Академический Документы

Профессиональный Документы

Культура Документы

Cold Startup

Загружено:

Gajanan JagtapИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cold Startup

Загружено:

Gajanan JagtapАвторское право:

Доступные форматы

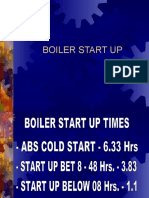

Unit Cold Start Up

Initial activities: ACW, CCW System, Instrument air and Service Air System, Cooling Tower, AHP and CHP are in Service. All Boiler vents and S/H drains are open. Clearance received for Boiler Filling. Activities 00:00 Boiler filling started with fill pump. Bottom Ash Hopper and Seal Trough filled. Run AC scanner Fan. 00:30 Start one LDO pump. Set pressure 7 kg/cm2. Start all Air Preheaters. Isolate PAHs from FG and Airside. 00:40 Start one BCW Booster pump. Charge Aux. steam header from other unit. Open AS 210 Valve. Extend aux. steam to OHP. Put HFO tank heating in service to get tank temp. 700C. 01:15 Start one HFO pump. Take one steam heater in service. Insert AB & CD oil elevation guns. Normalize the valves. Open atomizing steam valves and tracing line valves. At drum water level +300 mm start one BCW pump after closing purge and vent valves. Drum level will drop to +100 mm. 01:40 Start second BCW pump at +100 mm drum level and normalize the level. Put Boiler Fill Pump on recirculation and close filling valve. Line up air and flue gas path. Put aux. control damper on auto. Ensure turbine is on barring gear and SLC of lub oil and JOP ON. Boost H2 pressure to 3.2 kg/cm2. Purity > 98 %. Check turbovisory, bearing temp and Generator system parameters. 01:50 Start one ID fan and one FD fan. Start second ID fan and adjust airflow 700 T/Hr. Adjust Furnace draft -20 mmwcl. Start furnace purge. Purge Complete. 02:10 Open LDO trip valve. Set oil pressure 7-kg/cm2 and atomizing air pressure to 7 kg/cm2. Select LDO and air in AB elevation and give a start command. Light up boiler with AB elevation. Close drum vent B72, 73, 74 and 75. Open E19 Eco-recirculation valve. Set furnace draft to -5 mmwcl. Inform chemist on duty. Run ESP rapping motors on programmer mode. Start HP control fluid pump. Start deaerator filling with boiler fill pump. 02:30 Charge MDBFP and line up low load line.

Open turbine side MS line, CRH line and HRH line atmospheric drains. Line up CEP to deaerator and start one CEP. 03:30 Extend deaerator pegging from aux. steam. Start APH soot blowing with air. At boiler drum pressure 2 kg/cm2, close SH, RH, ECO and drum vents and throttle start up vents. Start MDBFP on recirculation. Start gland drain pump. Open CBD 50% to control drum level if necessary. At drum pressure 5 kg/cm2, close SH drains. 05:00 At drum pressure 7 kg/cm2, Start 3rd BCW pump. At drum pressure 10 kg/cm2, charge turbine gland steam header. Open AS2 valve. At drum pressure 15 kg/cm2, start second HFO pump and take second heater in service. 05:30 Start oil elevation CD as soon as furnace exit FG temp is more than 200C. Ensure HFO oil temp. at firing floor 1100C. Change LDO to HFO in AB elevation. Close MS line, CRH line, HRH line atmospheric drains at turbine side. Before closing ensure that water is not coming from drains. Start both vacuum pumps one by one and apply gland sealing at -2000 mmwcl vacuum. Start seal steam exhauster. Adjust gland steam pressure to 0.015 kg/cm2 and put control on auto. Ensure Gland steam header temp. > 1700C. Raise drum pressure to 25 kg/cm2. 06:00 At -8000 mmwcl vacuum in condenser, open MS, CRH, HRH, strainers, drain valves going to flash tank. Open boiler O/L MSV bypass valves. Open boiler O/L MSV. Open HP bypass warm up valves. Start second CEP. Reset the Turbine by lowering starting device to 'ZERO'. Open LP bypass. Open HP bypass. Set temp. to 320C. Close generator breaker isolators. Start one PA fan. Set PA Header pressure 780 mmwcl. PAHs to be taken in service from FG and air side. Open SH spray, RH spray block valves, if necessary. 06:15 Open HP bypass @60 % slowly. Open drains after stop valves. MAL 11,12,13,14. Set speed reference ZERO, starting device 0% and speeder gear 100%. Ensure stop valve opening criteria X1,X2,X3 fulfilled. Open stop valve HP/ IP by raising starting device upto 70%. Rolling of Turbine :- Ensure criteria X4,X5 fulfilled. TSE influence is 'ON'. Load limit set 60 MW. Load reference 50MW. Pressure control on 'Limit mode. Load control ON. Load gradient '25 MW/Min. Load gradient 'ON'. Set speed reference '360 rpm. Tracking device 'ON'.

