Академический Документы

Профессиональный Документы

Культура Документы

Air Conditioning Liebheer

Загружено:

diasfm100%(2)100% нашли этот документ полезным (2 голоса)

1K просмотров298 страницАвторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(2)100% нашли этот документ полезным (2 голоса)

1K просмотров298 страницAir Conditioning Liebheer

Загружено:

diasfmАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 298

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

This document must be used for training purpose only

Training DOCTR 039

Training on

Ventilation/Forced Ventilation/Heating and

Air Conditioning System of the

AB139 Helicopter

It will not be updated

Under no circumstances should this document be used as a reference

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

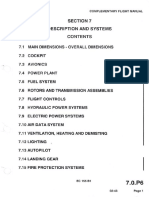

TABLE OF CONTENTS:

Table of Contents

Abbreviations

General description

Ventilation System including Forced Ventilation:

- Pilot Interfaces

- System Control

- Detailed System Operation

- Low Pressure Ducting

- Component description

- Trouble shooting

Heating and Ventilation System including Forced Ventilation:

- Pilot Interfaces

- System Control

- Detailed System Operation

- High Pressure Ducts

- Component description

- Trouble shooting

Training DOCTR 039

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

TABLE OF CONTENTS (cont'd):

Air Conditioning System:

- Pilot Interfaces

- System Control

- Detailed System Operation

- Component description

- Trouble shooting

Training DOCTR 039

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

LIST OF ABBREVIATIONS

A/C: Aircraft

AC Alternative Current

ACCB Air ConditioningControl Box

AFT Cabin zone

BAD: BleedAir Duct

CP: Cockpit Panel

CV: Check Valve

DTS: Duct Temperature Sensor

ECS: Environmental Control System

FMEA: Failure Mode And Effect Analysis

FMECA: Failure Mode, Effect andCriticalityAnalysis

FV: Flapper Valve

FWD Cockpit zone

HCB: HeatingControl Box

HMV HeatingModulationValve (see TCV)

HTR Heater

J P: J et Pump

LPD: LowPressure Ducting

LTS: LIEBHERR AEROSPACE Toulouse

OTS: Over Temperature Switch

SOV: Shut Off Valve

TCV Temperature Control Valve

Training DOCTR 039

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

LIST OF ABBREVIATIONS (cont'd)

Training DOCTR 039

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation

Enter

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forced Ventilation

Enter

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation/Heating

Enter

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forced

Ventilation/Heating

Enter

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation/Heating

Air Conditioning

Enter

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

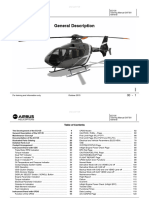

Gener al Desc r i pt i on

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

General description

The Environmental Control Systemon the AB139 is divided in several

subsystems which are the Ventilation and the Heating systemoptimised

by anAir Conditioning System.

- Heating is generated by mixing bleed air fromthe engine with outside

ramair flowin a jet pump and by diffusing it into the helicopter through a

lowpressure ducting system.

- Fresh air is provided by outside Ram Air flow controlled by Flapper

Valves and distributed into the helicopter trough a low pressure ducting

system.

- Cooling is provided by two splitted vapour cycle systems dedicated

respectively to the cockpit an cabin zones.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

The ECS system has 5 different versions :

- The cockpit and cabin ventilation system- P/N 3G2120A00111

- The forced cabin ventilation system- P/N 3G2121F00111

NOTE: VentilationandForcedVentilationarediscribedinthesamechapter.

- The heating* and ventilation system- P/N 3G2140F00111

- The heating* and forced ventilation system- P/N 3G2141F00111

NOTE: Heating withVentilation and Forced Ventilation are discribed in the

samechapter.

- The AIR conditioning* / heating and Ventilation System - P/N

3G2150F00111

*High and low pressure ducts are provided for the heating and the air

conditioning system.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Helicopter Ventilation System cut off view

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Helicopter Ventilation System cut off view

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation system components:

Item Components of the Cockpit ventilation P/ N20204A010000 P/ N Qty

001

Ventilation COCKPIT CONTROL PANEL 91100A010000

1

Ventilation COCKPIT CONTROL PANEL NVG 91100A010001

002 Ventilation Cockpit FLAPPER VALVE 6034A010001 2

003 Ventilation COCKPIT fan 8013A020000 2

004 Wedges for 6034 mounting 20204-72 2

005 P_CLIP PLENUM DISTRIBUTION COCKPIT 20204-4 2

006 FLEXIBLE between NACA & 6034 9869B010000 2

007 RIGID 6034 -> 8013 right 9871B010000 1

008 RIGID 6034 -> 8013 left 9870B010000 1

009 RIGID 8013 -> PLENUM DISTRIBUTION 9706B010000 2

010 PLENUM COCKPIT right - PART 1 - Fan side 9873B010000 1

011 PLENUM COCKPIT right - PART 2 - GASPER side 9896B010000 1

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation system main parts:

012 PLENUM COCKPIT left - PART 1 - Fan side 9872B010000 1

013 PLENUM COCKPIT left - PART 2 - GASPER side 9897B010000 1

014 COCKPIT LATERAL DIFFUSER - up right 9711B010000 1

015 COCKPIT LATERAL DIFFUSER - up left 9712B010000 1

016 COCKPIT LATERAL DIFFUSER - down right 9713B010000 1

017 COCKPIT LATERAL DIFFUSER - down left 9714B010000 1

018 CENTRAL DIFFUSER right 9895B010000 1

019 CENTRAL DIFFUSER left 9894B010000 1

020 brackets for 8013 20204-68 2

021 Y BRANCH ASSY for GASPERS 9709B010000 2

022 GASPERS 9710B010000 4

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation system main parts:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Addional Forced Ventilation system parts:

Components of the Cockpit/ Cabin Forced ventilation system

P/ N 20204B010000

P/ N Qty

Forced ventilation COCKPIT CONTROL PANEL 91102A010000

1

Forced ventilation COCKPIT CONTROL PANEL NVG 91102A010001

CABIN fan 8012A010000 1

CABIN fan bracket 20204-21 1

Forced ventilation CABIN CONTROL PANEL 91103A010000 1

Forced ventilation CABIN CONTROL PANEL - NVG 91103A010001 1

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

VENTI LATI ON SYSTEM

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation

LTS provides two different cockpit and cabin ventilation systems,

called Ventilation and Forced ventilation.

