Академический Документы

Профессиональный Документы

Культура Документы

GE-103002, Waste Oil Transfer Pumps, P-102A&B

Загружено:

Mohammed AnwerИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GE-103002, Waste Oil Transfer Pumps, P-102A&B

Загружено:

Mohammed AnwerАвторское право:

Доступные форматы

OPRNS

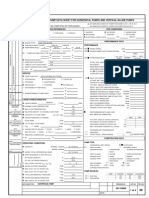

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

DCO

ENGG CERT PMT

NOTE: O INDICATES INFORMATION TO BE COMPLETED BY PURCHASER; PURCHASERS REFERENCES

APPLICABLE TO: PUMP MFR SIZE & TYPE SERIAL NO. DRIVER TYPE PROPOSALS PURCHASE AS BUILT

BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2 BY MANUFACTURER OF PUMPS OR PUMPS PER API-610

SITE CONDITIONS

INDOOR ON SHORE ELECTRICAL AREA CLASS OUTDOOR COASTAL , DIV. UNDER ROOF OFF SHORE , GROUP

SR

ELECTRIC MOTOR -G-GTWO(2) 102 A , , PUMP(S) P

PERFORMANCE DATA PERFORMANCE

-G-G-G-G102 B RATED SPEED DRIVER NAME PLATE POWER RATING MIN. CONT. STABLE FLOW RPM HP RPM PERFORMANCE AT Ft TOTAL DIFF. HEAD % EFFICIENCY REQUIRED POWER HP NPSH REQ'D FOR: 3% 1st STAGE ON H2O Ft 40,000 HRS LIQ'D PUMPED Ft SHUT-OFF HEAD AT ACTUAL IMP. DIAM. Ft AT MAX. IMP. DIAM. Ft USGPM CAPACITY AT END OF CURVE TOT.DIFF. HEAD AT END OF CURVE Ft RATIO. SHUT-OFF HEAD/RATED HEAD RATIO. END OF CURVE CAPACITY/RATED USGPM MINIMUM CONTINUOUS STABLE FLOW USGPM MINIMUM CONTINUOUS THERMAL FLOW SEC MAXIMUM OPERATING TIME AT SHUT-OFF FIRST CRIT. SPEED; DRY RPM FIRST CRIT. SPEED; WET RPM MAX. ALLOWABLE SPEED RPM MAX. POWER FULL CURVE ACTUAL IMP.DIAM. HP POWER AT SHUT-OFF HEAD HP PERFORMANCE WITH MAX. AND MIN. IMPELLER DIAMETERS MAX. PSIA PSIA PPM 1.45 UNKNOWN HARD SOFT UNKNOWN / / CI PPM TOT.DIFF. HEAD AT RATED CAPACITY EFFICIENCY AT RATED CAPACITY REQUIRED POWER AT RATED CAP. MAX. REQUIRED POWER FULL CURVE INTERMEDIATE TRANSMISSION GEAR BOX HYDR. COUPL. SPEED RANGE Ft % HP HP MIN. NORMAL FLOW 100% 120%

OF RATED CAPACITY

THIS DATA SHEET COVER P PUMP MARK NO(S).

DESCRIPTION

PUMPS OF IDENTICAL TYPE & SIZE IN OPERATION -G, -G, DRIVER DATA SHEET GEAR UNIT DATA SHEET N/A LUBE OIL SYST DATA SHEET

ISSUED FOR FINAL REVIEW

N/A

SAFETY INSTRUCTION SHEET LCC EF $/kW

SERVICE

PUMP FUNCTION CONTINUOUS ATTENDED INDIVIDUALLY WASTE OIL TRANSFER INTERMITTENT UNATTENDED IN SERIES IN PARALLEL -G-GDOWNSTREAM OF PUMP NO(S) -G-GSTANDY BY

DATE E

9-17-20

00081

JO

UPSTREAM OF PUMP NO(S)

REV. NO.

LIQUID CHARACTERISTICS

LIQUID PUMPED

WASTE OIL (Note 4)

TDS

OF OF

PPM 95 176 0.9 1.2

DISCIPLINE ENGINEER SR DATE: 09-17-2011 PROJECT ENGINEER NM DATE: 09-17-2011

NORMAL FLOW TEMPERATURE MAX. FLOW TEMPERATURE RELATIVE DENSITY AT NORMAL FLOW TEMP. VISCOSITY AT FLOW TEMP. VAPOR PRESSURE AT NORMAL FLOW TEMP. V.P. AT MAX. FLOW TEMP. TSS NONE PULPY VOL. %

CS / CP / SSU

CERTIFIED

DCO DATE: 09-17-2011

CHARACTER OF SOLIDS: GAS IN FLUID: NONE

GRITTY

RATIO % % OF DRIVER SPEED

CONSTRUCTION AGENCY

PRINCIPAL CORROSIVES: pH

CONSTRUCTION DATA PUMP TYPE

DATE:

