Академический Документы

Профессиональный Документы

Культура Документы

Internship Report On 'Power Generation, Utilization and Communication System of Marine Vessel

Загружено:

Engr. M. A. KawsarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Internship Report On 'Power Generation, Utilization and Communication System of Marine Vessel

Загружено:

Engr. M. A. KawsarАвторское право:

Доступные форматы

International University of Business Agriculture & Technology

Internship Report: Power Generation, Utilization and Communication System of Marine Vessel

Submitted To

Professor Md. Alimullah Miyan Vice-Chancellor, IUBAT

By

Mohammad Abu Kawsar Stud Id: 08305058 Bachelor of Science in Electrical and Electronics Engineering

Due date: 10th August, 2012

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Power Generation, Utilization and Communication System of Marine Vessel

Fig1. showing a cargo vessel, M.V. Kallol anchored in the Chittagong sea port, where Mr Kawsar is taking his on board training (Source: photo taken with permission from BSC, 2012)

Fig 2. showing M.V. Banglar Urmi anchored in the sea, the place Mr Kawsar is taking his practical training (Source: Shipspotting, 2012)

page 2

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Request for the Report

10th August, 2012 Engr. Md. Abul Bashar, Faculty and Course Coordinator, Department of Electrical and Electronics Engineering, CEAT, IUBAT, 4 Embankment Drive Road, Sector-10, Uttara Model Town, Dhaka-1230, Bangladesh Subject: Request for the report. Dear Sir, With due respect I would like to submit my report on Power Generation, Utilization and Communication System of Marine Vessel as partial fulfillment of Bachelor of Science in Electrical and Electronics Engineering program. It was excellent opportunity for me to work with marine electrical equipments to gain theoretical and practical knowledge as well as useful experience in this area. I would like to have my report to be assessed.

I hope you would be kind enough to evaluate my performance by assessing this report. Sincerely Yours,

Mohammad Abu Kawsar ID # 08305058 Program: BSEEE

page 3

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Letter of Transmittal

10th August, 2012

Engr. Md. Abul Bashar, Faculty and Course Coordinator, Department of Electrical and Electronics Engineering, CEAT, IUBAT, 4 Embankment Drive Road, Sector-10, Uttara Model Town, Dhaka-1230, Bangladesh Subject: Letter of Transmittal of the Practicum Report. Dear Sir, I am pleased to submit my practicum report on Power Generation, Utilization and Communication System of Marine Vessel. As part of the requirement of the program, I worked with marine vessel electric and electronic equipments under Bangladesh Shipping Corporation. It was a challenging work, because in our country Bangladesh Shipping Corporation is the only government shipping organization which has several ocean going cargo vessels transporting import and export business world-wide. A lot of marine nautical and engineering experts are involved in the global transport activities. It was certainly a great opportunity for me to work on this area to gain theory and practice of the electrical and electronics appliances required in every life of the marine vessel. Although, many interruptions have been confronted while working I managed to overcome all sorts of problem in conducting data and information for this project. I put best of my effort to achieve my goal to make a pragmatic and useful research report. Thank you. Sincerely Yours,

Mohammad Abu Kawsar ID # 08305058 Program: BSEEE

page 4

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

To Whom It May Concern

This is to certify that Mohammad Abu Kawsar, student of IUBAT has been continuing his internship program with us from 13th May, 2012 to till today. The subject matter of the internship program is Power Generation, Utilization and Communication System of Marine Vessel.

During his internship he has been following instructions according to the satisfaction of the management. He was very keen to learn the lessons and enthusiastic in completing any assignment given to him time to time.

I wish your every success with your career.

____________________

Engr. Md. Ahasan-ul-Karim Asst. General Manager (Marine Workshop) Bangladesh Shipping Corporation PABX: +88-031-716330-2, Ext.-104. E-mail: aukarim_2006@yahoo.com

page 5

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Student's Declaration

This is to inform that the Practicum Report on Power Generation, Utilization and Communication System of Marine Vessel has only been prepared as a partial fulfillment of the Bachelor of Science in Electrical and Electronics Engineering (BSEEE) Program. I hereby declare that the project embodied in this report in the result of my own handwork and has not been submitted for another degree to another university.

(Mohammad Abu Kawsar) ID # 08305058 Program: BSEEE

page 6

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Acknowledgement

I would like to thank Professor Md. Alimullah Miyan, the honorable Vice Chancellor for giving me the opportunity to prepare my research report on the globally important shipping area. I am highly grateful to my faculty specialist Engr. Md. Abul Bashar, Course Coordinator of EEE department, Dr. Md. Aziz-ul-Huq, Faculty of EEE department, Engr. Sadia Sultana Likhan for their valuable guidance and inspiration for the development of this project. My special appreciation to Engr. Md. Ahasan-ul-Karim, AGM (Marine Workshop) of Bangladesh Shipping Corporation, Md. Mazidul Hoque, Chief Engineer and Md. Abdul Hakim, 4th Engr. of M.V. BANGLAR URMI for guiding me at workplace, my special gratitude to Capt. M. A. Rahim, master mariner for his generous recommendation for the onboard internship for this project.

page 7

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Table of Contents

Sl. No. Name Page

1. Introductory Part: 1.1 Origin of the report.............................................................................12 1.2 Objective.............................................................................12 1.3 Scope...........................................................................................12 1.4 Background.................................................................................13 1.5 Methodology...............................................................................13 1.6 Limitations..........................................................................14 2. Organizational Overview: 2.1 Profile of BSC...15 2.2 Mission of BSC.....15 2.3 Vision of BSC.......15 2.4 Objective of BSC..16 2.5 Future Plane of BSC.16 2.6 Fleet Profile of BSC..17 2.7 Services of BSC.....18

3. Hierarchy Level of Onboard Ships Personnel: 3.1 Onboard Ships organogram ...20 3.2 Hierarchy Level of Deck Department of Onboard Ship..21 2.3 Hierarchy Level of Engine Department of Onboard Ship...23 3.4 Hierarchy Level of Electrical Department of Onboard Ship....25 4. Overview of Ships Electric Power System: 4.1 Introduction..27 4.2 Electric Power Generation System of Onboard Ships..28 4.3 Automatic Voltage regulator34 4.4 How to Synchronize Generators of Onboard Ship? ..............................................37 4.5 Why are Transformer and Alternator Ratings in kVA on Ships? .........................40 4.6 Parallel Operation of Two Generators..41 4.7 Principles of Power Factor.......43 4.8 Automatic Power Factor Improvement Controller (APFIC)...47 4.9 Emergency Power System of Onboard Ship.....51 4.10 Power Distribution System of Onboard Ship...52 5. Overview of Ships Power Utilization:

page 8

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8

Battery Charging System of Onboard Ship.....53 Navigational Lights Used Onboard Ships.......56 Different Types of Alarms of Onboard Ships.....58 Single Phasing in Electrical Motors: Causes, effects, & protection methods.....60 Maintenance of Electrical Relay on Ships Electrical Circuit......63 How to Install Electronic Circuits on Ship? ........................................................65 Procedure for Starting Emergency Steering System of Ship......68 General Overview of Types of Pumps on Ship..70

