Академический Документы

Профессиональный Документы

Культура Документы

2-TWO Phase Separator Design Guide by Manish Shah

Загружено:

dennis_ugarteИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2-TWO Phase Separator Design Guide by Manish Shah

Загружено:

dennis_ugarteАвторское право:

Доступные форматы

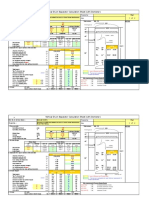

PRACTICAL SELECTION AND DESIGN GUIDE; FOR GAS LIQUID SEPARATOR WITH OPTIMIZATION

mvshah027@yahoo.com

By Manish V. Shah

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Before starting Separator Design, we should be aware of..

1 2

2

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Before starting Separator Design, we should be aware of..

4

3

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Gas Liquid Separator Selection Guide

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Sulzer

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Separator type and orientation depends on

Gas volumetric rate; & Gas to liquid volumetric ratio Slug volume Operating pressure and allowable pressure drop Turndown Feed source Separation efficiency required @ downstream unit Liquid property, fouling, viscous, solids etc.. Space and head room available Offshore / Onshore application

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

DEP : Vertical Vs Horizontal :

High gas rate : Vertical type * High liquid rate : Horizontal type

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

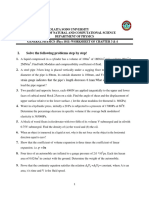

Quiz 1 : - Compressor KO DRUM

Pressure , KPag

Case 1 Case 2 9000 4000

Gas rate, kg/hr

1,55,000 1,00,000

Liquid rate kg/hr

1000 2500

Gas Liquid Density Density kg/m3 kg/m3

100 66 1000 1000

Case 3

Case 4 1) a) b) c)

6000

3000

60,000

40,000

2700

3000

66

30

700

1000

Which internal can be used for above service ? No internal Mist mat Vane pack

8

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Quiz 1 : - Compressor KO DRUM

Pressure , KPag

Case 1 Case 2 9000 4000

Gas rate, kg/hr

1,55,000 1,00,000

Liquid rate kg/hr

1000 2500

Gas Liquid Density Density kg/m3 kg/m3

100 66 1000 1000

Case 3

Case 4

6000

3000

60,000

40,000

2700

3000

66

30

700

1000

40,000 / 1,55,000 = ~ 26%

1) a) b) c) Which internal can be used for above service ? No internal Mist mat Vane pack

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Quiz 2 : - Production separator with heavy waxy oil and little solids.

1) a) b) c)

Which internal can be used for above service ? No internal Mist mat Vane pack

10

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Three principles used to achieve physical separation of gas and liquids or solids are momentum (impact / centrifugal), gravity settling, and coalescing

11

Sulzer

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

KOCH

12

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

KOCH

13

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

DEP

14

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

DEP

15

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

GPSA

DEP

16

DEP

GPSA

17

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Quiz 1 : - Compressor KO DRUM

Pressure , KPag

Case 1 Case 2 9000 4000

Gas rate, kg/hr

1,55,000 1,00,000

Liquid rate kg/hr

1000 2500

Gas Liquid Density Density kg/m3 kg/m3

100 66 1000 1000

Case 3

Case 4

6000

3000

60,000

40,000

2700

3000

66

30

700

1000

40,000 / 1,55,000 = ~ 26%

1) a) b) c) Which internal can be used for above service ? No internal X carries mist to compressor Mist mat Vane pack X 26 < 30 50 % turndown Pressure > 50 bar

18

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Quiz 2 : - Production separator with heavy waxy oil and little solids.

1) a) b) c)

Which internal can be used for above service ? No internal Best option Mist mat X It can block easily. Vane pack , only if to reduce vessel size with moderate fouling

19

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Gas Liquid Separator Design Guide

20

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Two phase separator design is divided in following sections.

Vessel Diameter Vessel Height Gas space height Liquid space height Nozzle sizing

21

SEPARATOR DIAMETER CALCULATION

Simplified Sauder-Brown equation:

1 2

UT

L V

Gas velocity < UT Gas velocity < Particle terminal falling velocity K = empirical constant for separator sizing, m/sec

V = gas phase density, kg/m3 L = liquid phase density, droplet or particle, kg/m3

22

SEPARATOR DIAMETER CALCULATION

Simplified Sauder-Brown equation:

1 2

UT

L V

Gas velocity < UT

Gravity Settling Stokes Law, Intermediate Law & Newtons Law Particle size and Reynolds Number

23

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Calculation worksheet

24

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Notes GPSA 11 & 12+

Instructions

25

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

26

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Collect following data from Heat & Mass balance.