OPERATIONS

OPERATING CONDITIONS

CAPACITY NORMAL USGPM RATED USGPM 352 (80 M3/Hr) 43.7 (13.3m)

DATE:

RATED TOTAL DIFFERENTIAL HEAD NPSH AVAILABLE AT SUCTION FLG. AT RATED CAPACITY AT 120% OF RATED CAPACITY

DATE: BY:

Ft

Ft Ft

28 25.7

VISC. CORR. FACTOR CQ; CH; CE RATED SUCTION PRESSURE MAX. SUCT. PR. AT RATED CAP. MAX. SUCT. PR. AT SHUT-OFF TOTAL DIFFERENTIAL PRESSURE RATED DISCHARGE PRESSURE MAX. DISCH. PR. AT RATED CAP.

DATA SHEET FOR

PSIA PSIA PSIA PSI PSIA PSIA

12.52

HORIZONTAL (BET. BRGS) OVERHUNG VERT. IN-LINE INTEGRAL SHAFT CASING MOUNT: CENTERLINE FLANGE CENTERLINE FOOT VERT. IN-LINE IN-LINE CASE SUPPORTED CASING SPLIT AXIAL RADIAL CASING TYPE DOUBLE VOLUTE SINGLE VOLUTE DIFFUSOR STAGGER SELF PRIMING YES NO DIR. OF ROT. CCW CW (VIEWED FROM DRIVER)

PUMP NOZZLES

19 31.5 SIZE SUCTION DISCHARGE RATING 150 150 FACING RF RF LOCATION END TOP

CENTRIFUGAL PUMP

DRAWING NO.

SHT.NO.

REV.NO.

GE103002

Job No : JO

1 of 4 f

00

OPRNS

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

DCO

ENGG CERT PMT

NOTE: O INDICATES INFORMATION TO BE COMPLETED BY PURCHASER; CONSTRUCTION DATA (CONT'D) FORCES AND MOMENTS

/ ALLOWABLE FORCES AND MOMENTS

TOP NOZZLE Fx Fy Fz LB Fx LB Fy LB Fz SIDE NOZZLE LB Fx LB Fy LB Fz END NOZZLE LB Mx LB My LB Mz EACH NOZZLE LB.FT LB.FT LB.FT

BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2 BY MANUFACTURER OF PUMPS OR PUMPS PER API 610

CONSTRUCTION DATA (CONT'D) STUFFING BOX DATA

INBOARD / OUTBORAD

SR

INSIDE DIAMETER DEPTH DISTANCE FACE OF STUFFING BOX FLANGE TO NEAREST OBSTRUCTION

IN IN IN

ISSUED FOR FINAL REVIEW

QTY. SIZE TYPE MISC CONNECTIONS LUBE OIL INLET LUBE OIL OUTLET SEAL LIQUID INLET SEAL LIQUID DRAIN CASING DRAIN(S) VENTS COOLING WATER STUFFING BOX BALANCE DRUM DRAIN & VENT INDIVIDUALLY PIPED WITH BLOCK VALVES TO TERMINATE AT EDGE OF BASE PLATE IN COMMON AREA O YES O NO FLANGE RATING in CLASS

DESCRIPTION

IMPELLER DATA

NUMBER OF STAGES ACTUAL DIAMETER MAXIMUM DIAMETER

FIRST STAGE IN IN FOLLOW STAGE

/ / / / /

PRESSURES

/

MAX. ALLOW. WORK. PRESS. HYDROST. TEST PRESS.

/ O/ / /

00081

PRESSURES CASE JACKETS COILS DUAL MECH. SEAL PSIG PSIG PSIG PSIG

AT

OF

REV. NO.

IN MINIMUM DIAMETER SINGLE / DOUBLE SUCTION SQ.IN EYE AREA IMPELLER O VANE ANGLE AT IMP. EXIT NUMBER OF VANES FT/S ACTUAL PERIPHERAL SPEED MAX.ALLOW.PERIPH.SP'D AT FLOW TEMP. FT/S PATTERN NUMBER YES - NO PRECISION CAST IN CUT WATER DIAMETER SPECIFIC SPEED SUCTION SPECIFIC SPEED AT 3% H IN WIDTH. IMPELLER DISCH. YES / NO UNDER / OVER FILING / V-CUT WEARING RINGS: YES NO IMPELLER

09-17-2 2011

DATE E

DISCIPLINE ENGINEER SR DATE: 09-17-2011 PROJECT ENGINEER NM DATE: 09-17-2011

SHAFT DATA

SHAFT DIAMETER AT MECH. SEAL SLEEVE SHAFT DIAMETER AT BEARINGS SHAFT DIAMETER AT 1ST STAGE IMPELLER BEARING SPAN STATIC SHAFT DEFLECTION