Cockpit ventilation system

For the cockpit, two separate systems provide air for pilot and co-

pilot. Outside RAM air enters the systems through two air intakes

located on the nose section.

For cockpit and cabin ventilation the outside ram air flow can be

selected by flapper valves, manually controlled by the crewwith a 4-

position switch on the Cockpit control Panel.

Ventilation

Forced outside air for cockpit ventilation or defogging is provided by

2-speed axial fans in each systems. The blowers are manually

controlled by the crewin Off, LowSpeed, or High Speed.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation

The Cockpit Control Panel (P/N 91100A010000) interfaces with:

- the cockpit fans (2 qty)

-the cabin (1 qty) and cockpit (2qty) flapper valves

VENT CREW 4 position switch:

OFF- FVs "Closed" and FANs "Off"

ON FVs "Open" and FANs "Off"

LOW- FVs "Open" and FANs "Lowspeed"

HIGH - FVs "Open" and FANs "High speed"

Ventilation

VENT

OFF

ON

VENT

91101A010000 or 91101A010001 (NVG)

Cabin Control Panel

91100A010000 or 91100A010001 (NVG)

Cockpit Control Panel

VENT CTRL

PAX

CREW

VENT

OFF

FAN

LOW

FAN

HIGH

ON

CREW

ON

PAX

OFF

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation cont.

CONTR 2-position switch control the availability of the passenger control

panel.

When CREW is selected, the control of the cabin area is done by the

cockpit panel.

When PAX is selected, the control of the cabin area is done by the

passenger panel.

The Cabin Control Panel (P/N 91101A010000) interfaces

with:

- the cabin flapper valve

The VENT indication light on the Cabin panel is illuminated when PAX has

been selected on the Cockpit panel.

OFF - Cabin FV " Closed"

ON Cabin FV " Open"

Ventilation

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

The cockpit panel CREW selected, allows the direct control of

two cockpit fans (off/low/high) and two single cockpit flapper

valves, PAX selected the cabin flapper valve is controled via the

cabin panel.

VENTILATION SYSTEM CONTROL

Cabin ventilation Cockpit ventilation

Lower Side

Window Demister

Upper Side

Window Demister

Main winshield

Demister

Front face outlets

Fan

Air intake

Lower Side

Window Demister

Upper Side

Window Demister

Main winshield

Demister

Front face outlets

Fan

Flapper valve

Air intake

To control panel

Air intake Flapper valve

Plenum

To control panel

Singular gaspers manifold

Side vents manifold

Singular gaspers manifold

Side vents manifold

Water

separation

duct

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

VENTILATION

Cockpit ventilation system (cont'd)

One 2-speed centrifugal fan on the L/H and one on the R/H side,

provides outside/ramair for ventilation or defogging.

They are manually controlled by the crew in Off, Low Speed, or High

Speed mode.

Cabin ventilation system

For the cabin, outside ramair enters the systemthrough one air intake

in the forward pylon fairing in the cabin roof, the air flowis admitted by

a flapper valve.

The air is then routed through ducts which are installed above the

cabin ceiling panels.

The cabin panel allows the direct control (open/close) of the cabin

flapper valve with the VENT switch.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

VENTILATION

FORCED VENTILATION

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

VENTILATION

Forced

Ventilation

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

VENTILATION

The Forced ventilation system provides an additional 2-speed

centrifugal fan for the cabin zone supplying outside/ramair.

The CABIN fan is controlled manually by the crew on the cockpit

control panel VENT in OFF, LOWor HIGH speed mode when "CREW"

selected or from the cabin panel by the passengers when "PAX"

selected.

Nota: For Air conditioning option, the air flow across the cabin

evaporators is provided by the cabin fan and a second addional fan.

The air conditioning option allows to run the cockpit and cabin fans in

recirculation mode (override of the VENT Switch).

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

VENTILATION

The COCKPIT panel for Forced Ventilation (P/N 91102A010000) interfaces with:

- the cabin fan (1)

- the cockpit fans (2)

- the cabin (1) and cockpit flapper valves (2)

Cockpit Control Panel

P/N 91102A010000

The CABIN panel for Forced Ventilation (P/N 91103A010000) interfaces with:

- the cabin fan (1)

- the cabin flapper valve (1)

Cabin Control Panel

P/N 91103A010000

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forced Ventilation:

When VENT CTRL "CREW" selected, the cockpit panel allows

the direct control of all fans (off/low/high), and flapper valves

(open/close) in the cabin and cockpit zone.

When VENT CTRL "PAX" selected, the cabin panel allows

independently the control of the cabin fan (off/low/high), and

flapper valve (open/close).

SYSTEM CONTROL

Cabin ventilation

Cockpit ventilation

Lower Side

Window Demister

Upper Side

Window Demister

Main winshield

Demister

Front face outlets

Fan

Air intake

Lower Side

Window Demister

Upper Side

Window Demister

Main winshield

Demister

Front face outlets

Fan

Flapper valve

Air intake

To control panel

Air intake Flapper valve

Plenum

Singular gaspers manifold

Side vents manifold

Singular gaspers manifold

Side vents manifold

To control panel

AFT Fan

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Ventilation/Forced

Ventilation System Logic :

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forward Ventilation :

+ If cockpit fans are operating, then the control panel sends the " Forward

Ventilation On " discrete signal to the helicopter general displayer (MAU).

After Ventilation :

+ If cabin fan is operating, and cabin flapper valves are not fully closed; then

the control panel sends the " After Ventilation On " discrete signal to the

helicopter general displayer (MAU).

Ventilation Failure:

+ If AFT-FAN-FAULT is active or FWD-FAN1-FAULT is active or FWD-

FAN2-FAULT is active , then the control panel sends the " Ventilation Failure

" discrete signal to the helicopter general displayer.

Heating system

Ventilation and Forced ventilation System Logic :

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Det ai l ed Vent i l at i on Syst em

Oper at i on

And

Component Desc r i pt i on

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Cockpit and Cabin Ventilation and Forced Ventilation

Cockpit ventilation system(basic)

For the cockpit, two separate systems

provide air for pilot and co-pilot. Outside

RAM air enters the systems through two air

intakes positioned on the helicopter nose

section.

Air for ventilation or defogging is provided

by either ramair and/or (on ground) by two

2-speed axial fans installed near to the pilot

and co-pilot pedestal (flapper valves open).

Air is then distributed to the different outlets,

front faces outlets, main windshield and side

windows diffusers.