Gas and liquid mass rate (kg/hr) Gas and liquid mass density (kg/m3) Operating pressure and temperature Liquid viscosity and gas molecular weight Tip : If liquid has two phases, then use density of light phase. This will give safe design.

27

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Process Data Input

28

DEP

29

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Following cases to be checked for separator sizing

Highest Volumetric Gas rate Highest Volumetric Liquid rate Lowest pressure case for higher volume Highest pressure case for difficult separation Lowest liquid density case for difficult separation

30

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Selection of K value

Type of internal Service Downstream requirement for gas quality Pressure correction Orientation correction Liquid loading correction

31

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

WP

GPSA GPSA

0.037 0.073 m/sec 0.055 0.107 m/sec

32

SELECTING K FOR HORIZONTAL VESSEL

WP

GPSA

33

SELECTING K BASED ON TYPE, SERVICE AND

OPERATING PRESSURE

34

SELECTING K BASED ON LIQUID LOADING

35

GPSA

SULZER K VALUES

36

Sulzer K Values

SULZER K VALUES

37

PRACTICAL SELECTION AND DESIGN GUIDE

GPSA

38

PRACTICAL SELECTION AND DESIGN GUIDE

SIMILAR TO K

39

DEP

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Enter K value based on type of internal, service, pressure liquid loading and orientation. Run all cases as mentioned earlier. Arrive biggest separator Diameter for vapour & liquid loadings.

40

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Weight / Space / Cost Optimisation For following cases High gas rate High design / operating pressure Exotic / Expensive MOC Low liquid with clean service Space constraint (Offshore platform)

Use vane pack / cyclone Internal; to reduce size of the separator; and thus weight & cost of the separator.

41

SEPARATOR HEIGHT CALCULATION

Use Inlet Device Height

WP

42

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

GAS Height Calculation depends on :

1) With / without Internals 2) Type of Internals (distance between internal and feed pipe) 3) Type of feed device (distance between HHL & feed pipe and distance between internal & feed pipe) 4) Mist / Foaming service ??

43

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Liquid Height Calculation :

1) Check liquid discharge is on Level Control OR On Off Control between high & low level (do not use spread-sheet defaults, one can go badly wrong) 2) Find surge volume / time 3) Degassing service ??

44

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Liquid Height Calculation :

4) Check P & ID for number of levels, alarms and trips number of instruments installed 5) Find type of level measurement Magnetic type, radar, differential pressure .. Different types of instruments has different minimum distance requirements

45

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Liquid Height Calculation :

6) Most important liquid control & hold-up volume is based on (A) service (Production separator, KO drum, flash drum) and (B) downstream equipment requirement, i.e. Feed to pump Feed to vessel / column Feed to exchanger

46

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Liquid Height Calculation :

7) Check P & I D for other nozzles; i.e. , size & locations for PSV, manhole etc.. This can effect vessel height.

47

GPSA

48

SURGE

SURGE

SURGE

HOLDUP

HOLDUP

HOLDUP

LIQUID LEVELS DEFINITION

NLL HLL HHLL LLL

Normal Liquid Level Liquid level maintained by controls during operation High Liquid Level First liquid level above NLL to trigger an alarm High High Liquid Level Second liquid level above NLL to trigger a shutdown Low Liquid Level First liquid level below NLL to trigger an alarm

LLLL

Low Low Liquid Level Second liquid level below NLL to trigger a shutdown

Hold-up time Time to fill separator from empty to NLL at design (Residence Time) liquid feed rate.

Surge Time Time to fill separator from NLL to HLL at design liquid feed rate.

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

GPSA

WP

56

WP

Calculate Total height, and check surge volume% & L/D ratio, otherwise increase diameter or liquid (vessel) height.