IN IN IN IN IN

CASE CLEARANCE

YES

NO IN IN

INBOARD OUTBOARD

1st STAGE IMPELLER INLET GEOMETRY

CERTIFIED

DCO DATE: 09-17-2011 CONSTRUCTION AGENCY

SHAFT SEALING

O PACKED STUFFING BOX PACKING MAT'L. (Note 3) PROVIDED WITH LANTERN RING: O YES O NO SEALING ARRANGEMENT THROUGH SEALING DEAD ENDED LIQUID PUMPED FLUSH WITH FOREIGN LIQUID MECHANICAL SEAL API CODE MAKE MANUFACTURER MAT'L CODE MODEL API CODE MAT'L 3RD LETTER 4TH LETTER 5TH LETTER PIPING FOR PRIMARY SEAL API FIG. D-2 PLAN PIPING FOR THROTTLE BUSHING OR AUXILIARY SEAL API FIG. D-3 PLAN COOLING WATER PIPING, API FIG. D-4 PLAN CYCLONE SEPARATOR FLOW ORIFICE IN SEAL FLUSH SUPPLY LINE SEAL LEAKAGE PIPING WITH ORIFICE BUFFER LIQUID SYSTEM METHANOL DRIP SYSTEM REQUIRED: PRESSURE PSIG; FLOW CARTRIDGE DESIGN CENTRIFUGAL PUMP

GREASE BLEED OFF

DATE:

OPERATIONS

O / / / /

DATE:

Dh1

Dh2

Dsl

Dp

O O O

O YES O YES O YES O YES O YES O YES

O NO O NO O NO O NO O NO

USGPM

Dp Dsl Dh1 Dh2 d p h

= = = = = = =

IN IN (IF APPLICABLE) IN IN IN DEGREES DEGREES

O NO

DRAWING NO. SHT.NO. REV.NO.

DATA SHEET FOR

GE103002

SAUDI ARABIA

2 of 4 f

00

OPRNS

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

DCO

ENGG CERT PMT

NOTE: O INDICATES INFORMATION TO BE COMPLETED BY PURCHASER; CONSTRUCTION DATA (CONT'D) BEARINGS AND LUBRICATION

BEARING TYPE SLEEVE ANTI-FRICTION TILTING PAD LUBRICATION METHOD GREASE RING-OIL CONSTANT LEVEL LUBRICATOR, MAKE OIL BATH WITH EXT'L CIRCULATION FORCED FEED OIL MIST LUBE OIL PIPING TO AND FROM BEARINGS LUBE OIL PIPING UP TO L.O. SYSTEM TERMINATION WITH FLANGED CONNECTIONS AT RADIAL COUPLING PLANE SIGHT FLOW INDICATOR IN EACH RETURN BRANCH MAKE THRUST BEARING LOADS: MAX. ALLOWABLE AXIAL FORCE: DESIGN AXIAL FORCE: RADIAL THRUST

BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2 BY MANUFACTURER OF PUMPS OR PUMPS PER API 610

CONSTRUCTION DATA (CONT'D) COUPLING

/ MAKE MODEL SIZE SUPPLIED BY: TYPE O DIAPHRAGM O DISC PACK O RIGID ADJUSTABLE O CLOSE COUPLED O ELASTOMERIC HYDRAULIC FIT KEYED IN SPACER: O NO O YES, COUPLING GUARD O PARTIALLY ENCLOSED COMPLETELY ENCLOSED PUMP SHAFT END CYLINDRICAL TAPERED MOUNT COUPLING HALF: PUMP YES NO DRIVER HALF NO. IF SHIPPED TO DRIVER SUPPLIER YES PILOT BORED COMPLETELY MACHINED

SR

RADIAL

THRUST

/ DESCRIPTION

YES YES

NO NO

ISSUED FOR FINAL REVIEW

YES MODEL

NO

BASE PLATE

O O N N O OIL FIELD SKID BASE PLATE SUPPLIED BY PUMP VENDOR O GEAR O PUMP TO ACCOMMODATE: O DRIVER O L.O. AND/OR S.O. SYSTEM MOUNTED O ON BASE O OFF BASE DESIGNED FOR INSTALLATION ON: O CONCRETE FOUNDATION O STEEL PLATFORM DRILLED FOR DRIVER O YES O NO O NO GEAR O YES HORIZONTAL ALIGNMENT JACKSCREWS O YES O NO

00081

JO

LUBRICANTS

O BEARING LUBRICANT OIL O GREASE

09-17-2 2011

DATE E

MATERIALS OF CONSTRUCTION

FLOW OR SUPPLY CAPACITY PRESSURE GPM/USGAL INB. BRG. OUTB. BRG. THRUST BRG. PSIG HEAT REMOVAL BTU/MIN MAX. OIL OUTL. TP.

OF

REV. NO.