The cockpit and the cabin ventilation systems are two different and

separate sub-systems.

Lower Side

Window Demister

Upper Side

Window Demister

Main winshield

Demister

Front face outlets

Fan

Air intake

Lower Side

Window Demister

Upper Side

Window Demister

Main winshield

Demister

Front face outlets

Fan

Flapper valve

Air intake

To control panel

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cabin ventilation system (basic)

For the Cabin, outside ramair enters the systemthrough one air intake in

the forward pylon fairing in the cabin roof. The air is then routed through a

duct to the flapper valve.

The outside Ram air flow is supplied by an Open/Close flapper valve

controlled manually by the crew with a 2 position switch on the cockpit

control Panel " VENT PAX or by the cabin panel provided CONTR PAX

has been selected.

Air is then distributed via the plenumto both lateral manifolds, each one

being separated supplying fresh air via singular gaspers to the

passengers.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

FORCED ventilation for the cabin is provided by an additionel two

speed axial fan.

The fan and flapper valve control can be achieved by the crew through

the cockpit panel or when VENT CTRL PAX selected by the

passengers through the cabin panel.

Air intake Flapper valve

Plenum

Singular gaspers manifold

Side vents manifold

Singular gaspers manifold

Side vents manifold

To control panel

Fan

Water

separation

duct

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

The demisting outlets are composite diffusers with fins to control the air jet

characteristics to performthe windscreen bay demisting.

The cockpit gaspers are wide diffusers to provide comfortable diffusing

with large air flow.

The cabin gaspers are standard airplane gaspers.

The cabin and cockpit pedestals are composite outlets to diffuse air to

crewand passengers feet.

Characteristics:

The ventilation distribution system is designed to withstand pressure

variations in a range of 15 mBars and +150 mBars.

The maximumoperating temperatures should be in-between 40 C to +

85 C.

Distribution system description:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Distribution system description

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation Low Pressure Ducting Cockpit view:

Flapper

Valve

Pluged Heating

System connections

Fan

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

The lowpressure ducting LPD systemconsists of air distribution ducts,

manifolds, cabin diffusors, pedestral outlets, window demister, front face

outlets and a plenum. Depending on the configuration to be installed on

the helicopter, we can distinguish 5 subsystems :

The LPD for Cockpit Ventilation Subsystem(basic)

The LPD for Cabin ventilation Subsystem(basic)

The LPD for Forced Cabin Ventilation Subsystem(kit)

The LPD for Heating Subsystem(kit)

The LPD for Air Conditioning Subsystem(kit)

The ventilation system distribution ducting for cockpit and cabin is the

basic version for the helicopter.

Low Pressure Ducting

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Low Pressure Ducting views (exampels):

Cabin ceiling plenum with diffuser

Cabin diffuser (exampel)

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Vent i l at i on Syst em Mai n

Component desc r i pt i on

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Ram Air Flapper valves

General information:

The pilot drives the Flapper Valves fromthe cockpit panel, to open or shut off

the ramair intakes of cabin and cockpit lowpressure distribution system.

Installation:

The valves are located after the ramair intakes of the ECS before fans.

They are attached to the structure by metallic brackets and to the ducting with

minox clips.

The mounting brackets ensure bondingbetween the valve and the helicopter.

Pressure drop (valve full open) :

With a nominal Cockpit flow of 125g/s =0,2 mbar

With a nominal Cabin flow of 350 g/s =0,3 mbar

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cockpit FLAPPER valve 6034A010001 (ventilation + heating)

The two flapper valves are derived composed of :

a 3cylindrical composite body,

a tangential gear box,

a shaft which transmits the rotational movement by a tenon-mortise type

drive

brushes direct current motor,

one end of travel opening and one end of travel closing position switch,

an aluminium flap.

Characteristics: Nominal power supply : 28 Vdc for a limit of 17 Vdc to 32 Vdc

Current consumption at nominal torque of 0.12 mdaN : <1,0A

Normal operation temperature: -40C to +70C ( a max of 85C

during short time -valve not operating)

Nominal operation pressure: 35 mBars rel.

Maximum opening/closing time: 5 s

Weight max.: between 0,42 kg and 0,58 kg

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cockpit Flapper valve pin location :

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cockpit FLAPPER valve (6034A010001 ventilation + heating) general

view:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cabin FLAPPER valve 6035A010001:

The Ramair cabin valve is a 4 diameter, single cylindrical composite body butterfly

valve.

Inside the valve core an aluminium circular flap, held by 2 half-shafts, perform the

shut-off function.

The flapper valve shaft is driven by an electrical actuator.

The electric actuator, consists of an endless screwand an 28Vdc electrical motor.

Two end of travel micro-switches indicates the state of the valve: Open or Close.

Characteristics: Nominal power supply : 28 Vdc for a limit of 17 Vdc to 32 Vdc

Current consumption at nominal torque of 0.12 mdaN : <1,0A

Normal operation temperature: -40C to +70C ( a max of 85C

during short time -valve not operating)

Nominal operation pressure: 35 mBars rel.

Maximum opening/closing time: <5 s

Weight: 0,5 kg

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cabin Flapper Valve pin location :

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cabin FLAPPER valve 6035A010001 general view:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cockpit Fan 8013A020000 function (ventilation/heating system only):

There are 2 two speed brush less cockpit fans per helicopter on 2 symmetrical

ventilationsystems.

Both fans sucks air fromthe ramair intake and generates ventilation air flow towards

the cockpit outlets and are used for ground and flight operation.

They are controlled by the ECS Cockpit panel at high and lowspeed and are equipped

with a thermal switch and a under speed detection. To reset the fan, select OFF/ON.

Fan characteristics:

Power supply: 28Vdc

Normal working temperature range: - 40 C to +70 C

Low speed flow rate at 30 C and at see level: 7350 rpm / 35 g/s

High speed flow rate at 30 C and at see level: 14200 rpm / 6.5 A / 70 g/s

Max. current consumption: 7 A (start up 14 A)

Weight: 0.9 kg

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

In On mode, a fault is indicated (Ground) only if the speed is inferior to the

under speed limit during 3 to 5s.

With no power supplied the under-speed pin detection shall be Open.

With power supplied and OFF selection the under-speed pin detection shall

be open circuit.

The under-speed detection level is the half off low speed and half off high

speed 15% (in tr/mn).

During the start up phase when ON selection is activated the under-speed

pin detection is open circuit during 5 seconds.

