Академический Документы

Профессиональный Документы

Культура Документы

L 8 Ihjnmklgf

Загружено:

brintopvОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

L 8 Ihjnmklgf

Загружено:

brintopvАвторское право:

Доступные форматы

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: :

SHRIRAM EPC LIMITED 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-013 REV. 0 SYSTEM : STEAM LINE FROM TURBINE BLEED TO DEAERATOR

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

min

W.P. X D + (2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

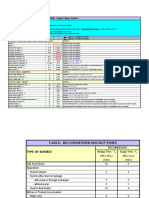

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 3 PIPE PIPE PIPE 168.30 114.30 33.40 mm 7.11 6.02 3.38

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 200 200 200

ALLOWABLE STRESS @ DESIGN TEMPERATURE kg/cm2 1202.50 1202.50 1202.50

THICKNESS WITH 12.5% NEGATIVE TOLERANCE mm 6.22 5.27 2.96

tmin REQUIRED mm 1.03 0.94 0.81

SA 106 GR B SA 106 GR B SA 106 GR B

4.00 4.00 4.00

PREPARED BY

Page 1 of CHECKED BY 27

APPROVED BY

MITED S POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 2 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-007 REV. 0 SYSTEM : MAIN STEAM LINE FROM BOILER TO TURBINE

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

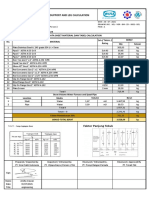

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 3 4 5 PIPE PIPE PIPE PIPE PIPE 168.30 141.30 114.30 48.30 33.40 mm 10.97 9.53 8.56 5.08 3.38

MATERIAL

MAXIMUM DESIGN WORKING TEMPERAT PRESSURE URE kg/cm2(g) DEG. C 495 495 495 495 495

ALLOWABLE STRESS @ DESIGN TEMPERATURE kg/cm2 817.30 817.30 817.30 817.30 817.30

THICKNESS tmin WITH 12.5% NEGATIVE REQUIRED TOLERANCE mm 9.60 8.34 7.49 4.45 2.96 mm 8.04 6.87 5.70 2.84 2.20

SA 335 GR P11 SA 335 GR P11 SA 335 GR P11 SA 335 GR P11 SA 335 GR P11

74.00 74.00 74.00 74.00 74.00

PREPARED BY

Page 3 of 27 CHECKED BY

APPROVED BY

LIMITED SS POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 4 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-008 REV. 0 SYSTEM : MAIN STEAM LINE TO PRDS & PRDS OUTLET TO AUXILLARY STEAM HEADER

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 PIPE PIPE 114.30 60.30 mm 6.02 5.54

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 340 495

ALLOWABLE THICKNESS tmin STRESS @ WITH 12.5% DESIGN NEGATIVE REQUIRED TEMPERATURE TOLERANCE kg/cm2 1202.50 817.30 mm 5.27 4.85 mm 1.46 3.36

SA 106 GR B SA 335 GR P11

15.00 74.00

PREPARED BY

Page 5 of 27 CHECKED BY

APPROVED BY

LIMITED SS POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 6 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: :

SHRIRAM EPC LIMITED 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-009 REV. 0 SYSTEM : STEAM LINE FROM AUXILIARY STEAM HEADER TO DEAERATOR

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 3 PIPE PIPE PIPE 219.10 168.30 88.90 mm 6.35 7.11 5.49

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 340 340 340

ALLOWABLE STRESS @ DESIGN TEMPERATURE kg/cm2 1202.50 1202.50 1202.50

THICKNESS tmin WITH 12.5% NEGATIVE REQUIRED TOLERANCE mm 5.56 6.22 4.80 mm 2.11 1.79 1.30

SA 106 GR B SA 106 GR B SA 106 GR B

15.00 15.00 15.00

PREPARED BY

Page 7 of 27 CHECKED BY

APPROVED BY

LIMITED SS POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 8 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-020 REV. 0 SYSTEM : SPARY WATER LINE TO PRDS

