Академический Документы

Профессиональный Документы

Культура Документы

AWWA D100-11 Pre

Загружено:

mojeebmashalИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AWWA D100-11 Pre

Загружено:

mojeebmashalАвторское право:

Доступные форматы

ANSI/AWWA D100-11 (Revision of ANSI/AWWA D100-05)

AWWA Standard

Welded Carbon Steel Tanks for Water Storage

SECTION 1:

Sec. 1.1 Scope

GENERAL

The purpose of this standard is to provide minimum requirements for the design, construction, inspection, and testing of new welded carbon steel tanks for the storage of water at atmospheric pressure. 1.1.1 Tank roofs. All tanks storing potable water shall have roofs. Tanks storing nonpotable water may be constructed without roofs. 1.1.2 Items not covered. This standard does not cover all details of design and construction because of the large variety of sizes and shapes of tanks. Details that are not addressed shall be designed and constructed to be adequate and as safe as those that would otherwise be provided under this standard. This standard does not cover concretesteel composite tank construction.* With the exception of aluminum dome roofs, this standard does not cover tanks constructed with materials other than carbon steel. This standard does not cover painting and disinfecting of tanks (see ANSI/AWWA D102, Coating Steel Water-Storage Tanks, and ANSI/ AWWA C652, Disinfection of Water-Storage Facilities). 1.1.3 Design method. With the exception of reinforced concrete foundations, this standard is based on the allowable-stress design method.

* Refer to ANSI/AWWA D107, Composite Elevated Tanks for Water Storage.

1

Copyright 2011 American Water Works Association. All Rights Reserved.

AWWA D100-11

Sec. 1.2

Definitions

The following definitions shall apply in this standard: 1. Capacity: The net volume, in gallons (liters), that may be removed from a tank filled to top capacity level (TCL) and emptied to the bottom capacity level (BCL). 2. Constructor: The party that furnishes the work and materials for placement and installation. 3. Elevated tank: A container or storage tank supported on a tower. 4. Head range: The vertical distance between the TCL and BCL. 5. Potable water: Water that is safe and satisfactory for drinking and cooking. 6. Purchaser: The person, company, or organization that purchases any materials or work to be performed. 7. Reservoir: A ground-supported, flat-bottom, cylindrical tank having a shell height equal to or smaller than its diameter. 8. Standpipe: A ground-supported, flat-bottom, cylindrical tank having a shell height greater than its diameter. 9. Tank: An elevated tank, a standpipe, or a reservoir. 10. Water levels: The following water levels are used in this standard: 10.1 Bottom capacity level (BCL): The water level above which the specified capacity is provided. In a ground-supported tank (reservoir or standpipe), the BCL shall be the water level in the tank shell when the tank is emptied through the specified discharge fittings, unless otherwise specified. 10.2 Maximum operating level (MOL): The specified maximum water level under normal operating conditions. The MOL shall be taken as the TCL, unless otherwise specified. 10.3 Top capacity level (TCL): The water level defined by the lip of the overflow. Construction drawings for the foundation, tank, and accessories shall be provided. Where foundation and tank design are performed by separate parties, each party shall provide construction drawings. If anchorage is required, anchorage details, including required embedment, local reinforcement, and minimum required concrete strength, shall be provided as part of the tank design. Details of all welded joints shall be provided when specified. Standard weld symbols as listed in ANSI/AWS A2.4, Standard Symbols for Welding, Brazing,

Sec. 1.3 Drawings to Be Provided

Copyright 2011 American Water Works Association. All Rights Reserved.

WElDED CARBON STEEl TANkS FOR WATER STORAGE

and Nondestructive Examination, shall be used, unless joint details are shown.

Sec. 1.4

References

This standard references the following documents. In the editions specified, these documents form a part of this standard to the extent specified within the standard. In any case of conflict, the requirements of this standard shall prevail. ACI* 301-05Specifications for Structural Concrete. ACI 318-08Building Code Requirements for Structural Concrete. AISCSteel Construction Manual, 13th Edition. ANSI/AWS A2.4-07Standard Symbols for Welding, Brazing, and Nondestructive Examination. ANSI/AWS A3.0-10Standard Welding Terms and Definitions; Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying. ANSI/AWS A5.1-04Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding. ANSI/AWS A5.5-06Specification for Low-Alloy Steel Electrodes for Shielded Metal Arc Welding. ANSI/AWS B2.1-09Specification for Welding Procedure and Performance Qualification. ANSI/AWS D1.1-08Structural Welding CodeSteel, 2009 Errata. ANSI/AWS QC1-07Standard for AWS Certification of Welding Inspectors. ANSI/AWWA C652-02Disinfection of Water-Storage Facilities. ANSI/AWWA D102-06Coating Steel Water-Storage Tanks. ANSI/AWWA D108-10Aluminum Dome Roofs for Water Storage Facilities. API 5LSpecification for Line Pipe, 44th Edition, February 2009 Addendum. API 650Welded Steel Tanks for Oil Storage, 11th Edition. ASCE** 7-05Minimum Design Loads for Buildings and Other Structures.