An under-speed fault is detected if the under-speed pin detection is ground

after the start up phase. In this case the fan will be stop and a OFF/ON

selection is necessary for start again the fan.

Cockpit Fan 8013A020000 under speed detection:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

ON/OFF selection : Under-speed detection :

o Ground ON o Ground Fault

o Open Circuit OFF o Open Circuit No fault

High speed / Lowspeed selection :

o Ground Lowspeed

o Open Circuit High speed

Cockpit Fan 8013A020000 electrical logic:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cockpit Fan 8013A020000 Pin Location (idem for FAN 2):

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cockpit Fan 8013A020000 (ventilation/heating system only) general view:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cabin Fan 8012A020000 function (Forced ventilation + heating):

In this configuration we will find one 2 speed brush less cabin fan per

helicopter.

The fan sucks air from the ram air intake and generates ventilation air flow

towards the cabin overhead outlets. The cabin fan is used for ground and flight

operation.

It is controlled either by the ECS Cockpit panel or Cabin panel.

Fan characteristics:

Power supply: 28 Vdc

Normal working temperature range: - 40 C to max. +85 C

Low speed flow rate at 30 C and at see level: 8000 rpm / 5A / 110 g/s

High speed flow rate at 30 C and at see level: 12300 rpm / 16A / 210 g/s

Nominal current consumption: 16 A (start up 23 A)

Weight: 1,6 kg

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

In On mode, a fault is indicated (Ground) only if the speed is inferior to the

under speed limit during 3 to 5s.

With no power supplied the under-speed pin detection shall be Open.

With power supplied and OFF selection the under-speed pin detection shall

be open circuit.

The under-speed detection level will be the half off low speed and half off

high speed 15% (in tr/mn).

During the start up phase when ON selection is activated the under-speed

pin detection is open circuit during 5 seconds.

An under-speed fault is detected if the under-speed pin detection is ground

after the start up phase. In this case the fan will be stop and a OFF/ON

selection is necessary for start again the fan.

Cabin Fan 8012A020000 under speed detection:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

ON/OFF selection : Under-speed detection :

o Ground ON o Ground Fault

o Open Circuit OFF o Open Circuit No fault

High speed / Lowspeed selection :

o Ground Lowspeed

o Open Circuit High speed

Cabin Fan 8012A020000 electrical logic:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cabin Fan 8012A020000 Pin Location :

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Cabin Fan 8012A020000 (Forced ventilation/heating) general view:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

VENTI LATI ON SYSTEM TROUBLE

SHOOTI NG PROCEDURE

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System trouble shooting using break-out box (BOB) -

P/N92612A010000 :

On the Cockpit panel : Switch VENT CREW Fan in low and high speed mode (both

FWD fans).

1a) No air flow, (cockpit gaspers fully open pedestral gaspers fully closed).

BOB indication :

- FWD Fan Off selected : FWD Fan-Ctl light Yellow, Fan-On light Off

- FWD Fan Low selected : FWD Fan-Ctl light Green, Fan-On light Green

-FWD Fan High selected : FWD Fan-Ctl light Yellow, Fan-On light Green

IMPORTANT:

Loose of FWD FAN-CTL order result automatically into a Fan High speed order!

Note BOB: Fan ON (Jumper-15) and Fan CTL (Jumper-16)

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System trouble shooting contd:

NO Red Failure light indication on BOB:

- FWD Fan 1 red light Off (to confirm remove J umper - 35),

- FWD Fan 2 red light Off (to confirm remove J umper - 44),

- AFT Fan 1 red light Off (to confirm remove J umper - 50),

- A/C version : AFT Fan 2 red light Off (to confirm remove J umper 43).

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System trouble shooting cont'd:

1b) NO air flow on left or/and right side (both sides are completely

independant):

Check power supply to the fan (FWD-FAN-ON [to confirm remove jumper 15 light goes

Off ],

if o.k. (fan running) check connections of the distribution ductings,

no 28Vdc power supply (BOB FWD-FAN-ON light Off ) check

wiring and power supply to the Cockpit Panel

wiring and power supply o.k. replace Cockpit panel

2) Low flow at the cockpit gaspers with fan running

a) Check if left/right Fan is/are running in high speed mode (different noise level use

flowmeter)

-If not, check High speed order (BOB: FWD Fan-Ctl light Yellow, Fan-On light Green)

no High speed order replace Cockpit panel

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System trouble shooting cont'd:

Reminder BOB: Fan On (Jumper-15) + Fan CTL (Jumper-16), to confirm

signal remove jumpers.

High speed order o.k. check wiring and 28Vdc on fan connector

If O.K. - replace concerned fan

b) Low flow and Fan running in low and high speed mode

- check visually the position indicator on the Flapper valve,

- check power supply order to the flapper valve(s) which should be fully open BOB

FWD FV CMD green light On (J umper-23),

if o.k. and valve still closed - BOB FWD FV Full Close green light "On [J umper 51],

- check wiring and 28Vdc on FV connector,

If wiring and 28Vdc O.K. - replace concerned FV,

BOB FWD FV CMD light Off check wiring and 28Vdc power supply to the

Cockpit panel between jumper 25 and 32,

If O.K. - replace Cockpit Panel

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forced Ventilation System trouble shooting:

On the Cockpit VENT PAX or on the cabin panel VENT switch fan in low and

high speed mode (all 12 cabin gaspers open), select CREW

Note: PAX selected Cabin panel provides order to cockpit panel which

controls the cabin Fan.

1) No flow at the cabin outlets:

check power supply to the AFT fan, BOB-AFT FAN-ON

Green light On (J umper-8) and FAN CTL Yellow light

ON =High Speed order (J umper-9) ,

if o.k. (fan running) check cabin distribution ducting

connection downstream of the plenum,

no 28Vdc power supply check wiring and connection

wiring o.k. check power supply to cockpit and/or cabin

panel

Wiring o.k. replace cockpit or cabin panel

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forced Ventilation System trouble shooting cont'd:

2) "Low" flow at the cabin outlets:

a) Fan not running in high speed mode

-check High speed order to the fan, using break out box.

