Академический Документы

Профессиональный Документы

Культура Документы

Cevi Uni

Загружено:

Goran PatekОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cevi Uni

Загружено:

Goran PatekАвторское право:

Доступные форматы

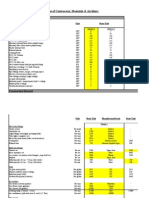

TUBES FOR PRESSURE PURPOSES - STANDARD CORRELATION

EN EN 10216 Part 1 - TR2 Unalloy General use Ambient Temperat. Pressure purposes P195TR1 * P195TR2 P235TR1 * P235TR2 P265TR1 * P265TR2 St 52.0 EN EN 10216 Part 2 Unalloy Alloy Elevated Temperature Pressure purposes P195GH P235GH P265GH 360 440 360 430 BS 3059-2:90 Carbon Alloy Boiler Superheater Elevated Temp. 320 400 440 St 35.8 TU 37 F St 45.8 17 Mn 4 19 Mn 5 20MnNb6 16Mo3 8MoB5-4 243 500 Nb 243 261 15Mo3 Pressure purposes Elevated Temperat. Pressure purposes Elevated Temperat. Heat Exchangers Elevated Temperat. Elevated Temperat. For Hydrogen Service 3602-1:87 Carbon and C-Mn 3604-1:90 Alloy (Ferritic) 3606:92 DIN 17175:79 17176:90 430 St 44.0 St 44.4 St 52.4 NF 49-210 360 St 37.0 St 37.4 TU 37-a BS 3059-1:87 Carbon Boiler Superheater No elevated Temp. 320 3601:87 Carbon Steel Special Delivery Cond. Ambient Temperat. Pressure purposes 0 DIN 1629:84 Unalloyed Special Quality Requirem. 1630 Unalloyed Pressure purposes 300 C max Commercia Medium Pr NF 49-111:78 (

14MoV6-3 10CrMo5-5 13CrMo4-5 620-460

660 621 620 - 440 621 620

14MoV63 13CrMo44 13CrMo44

10CrMo9-10 11CrMo9-10

622-490

622

622

10CrMo910 10CrMo910 12CrMo910

25CrMo4 20CrMoV13-5-5 15NiCuMoNb5-6-4 X11CrMo5+I X11CrMo5+NT1 X11CrMo5+NT2 X11CrMo9-1+I X11CrMo9-1+NT X10CrMoVNb9-1 X20CrMoV11-1 629-470 629-590 91 762 762 629-470 629-590 X10CrMoVNb91 X20CrMoV121 591 625 625

12 Cr Mo 12 10 25CrMo4 20CrMoV135 12CrMo195(G) 12CrMo195(V1) 12CrMo195(V2) X12CrMo91(G) X12CrMo91(V) X20CrMoV121

* Tubes made of these material grades (TR1) are unlikely to support the essential requirements of the PED - Directive 97/23/EC ** Steel correlation between Grade B and P235TR1 is based on yield strenght. Grade B can be steel related to P26 5TR1 if reference is made to tensile strenght.

UNI 49-112:87 663:68 (p) 7088:72 Unalloyed steel Ambient Temperat. General Purposes

ASTM A 53 A 106 Carbon Steel Black Hot-dip zinc-coat. A + Carbon equival A + Carbon equiva B + Carbon equiva High Temperat.

(p)

al quality

Pressure

TUE 220 A TUE 235 A

Fe 35-1 Fe 35-2 Fe 45-1 Fe 45-2

Fe 35-1 Fe 45-1

B + Carbon equival

C + Carbon equiva Fe 52-1 Fe 52-2 UNI 49-211:89 Alloy Elevated Temperat. 49-213:90 Unalloy Alloy (Mo & Cr-Mo) Elevated Temperat. 49-215:81 (p) Unalloy Alloy (Ferritic) Heat-Exchanger 49-219:90 Unalloy Alloy (Mo & Cr-Mo) Elevated Temperat. Furnaces High-pressure Elevated Temperat. A + High temp serv TU E 220 TU 42 F C 18 TU E 250 TU E 275 TU 48 C - TU 48 CR TU 48 C - TU 48 CR TU 52 C 16 Mo 5 TU 15 D 3 TU 15 D 3 TU 15 D 3 C + High temp serv TU 48 c B + High temp serv TU 37 C - TU 42 C - TU 42 CR TU 37 C - TU 42 c C 14 High Temperat. Cold-Drawn Heat-Exchanger Low C 5462:64 ASTM A 106 Carbon Steel A 179 Low-Carbon Steel