* **

American Concrete Institute, 38800 Country Club Dr., Farmington Hills, MI 48331. American Institute of Steel Construction, 1 East Wacker Drive, Suite 700, Chicago, IL 60601. American National Standards Institute, 25 West 43rd Street, Fourth Floor, New York, NY 10036. American Welding Society, 550 NW LeJeune Road, Miami, FL 33126. American Petroleum Institute, 1220 L Street NW, Washington, DC 20005. American Society of Civil Engineers, 1801 Alexander Bell Drive, Reston, VA 20191.

Copyright 2011 American Water Works Association. All Rights Reserved.

AWWA D100-11

ASME* B16.5-09Pipe Flanges & Flanged Fittings: NPS 1/ 2 Through NPS 24. ASME BPVC Sec. VBoiler and Pressure Vessel Code; Nondestructive Examination, 2007 Edition, 2009b Addenda. ASME BPVC Sec. VIII, Div. 1Boiler and Pressure Vessel Code; Rules for Construction of Pressure Vessels, 2007 Edition, 2009b Addenda. ASME BPVC Sec. VIII, Div. 2Boiler and Pressure Vessel Code; Alternative Rules; Rules for Construction of Pressure Vessels, 2007 Edition, 2009b Addenda. ASME BPVC Sec. IXBoiler and Pressure Vessel Code; Qualification Standard for Welding and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators, 2007 Edition, 2009b Addenda. ASNT SNT-TC-1A-06Recommended Practice for Personnel Qualification and Certification in Nondestructive Testing. ASTM A6-09Standard Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling. ASTM A20-09Standard Specification for General Requirements for Steel Plates for Pressure Vessels. ASTM A27-08Standard Specification for Steel Castings, Carbon, for General Application. ASTM A36-08Standard Specification for Carbon Structural Steel. ASTM A53-07Standard Specification for Pipe, Steel, Black and HotDipped, Zinc-Coated, Welded and Seamless. ASTM A105-09Standard Specification for Carbon Steel Forgings for Piping Applications. ASTM A106-08Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service. ASTM A108-07Standard Specification for Steel Bar, Carbon and Alloy, Cold-Finished. ASTM A131-08Standard Specification for Structural Steel for Ships. ASTM A139-04Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and over).

* ASME International, Three Park Avenue, New York, NY 10016. American Society for Nondestructive Testing, P.O. Box 28518, 1711 Arlingate Lane, Columbus, OH 43228. ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

Copyright 2011 American Water Works Association. All Rights Reserved.

WElDED CARBON STEEl TANkS FOR WATER STORAGE

ASTM A181-06Standard Specification for Carbon Steel Forgings for General-Purpose Piping. ASTM A193-09Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for High Temperature or High Pressure Service and Other Special Purpose Applications. ASTM A283-03 (Reapproved 2007)Standard Specification for Low and Intermediate Tensile Strength Carbon Steel Plates. ASTM A307-07bStandard Specification for Carbon Steel Bolts and Studs, 60,000 psi Tensile Strength. ASTM A325-09ae1Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength. ASTM A333-05Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service. ASTM A350-07Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components. ASTM A370-09ae1Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM A435-90 (Reapproved 2007)Standard Specification for StraightBeam Ultrasonic Examination of Steel Plates. ASTM A500-09Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes. ASTM A501-07Standard Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing. ASTM A516-06Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower-Temperature Service. ASTM A517-06Standard Specification for Pressure Vessel Plates, Alloy Steel, High-Strength, Quenched and Tempered. ASTM A524-96 (Reapproved 2005)Standard Specification for Seamless Carbon Steel Pipe for Atmospheric and Lower Temperatures. ASTM A537-08Standard Specification for Pressure Vessel Plates, HeatTreated, Carbon-Manganese-Silicon Steel. ASTM A568-09aStandard Specification for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements for. ASTM A573-05 (Reapproved 2009)Standard Specification for Structural Carbon Steel Plates of Improved Toughness.