Reminder: Fan-On green light (Jumper-8) and Fan-CTL Yellow light (high

speed Jumper-9)

Check wiring and 28Vdc on Fan connector,

if o.k. - replace fan,

no High speed order Fan CTL Green light ON (low speed)

disconnect helicopter wiring from BOB and check if Fan CTL Yellow light

comes on (high speed)

check helicopter wiring, if O.K. - replace Cockpit panel,

PAX selected for Cabin panel check wiring and if o.k. - replace cabin panel

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forced Ventilation System trouble shooting cont'd:

2 b) Low flow and Fan running in low and high speed mode

- visually check the Flapper Valve position indicator,

- check power supply to the flapper valve which must be fully open, BOB AFT

FV-CMD green light "On"[J umper-21] and AFT FV Full-close green light Off

(J umper-55),

Check 28Vdc power supply on connector, if o.k. and valve

still closed, BOB green light "On"[J umper-55]) - replace FV

no 28Vdc power supply (BOB between jumper 25 and 32)

replace Cockpit panel,

for Cabin panel check wiring and if o.k., replace Cabin panel

c) Fan running in low and high speed mode and FV open

Attention: In A/C configuration, FV might be closed

- Look for a leakage located upstream of the plenum in the upper deck zone

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forced Ventilation System trouble shooting cont'd:

3) Flow misbalance between left and right side, (Fan running in low and

high speed mode, Flapper valve open)

- Look for a leakage located either on the plenum connection or on the manifold

and Not in the upper deck zone.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

HEATI NG

AND

VENTI LATI ON SYSTEM

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Helicopter Heating System cut off view

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Low Pressure Ducting (Vent/Heating) Cockpit view:

Flapper Valve

From Heating

System

Fan

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

I tem

Heating system Components (ventilation) 20204C010000

P/ N Qty

042

HEATINGCOCKPIT CONTROL PANEL 91104A010000

1

HEATINGCOCKPIT CONTROL PANEL - NVG 91104A010001

043 TEMPERATURE CONTROL VALVE 14422A030001 1

044 FACIAL E-SEAL J OINT 3475 4

045 Check Valve clamps 6354-100 2

046 HIGHPRESSURE DUCT Left 12771A010000 1

047 HIGHPRESSURE DUCT Right 12772A010000 1

048 HP Duct 12760A020001 2

049 HP Duct 12761A020001 1

050 1'' HP Check valve 2298A020000 2

051 Composite J et Pump 428B010000 1

052 Shut off valve 6916A020000 2

053 Heating control box 92177A020000 1

054 Duct Temperature sensor 93260A010000 1

055 OVERHEAT THERMAL SWITCH 92252A010000 1

056 Heating air inlet 9804B010000 1

057 flexible hose between 9804 &J ET PUMP 9805B010000 1

058 flexible hose downstreamthe J ET PUMP 9806B010000 1

Helicopter Heating/Ventilation System components:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

059 NOISE ATTENUATOR ASSY 9807B020000 1

060 Y BRANCH ASSY between 9807 &9810 9808B020000 1

061 between 9808 &9810 left 9809B010000 1

062 Heating distribution flexible 9810B010000 2

063 T Branche to 9892 &9893 9811B010000 2

064 Left Bwd heating diffuser 9893B010000 1

065 Right Bwd heating diffuser 9892B010000 1

066 Flexible hoses after 9810 9816B010000 2

067 T BRANCHE +flexible to SBAND 9922B010000 2

068 FLEXIBLE 9817 to 9891 9818B010000 1

069 FLEXIBLE 9817 to 9890 9819B010000 1

070 Left Fwd heating diffuser 9891B010000 1

071 Right Fwd heating diffuser 9890B010000 1

072 Left RIGIDSBANDthrough wall 9823B020000 1

073 Right RIGIDSBANDthrough wall 9824B020000 1

074 Left right balancing flexible 9825B010000 1

075 Y BRANCHE to GASPER or COCKPIT right 9826B020000 1

076 Foot GASPER holder right 9827B010000 1

077 Y BRANCHE to GASPER or COCKPIT right 9829B020000 1

078 Foot GASPER holder left 9830B010000 1

079 Heating arrival in the left cockpit - H&V 9908B010000 1

080 Heating arrival in the right cockpit - H&V 9874B010000 1

081 Connection of 9826 to COCKPIT right - common 9927B010000 1

082 Connection of 9829 to COCKPIT left - common 9875B010000 1

083 H&V - flexible between the 9874 and the 9870 &9871 9924B010000 2

084 RIGID6034 ->8013 right 9871B010000 1

085 RIGID6034 ->8013 left 9870B010000 1

Helicopter Heating/Ventilation System components:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

075 Y BRANCHE to GASPER or COCKPIT right 9826B020000 1

076 Foot GASPER holder right 9827B010000 1

077 Y BRANCHE to GASPER or COCKPIT right 9829B020000 1

078 Foot GASPER holder left 9830B010000 1

079 Heating arrival in the left cockpit - H&V 9908B010000 1

080 Heating arrival in the right cockpit - H&V 9874B010000 1

081 Connection of 9826 to COCKPIT right - common 9927B010000 1

082 Connection of 9829 to COCKPIT left - common 9875B010000 1

083 H&V - flexible between the 9874 and the 9870 &9871 9924B010000 2

084 RIGID6034 ->8013 right 9871B010000 1

085 RIGID6034 ->8013 left 9870B010000 1

Helicopter Heating/Ventilation System components:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Helicopter Heating/Ventilation System components:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Helicopter Heating/ForcedVentilation System

components:

Components of the Heating + Cockpit/ Cabin Forced ventilation

system P/ N 20204D010000

P/ N Qty

Heating + Forced ventilation COCKPIT CONTROL PANEL 91106A010000

1

Heating + Forced ventilation COCKPIT CONTROL PANEL NVG 91106A010001

CABIN fan 8012A010000 1

CABIN fan bracket 20204-21 1

Forced ventilation CABIN CONTROL PANEL 91103A010000 1

Forced ventilation CABIN CONTROL PANEL - NVG 91103A010001 1

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating System

The heating system consists of the elements described on the

following schematic and a distribution system.

ENG1

ENG2

SOV1 (1)

SOV2 (1)

TCV (4)

J P (5)

ADTS (7)

DOTS (8)

HCB (6)

CV2 (2)

CV1 (2)

BAD (3)

AMBIANT AIR

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating System

Distribution ducting:

Fan

Fan

Pedestral outlets

Front cabin diffusor Rear cabin diffusor

J et Pump

Pedestral outlets

Front cabin diffusor Rear cabin diffusor

From cockpit ventilation

From cockpit ventilation

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

The Heating Control Box and the Cockpit Panel controls and monitors the Heating

Systemaccording to the pilot demand.