DISCIPLINE ENGINEER SR DATE: 09-17-2011 PROJECT ENGINEER NM DATE: 09-17-2011

VENDOR TO COMPLETE FOLLOWING MAT'L LISTING (Note 2) / 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13.1 13.2 14. 15. 16. 17. 18. 19. CASING IMPELLER(S) CASE WEAR RINGS IMPELLER WEAR RINGS SHAFT SHAFT SLEEVES THROAT BUSHINGS INTERSTAGE SLEEVES INTERSTAGE BUSHINGS LANTERN RING (PACKED PUMPS) GLAND / MECH. SEAL FLANGE BEARING BRACKETS NON-WETTED STUDS / NUTS WETTED FASTENERS PIPING: PIPE / FITTINGS BASE PLATE MECH. SEAL SPRINGS MECH. SEAL OTHER METAL PARTS ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM ASTM A743CF8M A743CF8M

CERTIFIED

DCO DATE: 09-17-2011 CONSTRUCTION AGENCY

O PUMP VENDOR O OTHER IN ACCORDANCE WITH DATA SHEET FORM 8004-ENG YES, DRAWING NO. O NO

TOTAL LUBE OIL SYSTEM SUPPLIED BY:

A276 XM19 SS316 A276 316 N/A N/A N/A A216 WCB A193-B7/A194-GR 2H

COOLING

BEARING COOLING NON-CIRCULATING SYSTEM BY: SHAFT MOUNTED FAN COILS IN BEARING HOUSING EXTERNAL CIRCULATING SYSTEM OIL COOLING BY: LIQ. PUMPED FOREIGN LIQ. STUFFING BOX COOLING PEDESTAL COOLING COOLING PIPING FOR BEARINGS STUF. BOX IN ACCORDANCE WITH API-610. FIG. D-4.

JACKETED BEARING HOUSING

DATE:

A516 GR 70

OPERATION

DATE:

AIR YES YES PEDESTALS

NONE NO NO SEAL COOLER

NOISE SPECIFICATION

COOLANT DATA

O BRG HSG USGPM PSIG OF OF STUF BOX PEDESTAL SEAL COOLER

TOTAL FLOW INLET PRESS. TEMP. INLET TEMP. OUTLET COOLING MEDIUM

DATA SHEET FOR

MAXIMUM ALLOWABLE SOUND LEVEL BY PURCHASER AT 3 FT. DISTANCE MANUFACTURER GUARANTEED MAXIMUM PUMP DRIVER OTHER COMPLETE TRAIN

85

dBA dBA dBA dBA

85

dBA

CENTRIFUGAL PUMP

DRAWING NO.

SHT.NO.

REV.NO.

GE103002

JUBAIL

SAUDI ARABIA Job No :

3 of 4 f

00

OPRNS

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

NOTE:

DCO

ENGG CERT PMT

BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2 BY MANUFACTURER OF PUMPS OR PUMPS PER API 610

O INDICATES INFORMATION TO BE COMPLETED BY PURCHASER;

UTILITIES

O ELECTRIC POWER AC DC MAIN ELECTRIC DRIVER CONTROLS AND PROTECTION O AIR CONTROLS AND PROTECTION AC AC AVAILABLE VOLTS 480 120 PHASE HZ 3/60 1/60 AVAILABLE PSIG

INSPECTION AND TESTS

OBSER'D WITN'D O VENDOR'S STANDARD SHOP TEST O AS FOLLOWS HYDROSTATIC TEST O WATER RUNNING TEST PERFORMANCE TEST MEASURE P ACROSS STUFFING BOX NPSH TEST DISMANTLING RADIOGRAPHIC INSPECTION IMPELLER DYE PENETRANT EXAMINATION IMPELLER O KEROSENE CERT'D O O O O O O O O O O O O O

SR

O O O O O O O O O O O O O

O O O O O O O O O O O O O

DESCRIPTION

AVAIL COOLING WATER

ISSUED FOR FINAL REVIEW

AVAIL PSIG

INLET OF

OUTLET OF

REQ'D OF

DYNAMIC BALANCE IMPELLER(S) DYNAMIC BALANCE ROTOR DYNAMIC BALANCE COUPLING VIBRATION, MEASUREMENTS TESTS TO BE CARRIED WITH: O ACTUAL DRIVER O MANUFACTURER'S DRIVER O DERATED SPEED: AT O RATED SPEED

O WELL WATER O TREATED WATER O SEA WATER O ONCE THROUGH SYSTEM O CLOSED LOOP SYSTEM

INSTRUMENTATION & CONTROLS

RPM

DRAWINGS AND OTHER DATA

TEMPERATURE MONITORING YES PROVISIONS ONLY ALARM SETTING SHUTDOWN SETTING

OF OF

RADIAL BEARINGS O O

THRUST BEARINGS O O

CASING THERMOWELL O O

00081

MANUFACTURER'S DRAWING OR DOCUMENT NO. REQUIRED YES NO DIMENSIONAL DRAWING OF COMPLETELY ASSEMBLED UNIT OPER. & MAINT. INSTRUCTIONS CROSS SECT. DRW. WITH PART NO'S. MECHANICAL SEAL DRAWING BILLS OF MATERIALS COMPLETED PUMP DATA SHEET AUXILIARY PIPING DWG. CERTIFIED TEST CURVE & DATA RECOMMENDED SPARES LIST INSTR. WIRING DIAGRAM SPEED TORQUE CURVE COLD ALIGNMENT CURVE DATA L. & T. VIBR. ANALYSIS O O O O O O O O O O O O O O O O O O O O O O O O O

REV. NO.