5.9 The Basics of Air Compressor of Onboard Ship...72 5.10 Construction and Working of Ships Refrigeration Plant..74 5.11 How to Find an Earth Fault On board Ships?.....................................................76 5.12 How to Minimize the Risks of an Electrical Shock of Onboard Ship?.............79 6. Overview of Ships Communication System: 6.1 Overview of Radar.....80 6.2 Overview of LRIT.....85 6.3 Electronics Navigation................................................................................88 6.4 AIS Transponders.......................................................................................89 6.5 Marine VHF Radio....89 6.6 Ships Voyage Data Recorders (SVDR)....90 7. Conclusions: 8. Recommendations......91 9. References .92 9.1 Online resources92 9.2 Bibliography..92 10. Appendix.94 10.1 List of acronyms....94 10.2. Glossary.97 10.3 Photo/pictures/videos.100

List of Figures

Fig No. Fig 1. Fig 2. Fig 3. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Figures Photo of Banglar Kallol Photo of Banglar Urmi Organogram of Onboard Ships Personnel A Ship Master/Captain on navigational operation A Ship Chief Officer on navigational operation A Chief Engineer working on ships control board A switchboard, fault detected in Banglar Urmi by a trainee E/Engineer 850 KVA Generator operated by a trainee Electrical Engineer in Banglar Urmi Magnetization of the rotor winding, Left: Brushed; Right: Brush-less magnetization Two Types of Rotor Construction: page 2 2 19 22 23 25 25 28 30 page 9

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

(a) Cylindrical Type Rotor and (b) Salient Type Rotor 33 Fig. Over all Circuit of AVR for the Diesel Engine Type Synchronous Generator 35 Fig. AVR Design for the Diesel Engine Type Synchronous Generator 36 Fig. Circuit Diagram of Synchroscope Method 37 Fig. Circuit Diagram of Emergency Synchronizing Lamps Method 38 Fig. Two Generators Set in M.V. Banglar Kallol 41 Fig. Circuit Diagram of Generators Set in MV Banglar Kallol 42 Fig. Vector Diagram of Parallel Operation, Fig-4.6.2 Generators Governor Characteristic Fig-5.5.2 Location of Installation, where installed PCB, Fig-5.7.1 Steering Motor, Fig-5.7.2 Procedure of Steering Operation, Fig-5.8.1 Positive Displacement Pump, Fig-5.8.2 Dynamic pressure pumps, Fig-5.9.1 Main air compressor Fig-5.10.1 Refrigeration Plant Fig-5.11.1 Finding Earth Fault on 440V circuit, Ref. ABB Marine Fig-5.11.2 Earth Fault Detecting on 440V circuit, Ref. ABB Marine Fig-6.1.1 Commercial marine radar antenna, Ref. M.V. BANGLAR URMI Fig-6.1.2 An Electrical Engineer is operating the radar (Left), Display of Radar Screen (Right) Fig-6.1.3 Over all connection diagram of radar signal processing Fig-6.2.1 Data exchange system of LRIT, Ref. ABB Marine Fig-6.3.1 Eleectronics Navigation Fig-6.6.1 Location of SVDR

List of Table

No. Table page 17 36 Table 1 A fleet profile of BSC Table 2 Results of field voltage and field current when the input voltage fluctuation occurred

page 10

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Executive Summary

Ship power supply system consists of ship power plants and auxiliary systems. In accordance with the most popular classification, power plants can be classified by source of energy (coal, diesel, petrol, natural gas, hydropower, geothermal, solar, wind and nuclear, etc) or operational principle (steam, turbine, etc). The most commonly encountered type is diesel power plant. It is used in 90% of ships. In addition to high power, it has relatively small dimension which is very important at sea. Other plants (gas and steam turbine or nuclear plant) also have their own strong points and are used on various ships. Altogether, selection of optimum ship power plant depends on type, dimensions, proposed characteristics and conditions of operation of a vessel. Each system studied employed rotating machines that were built using HTS (high temperature superconductor) wires. The software enabled modeling of electrical systems with full transient details to study the dynamic response of the electric system over a wide frequency range. The default models and standard features available in online served all the requirements. A number of fault and load scenarios were studied. The goal of this simulation work was to develop a model for studying the dynamic behavior of the ships electrical system. This goal was successfully achieved. Recent advances in the development of all electric ships for the U.S. Navy indicate that the total power requirements on large surface ships could approach 100 MW. New technologies and techniques are emerging that manage the generation and utilization of the anticipated power level. As the power level and the number of critical electrical components on the ship increase, so does the complexity of analyzing the system. Traditionally, naval ships had relatively low electric power and simple electric systems, which could be analyzed using simple calculations. As a result, the experience in the application of advanced dynamic tools to analyze power systems of large combatant electric ships is limited. This report shows how a power system simulation tool could be used to study the ship electrical system dynamics.

page 11

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

1. Introductory Part

1.1 Origin of the Report

This report on Power Generation, Utilization and Communication System of Marine Vessel is prepared by Mohammad Abu Kawsar for the Bachelor of Science in Electrical and Electronics Engineering program for the department of Electrical & Electronics Engineering under IUBAT (International University of Business Agriculture and Technology) as an integral part of the internship. He has done this practicum report based on onboard ships of Bangladesh Shipping Corporation, under the supervision of Engr. Md. Ahasan-ul-Karim, Assistant General Manager (BSC Marine Workshop), Saltgola, Chittagong.

1.2 Objectives

Broad Objective

The broad objective of the report has been made on Power Generation, Utilization and Communication System of onboard ships of Bangladesh Shipping Corporation.

Specific Objectives

The specific objectives of this report include: Studying on power generation system of marine vessels, Identifying the different types of problem which arise for power generation and utilizations, and Studying on communication system and electronic navigation of marine vessels.

1.3 Scope

Electrical installations are present in any ship for empowering of communication and navigation equipment, alarm and monitoring system, running of motors for pumps, fans or winches, high power installation for electric propulsion. Electric propulsion is an emerging area where various competence areas meet. Successful solutions for vessels with electric propulsion are found in environments where naval

page 12

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

architects, hydrodynamic and propulsion engineers, and electrical engineering expertise cooperate under constructional, operational, and economical considerations.

1.4 Background

The concept of electric propulsion is not new; the idea originated more than 100 years ago. However, with the possibility to control electrical motors with variable speed in a large power range with compact, reliable and cost competitive solutions, the use of electrical propulsion has been emerged in new application areas.

Electric propulsion with gas turbine or diesel engine driven power generation is used in hundreds of ships of various types and in a large variety of configurations. Installed electric propulsion power in merchant marine vessels was the range of 6-7 GW (Giga Watt) in 2002, in addition to a substantial installation in both submarine and surface war ship applications. At present, electric propulsion is applied mainly in following type of ships: Cruise vessels, ferries, DP drilling vessels, thruster assisted moored floating production facilities, shuttle tankers, cable layers, pipe layers, icebreakers and other ice going vessels, supply vessels, and war ships. There is also a significant on-going research and evaluation of using electric propulsion in new vessel designs for existing and new application areas.

1.5 Methodology

Both primary and secondary data has been collected for the purpose of this report that is concentrated to on-board Ships of Bangladesh Shipping Corporation.

Primary Data

Primary data are collected from the ships while working on-board, books about marine power generation, the user manual handbook of Electrical equipment and personal meet to the host supervisor, Electricians of BSC Marine Workshop and engine room operation manuals.

Secondary Data

Secondary data has been collected from the online resources.

page 13

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

1.6 Limitations

This report is also having some limitations as I didnt get a soft copy of datum or help from on-board mariners. I have seen that most marine officers and marine engineers are very overconfident and stubborn. They dont want to provide any information to internship candidates, like me, while working on-board ships. I had little chance to take photos and other information because the engine and control room is a restricted and sensitive area. As I was very new there, they didnt allow me the spontaneous access to all of the equipment and which prevents me from collecting sufficient information as I desired to.