TU 15 CD 2-05

TU 10 CD 5-05 TU 13 CD 4-04

TU 10 CD 5-05

TU 10 CD 5-05 TU 13 CD 4-04

14 Cr Mo 3

12 Cr Mo 910 TU 10 CD 9-10 TU 10 CD 9-10 TU 10 CD 9-10

TU Z 12 CD 05-05 a TU Z 12 CD 05-05 b TU Z 10 CD 5-05 TU Z 10 CD 09 a TU Z 10 CD0 9 b TU Z 10 CDVNb 09-01 TU Z 10 CD 9

TU Z 12 CD 05-05 a TU Z 12 CD 05-05 b TU Z 10 CD 09 a TU Z 10 CD 09 b TU Z 10 CDVNb 09-01

TU Z 10 CDNbV 09-02

VALUES REQUESTED BY ENs FOR COMPLIANCE WITH PED KV Trasvers AVERAGE J Min TEMPERATURE C ELONGATION A% Min

val

al ** 27 0 14

al

VALUES REQUESTED BY ENs A 192 Carbon Steel Boiler High-pressure Low C 0 A1 C A 209 C-Mo Superheater A 210 Medium-carbon Boiler Superheater A 213 Alloy (Ferr.& Aust.) Heat-Exchanger Boiler Superheater A 335 Alloy (Ferr.) High Temperat. FOR COMPLIANCE WITH PED KV Trasvers AVERAGE J Min TEMPERATURE C ELONGATION A% Min

T1

T1a

T1b T2

P1 P2

T17 T11 T12 T21 T22 T23 P11 P12 P15 P21 P22 27 14

20 T5 P5

T9 T91

P9 P91

T23 T 24 T 911 T92 T122 18Cr-2Mo

P23 P911 P92 P122

TUBES FOR PRESSURE PURPOSES - STANDARD CORRELATION

EN EN 10216 Part 3 Unalloy Alloy Fine Grain Pressure purposes Special requirements St E 255 WSt E 255 TSt E 255 430 LT E St E 255 St E 285 P275NL1 P275NL2 P355N P355NH P355NL1 P355NL2 WSt E 285 T St E 285 E St E 285 St E 355 W St E 355 T St E 355 E St E 355 St E 420 WSt E 420 TSt E 420 P460N P460NH P460 NL1 P460NL2 P620Q P620QH P620QL P690Q P690QH P690QL1 P690QL2 EN EN 10216 Part 4 Unalloy Alloy Low Temperature Pressure purposes P215NL P255QL P265NL 26CrMo4-2 11MnNi5-3 13MnNi6-3 12Ni14 12Ni14+QT X12Ni5 X12Ni5+QT X10Ni9 X10Ni9+QT 509 LT 509 LT 503 LT 503 LT 430 LT 26CrMo4 11MnNi53 13MnNi63 TU 17 N 2 10Ni14 10Ni14 12Ni19 12Ni19 X8Ni9 X8Ni9 TU Z 6 N 9 TU Z 6 N 9 TU Z 6 N 9 TU Z 6 N 9 TU 10 N 9 TU 10 N 14 TU 10 N 14 TU 17 N 2 TU 10 N 9 TU 10 N 14 TU 10 N 14 BS 3603: 91 (p) Carbon Alloy Low Temperature Pressure purposes TT St35 N TT St 35 V TU 42 BT TU 42 BT DIN 17173: 85 NF 49-215:81 (p) Unalloy Alloy (Ferritic) Heat-Exchanger ESt E 420 St E 460 W St E 460 T St E 460 E St E 460 BS 3603:91 (p) DIN 17179:86 Fine Grain NF

