Академический Документы

Профессиональный Документы

Культура Документы

Applications of Nonwovens in Medical Textile

Загружено:

Dipesh JainАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Applications of Nonwovens in Medical Textile

Загружено:

Dipesh JainАвторское право:

Доступные форматы

Applications of nonwoven in Medical Textile

Introduction: The term medical textile literally means textile used for medical purposes. Textile apart from being a vital part human life is long since been used in medical field, though the term has been coined very recently. Textile materials have wide range properties such as flexibility, elasticity, strength etc. Textiles used for medical purposes should be nonallergic, noncarcenogenic, non-toxic, and antistatic in nature, optimum fatigue endurance, biocompatibility, flame proof, dyes must be non-irritant. An important and growing part of the textile industry is the medical and related health care and hygiene sectors. The extent of the growth is due to the constant improvements and innovations in both textile technology and medical procedures. They are used in a number of separate and specialized applications, which can be categorized as follows:

In the present scenario, Medical textile market is totally saturated with nonwoven products today. Nonwovens, because of their easily modifiable properties and excellent performance have become indispensable in this field. Nonwovens are developed to impart special properties to product. In order to be competitive today, nonwovens producers must show high productivity at low cost. At the same time, the market demands higher quality. In the medical and sanitary domain the use of appropriate fibers is an important condition for obtaining the required properties. The Medical Textiles includes vast range of applications viz. adhesive tapes, bandages, beddings, blankets, castings, diapers, dressings, eye pads, gauzes, protective clothing's, sutures, surgical covers, surgical clothing's, swabs, supports, sanitary products, hospital gowns

etc. It also finds application in extra-corporeal devices like artificial kidney, liver, heart & mechanical lung, ligaments, vascular grafts, heart valves, blood vessels, artificial skins etc. Range of natural fibers and biodegradable polymers with non-biodegradable synthetic polymers is being utilized for developing new products in medical textiles. Since the medical textile applications are directly related to the life of human being, those are required to undergo stringent testing and hygienic criteria, which led to innovative use of variety of fibers and lot of developments, took place in this area. The article will discuss the development in Medical Textiles field, which will continue to help to improve the life of human being considerably with the aid of non-woven textiles. Medical Textiles: Based on applications the medical textile can be broadly categorized as follows, Personal health care/hygienic products: Bedding, clothing, surgical gowns, Cloths, wipes surgical curves, surgical hosiery, diapers, etc. Non-implantable material or medical dressings & auxiliaries: wound dressing, bandage, plasters, gauge, lint wadding etc. Implantable materials: sutures, vascular grafts, artificial ligaments, and artificial joints Extra corporal devices: Artificial kidneys, liver & lungs etc. The nonwovens are used for the given applications in different forms. Wound care was and still is the primary use for medical and surgical nonwovens. Nonwovens find applications in a variety of products viz. absorbent pads, incontinence products, apparel for patients and staff. Baby diapers, bed linen and blankets, burn dressings, gowns, disposable underwear, dressings, drug delivery devices, face masks, filter media, nasal strips, pillows, shoe covers, sponges, sutures, tissue scaffolds, towels, wraps etc. Categories of medical textiles Based on applications the medical textile can be broadly categorised as follows: Personal health care/hygienic products: Bedding, clothing, surgical gowns, cloths, wipes surgical curves, surgical hosiery, diapers, etc. Non-implantable material or medical dressings & auxiliaries: Wound dressing, bandage, plasters, gauge, lint wadding, etc. Implantable materials: Sutures, vascular grafts, artificial ligaments, and artificial joints. Extra corporal devices: Artificial kidneys, liver & lungs, etc. The nonwovens are used for the given applications in different forms.

Implantable Medical Textiles: The materials are used in effecting repair to the body whether it is wound closure (sutures) or replacements Surgery like vascular grafts, artificial ligaments, etc). There are of many shapes and sizes, for duplications as found in human body. Filament texturised yarns used nowadays, which are coated to prevent leakage of blood while tissue, is forming on the inner walls. Carbon fiber is a popular material for tissue repair. Suspensory and reinforcing surgical meshes are used in plastic surgery for repairing defects of the abdominal wall. Surgical treatments of hernia in Urology etc Hydrophobic sanavel felt dressings are high porosity textiles made from man- made fibers designed for treatment of bums and different dermatological defects. Generally the following boding processes are used for nonwovens made of pulp fibres: thermal bonding, binder bonding, combined bonding, spunlace bonding.

Non implantable materials: These materials are used for external applications on the body and may or may contact with skin. They are made form co-polymer of two amino acids. They are employed as covering, absorbent, protective and supports for injured or diseased part. They are different types. Primary wound dressings: Placed next to the wound surface. Nonwoven with a binder content of 60% and made from cellulose fabrics are being used.

Absorbent: Similar to wound pads used in surgery. Manufactured from well-bleached, carded and cleaned cotton fabrics.

Bandages: These are narrow cotton or linen, plain weave cloth of low texture, either woven or knitted. Ex: Plaster of Paris Bandage, orthopaedic bandage, crepe Bandage.