2. Organizational Overview

2.1 Profile of Bangladesh Shipping Corporation

The Bangladesh Shipping Corporation, a state owned and managed public sector Corporation, is the largest ship owner in Bangladesh. It was established on 5th February 1972 under Presidents Order No. 10 of 1972 with the objectives of providing efficient, safe, reliable and economic shipping services to the local exporters, importers and business houses, to develop sustainable shipping and ancillary infrastructures in a sovereign nation which just became independent on 16th December 1971 after a nine month long liberation war and thereby reducing dependence on foreign flag vessels to stop drainage of hard earned foreign exchange from the national exchequer. BSC is managed by the managing director, directors, a secretary, a general manager, an assistant general manager and office staff headed by the shipping minister as ex officio chairman. The corporation did not have any ship at the beginning when it started working as agents for other shipping company. The Board of Directors for BSC is formed by the Hon'ble Minister for Shipping as its ex officio Chairman, Secretary, Joint Secretary, Finance Division, Ministry of Finance, Managing Director, Executive Director (Finance), Executive Director (Commercial) and Executive Director (Technical) of BSC as members.

page 14

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

The head office of BSC is situated in Chittagong, Bangladesh with branch offices in Dhaka and Khulna. All of its offices are dealing in marketing and chartering ships. The marketing department takes care of maintaining the corporation's ships and the chartering department looks after the chartering ships, maintaining public relations and recruiting officers and staff. It maintains offices in Singapore and London. The corporation owned its first ship Banglar Doot in 1974. By 2001 it had 13 ships, including 2 oil tankers. It charters out its container ships and tankers and also charters in ships from other companies. The BSC has been playing a significant role in exporting and importing oil products, readymade garments, machinery and food stuff. The biggest vessel is considered to be Banglar Doot (carrying capacity 16,771MT) and Banglar Kakali (carrying capacity 16,764MT). The corporation has two dockyards one at Khulna and other at Chittagong where its ships are being maintained regularly.

2.2 Mission of BSC

To provide safe and efficient shipping services on international routes and to carry out all forms of activities connected with or ancillary to shipping as national flag carrier and thereby contributing to the national economy.

2.3 Vision of BSC

We want to emerge as a respectable competitor in all the sectors of shipping industry in which we compete. We are optimistic that accomplishment of our corporate goals and objectives will be founded on our absolute dedication, integrity, and sincerity to serve up to the satisfaction of our clients, associates and partners through constant innovation, operational excellence, cost effectiveness and the talents of our people.

2.4 Objectives of Bangladesh Shipping Corporation

To acquire, charter, hold or dispose of ships or crafts, To provide safe, reliable, efficient and economic shipping services,

page 15

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

To promote any organization, in or outside Bangladesh, for the purpose of engaging in any activity falling within the function of the Corporation, or to associate with any such organization, To undertake the repairs, overhaul construction, reconditioning or assembly of ships, vessels and other vehicles, To assemble, manufacture, recondition, overhaul and repair machines, parts, accessories and instruments pertaining to ships, vessels and other vehicles, To establish institutes or make other arrangements for the instruction and training of persons engaged or likely to be engaged in any activities connected with or ancillary to shipping, To acquire, hold or dispose of any property, whether moveable or immovable, To be a profitable and commercially viable organization and contribute to the national economy by securing a reasonable share of the countrys total export and import through sea.

2.5 Future Plan of Bangladesh Shipping Corporation

Bangladesh Shipping Corporation has been relentlessly trying for balancing and modernizing the national fleet under replacement and expansion scheme. With this in mind, a fleet planning study was conducted. A strategic plan was sketched to build up a mixed fleet of 24 vessels with an aim of acquiring 15 ships (1 second hand mother tanker, 8 second hand / new full cellular container vessels and 6 second hand multipurpose cargo vessels) gradually during the time scale started from the fiscal year 1996-97 to 2004-2005. Unfortunately due to non-availability of fund BSC could not procure any ship according to the plan. Nevertheless, in accordance with present trend of the shipping trade BSC has been trying to acquire container vessels on priority basis.

2.6 Fleet Profile of Bangladesh Shipping Corporation

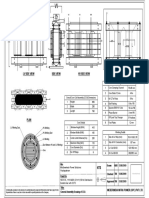

Table1. The fleet profile of BSC

Sl. No 1 2 3 4 5 Name of Vessels M.V. Banglar Kakoli M.V. Banglar Kallol M.V. Banglar Mamata M.V. Banglar Maya M.V. Banglar Robi Year of Built 1979 1980 1980 1980 1981 Country of Built Japan Japan Japan Japan East Germany DWT 17234 17222 15877 15833 12720 GRT 12521 12521 11764 11764 10383 Class BV BV BV BV BV Date of Acquisition 18-12-1979 24-01-1980 04-06-1980 10-09-1980 07-01-1983

page 16

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

6 7 8 9 10 11 12 13

M.V. Banglar Gourab M.V. Banglar Moni M.T. Banglar Jyoti M.V. Banglar Urmi M.T. Banglar Shourabh M.V. Banglar Doot M.V. Banglar Mookh M.V. Banglar Shikha

1983 1983 1987 1984 1987 1988 1989 1991

France East Germany Denmark Spain Denmark China China China

13934 12680 14541 15552 14541 16771 16769 12945

9782 10383 8672 9840 8672 13125 13125 9927

BV BV BV BV BV BV BV BV

21-01-1983 09-09-1983 15-05-1987 14-07-1987 14-10-1988 12-12-1988 12-10-1989 16-07-1991

2.7 Services of Bangladesh Shipping Corporation

2.7.1 Bangladesh-Pakistan-West Asia Gulf Liner Service

From 1980 BSC is regularly operating vessels in the Bangladesh-Pakistan-West Asia Gulf Liner route. BSC offers monthly sailing in this route.

2.7.2 Bangladesh/UK-Continent/Africa Liner Service

Since inception BSC has been operating liner service in the Bangladesh/UK-Continent/Africa route on regular basis. Due to rapid containerization of break bulk cargoes, the pattern of sea borne trade has been changed radically over the last one decade and as such the traditional liner service of breakbulk cargo vessels between Bangladesh/UK-Continent and African routes became economically non-viable. Besides due to the increasing number of regulations enacted by IMO the regulatory bodies in the European Union ratified their shipping policies and set a very high standard for the vessels calling European ports. It has become a rigorous task for the ship owners to maintain an aged traditional liner vessel up to such a high standard. Under the circumstances BSC had to suspend its regular liner service between Bangladesh/UKContinent ports and the Africa service since year 2000. However, procurement of new vessels may open opportunities in future to reopen the liner service subject to the inducement of sufficient cargo.

2.7.3 Bangladesh/Far East/Japan Liner Service

BSC started its regular liner service in the Bangladesh/Far East/Japan route from 1980. But due to scarcity of export cargo from Bangladesh to Far East BSC's service in Bangladesh/Far East/Japan route was suspended since 1998. In order to retain the membership of Benjap

page 17

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Conference BSCs sailing right has been sublet to an active Benjap Conference member Everett Orient Line.

2.7.4 Chartering & Tramping Service

BSC engages its vessels both on time and voyage charter. At present most of the vessels are under time charter to various local and foreign companies. With these vessels charterers are operating tramp services in the ports of South America to East/West Africa and SubContinent to Middle East/Gulf region.

