Академический Документы

Профессиональный Документы

Культура Документы

Belt Tension Figure

Загружено:

Duwi SeptiantoroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Belt Tension Figure

Загружено:

Duwi SeptiantoroАвторское право:

Доступные форматы

HOW TO USE A V-BELT TENSION GAUGE

1. CAUTION: Before doing maintenance or tensioning on belt drives, turn equipment off and lock out the power source. Use guards on machinery when running. Place a matched set of belts over the sheave grooves. Take up the slack until the belts appear fairly taut. 2. With the drive stopped, measure the belt span length of your drive (see sketch). Set the rubber O-ring on the body of the tension gauge at the dimension equal to 1/64 inch for every inch of span length. For example, the deflection for a 32 inch span is 1/64 inch x 32, 1/2 inch. 3. Set the O-ring on the plunger at 0 against the body of the tension gauge. 4. With the tension gauge perpendicular to the span, apply a force to a belt in the center of the span. Deflect the belt until bottom of the large O-ring is even with the top of the next belt, or the bottom of a straight edge laid across the top of other belt(s) on the drive. Release pressure and read pounds of force used at O-ring on plunger. Note: When new belts are installed on a drive, the tension will drop rapidly during the first few hours. Thus, for new belts, tighten to the initial installation defection force shown in the tables below. Check tension frequently during the first 24 hours of operation. Subsequent retensioning should fall between the minimum and maximum forces shown in the tables. 5. Compare the force required in step 4 with the ranges in the tables below. Tighten or loosen belts to bring them into the recommened range. Note: The proper tension for V-belt drive is the lowest tension at which the belts won't slip under peak load conditions.

3-8

08/00

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Bouveault-Blanc Ester ReductionДокумент3 страницыBouveault-Blanc Ester ReductionAriel GarciaОценок пока нет

- CS 161 (Stanford, Winter 2024)Документ2 страницыCS 161 (Stanford, Winter 2024)Catriel LopezОценок пока нет

- HR Wallingford-009 - Wave - GaugeДокумент2 страницыHR Wallingford-009 - Wave - GaugeSutanto HadiОценок пока нет

- B28 VivaДокумент27 страницB28 VivashubhamОценок пока нет

- Whitepaper 10G Ethernet 10-08Документ16 страницWhitepaper 10G Ethernet 10-08Bogdan IhnatiucОценок пока нет

- Sri Chaitanya: KEY SheetДокумент13 страницSri Chaitanya: KEY SheetMODALAVALASA SRIHARSHAОценок пока нет

- 3questions Measurements and UncertaintyДокумент2 страницы3questions Measurements and UncertaintyLeanne DerigeОценок пока нет

- Critically Reviewing The Literature ClassДокумент32 страницыCritically Reviewing The Literature ClassSoman Rajpoot100% (1)

- Manual Prevention An Control of Lost Cir PDFДокумент222 страницыManual Prevention An Control of Lost Cir PDFAna Maria TovarОценок пока нет

- Laser in ProsthodonticsДокумент84 страницыLaser in ProsthodonticsmarwaОценок пока нет

- Modding ManualДокумент25 страницModding ManualSebastian SallerОценок пока нет

- Nut & Bolt ScienceДокумент3 страницыNut & Bolt SciencetanujaayerОценок пока нет

- Battery SubsystemДокумент7 страницBattery SubsystemahmaborashedОценок пока нет

- Astm A106-2002Документ13 страницAstm A106-2002henryОценок пока нет

- Ec2203-Unit IV Memory Devices Digital ElectronicsДокумент38 страницEc2203-Unit IV Memory Devices Digital ElectronicsKarthikeyan_Go_952567% (6)

- Transmission Line TowersДокумент3 страницыTransmission Line TowersSoumik Dandapat100% (2)

- Plate Fin Heat ExchangerДокумент14 страницPlate Fin Heat ExchangerTushar PanchalОценок пока нет

- Concrete Mix DesignДокумент11 страницConcrete Mix DesignV Vinoth Edac100% (1)

- DAPS2015 AbstractsДокумент220 страницDAPS2015 AbstractsAnonymous atZc0NCОценок пока нет

- Bluetooth PresentationДокумент18 страницBluetooth Presentationarjun_rathore8178Оценок пока нет

- Studi Dampak Lalu Lintas Pembangunan Gudang Dan Kantor Pt. Wismilak Group Di Jalan Raya Solo SragenДокумент8 страницStudi Dampak Lalu Lintas Pembangunan Gudang Dan Kantor Pt. Wismilak Group Di Jalan Raya Solo SragenIlung MarpaungОценок пока нет

- Fire InvestigationДокумент126 страницFire InvestigationAbcede IloiloОценок пока нет

- Abhilash Betanamudi: AchievementsДокумент3 страницыAbhilash Betanamudi: AchievementsAbhilashBetanamudiОценок пока нет

- Handwritten English Alphabet RecognitionДокумент8 страницHandwritten English Alphabet RecognitionIJRASETPublicationsОценок пока нет

- The Effect of Axial Flow Velocity On Annular Gap Windage Power LossДокумент12 страницThe Effect of Axial Flow Velocity On Annular Gap Windage Power Losskien nguyenОценок пока нет

- Efectele Pe Termen Lung Ale Alaptatului OMSДокумент74 страницыEfectele Pe Termen Lung Ale Alaptatului OMSbobocraiОценок пока нет

- CDB Aia - Data Integration - Internship - Detailed HandbookДокумент3 страницыCDB Aia - Data Integration - Internship - Detailed HandbookRama KrishnanОценок пока нет

- The Mathematical Society of Serbia - 60 YearsДокумент23 страницыThe Mathematical Society of Serbia - 60 YearsBranko Ma Branko TadicОценок пока нет

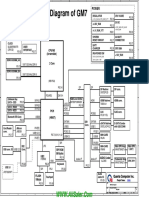

- Dell XPS 17 Quanta GM7 Rev D SchematicsДокумент39 страницDell XPS 17 Quanta GM7 Rev D SchematicsvcompumatikОценок пока нет

- Chapter 11Документ53 страницыChapter 11Vijendhar ReddyОценок пока нет