Protective eye paid: Scientifically shaped 2 x2 x to lit over the eye used in outpatient clinic and industrial medical department. Adhesive tapes: It is narrow, plain weave fabric having a coating of adhesive paste. It is used with other pads to conform them to the injury.

Extra corporeal devices: Extra corporal devices are mechanical organs that are used for blood purification and include the artificial kidney, the artificial liver and the mechanical lung. Artificial kidney: Tiny instrument, about the size of a two cell flashlight. Made with hollow hair sized cellulose fibres or hollow polyester fibre slightly latest than capillary vessels. Fabric which is used to remove waste products from patients blood.

Artificial liver: Made with hollow viscose to separate and dispose patients plasma and supply fresh plasma. Artificial heart: An 8 ounce plastic pump lined with dacom velour to reduce damage to blood and is a chambered apparatus about the size of a human heart. Silastic backing makes the fabric imperious to emerging gas that is not desirable in the blood.

Mechanical lung: Made with hollow polypropylene fibre or a hollow silicone membrane. Used to remove carbon-di-oxide from patients blood and supply fresh oxygen. Health care textiles An important area of the textiles is the health care and hygiene sector among other medical applications. The range of products available for health care and hygiene is vast, but they are typically used either in the operation theatre or in the hospital wards for hygiene, care and safety of the staff and patients.

Application of non woven in medical The properties of non-woven fabrics are determined by those of the constituent polymer or fiber and by the bonding process. For instance, expanded PTFE products can be formed to meet varying porosity requirements. Because of the expanded nature of their microstructure, these materials compress easily and then expand-a suture, for example, can expand to fill the needle hole made in a tissueallowing for tissue in growth in applications such as arterial and patch grafts. Polyurethane-based nonwovens produce a product that resembles collagen us material in both structure and mechanical properties, particularly compliance (extension per unit pressure or stress). The porosity of both PTFE- and polyurethanederived nonwovens can be effectively manipulated through control of the manufacturing processes. Hence by controlling the various parameter of non-woven they can utilize effectively in different applications of medical. Reasons due to which Nonwovens became famous in medical field: Nonwoven possesses following properties due to which they became famous in medical field. Better performance w.r.t. comfort, thickness and weight, water vapor transmission and air permeability. Increased protection for user better physical properties like tensile, tear resistance, abrasion resistance etc Various parameters can be controlled easily like Porosity, Weight of fabric and Thickness Nonwovens are easy to sterilize Various manufacturing technique options according to applications Economical manufacturing process etc. Excellent barrier properties Superior efficiency Less potential for cross contamination. Fibers used in manufacturing of Nonwovens for medical applications Cotton, Polyester, Polypropylene, Viscose, Glass Fiber, Wood fluff & Polyamide Chitin Layocell Developments in medical nonwoven Advanced cellulosic nonwovens: Previously regenerated cellulosic fibers enjoyed half century of rapid expansion. Since then, synthetics have grown to dominate the market. Cotton, for centuries the most important of all fibers is taking second place to the combined weight of synthetics and viscose rayon. Rayon now appears relegated to little more than a niche in a global fiber market driven by the ready availability of cheap fossil fuels and the demand for commodity textiles and nonwovens. Nonwoven production

was founded on the ready availability of low-cost viscose rayon fibers and these continued to dominate the industry until the mid seventies. Since then the reducing cost of synthetics coupled with their easy conversion into binder-free spun-laid and melt-blown fabrics caused a steady decline in rayon's nonwoven market share. Previously when disposable diapers came in two pieces (reusable plastic pant with rectangular absorbent pad), latex bonded rayon was the cover of choice. At this time, 'flush ability' was becoming a key development issue. The rectangular inserts with their heat-sealed latex-bonded rayon covers were too stable to be disposed of in the toilet even after tearing in half. New wet-laid nonwovens made from the specially developed self-bonding collapsed-tube rayon fibers had no wet-strength at all and dispersed easily in flowing water. However when treated with the standard wetstrength agents used in the paper industry it became strong enough in use and remained disintegratable in toilet turbulence. The introduction of the more convenient one-piece diaper pushed mothers concerns about flush ability into the background. Latex-bonded 100% rayon continued as the leading cover on one-piece diapers, but in 1974 coverstocks containing 50% polyester were market-tested for the first time. Consumers found they could not really spot the difference from the 100% rayon fibre versions so in a second test the latex bonded rayon/polyester blend was put through a point embossing calendar to give it a textured surface. This time the mothers could express a preference for the patterned over the plain and a "unique" new product was born. This first use of synthetic fibre in what had been regarded as an absorbent fibre 'fortress' appeared to be driven by nothing more than the concern over the escalating price of rayon. Lyocell nonwovens: Lyocell makes excellent nonwovens, especially in those processes that allow its superior aesthetics shine through, like needle punching and HE. Its high strength is of little intrinsic value in disposables, but enables the nonwoven producer to reduce basis weight while meeting targets. Its freedom from shrinkage and high wet stability allows higher area yields in HE processes and its high modulus prevents it from collapsing in the wet to the same extent as viscose rayon. Fibrillation, the development of surface micro fiber on wet abrasion or in high-pressure entanglement, adds an additional dimension for the nonwoven development. Unfortunately, while it has established itself in several profitable niches, its premium positioning has so far prevented its use in mainstream disposables. Spun-laid lyocell: Most fiber-forming polymer solutions can also be converted into continuous yarns, film sponges or indeed nonwoven fabrics. Lyocell dope is no exception and many of the characteristics of the lyocell process make it a better basis for spun-laid nonwovens than the viscose process ever was. Technically speaking the challenges is not great. In nonwoven industry the leading product are nearly always with those the lowest cost and justification of spun laid cellulosic on added value alone has failed several times already. The ultimate in economy is arises from inherently low cost raw material converted on state of the art machinery at the largest possible