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 PIPE PIPE 33.40 33.40 mm 4.55 4.55

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 130 130

ALLOWABLE THICKNESS tmin STRESS @ WITH 12.5% DESIGN NEGATIVE REQUIRED TEMPERATURE TOLERANCE kg/cm2 1202.50 1202.50 mm 3.98 3.98 mm 2.04 2.04

SA 106 GR B SA 335 GR P11

97.00 97.00

PREPARED BY

Page 9 of 27 CHECKED BY

APPROVED BY

LIMITED SS POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 10 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-012 REV. 0 SYSTEM : AUXILIARY STEAM HEADER TO STEAM EJECTOR

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 PIPE 60.30 mm 3.91

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 340

ALLOWABLE THICKNESS tmin STRESS @ WITH 12.5% DESIGN NEGATIVE REQUIRED TEMPERATURE TOLERANCE kg/cm2 1202.50 mm 3.42 mm 1.12

SA 106 GR B

15.00

PREPARED BY

Page 11 of CHECKED BY27

APPROVED BY

LIMITED SS POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 12 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-010 REV. 0 SYSTEM : AUXILIARY STEAM HEADER TO GLAND SEALLING LINE

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 PIPE 60.30 mm 3.91

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 340

ALLOWABLE THICKNESS tmin STRESS @ WITH 12.5% DESIGN NEGATIVE REQUIRED TEMPERATURE TOLERANCE kg/cm2 1202.50 mm 3.42 mm 1.12

SA 106 GR B

15.00

PREPARED BY

Page 13 of CHECKED BY27

APPROVED BY

LIMITED SS POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 14 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-014 REV. 0 SYSTEM : TURBINE BLEED STEAM LINE TO LP HEATER

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 3 4 PIPE PIPE PIPE PIPE 273.10 219.10 114.30 33.40 mm 6.35 6.35 6.02 3.38

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 85 85 85 85

ALLOWABLE THICKNESS tmin STRESS @ WITH 12.5% DESIGN NEGATIVE REQUIRED TEMPERATURE TOLERANCE kg/cm2 1202.50 1202.50 1202.50 1202.50 mm 5.56 5.56 5.27 2.96 mm 0.86 0.84 0.80 0.76

SA 106 GR B SA 106 GR B SA 106 GR B SA 106 GR B

1.00 1.00 1.00 1.00

PREPARED BY

Page 15 of CHECKED BY27

APPROVED BY

IMITED S POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 16 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-011 REV. 0 SYSTEM : GLAND LEAK OFF STEAM LINE FROM TURBINE TO DEAERATOR

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 3 PIPE PIPE PIPE 141.30 114.30 33.40 mm 6.55 6.02 3.38

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 373 373 373

ALLOWABLE THICKNESS tmin STRESS @ WITH 12.5% DESIGN NEGATIVE REQUIRED TEMPERATURE TOLERANCE kg/cm2 1084.60 1084.60 1084.60 mm 5.73 5.27 2.96 mm 1.01 0.96 0.81

SA 106 GR B SA 106 GR B SA 106 GR B

4.00 4.00 4.00

PREPARED BY

Page 17 of CHECKED BY27

APPROVED BY

LIMITED SS POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 18 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: :

SHRIRAM EPC LIMITED 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-029 REV. 0 SYSTEM : FEED WATER DISCHARGE HEADER

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 3 PIPE PIPE PIPE 114.30 33.40 88.90 mm 8.56 4.55 7.62

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 130 130 130

ALLOWABLE STRESS @ DESIGN TEMPERATURE kg/cm2 1202.50 1202.50 1202.50

THICKNESS tmin WITH 12.5% NEGATIVE REQUIRED TOLERANCE mm 7.49 3.98 6.67 mm 5.18 2.04 4.20

SA 106 GR B SA 106 GR B SA 106 GR B

97.00 97.00 97.00

PREPARED BY

Page 19 of CHECKED BY 27

APPROVED BY

Page 20 of 27

IMITED S POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 21 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: SHRIRAM EPC LIMITED : 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-027 REV. 0 SYSTEM : BOILER FEED PUMP DISCHARGE HEADER TO BOILER TERMINAL POINT