2.7.4 Crude Oil Lightening

BSC provides crude oil lightening service to BPC (Bangladesh Petroleum Corporation) for carrying crude oil from the mother vessels anchored at Kutubdia outer anchorage to ERL (Eastern Refinery Limited) shore tank as their lighterage contractor with the two purposes built lighter vessels M.T. Banglar Jyoti and M.T. Banglar Shourabh.

2.7.5 Food Grain Carrying

Bangladesh Shipping Corporation provides Ministry of Food a total transportation solution for carriage of food grain from Australia and Canada. It organizes to carry wheat in bulk from Australia and Canada once a year by hiring mother vessels.

2.7.5 Food Grain Lightening

BSC as lighterage contractor provides food grain lightening service to Food Department under Ministry of Food of Bangladesh Government for carrying bulk wheat from the mother vessel anchored at Kutubdia or outer anchorage of Chittagong Port to Grain Silo Jetty at Chittagong or Khulna.

2.7.6 Ship Repair

BSC has its own marine workshop situated on the bank of the river Kharnaphully to carry out maintenance and repair of BSC vessels during vessels stay at Chittagong. The workshop is well equipped and situated in a very good strategic place to provide repair service to the

page 18

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

vessels calling Chittagong. BSC Marine Workshop not only provides repairing service to BSC vessels but also to local private vessels.

3. Hierarchy Level of Onboard Ships Personnel

3.1 Onboard Ships Organogram

Basically crew on ship is divided into two departments; Deck and Engine Department. For a safe and perfect sailing these department play vital role.

Fig 3. Organogram of Onboard Ships Personnel

page 19

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

3.2 Hierarchy Level of Deck Department of Onboard Ship

Introduction

The deck department is concerned with the effective management of vessel crew; maintaining proper watches; maintaining vessel logs for company and customer; maneuvering vessel in port at various docks and offshore at various offshore facilities; general navigation of vessel and overseeing the enforcement of and adherence to all company policies and procedures on board as described under SEACOR's Safety Management System (SMS) manual.

Duties of Captain/Master

Fig 4. showing the Ship Captain on navigational operation (Ref. marineinsight.com)

The captain is in overall command of a Merchant Ship and is responsible for the safety, efficiency and commercial feasibility of his ship. His duties are navigational at sea. While in ports he is responsible for cargo operations. He maintains orderliness and discipline in the ship. He ensures safety of officers crew and the cargo and assigns organizational duties for ship's operation, navigation and maintenance of the ship. He acts as the ship owner's representative with all outside parties. He implements the company's policies for operations and safety and the commercial instructions that may be given by the owners time to time. He is also the legal head of the ship.

page 20

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Duties of Chief Officer

The Chief Officer as he is often called is second in position to the Captain. He is in charge of the deck department and also the deck crew. He oversees all the cargo operations including its handling and stability. He is also responsible for training the deck crew in safety and rescue operations besides other emergency procedures. He is also given the duty as ship security officer in most of the ships.

Fig 5. showing a Chief Officer on navigational operation (Ref. marineineinsight.com)

Duties of Second Officer

The Second Officer is responsible for all the navigation and holds his rank below the Chief Officer. A second officer has the responsibility of maintaining the charts and also plots the routes for navigation. Although on various oil tankers a second mate may assist the chief officer for tank cleaning and maintenance as well. A second officer keeps the 12:00-04:00 at night and 12:00- 16:00 watch in the evening.

Duties of Third Officer

The Third Officer is responsible for all the safety related operations onboard which include regular maintenance of all the firefighting equipment and lifeboats. He is the most junior officer of the deck department and also keeps the 08:00-12:00 and 20:00-12:00 evening watch.

page 21

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Duties of Deck Cadet

A deck cadet is more of a marine graduate who works directly under the chief officer on the ship. Normally a deck cadet has to complete one full year of training on board under the senior ranks.

3.3 Hierarchy Level of Engine Department of Onboard Ship

Introduction

Engine Department is most important equipment of ship organization for safe and economic sealing in sea. Marine engineers are responsible for maintenance of the engine room. The chief engineer and ship engineer are responsible for ensuring that all planned mechanical and electrical maintenance takes place and Co-ordinates operations with shore-side port engineer. With the supervision of chief engineer whole department performs all technical aspect which is required for perfect and smooth running of the ship.

Duties of Chief Engineer

The chief engineer is head of engine department which is responsible for the entire technical operations of the vessel including engineering electrical and mechanical divisions. The whole engine department is worked under the supervision and command of chief engineer.

Fig 6 showing a Chief Engineer working on ships control board (marineinsight.com, 2012)

Duties of the chief engineer in both general and emergency conditions on the ship are:

page 22

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Chief engineer ensures that all the ships machinery and equipment are working in efficient manner in order to support safe navigation of the ship. Frequent inspections of equipment dealing with ship and personal safety must be carried out by him at regular interval of time.

Duties of Second Engineer

The second engineer performs daily maintenance and operations of the engineering and technical aspect of ship in the command of Chief Engineer and in some cases 1st Engineer. Second engineer is known as a watch keeping engineer who watches and assign repair and maintenance duties to crew in engine room.

Duties of Third Engineer

The third engineer is responsible for maintenance and repair of engines and its relative equipments in ship. All the engine crews work under the guidance of Third Engineer.

Duties of Fourth Engineer

The fourth engineer should take a thorough round of the engine department with the signing off engineer and do a proper taking over of the duties. He should check general condition of machinery and special procedure for operation. Condition and layout of bunkering system including valve operation, tanks and sounding pipe location should be checked. Daily consumption of lube oil, fuel oil, marine diesel or gas oil and cylinder oil for daily record keeping in sounding log is to be maintained. After completion of the engine room round together, the 4th Engineer shall report the details to the 2nd engineer and notify discrepancies observed, if any.

Duties of Engine Cadet

Stands engine room watch, assist engine cadet with control room operations and maintain the shipboard propulsion equipment and auxiliary machinery. He should check Inventory and location of pumps spares and tools.

page 23

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

3.4 Hierarchy Level of Electrical Department of Onboard Ship

Introduction

All the machinery onboard ship is a combination of mechanical and electrical systems. The modern day shipping is more reliable on automations and electronics whose knowledge and maintenance can only be handled by an engineer expert in the electrical field. Marine electrical engineers are perfect for such jobs and for this they hold an important role on board and in offshore industry.

Duties of Electrical Engineer on board Ship

Electrical Engineer is one of the most vital positions in the technical hierarchy of a ship and an engineer is responsible for his assigned work under the command of Chief Engineer.

Fig. 7 showing a switchboard, fault detected in M. V. BANGLAR URMI by a trainee Electrical Engineer (Photo was taken while Mr. Kawsar working on board)

page 24

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

The general duties of electrical engineer are:

He is responsible for maintenance of all the electrical motors on ship i.e. in engine room and on deck, He is in charge of maintenance of all switchboard including main switchboard and emergency switchboard, He is responsible for maintenance of fire detectors and fire alarm system, He has to maintain all the ships alarm system, He is responsible for the electronic system fitted onboard ship, He is responsible for the ships navigational lights and other navigational equipments, He is responsible for all the batteries that are connected to machineries onboard. It includes: Emergency batteries for alarm and lights, Batteries for emergency generator, Other batteries fitted onboard.