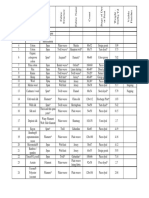

scale. The nonwoven industry enjoys the economies of (say) polypropylene because PP is a byproduct of the world's largest industry, energy. Viscose rayon, a premium product of the timber industry, requires the most costly grades of wood pulp. Lyocell is currently similar, but its simple production process has the so far unexplored potential to use cheaper pulps. It also have potential to achieve very high level of scale in textile, and hence the economies of scale that may ultimately interest the major nonwoven converters. New development in biodegradable nonwovens Over the last 30 years the nonwovens industry fibre usage has not only grown by a factor of ten. The fibres used have changed from almost exclusively biodegradable to most exclusively non-biodegradable despite concern for the environment among consumers becoming progressively stronger. In fact in the largest and most potentially, environmentally-sensitive market, cover stock for disposal diapers, and biodegradable products are non-existent. An expressed consumer preference for environmentally friendly products, in the disposables area at least, appears to meet an unmet need. How the nonwovens are manufactured? Various techniques are used for manufacturing of nonwovens but some of the techniques that are used specially for the medical applications point of view are as follows: Needle punched nonwoven blankets Traditionally woven blankets where used in the Far East and Middle East countries. These methods are not economical and for that purpose a special technique has been developed known as needle punching. This process consists of three main stages: Predatory process Web formation Needling the fibres web The various particulars areas as follows: Variables Fabric weight (g/sq. metre) Needling density (p/sq. metre) Depth of penetration (mm) Particulars 350 250 9

It is observed the thermal insulation value increases with increase in the nonwoven bulk density and needling density. Air permeability value reduces as there is increase in the nonwoven bulk density. Application development foam substitution The objective for research is to develop a suitable nonwoven for the medical applications.

Web forming process development Forming a random nonwoven webs with the static method This development has taken place for random fibre arrangements of the roller card in nonwoven processed by different voltages and electro panel shapes. In this development it has been found that by changing shape of electrode panel can provide better random effects when the same voltage is used. The research indicates that the best panel shape is the circular holes and is positioned between the cylinder and doffer. The optimum random effect is obtained when original panel is electrified to 2kv between cylinder and doffer, or the panel with the circular holes is electrified with 20kv and placed over conveyor belts. This process becomes very useful: i) To maintain the uniformity of web ii) Iin manufacturing hybrid and composite products, which are used for implantation purpose effectively. Wet-laid nonwovens i) "Borrowed technology from the paper industry ii)Fibres: 0.3 mm 25 mm & 6.0 dtex max iii)Fibres are dispersed and suspended in water at 0.05 % concentration Cross-lapped nonwovens Cross-lapped nonwoven differs in many ways from other production process for nonwovens and the biggest advantage of this development is the flexibility regarding product and weight. Here the delivery belt is doubled, ie, batt of several layers are being formed; the card web enters the lappers with constant speed; the layering carriage has to perform an oscillating movement, as the layering carriage reduces its speed during reversal and is slowed down to zero so that it leads to accumulation of fibres in that area. Needle loom for nonwoven In recent years development has taken place for manufacturing all types of needle loom of nonwoven having the following advantagesI) The linger needle path results in better fibre orientation and fibre entanglement than the conventional needle machine II) Superior web properties can be obtained with fewer needle preparation III)It greatly enhances the construction of composites and hybrid products which are very useful for medical applications. Manufacturing processes for medical nonwovens Web Formation: The most popular techniques for medical nonwovens are spunbonding, meltblowing and their composites (SMS) in specific end uses. Spunbonding is used when more strong webs are needed. Spunbonded webs are strong in both machine direction (MD) and cross direction (CD). They are soft, porous