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 PIPE 88.90 mm 7.62

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 130

ALLOWABLE STRESS @ DESIGN TEMPERATURE kg/cm2 1202.50

THICKNESS WITH 12.5% NEGATIVE TOLERANCE mm 6.67

tmin REQUIRED mm 4.20

SA 106 GR B

97.00

PREPARED BY

Page 22 of CHECKED BY 27

APPROVED BY

Page 23 of 27

MITED S POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 24 of 27

ARK ENGINEERING & POWER CONSULTANTS PVT LTD

CUSTOMER SERVICE

: :

SHRIRAM EPC LIMITED 10 MW BIO-MASS POWER PLANT

REFERENCE DRG NO. : PC8001-00-02-026 REV. 0 SYSTEM : FEED WATER DISCHARGE PIPING FROM PUMPS TO DISCHAGE HEADER

PIPE THICKNESS CALCULATION : (I.B.R REG. NO. 350) (EQN. NO. 91)

W.P. =

WHERE, W.P f E D t

min

2 X f X E X (t-C) (D - t + C)

(OR)

W.P. X D

min =

(2 X f X E) + W.P.

= MAXIMUM WORKING PRESSURE IN kg/cm2 g = ALLOWABLE STRESS IN kg/ cm2 = EFFICIENCY FACTOR (1.0) = OUTSIDE DIAMETER OF THE PIPE = CALCULATED MINIMUM THICKNESS OF THE PIPE IN mm = 0.75 mm

0.75 1

OUTSIDE SELECTED DIAMETER PIPE SL NO DESCRIPTION OF PIPE THICKNESS mm 1 2 3 PIPE PIPE PIPE 114.30 33.40 73.00 mm 8.56 4.55 7.01

MATERIAL

MAXIMUM WORKING PRESSURE kg/cm2(g)

DESIGN TEMPERAT URE DEG. C 130 130 130

ALLOWABLE STRESS @ DESIGN TEMPERATURE kg/cm2 1202.50 1202.50 1202.50

THICKNESS tmin WITH 12.5% NEGATIVE REQUIRED TOLERANCE mm 7.49 3.98 6.13 mm 5.18 2.04 3.58

SA 106 GR B SA 106 GR B SA 106 GR B

97.00 97.00 97.00

PREPARED BY

Page 25 of CHECKED BY 27

APPROVED BY

Page 26 of 27

IMITED S POWER PLANT

REMARKS

PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT PROVIDED THICKNESS IS SUFFICIENT

APPROVED BY

Page 27 of 27

Вам также может понравиться

- Facilities On Offshore Installations: Guide For Building and ClassingДокумент209 страницFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyОценок пока нет

- Openings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1Документ1 страницаOpenings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1met-calcОценок пока нет

- Split-Tee ChamferingДокумент10 страницSplit-Tee ChamferingBerani JombloОценок пока нет

- Spreaer Beam&Lifting Line Beam p3Документ2 страницыSpreaer Beam&Lifting Line Beam p3Sabrang LorОценок пока нет

- Moment Baseplate Design Rev. 0Документ3 страницыMoment Baseplate Design Rev. 0Bok MortegaОценок пока нет

- Calculation of PipeReinforcement ASMEB31 1Документ4 страницыCalculation of PipeReinforcement ASMEB31 1threedlabsОценок пока нет

- Variable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)Документ227 страницVariable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)miladОценок пока нет

- Bolt Tensioning - E411 - GB PDFДокумент2 страницыBolt Tensioning - E411 - GB PDF4jawwy markme026Оценок пока нет