3600 series (p)

49-230:85

Low temperature

Low Temperature Pressure Vessels

ASTM

VALUES REQUESTED BY ENs FOR COMPLIANCE WITH PED KV Trasvers AVERAGE J Min TEMPERATURE C ELONGATION A% Min

According to Table 7 of EN 10216-3 Requested values are depending from steel grades and wall thickness 14

UNI 5949:67 Unalloy Special Alloy Low Temperature

UNI 5949:67 Unalloy Special Alloy Low Temperature

ASTM A 333

VALUES REQUESTED BY ENs A 334 Carbon Steel Alloy Low Temperature FOR COMPLIANCE WITH PED KV Trasvers AVERAGE J Min TEMPERATURE C ELONGATION A% Min

Low Temperature

C 15

gr1

gr1

C 20

gr6

gr6

According to Table 5 of EN 10216-4 18 Ni 9 18 Ni 14 18 Ni 14 gr3 gr3 gr3 gr3 Requested values are depending from steel grades and wall thickness 14

X 12 Ni 09 X 12 Ni 09

gr8 gr8 Gr 4 Gr 7 Gr 9 Gr 10 Gr 11

gr8 gr8 Gr 4 Gr 7 Gr 9

Tubes for pressure purposes Standard correlation

Вам также может понравиться

- KTMДокумент2 страницыKTMKevin TarlaОценок пока нет

- Astm A106 Ts EnglДокумент4 страницыAstm A106 Ts EnglxaviereduardoОценок пока нет

- Seamless Tubes For Utility Boilers Industrial Boilers and HRSGДокумент12 страницSeamless Tubes For Utility Boilers Industrial Boilers and HRSGsridharchowdary349Оценок пока нет

- 61502YДокумент9 страниц61502YbalajivangaruОценок пока нет

- Comparison Table For Tubes, Line Pipes and FittingДокумент2 страницыComparison Table For Tubes, Line Pipes and FittingNamye Yelus100% (1)

- FSH TigДокумент105 страницFSH TigChee WeiОценок пока нет

- Katalog 2011 enДокумент278 страницKatalog 2011 ener_wenОценок пока нет

- Piping ComponentДокумент19 страницPiping Componentreach_arindomОценок пока нет

- P91TPДокумент37 страницP91TPPhong ĐỗОценок пока нет

- Piping Material DetailsДокумент12 страницPiping Material DetailsJay Vinoth100% (2)

- Material AsmДокумент6 страницMaterial Asmrawalepushkar123Оценок пока нет

- FontargenДокумент282 страницыFontargenMIHAIОценок пока нет

- Welding Filler Metals For Power Plant EngineeringДокумент20 страницWelding Filler Metals For Power Plant EngineeringgogotigОценок пока нет

- Material API 610Документ8 страницMaterial API 610mishraenggОценок пока нет

- API 610 Centrifugal Pumps For Petroleum Petrochemical and Natural Gas Industries 11th Ed 2010 APPENDIX HДокумент8 страницAPI 610 Centrifugal Pumps For Petroleum Petrochemical and Natural Gas Industries 11th Ed 2010 APPENDIX HZlatko CvetkovskiОценок пока нет

- Valve Material EquivalentsДокумент3 страницыValve Material EquivalentsAndre Villegas Romero100% (1)

- Class 11085Документ9 страницClass 11085eww08Оценок пока нет

- ASTM A335 Pipe SpecificationsДокумент4 страницыASTM A335 Pipe SpecificationsDhruv GohelОценок пока нет

- DB Pump CurvesДокумент70 страницDB Pump CurvesMusheer Basha75% (12)

- Bohler Bestseller Engl NTДокумент28 страницBohler Bestseller Engl NTClaudia MmsОценок пока нет

