Академический Документы

Профессиональный Документы

Культура Документы

5R55S Pinpoint Tests

Загружено:

Jason WolfeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

5R55S Pinpoint Tests

Загружено:

Jason WolfeАвторское право:

Доступные форматы

307-01-1

Automatic Transaxle/Transmission

307-01-1

DIAGNOSIS AND TESTING

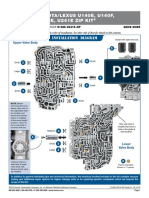

Pinpoint Tests OSC Equipped Vehicles

Special Tool(s) Transmission Fluid Pressure Gauge 307-004 (T57L-77820-A) Transmission Tester 307-F016 (007-00130) or equivalent 73 III Automotive Meter 105-R0057 or equivalent Special Tool(s) MLP-TR Cable 418-F107 (007-00111) or equivalent

Shift Solenoid Pre-Diagnosis

Trans Tester TR/MLP Overlay and Manual 007-00131 or equivalent

Anytime an electrical connector or solenoid body is disconnected, inspect the connector for terminal condition, corrosion and contamination. Also inspect the connector seal for damage. Clean, repair or install new as necessary. Use the following shift solenoid operation information when carrying out Pinpoint Test A.

Worldwide Diagnostic System (WDS) Vehicle Communication module (VCM) with appropriate adapters, or equivalent diagnostic tool

(Continued)

Solenoid Operation Chart Gearshift Selector Position P/N R D PCM Commanded Gear P/N R 1 2 3 4 5 D Cancelled 1 2 5R55S Solenoid States SSA ON ON ON ON ON OFF OFF ON ON SSB OFF OFF OFF OFF ON OFF OFF OFF OFF SSC OFF OFF OFF ON OFF OFF ON OFF ON SSD ON ON ON ON ON ON ON ON ON PCA L L/H H L/H H H H H L/H PCB H/L L H/L H L/H H/L H H/L H PCC L H L L L H H L L

Copyright 2004, Ford Motor Company

Last updated: 07/29/2004

2005 Mustang, 12/2004

307-01-2

Automatic Transaxle/Transmission

307-01-2

DIAGNOSIS AND TESTING (Continued)

Solenoid Operation Chart (Continued) Gearshift Selector Position PCM Commanded Gear 3 4 Manual 3 Manual 2 Manual 1 H = HIGH L = LOW H/L = PCM controlled Manual = if equipped Solenoid Failure Mode Charts 5R55S Actual Gear SSA Gear 1 2 3 4 5 1M 2M 3M 4M R ON 1 2 3 1 2 M1 M2 M3 M1 R OFF 1 2 3 4 5 M1 M2 M3 M4 R ON 3 2 3 4 5 M3 1.1 M3 M4 N SSB OFF D Position 1 2 1 4 5 M1 M2 M1 M4 R 2 2 3 4/5 5 M2 M2 1.1 5 R 1 1 3 4 4 M1 M1 M3 M4 R 1 2 3 4 5 1 2 3 4 R 1/M1 M2 3/M3 4/M4 5 M1 M2 M3 M4 R ON SSC OFF ON SSD OFF 3 2 1 5R55S Solenoid States SSA ON OFF ON ON ON SSB ON OFF ON OFF OFF SSC OFF OFF OFF ON OFF SSD ON OFF OFF OFF OFF PCA H L/H H H H PCB L/H H L L L PCC L H H/L H/L H/L

Shift Solenoid Failure Mode Chart Failed ON or OFF due to powertrain control module (PCM) and/or vehicle wiring concerns, solenoid electrically, mechanically or hydraulically stuck ON or OFF.

D Position (D) Cancelled

Slip = Slip due to low line pressure 1.1 = Actual ratio with Forward Clutch, Intermediate and Overdrive Band applied. Solenoid Failure Mode Charts 5R55S (Continued) Actual Gear PC A Gear 1/S 2 3 L 1 2 1/S H 1 2 3 L D Position 1 1 3 1 2 3 1 2 3 1 2 3 PC B H L PC C H

2005 Mustang, 12/2004

307-01-3

Automatic Transaxle/Transmission

307-01-3

DIAGNOSIS AND TESTING (Continued)

Solenoid Failure Mode Charts 5R55S (Continued) (Continued) Actual Gear PC A Gear 4 5 1M 2M 3M 4M R L 4 5 1 M2 1 M4 R/S H 4 5 M1 M2 M3 M4 R L 4 4 D Position (D) Cancelled 1 1 3 4 R/S M1 M2 M3 M4 R 1M 2M 3M 1 R M1 M2 M3 M4 R PC B H 4 5 L 1 2 PC C H 4 5

H = High L = Low Slip = Slip due to low line pressure 1.1 = Actual ratio with Forward Clutch, Intermediate and Overdrive Band applied.

Pinpoint Tests

PINPOINT TEST A: SHIFT AND TORQUE CONVERTER CLUTCH SOLENOIDS

NOTE: Refer to the Transmission Vehicle Harness Connector illustration preceding these pinpoint tests. NOTE: Read and record all DTCs. All Digital TR Sensor and VSS DTCs must be repaired before entering output state control (OSC).

A1 Test Step ELECTRONIC DIAGNOSTICS Key in OFF position. Select PARK. Check to make sure the transmission harness connector is fully seated, terminals are fully engaged in connector and in good condition before proceeding. Connect the diagnostic tool. Key in ON position. Enter the following diagnostic mode on the diagnostic tool: Diagnostic Data Link. Enter the following diagnostic mode on the diagnostic tool: PCM. Enter the following diagnostic mode on the diagnostic tool: Active Command Modes. Enter the following diagnostic mode on the diagnostic tool: Output State Control (OSC). Enter the following diagnostic mode on the diagnostic tool: Trans-Bench Mode. Does vehicle enter Trans-Bench Mode? WIGGLE TEST Remain in Trans-Bench Mode. Select PIDs to be monitored. Result / Action to Take

Yes

REMAIN in Trans-Bench Mode. GO to A2.