and dimensionally stable. Spunbonding is mostly used for products like face masks, head wears, shoe covers, bed linens and disposable clothing etc. Dry laying, wet laying and carding are used for different web properties depending on web thickness required, speed of bonding technique to be used etc. Carding is adapted for lightweight web production for technical and hygienic products. Carding produces very high quality webs at very high speeds. Bonding is carried out by many methods including thermal bonding for synthetic fibers and their blends. Hydroentangling as the fastest growing bonding technique is used explicitly in medical nonwovens for that textile-like hand and feel that's desirable in products like gauzes, dressings, hospital apparel etc. Needlepunching finds application in bonding various fibers or webs of medium thickness. Needlepunching is fast, effective and often chosen technique for varied applications. It is also cost effective. Apart from all these techniques, stitchbonding is also used. Chemical bonding is often used for making elastic nonwovens. Post process for medical nonwovens is to give the product a suitable finish for its specific end use. The different types of finishes used in medical nonwovens are: Soil Release Agents: for bed linens, gowns and apparel which are designed for multiple usages. May also be used on curtains, blankets etc. Softeners: to make the webs feel soft against the skin. May be used for disposable undergarments, pillows, bed sheets etc. Water repellents: used for bed sheets for kids, barrier apparel etc. Flame Retardant Finishes: used for bed linens, curtains, apparel, lab coats etc. Antibacterial Finish: very commonly applied to gauzes, dressings and sutures. The most popular one is silver nanocrystal finish. Resin and Hand Builders: used for apparel, gowns, bed linens etc. Nonwovens in disposable applications Disposable literally means designed for or capable of being thrown away after being used or used up. Disposable textiles are textiles used in or as apparel for functional applications, designed to be disposed off after use. They are bound by use and throw concept. Disposable nonwovens are those nonwovens for short life applications in single use including hygiene, medical, consumer wipes, industrial wipes and others. Hygiene nonwovens include baby diapers, training pants; adult diapers (adult incontinence) and feminine care products (external and internal). The external feminine care products include sanitary napkins and pads. The internal feminine care products refer to tampons. Medical nonwovens include drapes and gowns, sterile wrap, swabs and dressings. Among them, surgical gowns, drapes and drape pack parts account for almost two third. Following are the advantages of nonwovens in medical textiles: Excellent barrier Low linting Tear resistant Single use Always available

No repair Decreased storage space No hidden costs Cost effective to use

Some application of nonwovens in medical textiles

Products used for medical surgical dressings Wound care products: A wound dressing is used for many purposes including protection against infection, absorption and exudation of blood and excess fluids, healing and application of medication ideally a wound dressing should be soft pliable pad the wound to protect it from further injury, be easily applied and removed, be sterile lint free and non toxic. The wound dressing should not adhere to the wound allowing easy removal without disturbing new tissue growth. An absorbent cotton swab placed at the wound and tied with gauze forms the oldest form of wound dressing. However, this traditional method of wound covering is found to stick to the wound and does not provide a moist microclimate to the wound conducive to its faster healing. The modern wound dressing is usually made of three layers(a) Wound contact layer: - It should not stick to the wound or cause maceration of the skin if the dressing is not changed. It can be woven, knitted or non-woven made from silk, viscose, polyamide or polyethylene. (b) Middle absorbing layer: - If has to absorb blood or liquids while providing a cushioning effect to protect the wound. It is generally a non-woven composed of cotton or viscose. (c) Base Material: It provides a means by which the dressing is applied to the wound. The material is coated with acrylic adhesive to hold the dressing in place, eliminates the need for bandage.

Because sterilization is a major concern for surgical dressings, nonwovens are considered. Nonwovens can be smooth and lint-free for the most part. This allows lesser chance for debris to be left at the wound. Nonwoven can be made softer and more absorbent by latex or thermal calendaring. For postoperative dressing, sophisticated nonwoven structures such as perforated films on absorbent base, polymers/nonwoven welded laminate and metalised nonwoven are used. Polypropylene is promoted as most unwettable fibre, but it can also be quite wettable if converted to a fibrous web by melt blowing. In melt blowing a stream of molten polymer is subjected to blasts of air which form tiny fibrils that fall randomly as a web. This gives polypropylene a role of absorbable dressings material. Traditionally polypropylene is used in wound dressings in fibre or fabric form, coupled with absorbent material. Polysaccharide based dressings have increasingly become viable alternative to biologically incompatible and often problematic cotton and viscose gauzes used for wound dressings. Abundantly available alginates and their relatively ease of solubility in particular have been instrumental in developing these fibres and their applications as vehicles for drug delivering. The other polysaccharide is Branan ferulate that is gel spun. It is extracted from corn bran and has water soluble properties. This polysaccharide can infiltrate the biological activities in the body and hence accelerate wound healing. Bandages: Bandages are designed to perform a whole variety of specific functions depending upon the final medical requirement. They can be woven, knitted, non woven or composite in structure. They can be classified into various classes depending upon the function they serve as. (a) Simple bandages These are fixation bandages that can be elastic or inelastic in nature. Adhesive bandage, cohesive bandages and tubular bandages belong to this class. A simple non elastic bandage is required to the dressing in proper place over the wound. One such bandage is simple, open weave cotton or viscose fabric cut into strips which have been scoured, bleached and sterilized. The problems of fraying in the plain woven bandage are overcome by use of non-fraying cotton leno bandage. The structure of bandage is more stable with crossing warp threads in the leno woven structures. These can be further coated with paraffin to prevent sticking of the bandage to the wound. Further some ointment dressing can also be given along with paraffin to aid faster healing of the wound. Elasticated yarns are incorporated into bandages to form elastic bandage for providing support and comfort, (b) Light support bandages Woven light support bandages are used for sprains or strains. Elastic crepe bandages are used for sprained wrist or ankle support. The elasticated properties of these bandages are obtained by weaving cotton crepe yarns that have twist content. Similar properties can also be achieved by combination of two warp sets with normal and high tension. Stretch and recovery properties of these bandages apply sufficient tension to support the sprained limb. (c) Compression bandages Compression bandages are used to exert a certain compression for the treatment and prevention of deep vein thrombosis, leg ulceration and varicose veins. Depending upon the compression they provide, compression