07:30 Turbine rolled to 360 rpm. Ensure turning gear cuts off at 240 RPM. Check turbovisory and bearing temp. Soak the turbine till TSE margin +/- 300K. Gland steam charged through CRH (if required). GS Temp > 170C Ensure speed up criteria X6 are fulfilled. Check turbovisory and other parameters of TG set. Ensure drum level -100mm. Raise speed reference to 3000 rpm without stopping in between. Observe turbine vibration. Ensure critical speed 900,1548, 1896, 2700 passed quickly. Turbine rolled to 3000 rpm. JOP cuts off at 540 rpm. AOP cuts off at 2850 rpm. Ensure turbovisory and other parameters of TG set. Close field breaker. Switch AVR set point on 'AUTO'. 07:45 Voltage build up and increase set point to rated value 21 KV. Synchronizing: Put synchronization switch 'ON' (COD-8). Turn generator synchronization selector switch to Auto mode (ATRS) (COD-8) Release the synchronization (COD-7). Put the synchronizer 'ON'. After matching voltage and frequency, M/c is synchronized and 50 MW load picked up on the machine by raising speed reference. Check changeover from speed control to load control (if not, slowly raise load reference). Raise load limit to 200 MW. Put generator synchronization on OFF and synchronization switch 'OFF position (COD-8) Put synchronizer locked. Put synchronizer 'OFF' (COD-7). 08:00

Вам также может понравиться

- Cold Start Up (1) .Документ16 страницCold Start Up (1) .Tamojit Tarit RoyОценок пока нет

- Cold Start Up 1Документ16 страницCold Start Up 1Hassan SamiОценок пока нет

- Unit Start Up Sequence ActivitiesДокумент6 страницUnit Start Up Sequence ActivitiesranjanОценок пока нет

- Cold Start Up ProcedureДокумент18 страницCold Start Up ProcedurerahulОценок пока нет

- 660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCДокумент6 страниц660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCdjfffОценок пока нет

- Unit Start UpДокумент8 страницUnit Start UpDebabrata TantubaiОценок пока нет

- Boiler Light-Up ProgramДокумент5 страницBoiler Light-Up Programsaisrikanths5168Оценок пока нет

- 300 MW ThermalPower Plant Cold Start UpДокумент4 страницы300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- CCPP Cold Start ProcedureДокумент3 страницыCCPP Cold Start ProcedureSahariar Bin ShafiqueОценок пока нет

- Cold Strat Up PresentationДокумент34 страницыCold Strat Up Presentationmoovendan pОценок пока нет

- Boiler Lit-Up PDFДокумент2 страницыBoiler Lit-Up PDFHoncho Abhi Sinha100% (1)

- Operating Manual 670 MW Coal Fired Power Plant Training SimulatorДокумент134 страницыOperating Manual 670 MW Coal Fired Power Plant Training SimulatorsprotkarОценок пока нет

- Unit Sart Up 800mwДокумент12 страницUnit Sart Up 800mwVamsiKrishnaОценок пока нет

- Startup TurbinДокумент15 страницStartup TurbinHans AntartikaОценок пока нет

- Turbine RollingДокумент3 страницыTurbine RollingAnudeep Chittluri100% (1)