57

WP For New Design

DEP

NOZZLE SIZING CRITERIA

DEP DEP For 58 debottlenecking

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

Inlet Nozzle type is selected on following criteria Gas & Liquid loadings and ratio Separation quality required by inlet device To maintain reasonable ratio of vessel dia. to inlet pipe dia. Vessel Height can be reduced by providing proprietary device

Check sizing of all nozzles for different cases. Nozzles sizing case is NOT same as Vessel governing case. 59 Gas and liquid outlet nozzles governing case are generally different.

GAS LIQUID SEPARATOR PRACTICAL SELECTION AND DESIGN GUIDE

UK CEng, FIChemE mvshah027@yahoo.com

60

Selection Check list

Select Separator type and orientation based on following criteria Gas volumetric rate & Gas to liquid volumetric ratio Slug volume Operating pressure and allowable pressure drop Turndown Feed source Separation efficiency required @ downstream unit Liquid property, fouling, viscous, solids etc.. Space and head room available / Offshore / onshore application

Do's & Don't

a) b) c) d) Do not use vane pack for high turndown (< 30% design flow) Do not use wire or knitted mesh for fouling service Do not use vane pack above 50 bar operating pressure Vertical flow vane pack is not suitable for slug service. Is feed gas requires de-foaming ? Is liquid feed requires degassing? Is liquid heating required to prevent wax deposition ? Is solid handling required for this service ?

Design Check list

If liquid has two phases, then use density of light phase to calculate vessel diameter. This will give safe design. Apply flow margin based on service Following cases to be checked for separator and nozzles sizing Highest Volumetric Gas rate Highest Volumetric Liquid rate Lowest pressure case for higher volume Highest pressure case for difficult separation Lowest liquid density case for difficult separation Select of K value based on following criteria Type of internal Service Downstream requirement for gas quality Pressure correction

Prepared By Manish Shah : Lead Process Engineer : mvshah027@yahoo.com

Orientation correction Liquid loading correction

Liquid Height Calculation :

1) Check liquid discharge is on Level Control OR On Off Control between high & low level. (do not use spread-sheet defaults, one can go badly wrong) 2) Find surge volume / time 3) Degassing service ?? (more holding time) 4) Check P & ID for number of levels, alarms and trips number of instruments installed 5) Find type of level measurement, Magnetic type, radar, differential pressure .. Different types of instruments has different minimum distance requirements 6) Most important liquid control & hold-up volume is based on (A) service (separator, KO drum, flash drum) and (B) downstream equipment requirement, i.e. a) Feed to pump, b) Feed to vessel / column or c) Feed to exchanger 7) Check P & I D for other nozzles; i.e. , size & locations for PSV, manhole etc.. This can affect vessel height. Check L/D ratio based on orientation Check layout for footprint and head room availability Check API 12 J before preparing process data sheet. Check possibility of Weight / Space / Cost Optimisation by using vane pack / cyclone Internal for following cases High gas rate High design / operating pressure Exotic / Expensive MOC Low liquid with clean service Space constraint (Offshore platform)

Prepared By Manish Shah : Lead Process Engineer : mvshah027@yahoo.com

Вам также может понравиться

- Three Phase Separator DesignДокумент5 страницThree Phase Separator DesignAymen KhlifiОценок пока нет

- Spreadsheet To Design SeparatorsДокумент21 страницаSpreadsheet To Design SeparatorsreninbabaskiОценок пока нет

- 3 Oil and Gas Separation Design Manual by C Richard SivallsДокумент63 страницы3 Oil and Gas Separation Design Manual by C Richard SivallsSemih Özsağıroğlu100% (1)

- Filter Separator English LetterДокумент2 страницыFilter Separator English Lettermarcoo8Оценок пока нет

- Separator Design Guide PDFДокумент36 страницSeparator Design Guide PDFAdam RizkyОценок пока нет

- Three Phase Separators - Times DefinitionДокумент5 страницThree Phase Separators - Times DefinitionaytihdaОценок пока нет

- 2 Phase Flow Pressure Drop Calc Suresh1Документ6 страниц2 Phase Flow Pressure Drop Calc Suresh1NKОценок пока нет

- GasLiquid Separators-Design RulesДокумент21 страницаGasLiquid Separators-Design Ruleswahyuriansyah100% (1)

- PTC12.2-Steam Surface CondenserДокумент86 страницPTC12.2-Steam Surface Condenserlibid_raj100% (3)

- Vapor Liquid Separator PDFДокумент10 страницVapor Liquid Separator PDFClemenОценок пока нет