Copyright 2011 American Water Works Association. All Rights Reserved.

AWWA D100-11

ASTM A588-05Standard Specification for High-Strength Low-Alloy Structural Steel, up to 50 ksi (345 MPa) Minimum Yield Point, with Atmospheric Corrosion Resistance. ASTM A592-04 (Reapproved 2009)Standard Specification for HighStrength Quenched and Tempered Low-Alloy Steel Forged Fittings and Parts for Pressure Vessels. ASTM A633-01 (Reapproved 2006)Standard Specification for Normalized High-Strength Low-Alloy Structural Steel Plates. ASTM A662-03 (Reapproved 2007)Standard Specification for Pressure Vessel Plates, Carbon-Manganese-Silicon Steel, for Moderate and Lower Temperature Service. ASTM A668-04Standard Specification for Steel Forgings, Carbon and Alloy, for General Industrial Use. ASTM A678-05 (Reapproved 2009)Standard Specification for Quenched and Tempered Carbon and High-Strength Low-Alloy Structural Steel Plates. ASTM A992-06aStandard Specification for Structural Steel Shapes. ASTM A1011-09bStandard Specification for Steel, Sheet and Strip, HotRolled, Carbon, Structural, High-Strength Low-Alloy, and High-Strength LowAlloy with Improved Formability, and Ultra-High Strength. ASTM D1751-04 (Reapproved 2008)Standard Specification for Preformed Expansion Joint Filler for Concrete Paving and Structural Construction (Nonextruding and Resilient Bituminous Types). ASTM F1554-07aStandard Specification for Anchor Bolts, Steel, 36, 55, and 105-ksi Yield Strength. CSA* G40.21-04 (R2009)General Requirements for Rolled or Welded Structural Quality Steels. OSHAOccupational Safety and Health Standards, 29 CFR, Part 1910, latest edition. AISI T-192Steel Plate Engineering Data, Volumes 1 and 2, 1992 Edition.

* Canadian Standards Association, 178 Rexdale Blvd., Toronto, Ont., Canada M9W 1R3. Occupational Safety and Health Administration, 200 Constitution Ave., NW Washington, DC 20210. American Iron and Steel Institute, 1140 Connecticut Ave. NW, Suite 705, Washington, DC 20036.

Copyright 2011 American Water Works Association. All Rights Reserved.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Experimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFДокумент7 страницExperimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFmojeebmashalОценок пока нет

- Ahsanullah University of Science & Technology Dept. of Civil EngineeringДокумент14 страницAhsanullah University of Science & Technology Dept. of Civil EngineeringmojeebmashalОценок пока нет

- Functions and Installation of Paving Geosynthetics: S.K. ShuklaДокумент8 страницFunctions and Installation of Paving Geosynthetics: S.K. ShuklamojeebmashalОценок пока нет

- Chapter Forty-Six Pavement Rehabilitation: Bureau of Local Roads and Streets ManualДокумент60 страницChapter Forty-Six Pavement Rehabilitation: Bureau of Local Roads and Streets ManualmojeebmashalОценок пока нет

- Effective Maintenance Using Geotextile Reinforced Spray SealsДокумент11 страницEffective Maintenance Using Geotextile Reinforced Spray SealsmojeebmashalОценок пока нет

- A Low-Cost Robotic System For The Efficient Visual Inspection of TunnelsДокумент8 страницA Low-Cost Robotic System For The Efficient Visual Inspection of TunnelsmojeebmashalОценок пока нет

- Intro LabДокумент3 страницыIntro LabmojeebmashalОценок пока нет

- Consistence of The Concrete. Generally Speaking, This Time Shall Be Taken As 2 HR in ColdДокумент1 страницаConsistence of The Concrete. Generally Speaking, This Time Shall Be Taken As 2 HR in ColdmojeebmashalОценок пока нет

- Retrofitting of Existing RCC Buildings B PDFДокумент25 страницRetrofitting of Existing RCC Buildings B PDFmojeebmashalОценок пока нет

- Joints in Pavements PDFДокумент2 страницыJoints in Pavements PDFmojeebmashalОценок пока нет

- Seismic Behavior of Concrete Retaining Wall With Shear Key, Considering Soil-Structure InteractionДокумент6 страницSeismic Behavior of Concrete Retaining Wall With Shear Key, Considering Soil-Structure InteractionmojeebmashalОценок пока нет

- Nazli Azimikor - Composite Deck Design Report PDFДокумент23 страницыNazli Azimikor - Composite Deck Design Report PDFmojeebmashalОценок пока нет