No

REPEAT procedure to enter Trans-Bench Mode. If vehicle did not enter Trans-Bench Mode, REFER to the Powertrain Control/Emissions Diagnosis (PC/ED) manual for diagnosis of PCM or VCM.

A2

(Continued)

2005 Mustang, 12/2004

307-01-4

Automatic Transaxle/Transmission

307-01-4

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: SHIFT AND TORQUE CONVERTER CLUTCH SOLENOIDS (Continued)

A2 Test Step WIGGLE TEST (Continued) Result / Action to Take

PID Command SSA SSB SSC SSD TCC

PID Actual SSA SSB SSC SSD TCC

A3

Select ON to turn suspect solenoid(s) ON. Press SEND. Wiggle all wiring and connectors to the transmission. Monitor the solenoid state for changes. Select OFF to turn solenoid(s) OFF. Press SEND. Repeat steps for each solenoid. Does the suspect solenoid(s) fault state change? SOLENOID FUNCTIONAL CHECK Monitor each solenoid state. Turn each solenoid ON and OFF. Does the solenoid turn ON and OFF when commanded and can solenoid activation be heard? OSC TRANS-DRIVE Mode (GEAR OR TCC) Carry out OSC Trans-Drive Mode. Select GEAR for shift solenoids or follow procedures for GEAR as listed in this section. Select TCC for torque converter clutch solenoid. Follow procedures of TCC in Drive Mode as listed in this section. Does the transmission upshift and downshift or torque converter engage/disengage when commanded? CHECK FOR BATTERY VOLTAGE Disconnect: Transmission Vehicle Harness Connector. Visually inspect all wires and connectors for damage. Key in ON position. Measure the voltage on pin 3 harness side and ground.

Yes

REPAIR the circuit. TEST the system for normal operation.

No

GO to A3.

Yes

GO to A4.

No

GO to A5.

A4

Yes

CLEAR all DTCs. ROAD TEST to verify if concern is still present. If concern is still present, REFER to Diagnosis By Symptom to diagnose shift or torque converter concern.

No

GO to A5.

A5

Yes

GO to A6.

No

Is the voltage greater than 10 volts? REPAIR the circuit. TEST for normal operation.

(Continued)

2005 Mustang, 12/2004

307-01-5

Automatic Transaxle/Transmission

307-01-5

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: SHIFT AND TORQUE CONVERTER CLUTCH SOLENOIDS (Continued)

A6 Test Step ELECTRICAL SIGNAL CHECK Leave positive lead connected to pin 3 and connect negative lead to pin 5, 6, 14, 15 and 16. Result / Action to Take

A7

Enter the following diagnostic mode on the diagnostic tool: Trans-Bench Mode. Select Parameter SSA, SSB, SSC, SSD or TCC. Select ON. Press SEND. Measure the voltage while cycling the solenoids ON and OFF. Select OFF, press SEND. Does the voltage change? CHECK SOLENOID RESISTANCE AT SOLENOID Measure the resistance between pin 3 and pin 5, 6, 14, 15 and 16 solenoid side.

Yes

GO to A7.

No

REPAIR the circuit. TEST the system for normal operation.

Solenoid SSA SSB SSC SSD TCC

Resistance (ohms) 16-45 16-45 16-45 16-45 9-16

Yes

GO to A8.

No

Is the resistance within specification? INSTALL a new solenoid body assembly. TEST the system for normal operation.

(Continued)

2005 Mustang, 12/2004

307-01-6

Automatic Transaxle/Transmission

307-01-6

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: SHIFT AND TORQUE CONVERTER CLUTCH SOLENOIDS (Continued)

A8 Test Step CHECK SOLENOID FOR SHORT TO GROUND Measure the resistance between pin 3 and pin 5, 6, 14, 15 and 16 solenoid side and ground. Result / Action to Take

Yes

INSTALL a new solenoid body assembly.

No

Is the resistance less than 5 ohms? REFER to Diagnosis By Symptom in this section for diagnosis of shift or torque converter concerns.

PINPOINT TEST B: TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR

NOTE: Refer to the Transmission Vehicle Harness Connector illustration preceding these pinpoint tests.

B1 Test Step ELECTRONIC DIAGNOSTICS Key in OFF position. Select PARK. Check to make sure the transmission harness connector is fully seated, terminals are fully engaged in connector and in good condition before proceeding. Connect the diagnostic tool. Key in ON position. Select Diagnostic Data Link. Select PCM. Select PID/Data Monitor and Record. Enter the following diagnostic mode on the diagnostic tool: PIDs; TFT, TFTV. Does the vehicle enter PID/Data Monitor and Record? WARM-UP/COOL-DOWN CYCLE While monitoring the TFT PIDs, carry out the following test: If transmission is cold, run transmission to warm it up. If transmission is warm, allow transmission to cool down. Do the TFT PIDs increase as the transmission is warmed up or decrease as the transmission is cooled or does the TFT or TFTV drop in and out of range? Result / Action to Take

Yes

REMAIN in PID/Data Control. GO to B2.

No

REPEAT procedure to enter PID. If vehicle did not enter PID, REFER to the Powertrain Control/Emissions Diagnosis (PC/ED) manual for diagnosis of PCM and VCM.

B2

Yes

If the TFT PIDs increase as the transmission is warmed or decrease as the transmission is cooled, CLEAR all DTCs. ROAD TEST to verify if concern is still present. If concern is still present, REFER to Diagnosis By Symptom in this section to diagnose transmission overheating. If the TFT or TFTV drop in and out of range, INSPECT for intermittent concern in the internal/external harness, sensor or connector.