bandages are classified as light, moderate, high and extra high compression bandages. They can be woven, warp or weft knitted from cotton and elastomeric yarns. (d) Orthopaedic bandages These bandages are used under plaster casts and compression bandages to provide padding and prevent discomfort. Non woven orthopaedic cushion bandages are made from polyester or polypropylene and blends of natural and synthetic fibres. Polyurethane foam can also be used. Light needle punching gives bulk and left to the structure for greater cushioning effect. Knitting is commonly used for manufacture of bandages in tubular form with varying diameters. The weft knitting machine is chiefly used for production of two classes of medical textiles. Viz., support bandages and elastic bandages. Tubigrip is an example of circular weft knitted cotton fabric with rubber yarn laid in, manufactured in tubular lengths of different diameters. Since these garments are to be continuously worn, the seams should be strong enough to resist strong transverse forces. Also the seam should have high extensibility and recovery to allow for body movement. Similarity, the warp knitting machines is used to manufacture mainly the wound dressings, bandages and vascular grafts. The tubular structures can best be produced on circular warp knitting machines. However, these are traditionally produced on double bar Rachel machines due to the limitation of patterning on these machines. With the new developments of electronically controlled flexibility in production of various tubular medical devices has been achieved. Fabric shaping can be controlled by modifying the structure of fabric within the garment or altering the stitch length. In bandage applications control of elasticized yarn can be made using such electronically controlled pattern ring to alter the underlap or the stitch length being knitted. Circular warp knitting machines can be used for making stockings that can be sued provide pressure gradients along the leg after surgery aiding blood circulation. Electronic speed monitoring and variable speed drive to the let off for the feed packages have helped to obtain consistent yarn quality. Spacer knitted fabrics can be used as bandages in normal or composite form. Pressure garments for hypertrophic skin This is a special class of bandages used for healing wounds caused by burns. Pressure garments are made by using a variety of elastic fabrics and can be simple tubes to fit individual limbs or full garments if the burn area is large. These garments are useful for the care of burnt skin area for cuing of scars. The generated pressure on the affected area should help alleviate the itching of the scars. The average pressure to be applied to the treated tissue area is about 25 mm of Hg. During this burns rehabilitation process the pressure garment has to be worn continuously may be for periods as long as 12 months. There is a wide range of pressure garments due to the varying size of the patients and the different methods of fitting the garments by the therapists. So it is best for the hospitals to buy the pressure fabrics and make garments to suit the patients needs. Two main types of fabrics are currently used for making pressure garments. Firm elastic fabric containing elastane yarns is used for making pressure garments. This fabric is usually warp knitted. Tubigrip is a circular weft knitted cotton fabric with rubber yarn laid in, tubular lengths of different diameters. Since these garments are to be continuously worn, the

seams should be strong enough to resist strong transverse forces. Also the seam should have high extensibility and recovery to allow for body movement. In the various suitable fabric structures and garment constructions, the following have been established: Fabrics with low coefficient of friction are more comfortable than those with high coefficient of friction and are less likely to cause maceration. Hence, powernet, sleeknit fabrics are found to be more suitable as compared to weft or warp knit fabrics. However, the deviation in the coefficient of friction was found to be quite high for almost all fabrics. The face side of all fabrics was rougher than the reverse side. Hence an optimum construction is to be arrived at for comfort and recovery of the patient. Gauze: Gauze and paraffin coated gauzes are the most commonly used dressing. Most gauze is made up from cotton in the form of a loose plain weave. The typical yarn density per inch is 12 19 for warp and 8 15 for the weft. 44sNe warp and 54sNe carded weft yarn is generally used. Gauze is mostly used as a direct dressing for wounds or may be used in internal pads and general swabbing applications. The burns and skin grafts have their dressings changed frequently and the difficulty with this gauze is that its fibres stick to the wound. The removal is not only painful, but also destroys the regenerating tissues. This leads to delay in healing process and also leaves scars behind. The problems associated with the traditional woven cotton gauze are as below: A possibility of loose fibres getting caught in the wound A large adherence surface Irritation or mechanical injuring of the wound when the dressing is changed. Prolonged time of wound healing Paraffin coated gauze is usually multi layered, is a little easier to remove, but it does not rapidly absorb the wound liquids. Also this being a petroleum based coating can liquefy at body temperature and introduced foreign matter into the wound. It is used to treat burns and scalds. Plaster: Plasters are made up of three layers 1) Plaster fabrics, 2) adhesive and 3) wound pad. A simple plaster cast consists of gauze impregnated with plaster of Paris. The modern plaster fabric is made from spun bonded nonwovens of cotton, viscose, polyester or glass fibre. The adhesive used for plaster fabric is acrylic that doesnt stick to the skin. The cushioning wound pad is made from knitted viscose fabric impregnated with an antiseptic. The highly absorbent wound pad helps in rapid absorption of secretion from the wound. Others dressings: The other surgical dressings include wadding and lint. Wad ding is an absorbent material to prevent adhesion to wound or fibre loss, it is covered with a non woven fabric. Lint is a plain weave cotton fabric that is frequently used in treatment of mild burns.