He is responsible for maintaining refrigeration unit in the engine room, He has to take care of air conditioning unit of the vessel, Electrical officer is responsible for maintaining refrigerated containers carried on container ship, He is responsible for cargo and engine room cranes electrical system. He has to carry out routine maintenance for main engine alarms and trips along with the chief engineer, During the time of maneuvering, he has to be present in the engine room along with other engineers to tackle any kind of electrical and other emergencies, Electrical officer can assist in watch keeping routines at desired time by the chief engineer, He has to assist ships engineer and deck officer in all kind of electrical problems.

page 25

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

4. Overview of Ships Electric Power System

4.1 Introduction

The main difference between the marine and a land-based electrical power system is the fact that the marine power system is an isolated system with short distances from the generated power to the consumers, in contrast to what is normal in land-based systems where there can be hundreds of kilometers between the power generation and the load, with long transmission lines and several voltage transformations between them. The amount of installed power in vessels may be high and this gives special challenges for the engineering of such systems. High short circuit levels and forces must be dealt with in a safe manner. The control system in a land-based electrical power system is divided in several separated sub-systems, while in a vessel; there are possibilities for much tighter integration and coordination.

The design of power, propulsion and control systems for a vessel have undergone significant changes and advances over a relatively recent period of time. Because of the rapidly expanding capabilities of computers, microprocessors and communications networks, the integration of systems which were traditionally separate, stand alone systems is now not only feasible, but fast becoming industry standards. The increasing demand for redundant propulsion and Dynamic Positioning (DP) class 2 and class 3 vessels requires system redundancy with physical separation. The interconnections of the diverse systems on a vessel have become increasingly complex, making the design, engineering and building of a vessel a more integrated effort.

Merchant Ships use three phase power generated and distributed in an ungrounded delta configuration. Ungrounded systems are used to ensure continued operation of the electrical system despite the presence of a single phase ground. The voltages are generated at levels of 450 volts a.c. at 60 hertz. The most popular topology used in Marine electrical system is a ring configuration of the generators which provides more flexibility in terms of generation connection and system configuration. In this type of topology, any generator can provide power to any load. This feature is of great importance in order to ensure supply of power to vital loads if failure of an operating generating unit occurs.

page 26

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

4.2 Electric Power Generation System of Onboard Ships

A ship is like a floating city with all the privileges enjoyed by any normal land city. Just like a conventional city, the ship also requires all the basic amenities to sustain life on board; the chief among them is power or electricity. In this article we will learn as to how power is generated and supplied on board a ship. Shipboard power is generated using a prime mover and an alternator working together. For this an alternating current generator is used on board. The generator works on the principle that when a magnetic field around a conductor varies, a current is induced in the conductor.

Fig. 8 showing the 850 KVA Generator operated by an Electrical Engineer in M. V. BANGLAR URMI (Photo was taken while Mr Kawsar working on board)

The generator consists of a stationary set of conductors wound in coils on an iron core. This is known as the stator. A rotating magnet called the rotor turns inside this stator producing magnetic field. This field cuts across the conductor, generating an induced EMF or electromagnetic force as the mechanical input causes the rotor to turn.

page 27

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

The magnetic field is generated by induction (in a brushless alternator) and by a rotor winding energized by DC current through slip rings and brushes. Few points to be noted about power on board are:

AC, 3 phase power is preferred over DC as it gives more power for the same size. 3 phases is preferred over single phase as it draws more power and in the event of failure of one phase, other 2 can still work.

Prime Mover

The source for power is most often a generator set driven by a combustion engine which is fueled with diesel or heavy fuel oil. Occasionally one can find gas engines and also gas turbines, steam turbines or combined cycle turbines, especially for higher power levels, in light high-speed vessels, or where gas is a cheap alternative (e.g., waste product in oil production, boil-off in LNG carriers, etc.). In a diesel-electric propulsion system, the diesel engines are normally medium to high-speed engines, with lower weight and costs than similar rated low speed engines that are used for direct mechanical propulsion. Availability to the power plant is of high concern and in a diesel electric system with a number of diesel engines in a redundant network; this means high reliability but also sophisticated diagnostics and short repair times.

The combustion engines are continuously being developed for higher efficiency and reduced emissions, and at present, a medium speed diesel engine has a fuel consumption of less than 200g per produced kWh at the optimum operation point.

Moreover, the efficiency drops fast as the load becomes lower than 50% of MCR (Max Continuous Rating). At this working condition, the combustion is inefficient and with a high degree of soothing which increases the need for maintenance. In a diesel electric system with several diesel engines it is hence an aim to keep the diesel engines loaded at their optimum operating conditions by starting and stopping generator sets dependent on the load with an aim to keep the average loading of each diesel engine closest possible to its optimum load point.

page 28

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Generators

The majority of new buildings and all commercial vessels have an AC power generation plant with AC distribution. The generators are synchronous machines, with a magnetizing winding on the rotor carrying a DC current and a three-phase stator winding where the magnetic field from the rotor current induces a three-phase sinusoidal voltage when the rotor is rotated by the prime mover. The frequency f [Hz] of the induced voltages is proportional to the rotational speed n [RPM] and the pole number p in the synchronous machine:

A two-pole generator will give 60 Hz at 3600 RPM, a four-pole at 1800 RPM, and a six-pole at 1200 RPM, etc. 50 Hz is obtained at 3000 RPM, 1500 RPM, and 1000 RPM for two-pole, four-pole, and six-pole machines. A large medium speed engine will normally work at 720 RPM for 60 Hz network (10 pole generator) or 750 RPM for 50 Hz networks (8 pole generator). The DC current was earlier transferred to the magnetizing windings on the rotor by brushes and slip rings. Modern generators are equipped with brushless excitation for reduced maintenance and downtime, Fig. 4.2. The brush-less excitation machine is an inverse synchronous machine with DC magnetization of the stator and rotating three-phase windings and a rotating diode rectifier. The rectified current is then feeding the magnetization windings.

Fig - 9 Magnetization of the rotor winding, Left: Brushed; Right: Brush-less magnetization.

page 29

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

The excitation is controlled by an automatic voltage regulator (AVR), which senses the terminal voltage of the generator and compares it with a reference value. Simplified, the controller has PID characteristics, with stationary limited integration effect that gives a voltage drop depending on the load of the generator. The voltage drop ensures equal distribution of reactive power in parallel-connected generators. According to most applicable regulations, the stationary voltage variation on the generator terminals shall not exceed 2.5% of nominal voltage. Also, the largest transient load variation shall not give voltage variation exceeding -15% or +20% of the nominal voltage unless other has been specified and accounted for in the overall system design. In order to obtain this transient requirement, the AVR is normally also equipped with a feed-forward control function based on measuring the stator current. In addition to the magnetizing winding, the rotor is also equipped with a damper winding which consists of axial copper bars threaded through the outer periphery of the rotor poles, and short circuited by a copper ring in both ends. The main purpose of this winding is to introduce an electromagnetic damping to the stator and rotor dynamics. A synchronous machine without damper winding is inherently without damping and would give large oscillations in frequency and load sharing for any variation in the load. The stationary, transient and sub-transient models are known from the theory of synchronous machines. Simplified one could say that the flux linkages in the damper winding, which are trapped and resist changes due to being short-circuited, characterize the sub-transient interval. This is observed as an apparent lower inductance in the generator, which gives a stiffer electric performance during quick load variations, and helps to reduce transient voltage variations and the voltage variations due to harmonic distortion in load currents. This effect is only contributing for dynamic variations faster than characterized by the sub-transient time constant such as the first period of motor start transients and transformer inrush, and for harmonic distorted load currents. Often, the generators are connected to a propulsion engines shaft, i.e. a shaft generator. The shaft generators are in some applications made for two-directional power flow, which means that it can be run as motor.

page 30

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

This principle may be called a PTI-PTO concept (Power take-in Power take out). Shaft generators have the disadvantage of forcing the main propeller to work at fixed speed if the generator output shall have constant frequency. This will reduce the efficiency of the propeller in low load applications. Static converters may be installed to keep fixed frequency for variable speed.