No

GO to B3. B3 ELECTRICAL SIGNAL CHECK Disconnect: Transmission Harness Connector. Visually inspect all wires and connectors for damage.

(Continued)

2005 Mustang, 12/2004

307-01-7

Automatic Transaxle/Transmission

PINPOINT TEST B: TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR (Continued)

307-01-7

DIAGNOSIS AND TESTING (Continued)

Test Step ELECTRICAL SIGNAL CHECK (Continued) Measure the voltage between pin 2 harness side and ground. Result / Action to Take

B3

Yes

GO to B4.

No

B4 Is the voltage between 4.5 and 5.0 volts? CHECK RESISTANCE OF TFT SENSOR Measure the resistance between pin 2 and 12 at the solenoid body connector. REPAIR the circuit. TEST the system for normal operation.

Record the resistance. Resistance should be approximately in the following ranges:

Transmission Fluid Temperature C -40 to -20 -19 to -1 0 - 20 21 - 40 41 - 70 71 - 90 91 - 110 111 - 130 131 - 150

F -40 to -4 -3 - 31 32 - 68 69 - 104 105 - 158 159 - 194 195 - 230 231 - 266 267 - 302

Resistance (Ohms) 967K - 284K 284K - 100K 100K - 37K 37K - 16K 16K - 5K 5K - 2.7K 2.7K - 1.5K 1.5K - 0.8K 0.8K - 0.54K Yes

REFER to Diagnosis By Symptom in this section to diagnose an overheating concern.

No

Is the resistance in the range? INSTALL a new solenoid body assembly.

2005 Mustang, 12/2004

307-01-8

Automatic Transaxle/Transmission

PINPOINT TEST C: DIGITAL TRANSMISSION RANGE (TR) SENSOR

307-01-8

DIAGNOSIS AND TESTING (Continued)

NOTE: Refer to the Digital Transmission Range (TR) Sensor Connector illustration and Digital Transmission Range (TR) Sensor Diagnosis Chart preceding these pinpoint tests.

C1 Test Step VERIFY DIAGNOSTIC TROUBLE Codes Key in OFF position. Select PARK. Carry out on-board diagnostic test. Are only DTC codes P0705, P0708 present? VERIFY DIGITAL TRANSMISSION RANGE SENSOR ALIGNMENT Key in OFF position. Select PARK. Check to make sure the digital TR sensor harness connector is fully seated, terminals are fully engaged in connector and in good condition before proceeding. Apply the parking brake. Select NEUTRAL. Disconnect the shift cable/linkage from the manual lever. Verify that the TR Sensor Alignment Gauge fits in the appropriate slots. Is the digital TR sensor correctly adjusted? VERIFY SHIFT CABLE/LINKAGE ADJUSTMENT Place the range selector in D. Connect the shift cable/linkage. Verify that the shift cable/linkage is correctly adjusted. REFER to Section 307-05. Is the shift cable/linkage correctly adjusted? CHECK ELECTRICAL SIGNAL OPERATION Select PARK. Disconnect: Digital TR Sensor. CAUTION: Do not pry on connector. This will damage the connector and result in a transmission concern. Inspect both ends of the connector for damage or pushed out pins, corrosion, loose wires and missing or damaged seals. Is there damage to the connector, pins or harness? CHECK ELECTRICAL SYSTEM OPERATION (DIGITAL TR AND PCM) Key in OFF position. Connect the diagnostic tool. Connect: Digital TR Sensor. Key in ON position. Enter the following diagnostic mode on the diagnostic tool: TR PIDS TR D, TR V. Move transmission range selector lever into each gear and stop. Observe the PIDs, TR D, and TR V (vehicle-dependent) while wiggling harness, tapping on sensor or driving the vehicle. Use PIDs TR D for DTCs P0705, P1704 and P1705. Use PIDs TR V for DTC P0708. Compare the PIDs to the Digital Transmission Range (TR) Sensor Diagnosis Chart. Do the PIDs TR D and TR V match the Digital Transmission Range (TR) Sensor Diagnosis chart, and does the TR D PID remain steady when the harness is wiggled, the sensor is tapped on or the vehicle driven? CHECK DIGITAL TRANSMISSION RANGE SENSOR OPERATION Disconnect: Digital TR Sensor. Connect: TR-E Cable to Transmission Tester. Connect: TR-E Cable to Digital TR Sensor. Place the DIGITAL TR Overlay onto Transmission Tester. Carry out SENSOR Test as instructed on the digital TR Overlay. Does the status lamp on the tester TRS-E cable match the selected gear positions? Result / Action to Take

Yes

GO to C4.

No

GO to C2.

C2

Yes

GO to C3.

No

ADJUST the digital TR sensor; REFER to Digital Transmission Range (TR) Sensor in this section. PLACE transmission range selector lever into PARK and CLEAR DTCs. RERUN OBD Tests. GO to C3.

C3

Yes

GO to C4.

No

ADJUST the shift cable/linkage. REFER to Section 307-05. GO to C4.

C4

Yes

REPAIR as necessary. CLEAR DTCs and RERUN OBD Tests.

No

If diagnosing a DTC, GO to C5. If diagnosing a starting concern or a backup lamp concern, GO to C10.

C5

Yes

The problem is not in the digital TR sensor system. REFER to Diagnosis By Symptom in this section for further diagnosis.

No

If TR D changes when wiggling harness, tapping on the sensor or driving the vehicle, the problem may be intermittent. GO to C6.

C6

Yes

Concern is not in the digital TR sensor. GO to C7.

No

INSTALL a new digital TR sensor and ADJUST. REFER to Digital Transmission Range (TR) Sensor in this section. CLEAR DTCs and RERUN OBD Tests.