- SN359-1 Material Comparison German-Chinese 2012-06 E-1Документ44 страницыSN359-1 Material Comparison German-Chinese 2012-06 E-1apply1984237150% (2)

- Alloy Steels Nickel Cobalt AlloysДокумент1 страницаAlloy Steels Nickel Cobalt AlloysMichaelben MichaelbenОценок пока нет

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Документ2 страницыDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralОценок пока нет

- Lit RD10 ENДокумент6 страницLit RD10 ENlesonspkОценок пока нет

- Material Conversion TableДокумент5 страницMaterial Conversion TableMilin DesaiОценок пока нет

- Boiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSДокумент2 страницыBoiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSzarni77Оценок пока нет

- Imp-Comparison of SpecificationsДокумент7 страницImp-Comparison of SpecificationsKetan PatelОценок пока нет

- Thyssenkrupp Materials International: Material Data SheetДокумент4 страницыThyssenkrupp Materials International: Material Data SheetjaseerkannothОценок пока нет

- MaterialData - Aço 1045Документ2 страницыMaterialData - Aço 1045Victhor AraujoОценок пока нет

- MISC Materials ListДокумент10 страницMISC Materials ListWaqas WaqasОценок пока нет

- Chinese To DinДокумент7 страницChinese To Dindnageshm4n244Оценок пока нет

- Cahpter 5 Special SteelДокумент50 страницCahpter 5 Special SteelhealgoseОценок пока нет

- Metrode Dissimilar Consumable SelectorДокумент7 страницMetrode Dissimilar Consumable SelectorClaudia MmsОценок пока нет

- 1303287208Документ27 страниц1303287208Anurag JainОценок пока нет

- Ep33411 b11Документ9 страницEp33411 b11salamrefighОценок пока нет

- Astm A182Документ6 страницAstm A182Rayan AlfredОценок пока нет

- Asco Direct Acting Solenoid Valve - 320Документ6 страницAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Inosindt PDF Extended Surface Tubes 3-1Документ32 страницыInosindt PDF Extended Surface Tubes 3-1Hoover OrtizОценок пока нет

- Consumables For Duplex Stainless SteelДокумент6 страницConsumables For Duplex Stainless SteelMohamed FaragОценок пока нет

- Tubes PipesДокумент19 страницTubes Pipesmaria_bustelo_2Оценок пока нет

- Studbolts Astm, Bs & Din: Fields of ApplicationДокумент1 страницаStudbolts Astm, Bs & Din: Fields of ApplicationtriplbingaziОценок пока нет

- APT Special Offers WebДокумент8 страницAPT Special Offers Webjim_m_smithОценок пока нет

- Chinese To DinДокумент7 страницChinese To DinDamla KaymakçıОценок пока нет

- Comparison Table For Pipes and FittingsДокумент1 страницаComparison Table For Pipes and FittingsmasaminathanОценок пока нет

- Equivalents of Carbon Steel QualitiesДокумент7 страницEquivalents of Carbon Steel QualitieshardywillimОценок пока нет

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20От EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Оценок пока нет

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualОт EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualОценок пока нет

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363От EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Оценок пока нет

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39От EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Рейтинг: 5 из 5 звезд5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- XIAMETER™ OFS-6011 Silane: Features & BenefitsДокумент4 страницыXIAMETER™ OFS-6011 Silane: Features & BenefitsсветланаОценок пока нет

- PEM Self Clinching Nuts CL SeriesДокумент12 страницPEM Self Clinching Nuts CL SeriesAce Industrial SuppliesОценок пока нет

- Nav22 - Welding/Weld Repair Audit ChecklistДокумент23 страницыNav22 - Welding/Weld Repair Audit ChecklistdurraaiОценок пока нет

- Manual For Structural Inspection & Appraisal For BuildingsДокумент26 страницManual For Structural Inspection & Appraisal For BuildingsNoordin Abdul MajidОценок пока нет

- Wilson Tool X-Sharp CMGДокумент2 страницыWilson Tool X-Sharp CMGSM TECH SRLОценок пока нет