Synchronous Alternator

Synchronous alternators are the main machines used for the generation of electrical energy. They are intended to supply electrical power to the final loads through transmission and distribution systems. Besides, without going into technical details, by acting on the excitation of alternators, it is possible to vary the value of the generated voltage and consequently to regulate the injections of reactive power into the network, so that the voltage profiles of the system can be improved and the losses due to joule effect along the lines can be reduced.

Principles of Synchronous Generator

The operation of a generator is based on Faradays law of electromagnetic induction. If a coil or winding is linked to a varying magnetic field, then electromotive force or voltage is induced across the coil. Thus, a generator has two essential parts: one that creates a magnetic field and the other where the energy is induced. The magnetic field is typically generated by electromagnets. These windings are called field winding or field circuits. The coils where the electro motive force energies are induced are called armature windings or armature circuits. With rare exceptions, the armature winding of a synchronous machine is on the stator, and the field winding is on the rotor. The field winding is excited by direct current conducted to it by means of carbon brushes bearing on slip rings or collector rings.

The rotor of the synchronous generator may be cylindrical or salient construction. The cylindrical type of rotor has one distributed winding and a uniform air gap.

These generators are driven by steam turbines and are designed for high speed 3000 or 1500 rpm (revolution per minute, two and four pole machines respectively) operation. The rotor of

page 31

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

these generators has a relatively large axial length and small diameter to limit the centrifugal forces.

The salient type of rotor has concentrated windings on the poles and non-uniform air gaps. It has a relatively large numbers of poles, short axial length, and large diameters. The generators in hydroelectric power stations are driven by hydraulic turbines and they have salient pole rotor construction. The cylindrical and salient type rotors are shown in Figure (1). The rotor is also equipped with one or more short-circuited windings known as damper windings. The damper windings provide an additional stabilizing force for the machine during certain periods of operation. When a synchronous generator supplies electric power to a load, the armature current creates a magnetic flux wave in the air gap which rotates at synchronous speed. This flux reacts with the flux created by the field current, and electromagnetic torque results from the tendency of these two magnetic fields to align. In a generator this torque opposes rotation and mechanical torque must be applied from the prime mover to sustain rotation. As long as the stator field rotates at the same speed as the rotor and no current is induced in the damper windings. However, when the speed of the stator field and the rotor become different, currents are induced in the damper windings. Currents generated in the damper windings provide a counter torque. In this way the damper windings can keep the two speeds. Two types of rotor has been displayed in the following.

Fig 10. Two Types of Rotor Construction: (a) Cylindrical Type Rotor and (b) Salient Type Rotor (Ref. marineinsight.com, 2012)

4.3 Automatic Voltage regulator

A voltage regulator is defined as a device for varying the voltage of a circuit or for automatically maintaining it at or near a prescribed value. From this, it would appear that the

page 32

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

term automatic voltage regulator covers the apparatus used in the methods of obtaining a constant voltage. A voltage regulator is designed to automatically maintain a constant voltage level. A voltage regulator may be a simple "feed-forward" design or may include negative feedback control loops. It may use an electromechanical mechanism, or electronic components. Depending on the design, it may be used to regulate one or more AC or DC voltages. Electronic voltage regulators are found in devices such as computer power supplies where they stabilize the DC voltages used by the processor and other elements. In automobile alternators and central power station generator plants, voltage regulators control the output of the plant. In an electric power distribution system, voltage regulators may be installed at a substation or along distribution lines so that all customers receive steady voltage independent of how much power is drawn from the line.

Circuit Design of the AVR for the Synchronous Generator

The circuit arrangement of the field control circuit of the synchronous generator is shown in Fig.7. In this system, the output voltage of the generator is sampled through the transformer and is rectified by simple circuit and the bridge rectifier. In the initial state condition, the output of the generator may be 25V or 30V which depends on the electromagnetic field in the machine, at the time, the 12V relay is normally close position. At the time, the gate voltage is fed to the synchronous generator field coil until the output voltage is 230V. Now, 12V relay is normally open position.

When the mains supply voltage falls, Q2 produce negative current to the bridge circuit and the bridge circuit supplies positive current to the gate of SCR and the required current is fed to the field coil and the output voltage of the synchronous generator is increased.

When the output is 230V, the output positive current of the bridge is balanced with the output negative current of the Q1. When the main supply voltage raises, Q2 will give a little current is fed to the gate of SCR and the required field current is fed to the field coil and absorbs the required reactive power from the supply line.

page 33

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Fig 11. Over all Circuit of AVR for the Diesel Engine Type Synchronous Generator (Ref. marineinsight.com, 2012)

page 34

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Fig 12. AVR Design for the Diesel Engine Type Synchronous Generator

Tests and Results

These results are obtained by feeding the variable over or under input voltage to the electronic control circuit, and 100 watts bulb is used as a field coil. The output of the generator voltage must be stable although the various input voltage pass through electronic control circuit.

Table 2 Results of field voltage and field current when the input voltage fluctuation occurred

page 35

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

4.4 How to Synchronize Generators of Onboard Ship?

Synchronizing of an incoming generator or alternator is very important before paralleling it with another generator. The synchronizing of the generator is done with the help of synchroscope or with three bulb method in case of emergency. It is of utmost importance that before paralleling the generators the frequency and voltage of the generators need to be matched. In this article we will describe the method for synchronizing generators on a ship. There are two methods to synchronize generators on a ship one is the normal and other is the emergency method.

Synchroscope Method

Fig 13. Circuit Diagram of Synchroscope Method (Ref. marineinsight.com, 2012)

The synchroscope consists of a small motor with coils on the two poles connected across two phases. Lets say it is connected in red and yellow phases of the incoming machine and armature windings supplied from red and yellow phases from the switchboard bus bars.

page 36

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

The bus bar circuit consists of an inductance and resistance connected in parallel. The inductor circuit has the delaying current effect by 90 degrees relative to current in resistance.

These dual currents are fed into the synchroscope with the help of slip rings to the armature windings which produces a rotating magnetic field.

The polarity of the poles will change alternatively in north/south direction with changes in red and yellow phases of the incoming machine.

The rotating field will react with the poles by turning the rotor either in clockwise or anticlockwise direction.

If the rotor is moving in clockwise direction this means that the incoming machine is running faster than the bus bar and slower when running in anticlockwise direction.

Generally, it is preferred to adjust the alternator speed slightly higher, which will move the pointer on synchroscope is in clockwise direction.

The breaker is closed just before the pointer reaches 12 o clock position, at which the incoming machine is in phase with the bus bar.

Emergency Synchronizing Lamps Method

This method is generally used when there is a failure of synchroscope. In case of failure a standby method should be available to synchronize the alternator, and thus the emergency lamp method is used. Three lamps should be connected between three phases of the bus bar and the incoming generator should be connected as shown in the diagram:

page 37

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Fig-4.4.2 Circuit Diagram of Emergency Synchronizing Lamps Method, (Ref. marineinsight.com, 2012)

The lamps are connected only in this manner because if they are connected across, the same phase lamps will go on and off together when the incoming machine is out of phase with the switchboard.