Conclusion Medical textile market is totally saturated with nonwoven products today. Nonwovens, because of their easily modifiable properties and excellent performance have become indispensable in this field. Products used for medical or surgery applications may at first sight seem either very simple or complex items. In reality, however in-depth research is required to engineer a textile for even a simplest cleaning wipe in order to meet stringent professional specifications. Advances in nonwovens have resulted in a new breed of medical textiles. Advanced composite materials containing combination of fibers and fabrics have been developed for applications where biocompatibility and strength are required. It is predicted that the nonwoven materials will continue to have greater impact in this sector owing to the large member of characteristics and performance criteria required from these materials. References Antimicrobial and medical use textiles. Textile Asia sept 2001. Nonwovens & Technical Textiles section published in ITJ Sept 2008 The use of innovative textile structures for medical applications. ATJ Nov 2001. Nonwovens as medical textiles by Priyadarshini Malshe published in f2f in Oct 2008 Handbook of Industrial Textiles by Sabit Adanur. Textile in hospital hygiene, IFB Jan 2004. G. Fisher, Technical Textiles Int., July/ August 2003, 19. Wound Treatment. Medical textiles Jan 2003 Meeting demand for cost efficient production of hollow fiber membranes for medical use.

Вам также может понравиться

- Importance Ofnon-Wovens in Medical FieldДокумент4 страницыImportance Ofnon-Wovens in Medical Fieldpa_ashokОценок пока нет

- Medical TextilesДокумент32 страницыMedical TextilesBabar Ramzan0% (1)

- Medical TextilesДокумент31 страницаMedical TextilesSagarika AdityaОценок пока нет

- Application of Nonwovens in Medical FieldДокумент7 страницApplication of Nonwovens in Medical FieldTamer Farouk KhalifaОценок пока нет

- Medica L Textile S: Click To Edit Master Subtitle StyleДокумент24 страницыMedica L Textile S: Click To Edit Master Subtitle StyleShazzad HossaIn100% (1)

- Medical TextilesДокумент20 страницMedical TextilesVaibhav ShuklaОценок пока нет

- Medical Textiles FinalДокумент2 страницыMedical Textiles FinalSudhir JainОценок пока нет

- Medical Textiles: Kavitha Rajan Lecturer in Textile TechnologyДокумент44 страницыMedical Textiles: Kavitha Rajan Lecturer in Textile TechnologyBebi WakaОценок пока нет

- Assignment On MEDICAL TEXTILEДокумент7 страницAssignment On MEDICAL TEXTILESaeed Pranto50% (2)

- Medical TextilesДокумент3 страницыMedical TextilesratultexОценок пока нет

- Recent Development of Circular KnittingДокумент32 страницыRecent Development of Circular KnittingHarshitha A100% (1)

- Santoni SeamlessДокумент2 страницыSantoni SeamlessSudheer SinghОценок пока нет

- Moisture Management of TextilesДокумент8 страницMoisture Management of TextilesMohammed Atiqul Hoque Chowdhury100% (1)

- Use of Enzymes in Textile Wet ProcessingДокумент6 страницUse of Enzymes in Textile Wet ProcessingMohammed Atiqul Hoque ChowdhuryОценок пока нет

- Application of Digital Cad in Knitting ManufacturingДокумент16 страницApplication of Digital Cad in Knitting ManufacturingNaimul HasanОценок пока нет

- Quality Assessment System For TextilesДокумент93 страницыQuality Assessment System For TextilesSahil SharmaОценок пока нет

- Fiber PropertiesДокумент24 страницыFiber Propertiessatheeshpag12367% (3)

- Textile Fibre Yarn CountДокумент30 страницTextile Fibre Yarn CountSujit GulhaneОценок пока нет

- Opportunities in Nonwovens and Technical TextilesДокумент46 страницOpportunities in Nonwovens and Technical Textilesawsmblosm100% (1)