(Continued)

2005 Mustang, 12/2004

307-01-9

Automatic Transaxle/Transmission

PINPOINT TEST C: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

307-01-9

DIAGNOSIS AND TESTING (Continued)

Test Step CHECK PCM HARNESS CIRCUITS FOR OPENS Key in OFF position. Disconnect: 150 Pin PTEC module Connector B. Inspect for damaged or pushed out pins, corrosion or loose wires. Disconnect: Digital TR Sensor. CAUTION: Do not pry the connector. This will damage the connector and result in a transmission concern. Measure the resistance between TR pin 2 harness side and signal return PCM pin 41 harness side. Result / Action to Take

C7

Measure the resistance between PCM pin 16 and TR pin 4 harness side.

Measure the resistance between PCM pin 17 and TR pin 5 harness side.

(Continued)

2005 Mustang, 12/2004

307-01-10

Automatic Transaxle/Transmission

PINPOINT TEST C: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

307-01-10

DIAGNOSIS AND TESTING (Continued)

Test Step CHECK PCM HARNESS CIRCUITS FOR OPENS (Continued) Measure the resistance between PCM pin 28 and TR pin 6 harness side. Result / Action to Take

C7

Measure the resistance between PCM pin 27 and TR pin 3 harness side.

Yes

GO to C8.

No

C8 Are the resistances less than 5 ohms? CHECK PCM HARNESS CIRCUITS FOR SHORT TO GROUND OR POWER Measure the resistance between PCM pin 41 and TR pins 10 and 12 harness side and ground. REPAIR the circuits. TEST the system for normal operation.

(Continued)

2005 Mustang, 12/2004

307-01-11

Automatic Transaxle/Transmission

PINPOINT TEST C: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

307-01-11

DIAGNOSIS AND TESTING (Continued)

Test Step CHECK PCM HARNESS CIRCUITS FOR SHORT TO GROUND OR POWER (Continued) Measure the resistance between pin 16 harness side and ground; and pin 41 harness side and ground. Result / Action to Take

C8

Measure the resistance between pin 17 harness side and ground; and pin 41 harness side and ground.

Measure the resistance between pin 28 harness side and ground; and pin 41 harness side and ground.

(Continued)

2005 Mustang, 12/2004

307-01-12

Automatic Transaxle/Transmission

PINPOINT TEST C: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

307-01-12

DIAGNOSIS AND TESTING (Continued)

Test Step CHECK PCM HARNESS CIRCUITS FOR SHORT TO GROUND OR POWER (Continued) Measure the resistance between pin 27 harness side and ground; and pin 41 harness side and ground. Result / Action to Take

C8

Yes

GO to C9.

No

Are the resistances greater than 10,000 ohms? CHECK FOR SHORT BETWEEN TR/PCM INPUT SIGNAL CIRCUITS Measure the resistance between pin 27 harness side; and between pin 16, pin 17 and pin 28 harness side. REPAIR the circuits. TEST the system for normal operation. CLEAR DTCs. RERUN OBD Tests.

C9

Measure the resistance between pin 16 harness side; and between pin 27, pin 17 and pin 28 harness side.

(Continued)

2005 Mustang, 12/2004

307-01-13

Automatic Transaxle/Transmission

PINPOINT TEST C: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

307-01-13

DIAGNOSIS AND TESTING (Continued)

Test Step CHECK FOR SHORT BETWEEN TR/PCM INPUT SIGNAL CIRCUITS (Continued) Measure the resistance between pin 17 harness side; and between pin 16, pin 27; pin 28 harness side. Result / Action to Take

C9

Measure the resistance between pin 28 harness side; and between pin 16, pin 17; pin 27 harness side.

Yes

INSTALL a new PCM. TEST the system for normal operation.

No

C10 Are the resistances greater than 10,000 ohms? CHECK THE NON-PCM INTERNAL CIRCUITS OR SENSOR Connect: TRS-E Cable to Transmission. Connect: TRS-E Cable to Digital TR Sensor. Place the Digital TR Overlay onto Transmission Tester. Carry out Switch Test as instructed on the digital TR Overlay. Does the status lamp on the tester indicate RED for the correct gear position? REPAIR the circuit. TEST the system for normal operation.

Yes

Concern is not in the digital TR sensor. For backup lamp concerns, REFER to Section 417-01.

No

INSTALL a new digital TR sensor and ADJUST; REFER to Digital Transmission Range (TR) Sensor in this section. CLEAR DTCs and RERUN OBD Tests.

PINPOINT TEST D: PRESSURE CONTROL (PC) SOLENOIDS (PCA, PCB, PCC)

NOTE: Refer to the Transmission Vehicle Harness Connector illustration preceding these pinpoint tests. NOTE: Read and record all DTCs. All digital TR Sensor and VSS DTCs must be repaired before entering output state control (OSC).

D1 Test Step ELECTRONIC DIAGNOSTICS Key in OFF position. Select PARK. Check to make sure the transmission harness connector is fully seated, terminals are fully engaged in the connector and in good condition before proceeding. Result / Action to Take

(Continued) 2005 Mustang, 12/2004

307-01-14

Automatic Transaxle/Transmission

307-01-14

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: PRESSURE CONTROL (PC) SOLENOIDS (PCA, PCB, PCC) (Continued)