In this method as per the diagram the two lamps will be bright and one lamp will be dark when incoming machine is coming in phase with the bus bar.

The movement of these bright and dark lamps indicates whether the incoming machine is running faster or slower.

For e.g. there is a moment when lamp A will be dark and lamp B & C will be bright, similarly there will be instance when B is dark and others are bright and C is dark and other two are bright. This example indicates that machine is running fast and the movement of the lamps from dark and bright gives an clockwise movement

Clockwise movement indicates fast and anti clockwise direction indicates slow running of incoming generator.

page 38

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

4.5 Why are Transformer and Alternator Ratings in kVA on Ships?

On ships, not only transformers, but also generators, protection devices etc., are mostly rated in kVA. A motor does mechanical work and thus has mechanical output expressed in kW. A transformer is a static device, which does not perform any mechanical work. But the main functions are stepping down and stepping up of voltage ratings. Invariably, while stepping up/down the voltage, it also steps down/up the current inversely. Thus the rating of a transformer can only be expressed as a product of Volts and Amp. (V x I)

Amps Rating

The current flowing through the transformer can vary in power factor, from zero PF lead (pure capacitive load) to zero PF lag (Pure inductive load) and is decided by the load connected to the secondary. The conductor of the transformer winding is rated for a particular current beyond which it will exceed the temperature for which its insulation is rated irrespective of the load power factor.

Voltage Rating

The maximum voltage which the primary winding can be subjected to has also a maximum limit. If the applied voltage to the primary winding exceeds the maximum rated value, then this will cause magnetic saturation of the core leading to distorted output with higher iron losses. Thus considering both the above ratings, it is usual for transformers to be rated in VA. It can further be understood as product of voltage & Current. But this does not mean that one can apply a lower voltage and pass a higher current through the transformer contributing to the rated VA value. The VA value is bounded individually by the rated voltage and rated current. All electrical equipments in connection with generation, transmission, distribution of a.c. power such as alternators, transformers, switchgear, cables etc are rated on k VA basis. We know that, Cos = kW / k VA, or kVA = kW / Cos . It is evident from the above equation that the larger the Power factor, the smaller is the k VA requirement of the machinery. Therefore at low power factors, the K VA rating of the

page 39

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

equipment has to be made more, making the equipment larger and expensive. Thus kVA rating is so important and it is assigned at the design stage itself.

4.6 Parallel Operation of Two Generators

When two synchronous generators are connected in parallel, they have an inherent tendency to remain in step, on account of the changes produced in their armature currents by a divergence of phase. Consider identical machines 1 and 2, Fig. 4.5.1 in parallel and working on to the same load. With respect to the load, their emfs (electromotive forces) are normally in phase: with respect to the local circuit formed by the two armature windings, however, their emfs are in phase-opposition. Suppose there to be no external load. If machine 1 for some reason accelerates, its e.m.f. will draw ahead of that of machine 2. The resulting phase difference 2 causes e.m.fs to lose phase-opposition in the local circuit so that there is in effect a local e.m.f Es which will circulate a current Is in the local circuit of the two armatures. The current Is flows in the synchronous impedance of the two machines together, so that it lags by = arc tan(xs/r) 90 on Es on account of the preponderance of reactance in ZsIs therefore flows out of machine 1 nearly in phase with the e.m.f., and enters 2 in opposition to the e.m.f. Consequently machine 1 produces a power Ps E1Is as a generator, and supplies it (IR losses excepted) to 2 as a synchronous motor. The synchronizing power Ps tends to retard the faster machine 1 and accelerate the slower 2, pulling the two back into step. Within the limits of maximum power, therefore, it is not possible to destroy the synchronous running of two synchronous generators in parallel, for a divergence of their angular positions results in the production of synchronizing power, which loads the forward machine and accelerates the backward machine to return the two to synchronous running.

The development of synchronizing power depends on the fact that the armature impedance is preponderating reactive. If it were not, the machines could not operate stably in parallel: for the circulating current Is would be almost in phase quadrature with the generated e.m.f.s, and would not contribute any power to slow the faster or speed up the slower machine.

page 40

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

When both machines are equally loaded pn to an external circuit, the synchronizing power is developed in the same way as on no load, the effect being to reduce the load of the slower machine at the same time as that of the faster machine is increased.

The conditions are shown in Fig. 35, where I1, I2 are the equal load currents of the two machines before the occurrence of phase displacement, and I1, I2 are the currents as changed by the circulation of the synchronizing current Is.

Fig 15. Two Generators Set, Ref. M.V. BAGLAR KALLOL

Fig 16. Circuit Diagram of Generators Set

page 41

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Fig-4.6.2 Vector Diagram of Parallel Operation, Ref. IIT, Madras, India

Fig-4.6.2 Generators Governor Characteristic

The argument above has been applied to identical machines. Actually, it is not essential for them to be identical, nor to have neither equal excitations nor power supplies. In general, the machines will have different synchronous impedance Zs1, Zs2; different e.m.f.s E1 and E2 and different speed regulations.

The governors of prime movers are usually arranged so that a reduction of the speed of the prime mover is necessary for the increase of the power developed. Unless the governor speed/load characteristics are identical the machines can never share the total load in

page 42

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

accordance with their ratings. The governor characteristics take the form shown in Fig. 4.5.2. If the two are not the same, the load will be shared in accordance with the relative load values at the running speed, for synchronous machines must necessarily run at identical speeds.

4.7 Principles of Power Factor

Definition of Power Factor

The cosine of angle between voltage and current in an a.c. circuit is known as Power Factor. Power factor (PF) can be represented by the power triangle to show the relationship between real powers in kilowatts (A), reactive power in kilovolt-amps reactive (B) and apparent power in kilovolt-amps (C):

Fig-4.7.1 Power Triangle (Ref. Books and Hand Work)

Real power performs actual work such as heating a burner element or illuminating an incandescent bulb. Reactive power does not perform work but energizes magnetic fields in motor windings or power supplies which create inductive loads. Apparent power is the result of combining real power and reactive power. It measures the true load of an electrical distribution system. If real power and reactive power exist simultaneously, why can't we just add them together to get apparent power? The reason is that purely reactive current (inductive load) is ninety degrees out of phase with real current (resistive load). Thus, we use the power triangle vectors to graphically represent this 90 degree relationship.

page 43

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Another way to look at this relationship is to compare the sine waves, or oscillograms, of voltage and current for resistive and inductive loads. In a purely resistive load the current sine wave and voltage sine wave are in sync with one another. The PF in this case is 100 percent or unity.

Fig-4.7.2 Sine wave of Real Power & Reactive Power (Ref. Books and Hand Work)

In a purely inductive load the current sine wave lags 90 degrees behind the voltage sine wave. The PF in this case would be zero. In the real world there are no purely inductive loads because there is always some amount of work being done by the device even if it is only the generation of heat. On the other hand, purely resistive loads do exist in the real world such as a burner element or incandescent bulb. When energized they have a PF of unity.