- Turbine SopДокумент8 страницTurbine SopDominic Daniel100% (1)

- Turbine Rolling Procedure Pre Rolling ActivitiesДокумент7 страницTurbine Rolling Procedure Pre Rolling ActivitiesPrakash Choudhary100% (1)

- Turbine Rolling & Synchronisation Indicative Flow PathДокумент11 страницTurbine Rolling & Synchronisation Indicative Flow Pathlp mishraОценок пока нет

- Shutdown ProcedureДокумент4 страницыShutdown ProcedureRahul KurmiОценок пока нет

- Boiler Normal Shut DownДокумент13 страницBoiler Normal Shut DownRajat SharmaОценок пока нет

- Steam Turbine Start UpДокумент24 страницыSteam Turbine Start Upmasoodism100% (2)

- Unit Lightup Synchronisation & ShutdownДокумент42 страницыUnit Lightup Synchronisation & ShutdownAshvani ShuklaОценок пока нет

- Cold Startup Procedure PDFДокумент6 страницCold Startup Procedure PDFSai SwaroopОценок пока нет

- M. Syed Amirsha Hakani, B.EДокумент29 страницM. Syed Amirsha Hakani, B.ESarah FrazierОценок пока нет

- Turbine StartupДокумент16 страницTurbine StartupSakthi Murugan100% (1)

- To Carry Out Cleanup ActivityДокумент4 страницыTo Carry Out Cleanup Activitysarojdubey0107Оценок пока нет

- 500 MW Unit Startup ProcedureДокумент39 страниц500 MW Unit Startup ProcedureMohammad Asif50% (2)

- 500MW Starting ProceduresДокумент38 страниц500MW Starting Proceduresthangarajm1984Оценок пока нет

- Emergency Operations: Shaikh Feroz AliДокумент15 страницEmergency Operations: Shaikh Feroz AliEXECUTIVE ENGINEEER BOILER MAINTENANCEОценок пока нет

- IR CFBC Cold Start Up ProcedureДокумент15 страницIR CFBC Cold Start Up ProcedureJose Angie CabreraОценок пока нет

- HP LP BypassДокумент34 страницыHP LP BypassharisankarОценок пока нет

- Cold Startup ProcedureДокумент8 страницCold Startup ProcedureRahul KurmiОценок пока нет

- Turbine Start Up Procedure-2Документ2 страницыTurbine Start Up Procedure-2kumarmm1234100% (2)

- Turbine Operation - PreparationДокумент30 страницTurbine Operation - PreparationMadhav Pande67% (3)

- Warm Light Up (Mahendra Singh)Документ35 страницWarm Light Up (Mahendra Singh)vinamrataОценок пока нет

- Boiler Sop RevДокумент17 страницBoiler Sop RevDhilip AnОценок пока нет

- Turbine OperationДокумент30 страницTurbine OperationAjay Chauhan100% (8)

- Sop TurbineДокумент4 страницыSop TurbinesambhuОценок пока нет

- 500mw Boiler Operating InstructionsДокумент8 страниц500mw Boiler Operating InstructionsRavindrababu Banothu100% (1)

- Operation Procedures For MDBFPДокумент7 страницOperation Procedures For MDBFPJackSparrow86100% (1)

- Cold Start UpДокумент31 страницаCold Start UpJijo JoseОценок пока нет

- Write Up On Turbine OperationДокумент5 страницWrite Up On Turbine OperationSarah Frazier100% (2)

- Coastal Cold Start Up ChecklistДокумент13 страницCoastal Cold Start Up ChecklistwonderstrikeОценок пока нет

- Precheck Before Light-Up: Drum Metal Temp. DiffДокумент12 страницPrecheck Before Light-Up: Drum Metal Temp. DiffAhemadОценок пока нет

- CFBC Boiler Startup and ShutdownДокумент42 страницыCFBC Boiler Startup and ShutdownAshvani Shukla100% (1)

- Kiln Start Procedure (Wonder Cement LTD)Документ3 страницыKiln Start Procedure (Wonder Cement LTD)Satish KumarОценок пока нет