09-17-2011

DAT TE

VIBRATION / DISPLACEMENT MONITORING POSITION TYPE RADIAL BRG'S THRUST BRG. PROXIMITY PROXIMITY O O O O BRG. HSG SEISMIC O O

DISCIPLINE ENGINEER SR DATE: 09-17-2011

PROJECT ENGINEER NM DATE: 09-17-2011

YES PROVISIONS ONLY ALARM / SHUTDOWN SETTING: MILS P-P MILS P-P IN / SEC RMS O SEISMIC O PROXIMITY

/ / / O PNEUMATIC O ELECTRICAL O YES O PNEUMATIC MODEL PSIG MODEL CONTR.ORIFICE IN O NO

CERTIFIED

DCO DATE: 09-17-2011

MISCELLANEOUS

PAINTING O BUYER'S PAINT SPECIFICATION: O VENDOR'S STANDARD:

CONSTRUCTION AGENCY

SHAFT SEAL LEAKAGE CONTROL: O ELECTRICAL

DATE:

OPERATIONS

PRES. SWITCH MAKE PRESSURE SETTING *SHUTDOWN* LEVEL SWITCH MAKE TIME DELAY SETTING

SPECIFICATION

DATE:

MASSES

PUMPS TO BE IN ACCORDANCE WITH: O API 610 O ASME B 73.1

O ASME B 73.2

PUMP PUMP ROTATING ASSEMBLY CASING (UPPER HALF) BASEPLATE COUPLING DRIVER DRIVER ROTATING ASSEMBLY TOTAL MASS

LBS LBS LBS LBS LBS LBS LBS LBS

O MANUFACTURER'S STANDARD (Note 2) NOTES:

1- Vendor shall confirm the material selection and ASTM grades for the specified service. 2- Vendor standard pump may be acceptable if better suits for application. 3- Provision shall be provided for mechanical seal installation in future. 4- Waste may contain traces of Cr, Pb, Cd etc.

DRAWING NO. SHT.NO. REV.NO.

DATA SHEET FOR

CENTRIFUGAL PUMP

WASTE OIL PUMPS TAG# P-102A/B

GE 103002 GE103002

SAUDI ARABIA

4 of 4

00

NONE O O O O O O O O O O O O O

Вам также может понравиться

- Data SheetДокумент6 страницData Sheetnalawade_pradeepОценок пока нет

- PTI RAW - Version 30 Manual PsseДокумент49 страницPTI RAW - Version 30 Manual PssedmauriciosОценок пока нет

- Data Sheet UPSДокумент13 страницData Sheet UPSAdi Toto HaryonoОценок пока нет

- API 650 Storage Tank Data Sheet March 2017Документ3 страницыAPI 650 Storage Tank Data Sheet March 2017Nasi GorengОценок пока нет

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentДокумент4 страницыProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmОценок пока нет

- Data SheetДокумент7 страницData SheetPaulkumar RamaiahОценок пока нет

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Документ28 страницSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaОценок пока нет

- Datasheets For Bucket Type StrainerДокумент2 страницыDatasheets For Bucket Type StrainerbecpavanОценок пока нет

- Purchase Spec. For Tubes (Sa213 TP321)Документ5 страницPurchase Spec. For Tubes (Sa213 TP321)Daison PaulОценок пока нет

- Dryer Data SheetДокумент1 страницаDryer Data Sheetacas35100% (1)

- 11d Pms Rev00a Ongc 27jul15Документ3 страницы11d Pms Rev00a Ongc 27jul15abhiОценок пока нет

- Special Support in PipingДокумент6 страницSpecial Support in PipingAKHIL JOSEPHОценок пока нет

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectДокумент10 страницClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarОценок пока нет

- Pressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)Документ6 страницPressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)KOMATSU SHOVELОценок пока нет

- ID Fan Motor Data Sheet, Rev. 1Документ8 страницID Fan Motor Data Sheet, Rev. 1Suman GhoshОценок пока нет

- Ventury Scrubber Purchase SpecificationДокумент15 страницVentury Scrubber Purchase SpecificationKamal RajuОценок пока нет

- Combined Status of BoqmДокумент22 страницыCombined Status of Boqmhemant1284Оценок пока нет

- Technical Data: 150x125 CNHA 5 18.5Документ5 страницTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىОценок пока нет