- SMARTДокумент16 страницSMARTSwati SharmaОценок пока нет

- Natural FabricsДокумент20 страницNatural FabricsSantosh BishtОценок пока нет

- What Is Home Tech?????Документ35 страницWhat Is Home Tech?????Md. Wahidur Rahman LimonОценок пока нет

- 3D Woven FabricДокумент9 страниц3D Woven FabricCrystal NewmanОценок пока нет

- Textile Yarns PDFДокумент35 страницTextile Yarns PDFVu Ngo Tuan100% (1)

- Lecture. - 03.1 SingeingДокумент5 страницLecture. - 03.1 SingeingMD. Tofazzal HossainОценок пока нет

- Textile FinishesДокумент12 страницTextile FinishesFakrul Hasan KhanОценок пока нет

- Properties Natural FibresДокумент46 страницProperties Natural FibresanishaОценок пока нет

- Definition of Technical TextilesДокумент9 страницDefinition of Technical TextilesAamer Shahzad67% (3)

- Textile ScienceДокумент22 страницыTextile ScienceAbhinav VermaОценок пока нет

- Shanti Kumari: Presented byДокумент21 страницаShanti Kumari: Presented byDr-Eng Amir ElsafraweyОценок пока нет

- Factors Affecting Yarn StrengthДокумент11 страницFactors Affecting Yarn StrengthAbhishek ThakurОценок пока нет

- Application of Knitting Structure Textiles in MediДокумент11 страницApplication of Knitting Structure Textiles in MediweaamkhateebОценок пока нет

- Textile InternshipДокумент62 страницыTextile InternshipNeetek SahayОценок пока нет

- Pilling of TextilesДокумент16 страницPilling of TextilesAthirah Mansor100% (2)

- Textile Training-Maintannance+knittingДокумент60 страницTextile Training-Maintannance+knittingAlamin KhanОценок пока нет

- SpiralityДокумент9 страницSpiralitySenthil KumarОценок пока нет

- Technical TextilesДокумент13 страницTechnical TextilesAchal Kanodia0% (2)

- Glowing FabricДокумент9 страницGlowing Fabricapi-291538480100% (1)

- Project Technical TextilesДокумент22 страницыProject Technical Textilesvijayabaskar777Оценок пока нет

- Water Proof Breathable FabricДокумент13 страницWater Proof Breathable Fabricjack omeОценок пока нет

- Textile StructureДокумент1 страницаTextile StructureBrooks OrtizОценок пока нет

- Smart FabricsДокумент10 страницSmart FabricsShweta KhatriОценок пока нет

- Serviceability, Wear, and Abrasion ResistanceДокумент6 страницServiceability, Wear, and Abrasion ResistanceNiaz IslamОценок пока нет

- Technical Textile A Promising FutureДокумент22 страницыTechnical Textile A Promising FutureDr Muhammad Mushtaq Mangat100% (1)

- Textile Testing and Product EvaluationДокумент64 страницыTextile Testing and Product EvaluationBhaswati PandaОценок пока нет

- Textile Proccessing - 1Документ10 страницTextile Proccessing - 1Shahzaib ButtОценок пока нет

- Smart TextilesДокумент36 страницSmart TextilesFaizan ShaikhОценок пока нет

- Defence TextilesДокумент28 страницDefence TextilesAzl10471% (7)

- Automobile TextileДокумент45 страницAutomobile TextileShamima akter100% (1)

- Handle Properties of FabricДокумент100 страницHandle Properties of FabricVasant Kothari67% (3)

- Agro TextilesДокумент5 страницAgro TextilesFarid Ahmad100% (1)

- Fibers Properties Textile MaterialsДокумент19 страницFibers Properties Textile MaterialsGarmentLearner100% (1)

- Study On Chemical FinishingДокумент10 страницStudy On Chemical FinishingZAyed100% (2)

- Knitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Документ5 страницKnitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Pradeep AhireОценок пока нет

- Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionДокумент4 страницыEfficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionElias KhalilОценок пока нет

- Carr and Latham's Technology of Clothing ManufactureОт EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerРейтинг: 4 из 5 звезд4/5 (1)

- Application of GeotextilesДокумент2 страницыApplication of GeotextilesDipesh JainОценок пока нет

- ErpДокумент24 страницыErpDipesh JainОценок пока нет

- Application of GeotextilesДокумент2 страницыApplication of GeotextilesDipesh JainОценок пока нет

- Entrepreneurship VisionДокумент1 страницаEntrepreneurship VisionDipesh JainОценок пока нет

- HJS Studio Understanding Twist AnglesДокумент6 страницHJS Studio Understanding Twist AnglesDipesh JainОценок пока нет

- ,loom TimingДокумент23 страницы,loom TimingDipesh Jain67% (3)

- Textile Fibres ClassificationДокумент43 страницыTextile Fibres Classificationnitishkohli91% (44)

- Us 4143825Документ7 страницUs 4143825Dipesh JainОценок пока нет

- Mukhopadhyay3 2Документ7 страницMukhopadhyay3 2Mark Bryan ToribioОценок пока нет