An overheat protection is provided to shut off the systemif required.

Two modes are basically proposedfor the system:

Semi-automatic mode where the control box controls the blowing temperature

in accordance with the selected temperature set by the crew on the cockpit

panel.

Manual mode to insure the safety defogging mode, in case of automatic mode

failure

The Cockpit Control Panel for Heating and Ventilation System interfaces with:

- the cockpit fans (2 qty.)

- the cabin (1 qty.) and cockpit flapper valves (2 qty.)

- the Shut Off Valves ( SOV1 &SOV2 )

- the Temperature Control Valve ( TCV ) (1 qty.)

- the Heating Control Box ( HCB ) (1 qty.)

HEATING

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

The different valves of the Heating systemare supplied with hot engine

air by HP-ducts which are equipped with insulation jackets in order to

keep the skin temperature below200 C.

High Pressure Ducts and Insulation Jackets

HP Duct

12761A010001

HP Duct

12772A010000

HP Duct

12760A020001

HP Duct 12771A010000

HEATING

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

PI LOT I NTERFACES

HEATING

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

HEATING

"Heating and Ventilation system" Cockpit Control P/N91104A010000 and

Cabin Control Panel P/N 91101A010000

CONTR

PAX

CREW

HTR

SOV

NORMAL

CLOSE

OFF

AUTO

VENT

OFF

FAN

LOW

FAN

HIGH

ON

CREW

ON

PAX

1 potentiometer

2 switches

TEMP

CONTR

OFF

VENT

OFF

ON

VENT

91101A010000 or 91101A010001 (NVG)

Cabin Control Panel

91104A010000 or 91104A010001 (NVG)

Cockpit Control Panel

AUTO

MAN HTR

MIN MAX

AUTO

MAN HTR

MIN MAX

MAN

1 2

HTR

Toggle switch

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

HEATING

Cockpit Control Panel "Heating and Ventilation system" P/N91104A010000

VENT part : please refer to "Ventilation" chapter

HEATER part :

Two 2-positions toggle switches control the SOV 1+2 :

NORMAL the SOV is open or closed.

CLOSE the SOV is closed for safety reason by the crew.

The switch goes back to the NORMAL position when the 28VDC to the control

panel is switched off.

Enter

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

HEATING

A 3-positions Off, Man/Demist, Auto switch allows to select the

control mode :

OFF selected, the Heating Control Box is switched Off, both SOVs are closed.

The pilot can choose ventilation mode.

AUTO selected, the Heating Systemis in automatic mode. The pilot can choose

ventilation mode. Both SOVs are open, the HCB is switched "On", and controls

automatically the blowing temperature (only if at least one of the SOV is open). For

proper selection, the control panel sends a discrete signal, and the HCB controls the

blowing temperature by modulating the TCV according to temperature demand, which

is set by the pilot using the rotary potentiometer. The manual control of the TCV with

the HMV rotary toggle switch is hence inhibited.

MAN selected, the Heating Control Box is switched Off. The pilot can choose

ventilation mode. Both SOVs are open, and the control of the Heating Systemis done

by direct TCV motor command fromthe TEMP CONTR rotary toggle switch, which

allows to adjust manually the blowing temperature.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

HEATING

A Rotary Potentiometer :

When HTR AUTO is selected, the potentiometer controls via the Heating

Control Box the Temperature in cabin and cockpit.

When OFF or MAN is selected, the potentiometer has no function.

A TEMP CONTR Rotary Toggle Switch :

When AUTO or OFF is selected, the Rotary Toggle Switch has no

function.

When MAN is selected, the Rotary Toggle Switch controls directly the

TCV, left position (-) for closing and right position (+) for opening.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

HEATING

Heating and Forced Ventilation system Cockpit Control P/N 91106A010000 and

Cabin Control Panel P/N 91103A010000

CREW CLOSE

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Cockpit Control Panel Heating and Forced Cabin Ventilation system

VENT part : please refer to "Ventilation" description

HEATER part : please refer to previous Heating and Ventilation system

description

HEATING

Enter

Enter

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

SYSTEM CONTROL

HEATING

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Cockpit panel functions, Ventilation/Heating system:

(VENT CTRL " CREW" selected)

Control Cockpit fans (off/low/high),

Control Cockpit and Cabin Flapper Valves*,

Control Shut Off Valve SOV 1+2 opening/closing (in Man and Auto

mode),

Control Temp Control Valve TCV opening/closing (in Man mode by

the Temp. Contr. RotaryToggle Switch),

Control Heating systemControl Box HCB on/off,

Provides Cockpit/Cabin zone temperature demand signal to the HCB

(potentiometer).

*With VENT CTRL " PAX" selected on the cockpit control panel the

cabin panel control the cabin flapper valve.

HEATING SYSTEM CONTROL

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Cockpit panel functions, Heating and Forced Ventilation

system: (VENT CTRL " CREW" selected)

Control Cockpit and CABIN fans (off/low/high)*,

Control Cockpit and Cabin Flapper Valves*,

Control Shut Off Valve SOV 1+2 opening/closing,

Control Temp Control Valve TCV with toggle switch ("MAN" mode)

Control Heating systemControl Box HCB On/Off,

Provides Cockpit/Cabin zone temperature demand signal to the HCB

(potentiometer).

*With VENT CTRL " PAX" selected on the cockpit control panel the

cabin panel control the cabin flapper valve and the cabin fan.

HEATING SYSTEM CONTROL

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Cockpit

panel pin

location:

HEATING SYSTEM CONTROL

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

HEATING SYSTEM CONTROL

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system Control Box HCB functions:

Monitoring of the External Air Temperature Sensor EATS,

Monitoring of theAir Duct Temperature Sensor ADTS,

Monitoring of the Duct Overheat Thermal Switch DOTS,

Monitoring the Shut Off Valves - SOV 1 +2 which are controlled by the

Cockpit Panel,

Control of the Temperature Control Valve TCV (inAuto mode)

Memorizing the EATS, ADTS, DOTS and the Temp. Control fault

message,

Triggering HTR-Failure.

HEATING SYSTEM CONTROL

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Det ai l ed Oper at i on

Heat i ng Syst em

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system operation:

Added to the cockpit and cabin ventilation system, this configuration includes the

heatingfunctions which consists of the elements shown here below.