D1 Test Step ELECTRONIC DIAGNOSTICS (Continued) Install 300 psi pressure gauges into Line and PC C tap. Connect the diagnostic tool. Key in ON position. Enter the following diagnostic mode on the diagnostic tool: Diagnostic Data Link. Enter the following diagnostic mode on the diagnostic tool: PCM. Enter the following diagnostic mode on the diagnostic tool: Active Command Modes. Enter the following diagnostic mode on the diagnostic tool: Output State Control (OSC). Enter the following diagnostic mode on the diagnostic tool: Trans-Bench Mode. Does the vehicle enter the Trans-Bench Mode? SOLENOID FUNCTIONAL TEST Monitor pressure gauges. Enter the following diagnostic mode on the diagnostic tool: Parameter; PCx. NOTE: Make sure that the solenoids not being tested are off or at zero. Select PC A, PC B or PC C. Select value - 15, 30, 45, 60, 70 or 90 psi. Press SEND. Select another value 0-90 psi. Press SEND. Enter the following diagnostic mode on the diagnostic tool: XXX. Press SEND. For PC A and PC B: Does the pressure reading for A or B follow the commanded pressure (actual A and B pressures will be higher than the commanded pressure)? For PC C: Does the pressure reading match the commanded pressure? CHECK FOR BATTERY VOLTAGE Disconnect: Transmission Harness Connector. Visually inspect all wires and connectors for damage. Key in ON position. Measure the voltage between pin 3 harness side and ground. Result / Action to Take

Yes

REMAIN in Trans-Bench Mode. GO to D2.

No

REPEAT procedure to enter Trans-Bench Mode. If vehicle did not enter OSC, REFER to Powertrain Control/Emissions Diagnosis (PC/ED) manual for diagnosis of PCM or VCM.

D2

Yes

CLEAR DTCs.

No

GO to D3.

D3

Yes

GO to D4.

No

Is the voltage greater than 10 volts? REPAIR the circuit. TEST the system for normal operation.

(Continued)

2005 Mustang, 12/2004

307-01-15

Automatic Transaxle/Transmission

307-01-15

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: PRESSURE CONTROL (PC) SOLENOIDS (PCA, PCB, PCC) (Continued)

D4 Test Step ELECTRICAL SIGNAL CHECK Leave positive lead connected to pin 3 and connect negative lead to pin 1, 4 and 11 harness side. Result / Action to Take

D5

Activate solenoids (ON and OFF) while monitoring the voltage reading. Enter the following diagnostic mode on the diagnostic tool: Trans-Bench Mode. Enter the following diagnostic mode on the diagnostic tool: Parameter; PCx. Select a value 0-90 psi. Press SEND. Select another value 0-90 psi. Press SEND. Enter the following diagnostic mode on the diagnostic tool: XXX. Press SEND. Does the voltage and solenoid state change? CHECK SOLENOID RESISTANCE AT SOLENOID Measure and record the resistance between PC solenoid pin 3 and pins 1, 4 and 11. Resistance should be between 3.3 and 7.5 ohms.

Yes

GO to D5.

No

CHECK for open or short circuit in harness or PCM.

Yes

GO to D6.

No

Is the resistance within specifications? INSTALL a new solenoid body assembly.

(Continued)

2005 Mustang, 12/2004

307-01-16

Automatic Transaxle/Transmission

307-01-16

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: PRESSURE CONTROL (PC) SOLENOIDS (PCA, PCB, PCC) (Continued)

D6 Test Step CHECK SOLENOID FOR SHORT TO GROUND Measure and record the resistance between the PC solenoid pins 1, 4, 11 and ground solenoid side. Result / Action to Take

Yes

INSTALL a new solenoid body assembly. TEST the system for normal operation.

No

Is the resistance less than 10,000 ohms? REFER to Diagnosis By Symptom in this section for diagnosis of pressure concerns. TEST the system for normal operation.

PINPOINT TEST E: TURBINE SHAFT SPEED (TSS), INTERMEDIATE SHAFT SPEED AND OUTPUT SHAFT SPEED (OSS) SENSORS

NOTE: Refer to the Turbine Shaft Speed (TSS), Intermediate Shaft Speed and Output Shaft Speed (OSS) Sensor Connector illustrations preceding these pinpoint tests.

E1 Test Step ELECTRONIC DIAGNOSTICS Check to make sure the transmission harness connectors are fully seated, terminals are fully engaged in connector and in good condition before proceeding. Connect the diagnostic tool. Key in ON position. Enter the following diagnostic mode on the diagnostic tool: Diagnostic Data Link. Enter the following diagnostic mode on the diagnostic tool: PCM. Select PID/Data Monitor and Record. Select the following PIDs: TSS, intermediate shaft speed or OSS. Does vehicle enter PID/Data Monitor and Record? DRIVE CYCLE TEST While monitoring the appropriate sensor PID, drive the vehicle so that the transmission upshifts and downshifts through all gears. Does the TSS, intermediate shaft speed or OSS PID increase and decrease with engine and vehicle speed? Result / Action to Take

Yes

REMAIN in PID/Data. GO to E2.

No

REPEAT procedure to ENTER PID. If vehicle did not enter PID, REFER to the Powertrain Control/Emissions Diagnosis (PC/ED) manual for diagnosis of PCM or VCM.

E2

Yes

GO to E3.

No

If the TSS, intermediate shaft speed or OSS PID does not increase and decrease with engine and vehicle speed, INSPECT for open or short in vehicle harness, sensor, a PCM concern or internal hardware concern. GO to E4.

E3

DRIVE CYCLE TEST ERRATIC While monitoring the appropriate sensor PID, drive the vehicle so that the transmission upshifts and downshifts through all gears. Is the TSS, intermediate shaft speed or OSS PID signal erratic (drop to zero or near zero and return to normal operation)? CHECK PCM HARNESS CIRCUITS FOR OPENS Key in OFF position. Disconnect: 150 Pin PTEC module Connector B. Inspect for damaged or pushed out pins, corrosion or loose wires.

Yes

If the sensor signal is erratic, INSPECT for intermittent concern in the harness, sensor or connector. GO to E4.

No

CLEAR all DTCs. RERUN OBD.