- SteelSpan MADДокумент6 страницSteelSpan MADAnonymous pD2ymRUguОценок пока нет

- Torispherical Cone With KnuckleДокумент2 страницыTorispherical Cone With KnuckleSajal KulshresthaОценок пока нет

- Detail Wall Thickness Calc. CorrosionДокумент69 страницDetail Wall Thickness Calc. Corrosionbagus handokoОценок пока нет

- Calculation of RC PAD2Документ1 страницаCalculation of RC PAD2m 418Оценок пока нет

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIДокумент5 страницReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiОценок пока нет

- Steam Drum, Water Wall & Evaporator - VWHA054Документ36 страницSteam Drum, Water Wall & Evaporator - VWHA054Mani SunОценок пока нет

- Design Calculations of Storage Tank: According To API 650 Code, 11 EditionДокумент3 страницыDesign Calculations of Storage Tank: According To API 650 Code, 11 EditionAkash KazamaОценок пока нет

- Isolated Footing (ACI)Документ4 страницыIsolated Footing (ACI)engyana engyyyОценок пока нет

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LДокумент7 страницSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukОценок пока нет

- PV Elite ResultДокумент239 страницPV Elite ResultChaitanya Sai TОценок пока нет

- Pipe Calculation Wall Thickness PDFДокумент1 страницаPipe Calculation Wall Thickness PDFPetroОценок пока нет

- PEC EN STN C 13619 17 Mar 2014Документ169 страницPEC EN STN C 13619 17 Mar 2014Raja RamОценок пока нет

- Calculations For Rectangular Storage TankДокумент44 страницыCalculations For Rectangular Storage TankSiva ShankarОценок пока нет

- Skid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialДокумент8 страницSkid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialAzharyanto FadhliОценок пока нет

- Boilers: - Asit MondalДокумент29 страницBoilers: - Asit MondalAJITSPATILОценок пока нет

- A320 NEO Abbreviations LEAP-1AДокумент5 страницA320 NEO Abbreviations LEAP-1AwenjukwaxОценок пока нет

- Auto PipeДокумент18 страницAuto PipeAdi SutardiОценок пока нет

- Steam Jet EjectorДокумент6 страницSteam Jet Ejectorjayanta_198967% (3)

- Multiflow InformationДокумент4 страницыMultiflow InformationsouthliОценок пока нет

- Cong Thuc Tinh Toan Piping ThicknessДокумент108 страницCong Thuc Tinh Toan Piping ThicknessTruong Ngoc SonОценок пока нет

- Offcom Completa - v.01Документ7 страницOffcom Completa - v.01Argonauta_navegadorОценок пока нет

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFДокумент4 страницыUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontОценок пока нет

- Lifting - Lug (Modification)Документ11 страницLifting - Lug (Modification)Sam LowОценок пока нет

- API 650 Tank Nozzle Stand OutДокумент5 страницAPI 650 Tank Nozzle Stand Outtry&tryОценок пока нет

- Steam Drum (Single) : Drum Thickness Calculation - Sa 516 Gr. 70 (As Per Ibr)Документ3 страницыSteam Drum (Single) : Drum Thickness Calculation - Sa 516 Gr. 70 (As Per Ibr)neelОценок пока нет

- Pressure Vessel Design Old (Eugyene F Megysey)Документ31 страницаPressure Vessel Design Old (Eugyene F Megysey)David FonsecaОценок пока нет

- Restriction Orifice Diamater CalculationДокумент1 страницаRestriction Orifice Diamater CalculationkodeesОценок пока нет

- PIG Handling TrollyДокумент1 страницаPIG Handling TrollyAnas Badar100% (1)

- Muk 61 2 PLL 0007 9H8Документ34 страницыMuk 61 2 PLL 0007 9H8Suresh MahalingamОценок пока нет

- Calculation Trunion (By Maniacs)Документ5 страницCalculation Trunion (By Maniacs)SyahkullahОценок пока нет