- Document No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneДокумент7 страницDocument No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneSachin5586Оценок пока нет

- QIPP-MPN013-M00-2302 Piping Tie-In Point List Rev.0Документ4 страницыQIPP-MPN013-M00-2302 Piping Tie-In Point List Rev.0Ganesh R NairОценок пока нет

- Project: Korba Super Thermal Power Project Wagon Tippler Conveying Plant Package OwnerДокумент2 страницыProject: Korba Super Thermal Power Project Wagon Tippler Conveying Plant Package Ownerrajatkatiyar2416Оценок пока нет

- Drive Control Philosophy - C & IДокумент11 страницDrive Control Philosophy - C & Irpaliwal1967Оценок пока нет

- 33 KV Data SheetДокумент4 страницы33 KV Data Sheetcherif yahyaoui0% (1)

- Tanky 53 KL Rev.1Документ187 страницTanky 53 KL Rev.1Priyo Jati WahyonoОценок пока нет

- Technical Data: 150x100 FS2KA 5 90Документ5 страницTechnical Data: 150x100 FS2KA 5 90infonetsmgОценок пока нет

- BomДокумент129 страницBomVemuri SudheerОценок пока нет

- Seismic Design Criteria For Polyethylene PipeДокумент184 страницыSeismic Design Criteria For Polyethylene PipephatmatОценок пока нет

- TABLE-3 LIST OF ATTACHMENTS - Rev 0Документ5 страницTABLE-3 LIST OF ATTACHMENTS - Rev 0Anonymous AyDvqgОценок пока нет

- Sizing Calculation For Equipment Earthing: 2x330MW TPP, Mundra SEZ Attachment-2 To Doc - No.6785-EL-DSN-633-001Документ2 страницыSizing Calculation For Equipment Earthing: 2x330MW TPP, Mundra SEZ Attachment-2 To Doc - No.6785-EL-DSN-633-001Harveen SinghОценок пока нет

- 7-12-0033 Rev 4Документ1 страница7-12-0033 Rev 4cynideОценок пока нет

- 10in 1500 MOV DatasheetДокумент1 страница10in 1500 MOV DatasheetkarthikОценок пока нет

- Switchgear Specification For High Voltage Switchgears CT PT BreakerДокумент26 страницSwitchgear Specification For High Voltage Switchgears CT PT BreakerSumit TyagiОценок пока нет

- Fresh water consumption and circulation in pulp mill processesДокумент3 страницыFresh water consumption and circulation in pulp mill processesSrinivasa Rao VenkumahanthiОценок пока нет

- M3BP315MLB6 110KW PDFДокумент1 страницаM3BP315MLB6 110KW PDFPablo CorreaОценок пока нет

- Thi!document S Subi R Spec Ex Co Rols A, Och Talp: Translation No. - OДокумент13 страницThi!document S Subi R Spec Ex Co Rols A, Och Talp: Translation No. - OBùi Hắc HảiОценок пока нет

- 01 PDFДокумент6 страниц01 PDFSherif AdelОценок пока нет

- Crane Specs - L. M. Handling - Sms Shed - 16.5 M SpanДокумент12 страницCrane Specs - L. M. Handling - Sms Shed - 16.5 M SpanekisangleОценок пока нет

- Voltage Drop & Power Cable Sizing CalculationДокумент46 страницVoltage Drop & Power Cable Sizing CalculationAnujGargОценок пока нет

- Main Electrical Equipment List1Документ4 страницыMain Electrical Equipment List1Qadir MohtashamОценок пока нет

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarДокумент1 страницаCG Power and Industrial Solutions Limited: LT Motors Division Ahmednagaranurag dhyaniОценок пока нет

- FGD - Technical DiaryДокумент61 страницаFGD - Technical DiaryanmohieyОценок пока нет

- Induced Vibration HXДокумент7 страницInduced Vibration HXPatricia.PОценок пока нет

- 43 (Lecture - Instrumentation For P&ID's - Cookbook)Документ55 страниц43 (Lecture - Instrumentation For P&ID's - Cookbook)Hoang-Vu BuiОценок пока нет

- Data Book Vendor RequirementsДокумент4 страницыData Book Vendor RequirementsTim HardingОценок пока нет

- Raw Water System Technical SpecsДокумент11 страницRaw Water System Technical SpecsChandraОценок пока нет

- Yanbu Export Refinery Piping Material SpecificationsДокумент6 страницYanbu Export Refinery Piping Material SpecificationsJanakiraman MalligaОценок пока нет

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Документ25 страницTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoОценок пока нет

- API 650 Baseplate DesignДокумент3 страницыAPI 650 Baseplate DesignmjlazoОценок пока нет

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFДокумент4 страницыUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiОценок пока нет

- Fire Pump Relief Valve Model 108FC/108FCA Sizes Features SpecificationsДокумент2 страницыFire Pump Relief Valve Model 108FC/108FCA Sizes Features SpecificationsAdil AzizОценок пока нет