- KIRK Sep-Calc SoftwareДокумент4 страницыKIRK Sep-Calc Softwaredhl_tuОценок пока нет

- Memoria de Calculo Separadores BifasicosДокумент1 страницаMemoria de Calculo Separadores BifasicosJhonnatan Fredy Gomez DominguezОценок пока нет

- DJM-MBA-PCS-CA-008 Low Temperature Separator REV-BДокумент6 страницDJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDIANTOROОценок пока нет

- No Yes No Yes No Yes No Yes No Yes No YesДокумент8 страницNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnОценок пока нет

- Sizing Separators and Accumulators PDFДокумент4 страницыSizing Separators and Accumulators PDFjt_breakdanceОценок пока нет

- Electrostatic Oil - Water Treater & Desalter: Calculated AnswersДокумент2 страницыElectrostatic Oil - Water Treater & Desalter: Calculated AnswersLeonardo ChávezОценок пока нет

- Maz - Design - Separator Capacity EvaluationДокумент5 страницMaz - Design - Separator Capacity EvaluationNaeem HussainОценок пока нет

- 4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesДокумент6 страниц4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDavid VMОценок пока нет

- Warning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Документ2 страницыWarning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Ajay TiwariОценок пока нет

- Validated SheetДокумент12 страницValidated SheetrohitkushОценок пока нет

- Art's Liquid-Vapor SeparatorДокумент13 страницArt's Liquid-Vapor Separatorlutfi awnОценок пока нет

- Heat Exchanger Sizing AC-6050 #1Документ2 страницыHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleОценок пока нет

- Process Calculation: Flare Diameter (D)Документ2 страницыProcess Calculation: Flare Diameter (D)kristian08100% (1)

- Sonic VelocityДокумент2 страницыSonic Velocityganeshdhage100% (1)

- 8-0241-4503-Flare System Design PDFДокумент8 страниц8-0241-4503-Flare System Design PDFVinothrajaОценок пока нет

- 3Ph Vert Sep 2010 Weir VerA FPS PDFДокумент5 страниц3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderОценок пока нет

- Flare Stack Design PDF ReportДокумент2 страницыFlare Stack Design PDF Reportrutuja100% (2)

- Pump CalcДокумент1 страницаPump CalcMoch WildanОценок пока нет

- PSV Calculation and PhilosophyДокумент33 страницыPSV Calculation and PhilosophysbmmlaОценок пока нет

- Separator SizingДокумент11 страницSeparator Sizingmusaveer50% (2)

- Horizontal Separator - V1.12 ERG PB 1Документ6 страницHorizontal Separator - V1.12 ERG PB 1Anonymous AtAGVssJОценок пока нет

- PSV Sizing SheetДокумент5 страницPSV Sizing SheetDhanraj Vasanth100% (1)

- Unit Operations Thumb RulesДокумент9 страницUnit Operations Thumb RuleshibhavuОценок пока нет

- Scrubber and Demister Sizing - Form 2Документ2 страницыScrubber and Demister Sizing - Form 2eka resmana100% (2)

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesДокумент5 страницSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierОценок пока нет

- Air Cooler 1Документ23 страницыAir Cooler 1Vipin SreekumarОценок пока нет

- Efficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer ChemtechДокумент31 страницаEfficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer Chemtechmisscolgate100% (1)

- Estimating Costs of Shell and Tube Heat Ex Changers by Purohit ComДокумент12 страницEstimating Costs of Shell and Tube Heat Ex Changers by Purohit Comhwang2Оценок пока нет

- Gas-Liquid Vertical Separator PDFДокумент2 страницыGas-Liquid Vertical Separator PDFRathish RagooОценок пока нет

- Sizing Sheet of Vertical 2-Phase Separator As Per API 12JДокумент5 страницSizing Sheet of Vertical 2-Phase Separator As Per API 12JWickyОценок пока нет

- FlareTot - Total Flare AnalysisДокумент8 страницFlareTot - Total Flare AnalysisArjun KapoorОценок пока нет

- Three Phase Separator Sizing - No InternalДокумент2 страницыThree Phase Separator Sizing - No InternalSaeid Rahimi MofradОценок пока нет

- Process Calculation ManualДокумент13 страницProcess Calculation ManualDHAVAL PANCHALОценок пока нет