- Pricelist-Tubes & ValvesДокумент39 страницPricelist-Tubes & ValvesHKRajesh100% (1)

- TLE Activity Sheet Carpentry 4th QuarterДокумент13 страницTLE Activity Sheet Carpentry 4th QuarterJymaer Geromo100% (2)

- BQ With PriceДокумент26 страницBQ With PriceLee Yuxuan100% (1)

- MD (BF) - 1 PDFДокумент5 страницMD (BF) - 1 PDFMaheswar SethiОценок пока нет

- EnvelopeДокумент51 страницаEnvelopeRam RamisettiОценок пока нет

- Al-Cu-Si General Purpose Casting Alloy: WeldabilityДокумент1 страницаAl-Cu-Si General Purpose Casting Alloy: Weldabilitymanjunath k sОценок пока нет

- Metric DIN 444 SpecДокумент6 страницMetric DIN 444 SpecJagadesh PОценок пока нет

- Billet Internal Cracks InvestigationДокумент11 страницBillet Internal Cracks InvestigationafzalОценок пока нет

- In Uence of The Cooling Rate On The Ageing of Lead-Calcium AlloysДокумент5 страницIn Uence of The Cooling Rate On The Ageing of Lead-Calcium AlloysDilfredo RuizОценок пока нет

- Soportes EricoДокумент12 страницSoportes EricoJulian RiverosОценок пока нет

- How To Build A Wendy HouseДокумент16 страницHow To Build A Wendy HouseDragos StoianОценок пока нет

- 039 Katalog KrisbowДокумент1 страница039 Katalog KrisbowDermawan PurbaОценок пока нет

- Introduction To CastingДокумент16 страницIntroduction To CastingOkari100% (1)

- Contech ChemicalsДокумент8 страницContech ChemicalskiОценок пока нет

- Sample Report Standard Quality On Crawlspace EplansДокумент1 страницаSample Report Standard Quality On Crawlspace EplansRyan De Vera PagalОценок пока нет

- Gypsum Board Fire Rated ConstructionДокумент5 страницGypsum Board Fire Rated ConstructionphrishelОценок пока нет

- QC Welding Inspector NotesДокумент26 страницQC Welding Inspector NotesSohail Aziz Ahmad MalikОценок пока нет

- Manual Refractario RefratecnikДокумент59 страницManual Refractario RefratecnikCristian Aguayo Diaz100% (1)

- Master File (BOQ) - OptДокумент322 страницыMaster File (BOQ) - OptMohsin RazaОценок пока нет

- Lab Manual - Mech 1051 Ay 2021-2022 EvenДокумент10 страницLab Manual - Mech 1051 Ay 2021-2022 EvenKoushik DebnathОценок пока нет

- House Building Cost DataДокумент17 страницHouse Building Cost Datasyed usman wazir100% (7)

- Sudha GadДокумент23 страницыSudha GadPravin MasalgeОценок пока нет

- Plastic Films Made From Low-Density Polyethylene and Linear Low-Density Polyethylene For General Use and Packaging ApplicationsДокумент5 страницPlastic Films Made From Low-Density Polyethylene and Linear Low-Density Polyethylene For General Use and Packaging ApplicationsNasrin Akhondi100% (1)

- PVA Fibre Reinforced High-Strength Cementitious Composite For 3D Printing Mechanical Properties and DurabilityДокумент12 страницPVA Fibre Reinforced High-Strength Cementitious Composite For 3D Printing Mechanical Properties and Durabilityhamed sadaghianОценок пока нет

- An Experimental Study of Coconut Shell With Sugarcane Bagasse Ash As Partial Replacement of Coarse Aggregates and Cement To ConcreteДокумент99 страницAn Experimental Study of Coconut Shell With Sugarcane Bagasse Ash As Partial Replacement of Coarse Aggregates and Cement To ConcreteInternational Journal of Innovative Science and Research TechnologyОценок пока нет