- BP Variable Catalog 09VДокумент52 страницыBP Variable Catalog 09VPetros IosifidisОценок пока нет

- BHEL - Agitator Specification PDFДокумент68 страницBHEL - Agitator Specification PDFRiyaz100% (1)

- Chiller Ton CalculationДокумент3 страницыChiller Ton CalculationGovinda Raj100% (1)

- GE-103009, Diesel Unloading Pumps, P-201 A, BДокумент4 страницыGE-103009, Diesel Unloading Pumps, P-201 A, BMohammed AnwerОценок пока нет

- Centrifugal pump data sheetДокумент4 страницыCentrifugal pump data sheetMohammed Anwer100% (1)

- V383773001X00 PDFДокумент4 страницыV383773001X00 PDFSIVAОценок пока нет

- GCI Storage Tank Data SheetДокумент4 страницыGCI Storage Tank Data SheetAlvin Smith60% (5)

- Site Comments Datasheets-DG SetДокумент14 страницSite Comments Datasheets-DG Setavinashpratap100% (1)

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpДокумент6 страницSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Оценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- The Opening: Surah 1: Al-FatihahДокумент0 страницThe Opening: Surah 1: Al-Fatihahaliuddin1Оценок пока нет

- GE-103009, Diesel Unloading Pumps, P-201 A, BДокумент4 страницыGE-103009, Diesel Unloading Pumps, P-201 A, BMohammed AnwerОценок пока нет

- The Letter Giving InformationДокумент1 страницаThe Letter Giving Informationeduard_erjaОценок пока нет

- Centrifugal pump data sheetДокумент4 страницыCentrifugal pump data sheetMohammed Anwer100% (1)

- Environment Development Company Ltd. (Edco) : Instrument Specification Sheet - Float and Board Level IndicatorДокумент1 страницаEnvironment Development Company Ltd. (Edco) : Instrument Specification Sheet - Float and Board Level IndicatorMohammed AnwerОценок пока нет

- GE-103009, Diesel Unloading Pumps, P-201 A, BДокумент4 страницыGE-103009, Diesel Unloading Pumps, P-201 A, BMohammed AnwerОценок пока нет

- PFD 100022Документ1 страницаPFD 100022Mohammed AnwerОценок пока нет

- GE-103002, Waste Oil Transfer Pumps, P-102A&BДокумент4 страницыGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerОценок пока нет

- GE-103009, Diesel Unloading Pumps, P-201 A, BДокумент4 страницыGE-103009, Diesel Unloading Pumps, P-201 A, BMohammed AnwerОценок пока нет

- GE-103002, Waste Oil Transfer Pumps, P-102A&BДокумент4 страницыGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerОценок пока нет

- GE-103002, Waste Oil Transfer Pumps, P-102A&BДокумент4 страницыGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerОценок пока нет

- PLT 5000 BrochureДокумент2 страницыPLT 5000 BrochureMohammed AnwerОценок пока нет

- GE-103002, Waste Oil Transfer Pumps, P-102A&BДокумент4 страницыGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerОценок пока нет

- Je-104005 Sh. 001Документ1 страницаJe-104005 Sh. 001Mohammed AnwerОценок пока нет

- GE-103002, Waste Oil Transfer Pumps, P-102A&BДокумент4 страницыGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerОценок пока нет

- SCOC 9677 2012 AramcoДокумент5 страницSCOC 9677 2012 AramcoMohammed AnwerОценок пока нет

- GE-103002, Waste Oil Transfer Pumps, P-102A&BДокумент4 страницыGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerОценок пока нет

- List of The Manufactures Nafri International Represent Throughout The WorldДокумент7 страницList of The Manufactures Nafri International Represent Throughout The WorldMohammed AnwerОценок пока нет

- DE-102006 (Tank Data Sheet TK-107)Документ3 страницыDE-102006 (Tank Data Sheet TK-107)Mohammed AnwerОценок пока нет

- Why NafriДокумент2 страницыWhy NafriMohammed AnwerОценок пока нет

- SCOC 9677 2012 AramcoДокумент5 страницSCOC 9677 2012 AramcoMohammed AnwerОценок пока нет

- Taskinator2 2011Документ1 страницаTaskinator2 2011Ibra AdraouiОценок пока нет

- Mohammed Anwar Khan: Opportunity To Advance ProfessionallyДокумент1 страницаMohammed Anwar Khan: Opportunity To Advance ProfessionallyMohammed AnwerОценок пока нет

- Profile With New LogoДокумент6 страницProfile With New LogoMohammed AnwerОценок пока нет

- RegistrationДокумент9 страницRegistrationMohammed Anwer100% (1)

- Jubail Operation and Maintenance Co (Jomel) : Vendors Registration FormДокумент1 страницаJubail Operation and Maintenance Co (Jomel) : Vendors Registration FormMohammed AnwerОценок пока нет