- Indirect Fired HeaterДокумент2 страницыIndirect Fired HeaterJoshua CollierОценок пока нет

- The Outside Diameter As Their Nominal DiameterДокумент75 страницThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- Section 7 - Separation EquipmentДокумент9 страницSection 7 - Separation Equipmentlulis171Оценок пока нет

- Scrubber NATCOДокумент22 страницыScrubber NATCOkalikamalaОценок пока нет

- Selection and Design of Vapour Liquid Separator by Manish V. Shah Mvshah027@yahoo - Com Http://hc-Mvs - Devhub.com/ UK Fellow Charter EngineerДокумент60 страницSelection and Design of Vapour Liquid Separator by Manish V. Shah Mvshah027@yahoo - Com Http://hc-Mvs - Devhub.com/ UK Fellow Charter Engineermvshah108Оценок пока нет

- Separator Sizing SpreadsheetДокумент40 страницSeparator Sizing SpreadsheetWalid Ben Husein100% (2)

- Gas/Liquids Separators - Part 3: Quantifying Separation PerformanceДокумент14 страницGas/Liquids Separators - Part 3: Quantifying Separation PerformanceWendellReeceFrankОценок пока нет

- Expro-API-RP-14E-Gas Wells PDFДокумент12 страницExpro-API-RP-14E-Gas Wells PDFRuben VillegasОценок пока нет

- Vdocuments - MX Separator Sizing SpreadsheetДокумент31 страницаVdocuments - MX Separator Sizing SpreadsheetYustianОценок пока нет

- Separator DesignДокумент8 страницSeparator Designmohamed_sahnoun_enisОценок пока нет

- Fdocuments - in Separator Sizing SpreadsheetДокумент31 страницаFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaОценок пока нет

- WATSON Separator 1Документ31 страницаWATSON Separator 1Apriliana DwijayantiОценок пока нет

- Calculation and Design of Separators (VS)Документ18 страницCalculation and Design of Separators (VS)Bhuran AkshayОценок пока нет

- LPG Storage Tanks: SMPV RulesДокумент7 страницLPG Storage Tanks: SMPV RulesavtandilОценок пока нет

- Guide For Vessel Sizing PDFДокумент24 страницыGuide For Vessel Sizing PDFManish542Оценок пока нет

- 2) Haseeb PresentationДокумент27 страниц2) Haseeb PresentationBilalAshrafОценок пока нет

- Separator PDSДокумент7 страницSeparator PDSprabhuarunkumarОценок пока нет

- Fisher Diaphragm Rotary ActuatorДокумент12 страницFisher Diaphragm Rotary Actuatordennis_ugarteОценок пока нет

- Services: Torispherical, Semi Ellipsoidal & Hemispherical Heads/EndsДокумент4 страницыServices: Torispherical, Semi Ellipsoidal & Hemispherical Heads/Endsdennis_ugarteОценок пока нет

- Start-Up and Operations Report PDFДокумент3 страницыStart-Up and Operations Report PDFdennis_ugarte100% (1)

- TD OPTIFLUX7300 en 110112 4000962501 R01Документ32 страницыTD OPTIFLUX7300 en 110112 4000962501 R01dennis_ugarteОценок пока нет

- Lanzadora Chanco Scraper CatalogoДокумент5 страницLanzadora Chanco Scraper Catalogodennis_ugarteОценок пока нет

- Brochure AesaДокумент6 страницBrochure Aesadennis_ugarteОценок пока нет

- Campos Subandino Sur PDFДокумент29 страницCampos Subandino Sur PDFAndrea CR100% (1)

- Ball-Float Traps For Draining Condensate From Compressed-Air and Other Gas Lines UNAДокумент1 страницаBall-Float Traps For Draining Condensate From Compressed-Air and Other Gas Lines UNAdennis_ugarteОценок пока нет

- Astm A-1005Документ6 страницAstm A-1005dennis_ugarteОценок пока нет

- D 2598 - 96 R01 - Rdi1otgtotzДокумент2 страницыD 2598 - 96 R01 - Rdi1otgtotzdelta lab sangliОценок пока нет

- Accred BP - Concrete BPДокумент2 страницыAccred BP - Concrete BPRafael Obusan IIОценок пока нет