- Procedure For Shutting Down of Turbine & EquipmentsДокумент4 страницыProcedure For Shutting Down of Turbine & EquipmentsPrakash ChoudharyОценок пока нет

- BFP SopДокумент2 страницыBFP SopCo-gen ManagerОценок пока нет

- Section F CFBC Startup Procedure R00Документ8 страницSection F CFBC Startup Procedure R00purvgargОценок пока нет

- Чеклист - Подготовка паровой системыДокумент5 страницЧеклист - Подготовка паровой системыСлава ТрофимовОценок пока нет

- 5 HCDPДокумент36 страниц5 HCDPAditya DubeyОценок пока нет

- Boiler Normal Shut DownДокумент13 страницBoiler Normal Shut Downgaurav tiwari100% (1)

- Warm StartДокумент4 страницыWarm StartMowaten MasryОценок пока нет

- Turbine Shutting Down From Full LoadДокумент7 страницTurbine Shutting Down From Full Loadrohit_0123100% (1)

- Presentation On Steam Turbine Operation by S ChandДокумент36 страницPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- Turbine Side PumpsДокумент25 страницTurbine Side PumpsPrakash Choudhary67% (3)

- Ppe Exp.3 ROLLNO 1Документ9 страницPpe Exp.3 ROLLNO 1Aniket SinghОценок пока нет

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОт EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Unit-2 Tripping 28 - 03 - 2009Документ1 страницаUnit-2 Tripping 28 - 03 - 2009Gajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Chandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedДокумент1 страницаChandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Unit-1 Tripping 28-3-2009Документ1 страницаUnit-1 Tripping 28-3-2009Gajanan JagtapОценок пока нет

- Event Ana U#6-2006Документ32 страницыEvent Ana U#6-2006Gajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент2 страницыEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Card SlipДокумент2 страницыEvent Analysis Card SlipGajanan JagtapОценок пока нет

- Event Ana U#7,2006 - CompletedДокумент31 страницаEvent Ana U#7,2006 - CompletedGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Unit-1 Tripping 30-01-2009 Mod FormataДокумент1 страницаUnit-1 Tripping 30-01-2009 Mod FormataGajanan JagtapОценок пока нет

- Event Analysis Report: 198 A, B, D, E, F NILДокумент1 страницаEvent Analysis Report: 198 A, B, D, E, F NILGajanan JagtapОценок пока нет

- U3 Tripping 12 - 02 - 2009 - AДокумент2 страницыU3 Tripping 12 - 02 - 2009 - AGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- SQ - 4.1 - Boiler (Table Format)Документ11 страницSQ - 4.1 - Boiler (Table Format)Gajanan JagtapОценок пока нет

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurДокумент1 страницаEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapОценок пока нет

- Officers Recreation Centre Urjanagar ChandrapurДокумент2 страницыOfficers Recreation Centre Urjanagar ChandrapurGajanan JagtapОценок пока нет

- Unit-2 Non Tripping 4-02-2009OLDДокумент1 страницаUnit-2 Non Tripping 4-02-2009OLDGajanan JagtapОценок пока нет

- Format For Oil Gun: Month/Year November 2012Документ2 страницыFormat For Oil Gun: Month/Year November 2012Gajanan JagtapОценок пока нет

- Fitting Catalog 2013: Maret 2013 - 112Документ39 страницFitting Catalog 2013: Maret 2013 - 112SujokoTeeОценок пока нет

- Ge7 ModДокумент5 страницGe7 Modaldo galloОценок пока нет

- BFK458 33002356 en 04 2017Документ36 страницBFK458 33002356 en 04 2017Vrushank PatelОценок пока нет

- +2 Physics Practical Readings 2019-2020Документ11 страниц+2 Physics Practical Readings 2019-2020Barkath Shalu100% (1)

- Business Model Canvas: Key Partners Key Activities Value Propositions Customer Relationships Customer SegmentsДокумент1 страницаBusiness Model Canvas: Key Partners Key Activities Value Propositions Customer Relationships Customer SegmentsRaihanAbdurrahmanОценок пока нет