- Battery Storage Systems and Smart Mini-Grid - Sharing Our Experiences - Parimita MohantyДокумент30 страницBattery Storage Systems and Smart Mini-Grid - Sharing Our Experiences - Parimita MohantyEnergy for All67% (3)

- Calculation Cover Sheet: Mechanical Generic Project Name Pipe Wall Thickness Calculations System Name Wall ThicknessДокумент2 страницыCalculation Cover Sheet: Mechanical Generic Project Name Pipe Wall Thickness Calculations System Name Wall Thicknessjmclaug502Оценок пока нет

- Storage Tank Venting Calculations For Site Tank FarmДокумент7 страницStorage Tank Venting Calculations For Site Tank FarmGusfi CarsurinОценок пока нет

- Power ConsultantДокумент10 страницPower ConsultantIAmaeyОценок пока нет

- 30 MW Power PlantДокумент151 страница30 MW Power Plantsambhu0% (1)

- Blind Flange Design CalculationsДокумент4 страницыBlind Flange Design CalculationsamaОценок пока нет

- Master Foods 12 MДокумент16 страницMaster Foods 12 MSarfarazОценок пока нет

- Vertical Two-Phase Separator Design: Liquid / Vapor ServiceДокумент11 страницVertical Two-Phase Separator Design: Liquid / Vapor ServiceDhanny MiharjaОценок пока нет

- Wind / Seismic Design For Horizontal Vessels: Longitudinal ForcesДокумент2 страницыWind / Seismic Design For Horizontal Vessels: Longitudinal ForcesMasoodMiyanОценок пока нет

- Stacks and Tanks WInd LoadДокумент2 страницыStacks and Tanks WInd LoaddantevariasОценок пока нет

- 4 - PFC To Hanging Plate ConnДокумент13 страниц4 - PFC To Hanging Plate Connabdul khaderОценок пока нет

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Документ36 страницMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Karina RoquelОценок пока нет

- "EMBEDPL" Sample Calculation: (4) H.S.A. Example - "EMBEDPL" WorksheetДокумент5 страниц"EMBEDPL" Sample Calculation: (4) H.S.A. Example - "EMBEDPL" WorksheetVigneshОценок пока нет

- Desuperheater Boiler Feed Water RequirementДокумент2 страницыDesuperheater Boiler Feed Water RequirementMichael HaiseОценок пока нет

- Seismic Load Calculation of The Tank As Per IS 1893Документ1 страницаSeismic Load Calculation of The Tank As Per IS 1893ParthibanОценок пока нет

- Anchor Bolts Calculations "90/150/10 Meter Antenna Tower" Footing NoДокумент1 страницаAnchor Bolts Calculations "90/150/10 Meter Antenna Tower" Footing Nokabardey46Оценок пока нет

- Base Ring (Welded) - Vertical Vessel REV.1Документ3 страницыBase Ring (Welded) - Vertical Vessel REV.1dskr fkshОценок пока нет

- DC S3-1301 REV.0 OriginalДокумент93 страницыDC S3-1301 REV.0 OriginalPeja JusohОценок пока нет

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdДокумент1 страницаRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutОценок пока нет

- Tailing Lifting Lug Design 57 V 202 r2Документ10 страницTailing Lifting Lug Design 57 V 202 r2Dinesh KhaparkarОценок пока нет

- 134004-SEP-MEC-DAT-0004 Rev.B2 PDFДокумент11 страниц134004-SEP-MEC-DAT-0004 Rev.B2 PDFDhakshina KОценок пока нет

- Split Tee Technical Data Sheet: NamdaranДокумент1 страницаSplit Tee Technical Data Sheet: NamdaranestudiemosОценок пока нет

- PV Newsletter - Skirt Connections PDFДокумент5 страницPV Newsletter - Skirt Connections PDFDivyesh PatelОценок пока нет

- Control Valve Technical Specification Sheet Globe Service: GasДокумент1 страницаControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessОценок пока нет