The Heating Control Box and the Cockpit Control Panel control the proper function

of the heating systemand provides alarmand overheat protection.

The basic heating systemuses bleed air fromthe compressor discharge port of

each engine. The bleed flow is limited down to 2% of the total air flow of each

engine by restrictions.

The bleed air is routed fromeach engine port to a Shut-Off Valve (1). Check valve

(2) avoids any back flowfromone engine to the opposite engine.

ENG1

ENG2

SOV1 (1)

SOV2 (1)

TCV (4)

J P (5)

ADTS (7) DOTS (8)

HCB (6)

CV2 (2)

CV1 (2)

BAD (3)

AMBIANT AIR

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system cont'd

Via the Bleed Air Tubes BAD (3), hot engine air under high pressure is

routed to the Temperature Control Valve (4) which controls the quantity of

bleed air to be mixed in the J et Pump (5) with the air outside ambient air.

An additional injector which by-pass the TCV enables the heating system

operation with outside ambient conditions up to 15 C in case of TCV

malfunction .

The mixed airflow is controlled by the Heating Control Box (6) by

comparison between the blowing temperature measured by the Air Duct

Temperature Sensor (7) and the selected temperature, given by the

Cockpit Control Panel potentiometer(9).

In case of overheat non-detected by this sensor, the Duct Overheat

Temperature Switch (8) closes directly the shut-off valves.

The Shut-Off Valves and the Temperature Control Valve can also be

controlled manually by the pilot via the Cockpit Panel (9).

The mixed air is ducted to the delivery distribution ducts (10).

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating System Architecture:

COCKPIT

PANEL

Air Duct

Temp

Sensor

Duct Overheat

Thermal Switch

AFT

-

FV

FWD

-

FV

TCV

SOV1

SOV2

FWD

-

FAN1

AFT

-

FAN2

FWD

-

FAN2

+28 Vdc2

0 Vdc2

+28 Vdc1

0 Vdc1

+ 5 Vdc DIMMING

0 Vdc DIMMING

HEATING

CONTROL

BOX

+28 Vdc1

0 Vdc1

+ 5 Vdc DIMMING

0 Vdc DIMMING

1

Heater Failure

5

Heater on

Forward ventilation on

After ventilation on

Ventilation Failure

ADTS

DOTS

* see acronyms in appendix 1

+28 Vdc2

0 Vdc2

+28 Vdc2

0 Vdc2

Maintenance

connector

Ext. Air

Temp

Sensor

EATS

HELICOPTER

AFT

-

FAN1

*

provision for

ECS

configuration

Provision

for forced

ventilation

*

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating System Architecture:

J01 J01

M

+

-

TCV

J02 J02

TEMP. SENSOR 1

TEMP. SENSOR 2

THERMAL SWITCH

M

+

-

FV 1

M

+

-

FV 2

SOV 2

SOV 1

Hi speed

Lowspeed

FWD FAN 1

Hi speed

Lowspeed

FWD FAN 2

+28 Vdc

GND +28 Vdc

COCKPIT

PANEL

HEATER

CONTROL BOX

+28 Vdc

+28 Vdc

+28 Vdc

+28 Vdc

Hi speed

Lowspeed

AFT FAN

+28 Vdc

+28 Vdc

+28 Vdc

+28 Vdc

A

B

4

3

1

2

A

B

A

B

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating System Architecture:

Temp - CTL1 - SIG

Temp - CTL1 - SUP

Temp - CTL1 - REF

AFT - FAN - CTL

AFT - FAN - ON

FWD - FAN - CTL

FWD - FAN - ON

AFT - FV - CMD - H

AFT - FV - CMD - L

FWD - FV - CMD - H

FWD - FV - CMD - L

A UTO - HTR - SEL

FWD FAN 1

FWD FAN 2

M

A FT FV

M

FWD FV1

HCB

HCB

12

10

11

41

8

9

+28 Vdc1

55

15

16

51

21

22

6

23

24

7

11

7

28

12

4

3

5

4

3

5

6

6

48

49

Selection and Speed

Control

M

F

D

Selection and Speed

Control

M

D

F

B

E

A

B

E

A

HELICOPTER

43

HTR Failu re

EATS

2

3

3

4

AFT FAN1

Selection and Speed

Control

M

A

F

D

B

C

0 Vdc1 TEMP_CONTR

OFF

MAN

V PWR2

HTR

AUTO

V

PWR1

HIGH

LOW

ON

OFF

HIGH

LOW

ON

OFF

PAX

V

PWR1

HIGH

LOW

ON

OFF

HIGH

LOW

ON

OFF

CREW

HIGH

LOW

ON

OFF

HIGH

LOW

ON

OFF

PAX/CREW

V

PWR1

HIGH

LOW

ON

OFF

HIGH

LOW

ON

OFF

PAX/CREW

V

PWR1

AFT FAN2

Selection and Speed

Control

M

A

F

D

B

C

0 Vdc1

HELICOPTER

46

44

+28 Vdc2

0 Vdc2

45

J 01

J 01

M

FWD FV2

4

3

5

6

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating System Architecture:

V

PWR2

H TR

SOV1 - CMD

SOV2 - CMD

AFT - VENTILATION

+5 Vdc

DIMMING

FWD - VENTILATION

SOV1 - ON

SOV2 - ON

0 - 5v

LAMPS

cc protection

0 Vdc1

+28 Vdc1

V

PWR1

SOV 1

SOV 2

V

PWR2

LOGICS

0 Vdc

DIMMING

FWD

-

FAN1

-

FAULT

FWD

-

FAN2

-

FAUL T

VENT - FAILURE

TCV

HCB

A

B

A

B

SOV1

SOV2

C

FWD

-

FAN1

E

AFT

-

FAN 1

C

FWD

-

FAN2

HELICOPTER

3

39

38

2

53

29

54

30

48

34

49

35

44

50

25

32

40

47

15

34

40

14

9

36

DOTS

B

A

3

1

2

5

6

ADTS

37

5

TCV

-

CMD

-

OPEN

-

OUT

TCV

-

REF

TCV

-

CMD

-

CLOSE

-

OUT

TCV

-

CMD

-

OPEN

-

IN

TCV

-

CMD

-

CLOSE

-

IN

Sp eed

option

4

8

TCV

-

FC

36

CASE GND

33

Heater on

0 Vdc2

31

20

26

+28 Vdc2

V

PWR2

SOV1

-

ON

SOV2

-

ON

3

1

2

TCV

-

FC

TCV

-

FO

M

CLOSE

NORMAL

CLOSE

NORMAL

HTR

AUTO/MAN

O FF

AUTO/MAN

OFF

SOV1

AUTO/MAN

OFF

AUTO/MAN

OFF

SOV2

CLOSE

NORMAL

CLOSE

NORMAL

+

+

-

-

AUTO

AUT O

MAN/OFF

MAN/OFF

AFT - FAN1 - FAULT

43

E

AFT

-

FAN 2

MAINTENANCE

CONNECTOR

8 9 13 7 5 4 6 12

17 18 26 10 37 50 38 39

J 01

J 01

* Forced ventilation configuration

* ECS configuration

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HCB - Control Principale:

System control is achieved by an analog closed loop.