- Communication EngineeringДокумент15 страницCommunication Engineeringhelloworld100100% (1)

- SalomeMeca AsterODactyleДокумент161 страницаSalomeMeca AsterODactyleIwan Sanjaya AwaluddinОценок пока нет

- Horizontal Tank ChecklistДокумент3 страницыHorizontal Tank ChecklistA.P.100% (1)

- Repair Instruction For Engine Repair Manual: PrecautionДокумент3 страницыRepair Instruction For Engine Repair Manual: PrecautionHenry SilvaОценок пока нет

- Oxford Learner's Bookshelf E-Books For Learning 3Документ1 страницаOxford Learner's Bookshelf E-Books For Learning 3Yesenia Mendoza HernandezОценок пока нет

- Chapter Five: Centrifugal Compressors, Fans and BlowersДокумент21 страницаChapter Five: Centrifugal Compressors, Fans and BlowerstemesgenОценок пока нет

- How To Install Kali Linux 2Документ36 страницHow To Install Kali Linux 2ᎦᏂᎯᎦᎲ ᏦᎯᏁᎿᏂОценок пока нет

- WAP To Find The Sum of The Series S 1 + (3/2!) + (5/3!) + (7/4!) + ....... To NДокумент8 страницWAP To Find The Sum of The Series S 1 + (3/2!) + (5/3!) + (7/4!) + ....... To NSOUMYA MAHAPATRAОценок пока нет

- Lab Manual.15 PDFДокумент34 страницыLab Manual.15 PDFBoovarahan ChakravarthyОценок пока нет

- How To Solder A Through-Hole Component: InstructablesДокумент6 страницHow To Solder A Through-Hole Component: InstructablesBobKatОценок пока нет

- Introduction To Industry 4.0 and Industrial IoT Week 3 Quiz SolutionsДокумент5 страницIntroduction To Industry 4.0 and Industrial IoT Week 3 Quiz SolutionssathyaОценок пока нет

- No Flange Barometric Relief Damper: Application & DesignДокумент3 страницыNo Flange Barometric Relief Damper: Application & DesignEduhar Jesus Vasquez FernandezОценок пока нет

- The Enlightenment Legacy of Darwin, Freud and MarxДокумент18 страницThe Enlightenment Legacy of Darwin, Freud and MarxPaula HicksОценок пока нет

- A 105 Vs A 350Документ3 страницыA 105 Vs A 350shОценок пока нет

- Focus ForecastingДокумент4 страницыFocus ForecastingVedant MishraОценок пока нет

- Homework 3Документ3 страницыHomework 3Haonan ZhangОценок пока нет

- How To Kill It at Law School - Harshil Vijayvargiya-Pages-8-15Документ8 страницHow To Kill It at Law School - Harshil Vijayvargiya-Pages-8-15VANSH CHOUHANОценок пока нет

- Review XXX ACS Guide 2014Документ2 страницыReview XXX ACS Guide 2014Vinod ManjuОценок пока нет

- AVR Assembly Tutorial CompleteДокумент611 страницAVR Assembly Tutorial CompleteTanvir Hussain100% (27)

- Eisi - Company & Product Profile (2022)Документ29 страницEisi - Company & Product Profile (2022)Loui BarciaОценок пока нет

- Alice in Wonderland Literary AnalysisДокумент5 страницAlice in Wonderland Literary AnalysisRica Jane Torres100% (1)

- civilBAMBOO AS A BUILDING MATERIALДокумент15 страницcivilBAMBOO AS A BUILDING MATERIALFajar KaruniaОценок пока нет

- 8207 DIS Learning PausesДокумент17 страниц8207 DIS Learning PausesAJAY YADAVОценок пока нет

- SSA c1510 Exercise GuideДокумент202 страницыSSA c1510 Exercise GuideSanjay KrishnanОценок пока нет

- Session 2004: 21, Rue D'artois, F-75008 Paris © CigréДокумент8 страницSession 2004: 21, Rue D'artois, F-75008 Paris © CigréOscar GarciaОценок пока нет