- BSPL 1242 Iot2 Me Cal 0004 Rev.a1Документ70 страницBSPL 1242 Iot2 Me Cal 0004 Rev.a1SachinОценок пока нет

- Foundation Load Table.Документ1 страницаFoundation Load Table.Lcm TnlОценок пока нет

- PPSC - Product Data Sheet 3lppДокумент1 страницаPPSC - Product Data Sheet 3lppjulianpirahОценок пока нет

- Support and Leg Calculation: Data Sheet Material Dan Tabel CalculationДокумент3 страницыSupport and Leg Calculation: Data Sheet Material Dan Tabel CalculationliusОценок пока нет

- Vessel THKДокумент8 страницVessel THKdigm25Оценок пока нет

- Cogeneration PDFДокумент26 страницCogeneration PDFSubrata DasОценок пока нет

- Radial Piston PumpДокумент5 страницRadial Piston Pumpمصطفى محمودОценок пока нет

- R&R Seremban - Suction PumpДокумент3 страницыR&R Seremban - Suction PumpJeghiОценок пока нет

- ASC Presentation PDFДокумент89 страницASC Presentation PDFAhmadHussain09Оценок пока нет

- Basic Thermodynamics Prof. S. K. Som Department of Mechanical Engineering Indian Institute of Technology, KharagpurДокумент24 страницыBasic Thermodynamics Prof. S. K. Som Department of Mechanical Engineering Indian Institute of Technology, KharagpurAshutosh ShuklaОценок пока нет

- Heater Selection GuideДокумент2 страницыHeater Selection Guidemacanipharoldf6220Оценок пока нет

- Solar Power Pesticides SprayerДокумент4 страницыSolar Power Pesticides SprayerRodriguez Arthurs100% (1)

- 3827-E10-062 - Two Position Valve - DДокумент4 страницы3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallОценок пока нет

- 1 L1 Unit1-GP-3Документ4 страницы1 L1 Unit1-GP-3Nursan Septhyani SaenNichanОценок пока нет

- Turbines 14Документ21 страницаTurbines 14Izal FrdsОценок пока нет

- Senr1677senr1677-01 Sis PDFДокумент2 страницыSenr1677senr1677-01 Sis PDFDennis OlayaОценок пока нет

- Sulzer Revamp CompressorДокумент4 страницыSulzer Revamp CompressorAli Barzegar100% (1)

- Carrier Semi Herm ComprДокумент13 страницCarrier Semi Herm CompribalcoОценок пока нет

- Pipe - 1Документ4 страницыPipe - 1Victor John PingkianОценок пока нет

- Reavell 4-20 HP Air Cooled Reciprocating CompressorДокумент2 страницыReavell 4-20 HP Air Cooled Reciprocating Compressorscrollock0428Оценок пока нет

- Sole Indian Manufacturer of of High Temperature In-Situ Oxygen Analyzer (HTO)Документ6 страницSole Indian Manufacturer of of High Temperature In-Situ Oxygen Analyzer (HTO)vishnu AОценок пока нет

- Reciprocating Compressor Calculation For Process EngineerДокумент5 страницReciprocating Compressor Calculation For Process EngineerDark KnightОценок пока нет

- Recommended Schemes & Writeup of Auto ControlsДокумент25 страницRecommended Schemes & Writeup of Auto ControlsShirshendu RoyОценок пока нет

- Overview of NTPC PDFДокумент40 страницOverview of NTPC PDFRahul KediaОценок пока нет

- Beli EqpДокумент115 страницBeli EqpRony CamaroОценок пока нет

- Assignment-No 3Документ2 страницыAssignment-No 3Adame ObinamОценок пока нет

- Thermal and Nuclear Power Plant Assignment QuestionsДокумент3 страницыThermal and Nuclear Power Plant Assignment QuestionsAshok KumarОценок пока нет

- Engine Sisu 11Документ1 страницаEngine Sisu 11Auto-Moto ZS.K.Оценок пока нет