Impact of Low Power Factor

Low PF causes an inefficient utilization of electric power. In other words, you are using more current to do the same amount of work when the PF is low. If we take the basic equation for single phase power: And solve for current we get: Power = Voltage x Current x Power Factor Current = Power__ Volts x PF

Voltage is assumed to remain constant in this example. If power is to be maintained, current must go up when PF decreases. This increased requirement for current is where the electrical inefficiency occurs.

page 44

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Lets look at it graphically with two power triangles:

Fig-4.7.3 Low Power Factor Affective Triangle (Ref. Books and Hand Work)

In the example on the left the PF was measured at 70 percent. If our goal is to produce 100 kilowatts of real power we find that 141 KVA are required.

The power triangle on the right shows a PF of 95 percent. In this instance only 105 KVA are required to produce the same amount of real power. Since voltage remains constant, the current must increase by 35 percent to deliver the desired power when the PF is at 70 percent.

Power Factor Correction

Is there a way to correct this inefficient use of current? The answer is yes, by using power factor correction capacitors. These capacitors are wired in parallel with the load. They may be installed at the service entrance of the building or be dedicated to a specific device with a low power factor. PF correction capacitors are sized by the amount of KVAR they are able to correct. To determine proper sizing, the PF for the building or the device must be measured under normal operating conditions. A target PF such as 95 percent is selected. Using the Pythagorean Theorem we can calculate the proper amount of correction as shown here:

page 45

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Fig-4.7.4 Power Factor Correction Triangle (Ref. Books and Hand Work)

If your home energy metering system can measure PF, take advantage of this information. Check the PF on the larger motors in your home such as HVAC compressors and fans or a pool pump if you have one. If it is below 80 percent you may want to consider power factor correction capacitors for these motors. Limit correction to only your larger motors as power factor correction capacitors can introduce additional harmonic currents into your electrical system.

Harmonics can interfere with power line carrier communications which may affect your home energy monitor system. Click here for more information about how PF and harmonics interrelate. Running motors with a higher PF has its benefits. Using more efficient power can lower operating temperatures which extends bearing and motor life. It also reduces the load on your transformer and decreases the amount of reactive currents circulating in your household wiring although you probably won't see any direct savings on your electric bill. This is because most residential utility rates only charge for kilowatt-hours (KWh), not kilovolt-amp hours (KVAh) nor do they apply a specific penalty for low power factor. Check the fine print on your power bill to be sure. This may change in the future as residential customers add more inductive loads with electronic power supplies and home automation equipment.

page 46

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

4.8 Automatic Power Factor Improvement Controller (APFIC)

Introduction

The power factor controller is used for compensation of the reactive power of power systems. The magnitude of the reactive power Q in the power system can be calculated from the apparent power S and the active power P.

The power factor cos is defined as the ratio between the active power and the apparent power:

Consequently, the power factor controller must permanently monitor the value of the power factor, which is used for calculating the reactive power component of the apparent power.

The power factor and the reactive power can be continuously calculated from the system voltages and currents. Based on the need for compensation at any given time, one to four capacitor banks can be switched on or off by the controller.

page 47

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Construction Diagram

Fig-4.8.1 Connection Diagram of PFI Controller (Ref. Hand Drawing)

The automatic power factor controller connection diagram is shown in Fig-4.7.1. The automatic power factor controller is consisting by capacitor bank, fuse, magnetic contactor, module case circuit breaker and power factor controlling Metter.

page 48

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Operation

The power factor controller features a manual and an automatic operation mode. At manual operation each capacitor bank can be switched on and off using the defined inputs of the function block. This means that pulse-type signals are to be used for switching on and off, which has to be considered in the configuration of the complete controller scheme. If a capacitor bank is switched on, a logical signal 1 will appear on the associated output. When this signal is switched off, the output will show a logical signal 0. To ensure that the controller is always informed of the switch status of the capacitor banks a check-back signal confirming the switch position must be fed back via the binary inputs. Fig-4.7.2 shows a configuration example for a power factor controller managing five capacitor banks.

Fig-4.8.2. The photo was taken from BSC marine workshop while changing damaged fuse

page 49

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

Compensation of reactive power is only required when the power system is in its operational state. Therefore, the operability of the power factor controller can be made dependent on the level of the system voltage. For this reason, the power factor controller should always include an over voltage and under voltage function for monitoring the system voltage. If one of the voltage limit pick-up values, either over voltage or under voltage, is exceeded and the respective time delay has expired, all active capacitor banks will be switched off immediately.

Time Setting

When the auxiliary supply is switched on, the power factor controller is blocked for the initialization period and will not start operating until the initialization time has expired. The same initialization time starts when the system voltage is recovering after a power system fault, e.g. when the under voltage signal has been reset and the binary input DISCONNECT is inactive. The initialization time is preferably given a value longer than the set blocking time for the capacitor banks to discharge. If, during an ongoing power factor control sequence, a capacitor bank is switched on to compensate for the reactive power, transient phenomena will generally occur. This is why the calculation of the power factor control must be delayed until most of the transient phenomena have subsided. A dead time must be set for the power factor controller to bridge the transient condition of the system. Further switching of the capacitor group will not be enabled until the dead time has expired. However, a prerequisite for enabling switching of the capacitor group is that the concerned capacitor bank is fully discharged.

Setting Example

Two capacitor banks of 6.36 F each shall be applied to compensate the reactive power in a 10 kV power system. Consequently, each capacitor bank is able to compensate a reactive power of

, which equals the capacity of the smallest capacitor bank.

The maximum number of switching cycles shall be limited to 10,000, which is given by the CB ratings provided by the manufacturer of the circuit breaker. The related setting parameter can be seen in Fig-4.7.2.

page 50

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

4.9 Emergency Power System of Onboard Ship

In case of the failure of the main power generation system on the ship, an emergency power system or a standby system is also present. The emergency power supply ensures that the essential machinery and system continues to operate the ship. Emergency power can be supplied by batteries or an emergency generator or even both systems can be used.

Fig-4.9.1. Emergency Generator (Ref. ABB Marine, 2012)

Rating of the emergency power supply should be made in such a way that it provides supply to the essential systems of the ship such as a) Steering gear system

b) Emergency bilge and fire p/p c) Watertight doors.

d) Fire fighting system. e) f) Ships navigation lights and emergency lights. Communication and alarm system.

Emergency generator is normally located outside the machinery space of the ship. This is done mainly to avoid those emergency situations wherein access to the engine room is not

page 51

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

possible. A switch board in the emergency generator room supplies power to different essential machinery.

4.10 Power Distribution System of Onboard Ship

The Power Distributed on board a ship needs to be supplied efficiently throughout the ship. For this the power distribution system of the ship is used.

Fig-4.10. Power Distribution Board (Ref. photo taken while working on board in M.V. Banglar Urmi)

A shipboard distribution system consists of different component for distribution and safe operation of the system. They are:

Ship Generator consisting of prime mover and alternator. Main switch board which is a metal enclosure taking power from the diesel generator and supplying it to different machinery.

Bus Bars which acts as a carrier and allow transfer of load from one point to another. Circuit breakers which act as a switch and in unsafe condition can be tripped to avoid breakdown and accidents. Fuses as safety device for machinery.

Transformers to step up or step down the voltage. When supply is to be given to the lighting system a step down transformer is used in the distribution system.

In a power distribution system, the voltage at which the system works is usually 440v. There are some large installations where the voltage is as high as 6600v.

page 52

Power generation, utilization and communication system of marine vessel

M. A. Kawsar (08305058)

For smaller supply fuse and miniature circuit breakers are used. The distribution system is three wires and can be neutrally insulated or earthed.

5. Overview of Ships Power Utilization

5.1 Battery Charging System of Onboard Ship