E4

(Continued)

2005 Mustang, 12/2004

307-01-17

Automatic Transaxle/Transmission

307-01-17

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: TURBINE SHAFT SPEED (TSS), INTERMEDIATE SHAFT SPEED AND OUTPUT SHAFT SPEED (OSS) SENSORS (Continued)

E4 Test Step CHECK PCM HARNESS CIRCUITS FOR OPENS (Continued) For OSS, measure the resistance between pin 3 and the appropriate sensor connector pin 2 harness side. Result / Action to Take

For intermediate shaft speed, measure the resistance between pin 41 and the appropriate sensor connector pin 2 harness side.

For TSS, measure the resistance between pin 41 and the appropriate sensor connector pin 2 harness side.

(Continued)

2005 Mustang, 12/2004

307-01-18

Automatic Transaxle/Transmission

307-01-18

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: TURBINE SHAFT SPEED (TSS), INTERMEDIATE SHAFT SPEED AND OUTPUT SHAFT SPEED (OSS) SENSORS (Continued)

E4 Test Step CHECK PCM HARNESS CIRCUITS FOR OPENS (Continued) For intermediate shaft speed, measure the resistance between pin 4 and the appropriate sensor connector pin 1 harness side. Result / Action to Take

For TSS, measure the resistance between pin 15 and the appropriate sensor connector pin 1 harness side.

For OSS, measure the resistance between pin 3 and the appropriate sensor connector pin 1 harness side.

Yes

GO to E5.

No

Are all resistances less than 5 ohms? REPAIR the circuit. TEST the system for normal operation.

(Continued)

2005 Mustang, 12/2004

307-01-19

Automatic Transaxle/Transmission

307-01-19

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: TURBINE SHAFT SPEED (TSS), INTERMEDIATE SHAFT SPEED AND OUTPUT SHAFT SPEED (OSS) SENSORS (Continued)

E5 Test Step CHECK PCM HARNESS CIRCUITS FOR SHORT TO GROUND For OSS, measure the resistance between pin 3 and sensor connector pin 1 harness side and ground. Result / Action to Take

For intermediate shaft speed, measure the resistance between PCM pin 4 and sensor connector pin 1 harness side and ground.

For TSS, measure the resistance between PCM pin 15 and sensor connector pin 1 harness side and ground.

Yes

GO to E6.

No

Are the resistances greater than 10,000 ohms? CHECK RESISTANCE OF TSS, INTERMEDIATE SHAFT SPEED OR OSS SENSOR Disconnect the appropriate vehicle harness connector from the TSS, intermediate shaft speed or OSS sensor. REPAIR the circuits. TEST the system for normal operation. CLEAR DTCs. RERUN OBD Tests.

E6

(Continued)

2005 Mustang, 12/2004

307-01-20

Automatic Transaxle/Transmission

307-01-20

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: TURBINE SHAFT SPEED (TSS), INTERMEDIATE SHAFT SPEED AND OUTPUT SHAFT SPEED (OSS) SENSORS (Continued)

E6 Test Step CHECK RESISTANCE OF TSS, INTERMEDIATE SHAFT SPEED OR OSS SENSOR (Continued) Connect ohmmeter negative lead to one pin of the sensor and the positive lead to the other pin on the sensor. Result / Action to Take

Record the resistance. Resistance should be as follows:

Resistance (ohms) 266-390 325-485 492-738

E7

Temperature -20C (4F) 21C (70F) 150C (302F) Yes

GO to E7.

Is the resistance within specification for the appropriate sensor? CHECK SENSORS FOR SHORT TO GROUND Measure the resistance between pin 1 and 2 of each sensor and ground.

No

INSTALL a new sensor.

Yes

INSTALL a new sensor.

No

Is the resistance less than 10,000 ohms? REFER to Diagnosis By Symptom for diagnosis of shift or torque converter concerns in this section.

2005 Mustang, 12/2004

307-01-21

Automatic Transaxle/Transmission

PINPOINT TEST F: SOLENOID MECHANICAL FAILURE

307-01-21

DIAGNOSIS AND TESTING (Continued)

NOTE: Repair all other DTCs before repairing the following DTCs: P1714, P1715, P1716, P1717 and P1740.

F1 Test Step ELECTRONIC DIAGNOSIS Connect the diagnostic tool. Select PARK. Key in ON position. Carry out Key ON Engine OFF (KOEO) test until continuous DTCs have been displayed. If any of the following DTCs are present, continue with this test: P1714, P1715, P1716, P1717 and P1740. Are other DTCs present for TFT or shift solenoids? TRANSMISSION DRIVE CYCLE TEST Carry out transmission drive cycle test. Refer to Transmission Drive Cycle Test in this section. Does the vehicle upshift and downshift OK? Result / Action to Take

Yes

REPAIR the DTCs for TFT or shift solenoids first. CLEAR DTCs and CARRY OUT transmission Drive Cycle test. RERUN Quick Test.

No

INSTALL a new solenoid and/or body. REFER to the Diagnostic Trouble Code Charts for code description. GO to F2.

F2

Yes

GO to F3.

No

REFER to Diagnosis By Symptom in this section to diagnose shift concerns.

F3

RETRIEVE DTCS Connect the diagnostic tool. Select PARK. Key in ON position. Carry out KOEO test until continuous DTCs have been displayed. Are DTCs P1714, P1715, P1716, P1717 and P1740 still present?

Yes

INSTALL a new PCM. ROAD TEST and RERUN Quick Test.

No

Testing completed. If a concern still exists, REFER to Diagnosis By Symptom in this section for concern diagnosis.