- Quran Hadith ScienceДокумент127 страницQuran Hadith ScienceMohammed AnwerОценок пока нет

- Osmaniye Bahce Wind Farm ESIA ReportДокумент50 страницOsmaniye Bahce Wind Farm ESIA Reportİsmail KayahanОценок пока нет

- Accelerator Pedal Position SensorДокумент4 страницыAccelerator Pedal Position SensorRicka AndriamadyОценок пока нет

- Exercises On Design of Biogas PlantДокумент2 страницыExercises On Design of Biogas Plantمحمود صالح محمود عليОценок пока нет

- Jobs in Rural vs Urban AreasДокумент10 страницJobs in Rural vs Urban AreasAnoshKhanОценок пока нет

- Electric FieldДокумент42 страницыElectric FieldMuhammad Kashif IshaqueОценок пока нет

- LowvoltageACdrivesforwaterandwastewater REVD enДокумент28 страницLowvoltageACdrivesforwaterandwastewater REVD enBalu MОценок пока нет

- Catmultisl 50 enДокумент4 страницыCatmultisl 50 enEko SetiawanОценок пока нет

- An Active-Clamp Push-Pull Converter For Battery Sourcing ApplicationsДокумент9 страницAn Active-Clamp Push-Pull Converter For Battery Sourcing ApplicationsYury KrivtsovОценок пока нет

- Ipad Pro 12.9inch 6gen 034 05977 InfoДокумент2 страницыIpad Pro 12.9inch 6gen 034 05977 Infobahidid797Оценок пока нет

- Ultrasonic Waves: 1. Production of UltrasonicsДокумент7 страницUltrasonic Waves: 1. Production of UltrasonicsAmit KumarОценок пока нет

- Differential Relay MiCOM P632Документ7 страницDifferential Relay MiCOM P632gjkjai0% (1)

- Nidhal Hafeez MTech Energy Rakuten MobileДокумент2 страницыNidhal Hafeez MTech Energy Rakuten MobileMahendra GajaОценок пока нет

- DST-PC, 02 PossibilitiesДокумент35 страницDST-PC, 02 PossibilitiestrutleptОценок пока нет

- Solar Charging Station For Electric VehiclesДокумент15 страницSolar Charging Station For Electric VehiclesnabihmezherОценок пока нет

- Master List of Approved Suppliers For Three Phase Electric Loco ComponentsДокумент99 страницMaster List of Approved Suppliers For Three Phase Electric Loco ComponentssumitshyamalОценок пока нет

- Tesda Multiple ChoiceДокумент8 страницTesda Multiple ChoiceAira Ronquillo67% (3)

- Microwave EngineeringДокумент5 страницMicrowave EngineeringHarikrishna KhariduОценок пока нет

- Triangular Wave Generator Using Op Amp - EEEGUIDEДокумент6 страницTriangular Wave Generator Using Op Amp - EEEGUIDEfauzan WaseemОценок пока нет

- Main Combustion ChamberДокумент31 страницаMain Combustion Chambershaliq28Оценок пока нет

- Infrastructure Planning for Proposed 314-Acre IT Township in KolkataДокумент92 страницыInfrastructure Planning for Proposed 314-Acre IT Township in KolkataManjunath Hrm100% (2)

- INVERTER FREEZER CHEAT SHEET EpcДокумент3 страницыINVERTER FREEZER CHEAT SHEET EpcHeco Hek Hek CanapiОценок пока нет

- Ground Source Heat Pumping: A Contractor's Guide To Understanding The Ground Source Heat Pump MarketДокумент19 страницGround Source Heat Pumping: A Contractor's Guide To Understanding The Ground Source Heat Pump MarketFitrianiОценок пока нет

- HP LP Bypass System (Turbine)Документ9 страницHP LP Bypass System (Turbine)Debasish Dewan67% (3)

- Thermal Engineering I Full Book FinalДокумент175 страницThermal Engineering I Full Book FinalKumar SubramanianОценок пока нет

- Summary-Response Essay ErnytaДокумент7 страницSummary-Response Essay Ernytaernyta nitaОценок пока нет

- Complete Range of BBL Crane & Hoist Duty Motors (0.12kW to 1250kWДокумент64 страницыComplete Range of BBL Crane & Hoist Duty Motors (0.12kW to 1250kWgayathrikanduriОценок пока нет

- TeSys Deca Contactors - LC1D326SDДокумент4 страницыTeSys Deca Contactors - LC1D326SDaligamers70Оценок пока нет

- Compressor Anti SurgeДокумент4 страницыCompressor Anti SurgeAboaliОценок пока нет

- FICCI India Office Repurposed To Scaleup ReportДокумент17 страницFICCI India Office Repurposed To Scaleup ReportRitesh KurarОценок пока нет

- EN Productoverview 0710 PDFДокумент13 страницEN Productoverview 0710 PDFOlbira DuferaОценок пока нет