phase Horizontal SeparatorHani KirmaniОценок пока нет

- Earth EvolutionДокумент37 страницEarth Evolutionkrish_mplОценок пока нет

- Centrifugal Pump CurvesДокумент2 страницыCentrifugal Pump CurvesBesan LaduОценок пока нет

- Nozzle CriteriaДокумент2 страницыNozzle CriteriaKhalil LasferОценок пока нет

- PDM-P-CS-002 - HP Prod SeparatorДокумент6 страницPDM-P-CS-002 - HP Prod Separatorfirman adiyantoОценок пока нет

- Calculation Cover SheetДокумент6 страницCalculation Cover SheetAnonymous a4Jwz14WОценок пока нет

- Electrostatic Oil - Water Treater & Desalter: Calculated AnswersДокумент2 страницыElectrostatic Oil - Water Treater & Desalter: Calculated AnswersLeonardo ChávezОценок пока нет

- DJM-MBA-PCS-CA-008 Low Temperature Separator REV-BДокумент6 страницDJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDIANTOROОценок пока нет

- Blocked OutletДокумент80 страницBlocked OutletJagan Bose100% (1)

- PTM-68-P3-CS-002 - Fuel Gas Filter - Rev.0Документ1 страницаPTM-68-P3-CS-002 - Fuel Gas Filter - Rev.0Indraharja FerryОценок пока нет

- Sizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JДокумент1 страницаSizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JekabudiartiОценок пока нет

- Dec 07Документ44 страницыDec 07c_nghiaОценок пока нет

- KIRK Sep-Calc SoftwareДокумент4 страницыKIRK Sep-Calc Softwaredhl_tuОценок пока нет

- Jan 10Документ45 страницJan 10c_nghia100% (1)

- Filter Vessel Shell VelocityДокумент12 страницFilter Vessel Shell VelocityAye KyweОценок пока нет

- The Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating MethodsДокумент4 страницыThe Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating Methodsgad48050% (2)

- Sizing Calculation - AC214312UJ - R0 PDFДокумент1 страницаSizing Calculation - AC214312UJ - R0 PDFPavendhan PavОценок пока нет

- Valve Sizing Calculation8Документ2 страницыValve Sizing Calculation8PIDОценок пока нет

- Bottomholemodaloil PCДокумент6 страницBottomholemodaloil PCKimiko ShopОценок пока нет

- Unit-4 TG Desk Engineer'S Log BookДокумент6 страницUnit-4 TG Desk Engineer'S Log BookJai GuptaОценок пока нет

- Feb 10Документ38 страницFeb 10c_nghiaОценок пока нет

- Feb 10Документ41 страницаFeb 10c_nghiaОценок пока нет

- Feb 10Документ29 страницFeb 10c_nghia100% (1)

- Feb 10Документ55 страницFeb 10c_nghiaОценок пока нет

- Jul 08Документ61 страницаJul 08c_nghiaОценок пока нет

- Feb 08Документ28 страницFeb 08c_nghiaОценок пока нет

- Petronas Technical StandardsДокумент38 страницPetronas Technical Standardsc_nghiaОценок пока нет

- Shear Strength of LateriteДокумент10 страницShear Strength of LateriteAndy UgohОценок пока нет

- The Interpretation of Incomplete Piezocone Dissipation TestsДокумент358 страницThe Interpretation of Incomplete Piezocone Dissipation Testsmaroof nahinОценок пока нет

- SOALAN BiologiДокумент12 страницSOALAN BiologiLoong Wai FamОценок пока нет

- Truss Problem 6.1 Johnston and Beer Book-Static 1-1Документ15 страницTruss Problem 6.1 Johnston and Beer Book-Static 1-1mahfuzul_haqueОценок пока нет

- Integration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmДокумент1 страницаIntegration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmMeteodyn_EnergyОценок пока нет

- Icho1986-1994p Technical and PhysicalДокумент38 страницIcho1986-1994p Technical and PhysicalAlexandra AlgueraОценок пока нет

- 4-Problems-Balancing-Rotating MassesДокумент5 страниц4-Problems-Balancing-Rotating MassesvrushОценок пока нет

- Tachi e 2004Документ12 страницTachi e 2004Ahsan Habib TanimОценок пока нет

- Line List DAR TBCДокумент3 страницыLine List DAR TBChafizszul AmirushamОценок пока нет

- Grade 7 Mixtures and Solutions Full ReviewДокумент28 страницGrade 7 Mixtures and Solutions Full Reviewblackcat657Оценок пока нет

- Manual of Metal Bellows - 0441e S 56-77!2!04!10!20 - WebДокумент11 страницManual of Metal Bellows - 0441e S 56-77!2!04!10!20 - Webadfafad gfadfОценок пока нет

- WT Chapter 6 2Документ21 страницаWT Chapter 6 2kanchanabalajiОценок пока нет

- Viado, Emmanuel Russell PДокумент27 страницViado, Emmanuel Russell PRussell ViadoОценок пока нет

- CG Industrial Product OverviewДокумент12 страницCG Industrial Product Overviewvanessa quispeОценок пока нет

- On A Stress Resultant Geometrically Exact Shell Model Part IДокумент38 страницOn A Stress Resultant Geometrically Exact Shell Model Part IzojdbergОценок пока нет

- Chapter 2 Process ControllДокумент29 страницChapter 2 Process ControllWeldush BrightОценок пока нет

- Force Relations and Dynamics of Cutting Knife in A Vertical Disc Mobile Wood Chipper - Leonardo El J Pract TechnolДокумент14 страницForce Relations and Dynamics of Cutting Knife in A Vertical Disc Mobile Wood Chipper - Leonardo El J Pract TechnolNguyenHuanОценок пока нет

- 2nd Sessional Test - Physics For Engineers-Bph-106Документ1 страница2nd Sessional Test - Physics For Engineers-Bph-106Saurabh Arya RspОценок пока нет

- Andover Standard Bandpass FiltersДокумент15 страницAndover Standard Bandpass FiltersAshish ChaturvediОценок пока нет

- Mark Scheme For Papers 1 and 2: Science TestsДокумент60 страницMark Scheme For Papers 1 and 2: Science TestsDavid MagasinОценок пока нет

- Rotational Dynamics: Physics 101Документ10 страницRotational Dynamics: Physics 101learningboxОценок пока нет

- GuidelinesДокумент15 страницGuidelinesKenn Fabre0% (1)