2005 Mustang, 12/2004

Вам также может понравиться

- TransTec Pocket GuideДокумент120 страницTransTec Pocket GuideMauricio Exequiel Chavez100% (9)

- Tran StarДокумент265 страницTran StarCecilia Gil100% (1)

- 307-01 Transmision 6r80Документ32 страницы307-01 Transmision 6r80Humberto Lojan100% (3)

- 5R55W-S Repair DiagnosisДокумент70 страниц5R55W-S Repair Diagnosisaxallindo100% (2)

- ATSGДокумент120 страницATSGAldar Zagdaev100% (3)

- 23 Automatic TransmissionДокумент45 страниц23 Automatic Transmissionossoski100% (1)

- 5R55S Exploded Diagram PDFДокумент6 страниц5R55S Exploded Diagram PDFMiguel Angel Saintjour Rudolph100% (4)

- Re4ro1a PDFДокумент106 страницRe4ro1a PDFженя евчин100% (1)

- JF016E-JF017E Vacuum Manual Valve BodyДокумент4 страницыJF016E-JF017E Vacuum Manual Valve Bodyak_adamОценок пока нет

- ATДокумент164 страницыATjacor96100% (1)

- A604 A606 42rle PDFДокумент2 страницыA604 A606 42rle PDFGuilherme Zoboli100% (2)

- 6R80 Service Manual Rev 1Документ427 страниц6R80 Service Manual Rev 1Jeff93% (29)

- JR405 PDFДокумент111 страницJR405 PDFGeorgi AleksievОценок пока нет

- Nissan Murano CVTДокумент234 страницыNissan Murano CVTtroublezaur100% (10)

- E4nb71 PDFДокумент99 страницE4nb71 PDFtambache69100% (1)

- Transtec HondaДокумент16 страницTranstec HondaFSR1407100% (4)

- U140e U241e Zip inДокумент10 страницU140e U241e Zip inAnonymous DNM4ZI100% (4)

- Diagnostic Trouble Code Index AllisonДокумент16 страницDiagnostic Trouble Code Index AllisonLuis Gongora100% (6)

- JF016E, JF017E, CVT8: (RE0F10D) (RE0F10E) Nissan, Mitsubishi, Renault, General Motors & Suzuki FWDДокумент3 страницыJF016E, JF017E, CVT8: (RE0F10D) (RE0F10E) Nissan, Mitsubishi, Renault, General Motors & Suzuki FWDhidraulicОценок пока нет

- 5r55 OverheatingДокумент46 страниц5r55 OverheatingAhmed Ali100% (2)

- FS5A Shop ManualДокумент192 страницыFS5A Shop ManualDorkDork08100% (1)

- P 0750Документ8 страницP 0750Jocelyn MattoonОценок пока нет

- Nissan R E 4 R 0 2 A: Automatic Transmission Service Group 18639 SW 107TH AVENUE Miami, Florida 33157 (305) 670-4161Документ95 страницNissan R E 4 R 0 2 A: Automatic Transmission Service Group 18639 SW 107TH AVENUE Miami, Florida 33157 (305) 670-4161skyship skyship50% (2)

- 6r140w IntroДокумент58 страниц6r140w IntroFrank Araya Diaz100% (1)

- 2008 - 7 - 4 4L30E PumpДокумент4 страницы2008 - 7 - 4 4L30E PumpJon Rodriguez100% (1)

- Ford 5R55 W/S 153: SOLENOID TEST: (Engine Off)Документ2 страницыFord 5R55 W/S 153: SOLENOID TEST: (Engine Off)Lojan Coronel José HumbertoОценок пока нет

- Honda Diagnostic CodesДокумент10 страницHonda Diagnostic CodesAngela Easter100% (1)

- Sonnax 45RFE, 545RFE, 68RFE Solenoid Identification & Connector Pin OutДокумент4 страницыSonnax 45RFE, 545RFE, 68RFE Solenoid Identification & Connector Pin OutJean Jose Morillo AñezОценок пока нет

- E4od PDFДокумент2 страницыE4od PDFmilerkОценок пока нет

- 5r55n How-To-Fix-ItДокумент87 страниц5r55n How-To-Fix-ItDavid Chalker100% (14)

- Technical Service Information: FORD 5R55N, 5R55W/SДокумент8 страницTechnical Service Information: FORD 5R55N, 5R55W/SJose garcua vargas 2006401321Оценок пока нет

- Valve Body PDFДокумент9 страницValve Body PDFTimur TOT100% (2)

- A650e VBДокумент2 страницыA650e VB陳瑞崇100% (1)

- Critical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55EДокумент2 страницыCritical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55ECesar Isac PalominoОценок пока нет

- Wrangler p0882Документ4 страницыWrangler p0882regeneris100% (1)

- JR405EДокумент8 страницJR405ELalo Barajas Garcia100% (2)

- 5r55e Diagnosis and TestingДокумент11 страниц5r55e Diagnosis and Testingbismark morales100% (2)

- RE5R05A Overview 2007 - 1 - 12Документ4 страницыRE5R05A Overview 2007 - 1 - 12Chee Bai100% (6)

- 5r55 Oil Control PDFДокумент14 страниц5r55 Oil Control PDFHumberto Lojan100% (2)

- 6T40 DetayДокумент52 страницы6T40 Detaysuattosun100% (11)

- Rights of An Accused Under Custodial InvestigationДокумент17 страницRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- Mitsubishi S Valve BodiesДокумент4 страницыMitsubishi S Valve BodiesReydeEspa1100% (1)

- F4ael PDFДокумент120 страницF4ael PDFPablo Cansas100% (2)

- Jactó 015eДокумент2 страницыJactó 015ehidraulic100% (3)

- 5R55S Cooler Thermal Bypass FixДокумент4 страницы5R55S Cooler Thermal Bypass FixDon Jenkins100% (2)

- Lincoln LS Fault CodesДокумент3 страницыLincoln LS Fault Codesfrancissimo185Оценок пока нет

- Abbreviations Used in This ManualДокумент126 страницAbbreviations Used in This ManualSteve Fisher100% (6)

- Code False Akpp 5r55Документ7 страницCode False Akpp 5r55VobsStrongОценок пока нет

- Habibillah Energi Adidaya Statement of QualificationsДокумент56 страницHabibillah Energi Adidaya Statement of QualificationsjakalegawaОценок пока нет