- DDM04 S310 16 SupplementДокумент4 страницыDDM04 S310 16 SupplementmojeebmashalОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 785 TrucksДокумент7 страниц785 TrucksJavier Pagan TorresОценок пока нет

- The Lafayette Driller: President's Message By: Lindsay LongmanДокумент7 страницThe Lafayette Driller: President's Message By: Lindsay LongmanLoganBohannonОценок пока нет

- Sony Ericsson Secret MenuДокумент2 страницыSony Ericsson Secret MenuZeljana MaksicОценок пока нет

- Opposition To Motion For Judgment On PleadingsДокумент31 страницаOpposition To Motion For Judgment On PleadingsMark Jaffe100% (1)

- Best of SEO#1 SEO Training & Content Marketing Course 2022Документ2 страницыBest of SEO#1 SEO Training & Content Marketing Course 2022Oscar MascarenoОценок пока нет

- Crime Report Management SystemДокумент49 страницCrime Report Management SystemAbimbolaÀdésíréAdegbiteОценок пока нет

- Danfoss Pvg32Tech InfoДокумент56 страницDanfoss Pvg32Tech Infoifebrian100% (2)

- River Planning AetasДокумент4 страницыRiver Planning AetasErika ReyesОценок пока нет

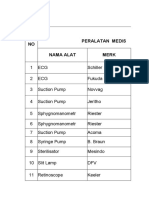

- Daftar Kalibrasi Peralatan MedisДокумент34 страницыDaftar Kalibrasi Peralatan Medisdiklat rssnОценок пока нет

- Virtual Asset Insurance Risk Analysis - OneDegreeДокумент3 страницыVirtual Asset Insurance Risk Analysis - OneDegreeShaarang BeganiОценок пока нет

- San Miguel ReportДокумент8 страницSan Miguel ReportTraveller SpiritОценок пока нет

- Diodat PDFДокумент4 страницыDiodat PDFFatmir KelmendiОценок пока нет

- 2.how To Boost Your Coating SalesДокумент23 страницы2.how To Boost Your Coating SalesAjaz Noor KhattakОценок пока нет

- Essays From Previous Years For HseeДокумент2 страницыEssays From Previous Years For HseeGagan TottempudiОценок пока нет

- Product Sold by APPLE AustraliaДокумент1 страницаProduct Sold by APPLE AustraliaImran KhanОценок пока нет

- St10 Flasher DLL: Stmicroelectronics ConfidentialДокумент10 страницSt10 Flasher DLL: Stmicroelectronics Confidentialeshwarp sysargusОценок пока нет

- Editing Packs I Maybe Will NeedДокумент3 страницыEditing Packs I Maybe Will NeedMijo SusićОценок пока нет

- No. 3 - Republic vs. DiazДокумент7 страницNo. 3 - Republic vs. DiazMark Gabriel MarangaОценок пока нет

- A Flight Plan in 10 StepsДокумент4 страницыA Flight Plan in 10 StepsThar LattОценок пока нет

- Ranbaxy Acquisition by DaiichiДокумент9 страницRanbaxy Acquisition by Daiichirupe59Оценок пока нет

- Harrod-Domar ModelДокумент13 страницHarrod-Domar ModelsupriyatnoyudiОценок пока нет

- Santa Letters 2013Документ16 страницSanta Letters 2013Lebanon_PublishingОценок пока нет

- Road Book - MoroccoДокумент28 страницRoad Book - MoroccoCarrie YangОценок пока нет

- LTE ID RNP StandardizationДокумент9 страницLTE ID RNP Standardizationahdanizar100% (1)

- Green Tyre TechnologyДокумент4 страницыGreen Tyre TechnologyAnuj SharmaОценок пока нет

- User's Guide: Smartpack2 Master ControllerДокумент32 страницыUser's Guide: Smartpack2 Master Controllermelouahhh100% (1)

- Eligibility To Become IAS Officer: Career As A IAS Officer About IAS OfficerДокумент4 страницыEligibility To Become IAS Officer: Career As A IAS Officer About IAS Officersamiie30Оценок пока нет

- Project On Brand Awareness of ICICI Prudential by SajadДокумент99 страницProject On Brand Awareness of ICICI Prudential by SajadSajadul Ashraf71% (7)

- Emailing Prime - Brochure - DigitalДокумент32 страницыEmailing Prime - Brochure - DigitalCASA VALLIОценок пока нет

- MetasploitДокумент9 страницMetasploitDhamlo KheralaОценок пока нет