- Structure, Mechanical and Thermal Properties of Polypropylene Based Hybrid Composites With Banana Fiber and Fly AshДокумент35 страницStructure, Mechanical and Thermal Properties of Polypropylene Based Hybrid Composites With Banana Fiber and Fly AshOnkar DeorukhkarОценок пока нет

- AM Fibres Data Sheet - HEPlus 55 35 GLДокумент1 страницаAM Fibres Data Sheet - HEPlus 55 35 GLuğur alparslanОценок пока нет

- An Overview of Hemp Fibre PDFДокумент4 страницыAn Overview of Hemp Fibre PDFscribbddОценок пока нет

- Assignment IДокумент36 страницAssignment ILavisha SanganeriaОценок пока нет

- Unit Repair of Floors: StructureДокумент12 страницUnit Repair of Floors: StructurePranjal DixitОценок пока нет

- Geo-Fiber Reinforced Flyash For Ground ImprovementДокумент7 страницGeo-Fiber Reinforced Flyash For Ground ImprovementGJESRОценок пока нет

- Classification of PolymersДокумент8 страницClassification of Polymerscmmalba100% (1)

- A Review On Interface Modification and Characterization Natural Fiber Reinforced Plastic CompositesДокумент15 страницA Review On Interface Modification and Characterization Natural Fiber Reinforced Plastic CompositesJerry HayesОценок пока нет

- Characteristics of Cellulose Nanofibers From Cassava Pulp and Its Use As Tapioca-Film ReinforcementДокумент8 страницCharacteristics of Cellulose Nanofibers From Cassava Pulp and Its Use As Tapioca-Film ReinforcementasdaОценок пока нет

- CSEB ThesisДокумент38 страницCSEB ThesisAngel MarkОценок пока нет

- Bake LiteДокумент55 страницBake LiteAli KayaniОценок пока нет

- Fabric Chart Young 3EДокумент10 страницFabric Chart Young 3EPuja PrasadОценок пока нет

- F CA-blowroom Lowres MarzoliДокумент28 страницF CA-blowroom Lowres MarzoliAshiqueОценок пока нет

- A New Millenniumof TextileprintingДокумент14 страницA New Millenniumof Textileprintingfathi mustafaОценок пока нет

- CBSE Class 8 Science Chapter 3 Synthetic Fibres Objective QuestionsДокумент7 страницCBSE Class 8 Science Chapter 3 Synthetic Fibres Objective Questionsg c lallОценок пока нет

- A Presentation On Fibre Identification Test and YarnДокумент22 страницыA Presentation On Fibre Identification Test and YarnSMJV AATLОценок пока нет

- ENGINEERING COMPOSITE MATERIALS. Bryan HarrisДокумент193 страницыENGINEERING COMPOSITE MATERIALS. Bryan HarrisABDULLAHSHARJEEL KHANОценок пока нет

- Study On Thermal Treatment of Hybrid Technical Yarns: Fibers and Polymers February 2004Документ7 страницStudy On Thermal Treatment of Hybrid Technical Yarns: Fibers and Polymers February 2004Satish KulkarniОценок пока нет

- The 90Th Textile Institute World Conference Proceedings of (2016) PDFДокумент802 страницыThe 90Th Textile Institute World Conference Proceedings of (2016) PDFJuanОценок пока нет

- Chemistry Investigatory Project (To Prepare A Sample of Cuprammonium Rayon Threads From Filter Paper)Документ11 страницChemistry Investigatory Project (To Prepare A Sample of Cuprammonium Rayon Threads From Filter Paper)Kavana ManjunathОценок пока нет

- Polyester &cotton Blend DyeingДокумент9 страницPolyester &cotton Blend DyeingPratik RaneОценок пока нет

- Textile Q & AДокумент5 страницTextile Q & Aমোঃগোলামসারোয়ারОценок пока нет

- Rockwool Insulation LRB MatressДокумент1 страницаRockwool Insulation LRB MatressJaveed KhanОценок пока нет

- Mechanical and Physcial Properties of Fibre Cement Board PDFДокумент5 страницMechanical and Physcial Properties of Fibre Cement Board PDFanhnguyenhaiОценок пока нет

- Turbine BladeДокумент27 страницTurbine BladesrtanandОценок пока нет

- 2 Flexural Performance of SIFCON Composites Subjected To High TemperatureДокумент10 страниц2 Flexural Performance of SIFCON Composites Subjected To High Temperaturemsheer hasanОценок пока нет

- Man Made FibereДокумент57 страницMan Made FibereSuraj RaghvОценок пока нет

- Pull Wire Switch - NHP - 55.4.00 GWNBBДокумент6 страницPull Wire Switch - NHP - 55.4.00 GWNBB生月Оценок пока нет

- Intro To Fiber Yarn FabricДокумент29 страницIntro To Fiber Yarn FabricAbu Naser Md AbdullahОценок пока нет

- Journal of Natural Fibers PDFДокумент16 страницJournal of Natural Fibers PDFKalusu Raman100% (1)