- Syllabus ClinPhar143Документ2 страницыSyllabus ClinPhar143Angel GoОценок пока нет

- Intercostal Drainage and Its ManagementДокумент36 страницIntercostal Drainage and Its ManagementAnusha Verghese67% (3)

- 45rfe GD PDFДокумент2 страницы45rfe GD PDFeurospeed2100% (4)

- D2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsДокумент46 страницD2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsMarcelo Gonçalves100% (1)

- 4 R 44 eДокумент4 страницы4 R 44 eArmando Kalel AlmanzaОценок пока нет

- Aw03 PDFДокумент15 страницAw03 PDFamazonagirl19Оценок пока нет

- Pinpoint Test CДокумент4 страницыPinpoint Test CAigars MulisОценок пока нет

- 5 R 55 NДокумент2 страницы5 R 55 NJoão EzerОценок пока нет

- 2008 Chevrolet HHR DTCДокумент6 страниц2008 Chevrolet HHR DTCTal Benyamin100% (1)

- Four-Wheel Drive Systems - Electronic Shift: Special Tool(s)Документ24 страницыFour-Wheel Drive Systems - Electronic Shift: Special Tool(s)julio797Оценок пока нет

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010Документ3 страницыA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010PeterОценок пока нет

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0013Документ3 страницыA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0013PeterОценок пока нет

- Auto TransmissionДокумент61 страницаAuto Transmissionlamping_apОценок пока нет

- JM at - 20040129Документ11 страницJM at - 20040129wreckedweaselОценок пока нет

- MSB 97e17 502 PDFДокумент10 страницMSB 97e17 502 PDFAutof FerreiraОценок пока нет

- Driveability Diag Part2Документ27 страницDriveability Diag Part2marcelo ustarezОценок пока нет

- IBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Документ27 страницIBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Milek Anil KumarОценок пока нет

- Acute Conditions of The NewbornДокумент46 страницAcute Conditions of The NewbornCamille Joy BaliliОценок пока нет

- KITZ - Cast Iron - 125FCL&125FCYДокумент2 страницыKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroОценок пока нет

- LPP - Problem Number 2Документ9 страницLPP - Problem Number 2CT SunilkumarОценок пока нет

- 67 9268Документ34 страницы67 9268Salvador ReyesОценок пока нет

- Support of Roof and Side in Belowground Coal MinesДокумент5 страницSupport of Roof and Side in Belowground Coal MinesNavdeep MandalОценок пока нет

- Declaration of Absence of Conflict of InterestДокумент1 страницаDeclaration of Absence of Conflict of InterestJvhelcoronacondat CondatОценок пока нет

- Compact Switch: Series 96201, 96211, 96221Документ2 страницыCompact Switch: Series 96201, 96211, 96221Sales DIGIHU100% (1)

- Perceptual Objective Listening Quality Assessment (POLQA), The Third Generation ITU-T Standard For End-to-End Speech Quality Measurement Part I-Temporal AlignmentДокумент19 страницPerceptual Objective Listening Quality Assessment (POLQA), The Third Generation ITU-T Standard For End-to-End Speech Quality Measurement Part I-Temporal AlignmentmewarulesОценок пока нет

- Pre-Qin Philosophers and ThinkersДокумент22 страницыPre-Qin Philosophers and ThinkersHelder JorgeОценок пока нет

- 27 Technip Energies - JD (PWD Students Only)Документ1 страница27 Technip Energies - JD (PWD Students Only)0901EE201067 KUNAL JOLLY SAXENAОценок пока нет

- Annex A2 - CS Form 100 - Revised 2023 - CSESP - A1 - Edited - A1Документ2 страницыAnnex A2 - CS Form 100 - Revised 2023 - CSESP - A1 - Edited - A1obs.obando2022Оценок пока нет

- Syllabus EM1Документ2 страницыSyllabus EM1Tyler AnthonyОценок пока нет

- Tok EssayДокумент2 страницыTok EssayNeto UkpongОценок пока нет

- FS1 Worksheet Topic 6Документ2 страницыFS1 Worksheet Topic 6ALMALYN ANDIHОценок пока нет

- Concept of ConstitutionДокумент32 страницыConcept of ConstitutionDorepe Icon0% (1)

- Letter For LACДокумент7 страницLetter For LACDahlia G. MaglasangОценок пока нет

- DRUG STUDY (Erythromycin)Документ3 страницыDRUG STUDY (Erythromycin)Avianna CalliopeОценок пока нет

- New Arrivals 17 - 08 - 2021Документ16 страницNew Arrivals 17 - 08 - 2021polar necksonОценок пока нет

- Prince Ryan B. Camarino Introduction To Philosophy of The Human PersonДокумент2 страницыPrince Ryan B. Camarino Introduction To Philosophy of The Human PersonKyle Aureo Andagan RamisoОценок пока нет

- Implementasi Sistem Pengenalan Candi Kecil Di Yogyakarta Menggunakan BerbasisДокумент7 страницImplementasi Sistem Pengenalan Candi Kecil Di Yogyakarta Menggunakan BerbasisRivan AuliaОценок пока нет

- Ellis Lived ExperiencesДокумент31 страницаEllis Lived ExperiencesJeanny Mae PesebreОценок пока нет

- 33kV BS7835 LSZH 3core Armoured Power CableДокумент2 страницы33kV BS7835 LSZH 3core Armoured Power Cablelafarge lafargeОценок пока нет

- E Catalog YooilДокумент10 страницE Catalog Yooilom jangidОценок пока нет

- Learner Cala Guide: PART A: Identification of Knowledgeable Elderly Part BДокумент5 страницLearner Cala Guide: PART A: Identification of Knowledgeable Elderly Part BPrimrose MurapeОценок пока нет