- Jan 11Документ66 страницJan 11c_nghia100% (2)

- Westfalia Service TrainingДокумент229 страницWestfalia Service Trainingalex_alexutzuu100% (1)

- Serway 6 e Problems 24Документ13 страницSerway 6 e Problems 24Iqra DadaОценок пока нет

- Construction and Building Materials: Marta Sánchez de Juan, Pilar Alaejos GutiérrezДокумент6 страницConstruction and Building Materials: Marta Sánchez de Juan, Pilar Alaejos GutiérrezChittibabu babuОценок пока нет

- Transat Particles in PipesДокумент17 страницTransat Particles in Pipesمحمد توفيق عراقيОценок пока нет

- TechNote - Mass Flow Vs Volumetric FlowДокумент1 страницаTechNote - Mass Flow Vs Volumetric Flowcool_rdОценок пока нет

- Radiation Protection - Guideline - Design and Validation of Shielding of Dental X-Ray Facility - 20220401Документ14 страницRadiation Protection - Guideline - Design and Validation of Shielding of Dental X-Ray Facility - 20220401Esteban PalaciosОценок пока нет

- Preparing O-Phophoric AcidДокумент3 страницыPreparing O-Phophoric AcidsangeetayvermaОценок пока нет

- SPE Paper DenSCRETEДокумент9 страницSPE Paper DenSCRETEeng7mohamed7hashimОценок пока нет

- Bs en 12390 7 Testing Hardened Concrete Part 7 Density of HardenedДокумент12 страницBs en 12390 7 Testing Hardened Concrete Part 7 Density of Hardenedញ៉ាន ណាឃីមОценок пока нет

- Shear-Wave Velocity Estimation in Porous Rocks PDFДокумент15 страницShear-Wave Velocity Estimation in Porous Rocks PDFMahmoud EloribiОценок пока нет

- Micro Motion 7829 Visconic Viscosity Meter: Product Data SheetДокумент16 страницMicro Motion 7829 Visconic Viscosity Meter: Product Data SheetEdwin Francisco Plaza RamirezОценок пока нет

- Practical Action How To Make Stabilised Earth BlocksДокумент14 страницPractical Action How To Make Stabilised Earth BlocksPeter W Gossner100% (1)

- Physical Properties of Chemicals - HTMLДокумент10 страницPhysical Properties of Chemicals - HTMLLopo SigyОценок пока нет

- RVT TowerPackings EN WEB 20220804Документ5 страницRVT TowerPackings EN WEB 20220804Göksel VATANОценок пока нет

- Back-Pressure Tests On. Gas-Condensate Wells: As - OndeisateДокумент9 страницBack-Pressure Tests On. Gas-Condensate Wells: As - OndeisateAura Cristina Villafañe GeraldinoОценок пока нет

- Properties of Plastics: Activity 1Документ5 страницProperties of Plastics: Activity 1Beatriz Ruiz GrageraОценок пока нет

- Astm D1434 - 82 - 09Документ13 страницAstm D1434 - 82 - 09César PaltánОценок пока нет

- 516 2 1Документ16 страниц516 2 1Indira BanerjeeОценок пока нет

- Module 8 Kinematics of FluidsДокумент51 страницаModule 8 Kinematics of FluidsClaire G. MagluyanОценок пока нет

- SDBC-Job Mix FinalДокумент31 страницаSDBC-Job Mix FinalAchintya DasОценок пока нет

- 5129 s12 QP 1Документ16 страниц5129 s12 QP 1airulyantiОценок пока нет

- RotametreДокумент9 страницRotametreJohn AdewaleОценок пока нет

- AP Chemistry Notes - Chapter 1 Chemistry Notes - Chapter 1, 2, 3, & 4Документ31 страницаAP Chemistry Notes - Chapter 1 Chemistry Notes - Chapter 1, 2, 3, & 4Qises QiskaОценок пока нет

- CL-4.Cement Additives and TДокумент56 страницCL-4.Cement Additives and TEslam Atif AzkolОценок пока нет

- General Physics Work Sheet Chapter 3-4Документ4 страницыGeneral Physics Work Sheet Chapter 3-4gurmesa teferaОценок пока нет

- Concrete Technology Practical PDFДокумент21 страницаConcrete Technology Practical PDFPrashant SahОценок пока нет