The loop controls the temperature by comparing a reference which is

set by the pilot with the real temperature measured by the

Temperature Sensor.

The error thus obtained via un internal logic drives the Temperature

Control Valve, taking care to avoid excessive overheating of the

Heating Ducts.

The comfort in the cabin is adjust by the pilot who adapts the blowing

temperature as a function of outside conditions, thermal loads in the

cabin, etc...

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating/Ventilation System Logic

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Forward Ventilation :

+ If cockpit fans are operating, then the control panel sends the " Forward

Ventilation On " discrete signal to the helicopter general displayer (MAU).

After Ventilation :

+ If cabin fan is operating, and cabin flapper valves are not fully closed; then

the control panel sends the " After Ventilation On " discrete signal to the

helicopter general displayer (MAU).

Ventilation Failure:

+ If AFT-FAN-FAULT is active or FWD-FAN1-FAULT is active or FWD-

FAN2-FAULT is active , then the control panel sends the " Ventilation Failure

" discrete signal to the helicopter general displayer.

Heating system

Heating/Ventilation System Logic Description:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating/Ventilation System Logic Description cont'd:

Ventilation Failure:

+ The Cockpit and cabin flapper valves even failed closed are NOT triggering the

Ventilation failure.

Heater On:

+ If SOV1 open command is active or SOV2 open command is active; then the

control panel sends the " Heater On " discrete signal to the helicopter general

displayer.

Heater Failure:

+If DOTS is open ( T 85 C ) , or regulated temperature is incorrect and HTR

selected, or others electronic conditions as EATS broken (open circuit) and Temp.

Potentiometer defect (open circuit); then the HCB sends the " Heater Failure "

discrete signal to the helicopter general displayer.

Nota: Air COND selection is associated to three additional signals (Forward

Ventilation On, After Ventilation On and NO Ventilation Failure).

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HCB Logic Functions:

OHEATER-Failuresignal is sent to Modular Avionic Unit

(MAU):

+if [(SOV1 is open or SOV2 is open) and (Duct Overheat Thermal Switch

(DOTS) is active then the " Heater Failure " discrete signal shall be sent to

the helicopter general displayer (MAU).

+if { [HTR is selected and (SOV1 is open or SOV2 is open)] and [(Duct

temperature sensor is in open circuit or External temperature sensor is in

open circuit or potentiometer is in open circuit)] } then the " Heater Failure "

discrete signal shall be sent to the helicopter general displayer (MAU).

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HCB - TCV control logic:

- if { [HTR is selected and (SOV1 is open or SOV2 is open)] and [fault

conditions are all inactive] then (TCV power stage is controlled

according to PWM signal and error sign signal) else wise (TCV power

stage is activated at maximum speed to close TCV).

The HCB close Flapper Valves with following logic:

- AFT FV and FWD FV power stages are activated during at least 15

seconds to close both Flapper Valves after HTR selection

(independently of SOV status)

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HCB Failure Logic:

OTo memorized following failures for maintenance operation:

- Duct Overheat Thermal Switch (DOTS) has been activated more than 8

seconds in automatic heater mode.

- External Air Temperature Sensor (EATS) has been during 15 seconds in open

state permanent condition in automatic heater mode.

- Air Duct Temperature Sensor (ADTS) has been during 15 seconds in open

state permanent condition in automatic heater mode.

- Temperature selection potentiometer (CTL1 FAULT) has been during 15

seconds in open state permanent condition in automatic heater mode.

NOTA : Memorized fault signals must be read and reseted using Special

Failure read-out Box 92599A010000.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HCB ANALOG FUNCTIONS

- To limit maximumduct air temperature to T max : 72.5 C +/- 2.5 C.

- To make temperature reference acquisition on 10 K potentiometer with +/- 2%

accuracy. Complete potentiometer range is corresponding to -10 C/90 C including

failure analysis.

- To make temperature acquisition on EATS (-50 C to 50 C) and on ADTS (-10 C

to 90 C) including failure analysis.

-To regulate duct air at selected temperature 5 C in normal automatic conditions,

in function of External Air Temperature Sensor ( EATS ) using PWM motor drive on

TCV actuator.

Regulationlaw:

T regulation=T external +alfa(T

selected

) +(40 C +/-5 C) if T regulation <T max

- HCB failure detection logic for temperature sensor and potentiometer:

Potentiometer open circuit: temperature reference >85 C

Sensor open circuit: external temperature >45 C or duct temperature >80 C

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

TEMPERATURE

CONTROL1

FAULT

MODUL

ADTS

DOTS

TCV OPEN

AUTO-HTR-

SEL

HTR-FAILURE

FAULT

MEMORY

DOTS

FAULT

MODUL

ADTS

FAULT

MODUL

EATS

EATS

FAULT

MODUL

CTL1

FAULT

MODUL

TEMPERATURE

CONTROL1

SOV1 ON

TCV CLOSE

SOV2 ON

OR

AND

+

- 0,5

-

ADTS

PID

PWM

MODUL

TCV-FC

TCV

CONTROL

MODUL

FV

CONTROL

MODUL

AFT-FV-

CLOSE

FWD-FV-

CLOSE

FAULT-READ

FAULT-RESET

FAULT-TEST

EATS

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Ventilation System

Heat i ng Syst em

Mai n Component

desc r i pt i on

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

92177A020000

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating Control Box 92177A020000:

The HCB drives the Heating system. It monitors the sensors and warns the

crewwhen a fault occurs.

The Electronic Control Box is an analog & logic array card fitted inside a

metallic housing.

The following equipments are interfacing with the HCB:

- Temperature Sensors ADTS (PT1000) and EATS (PT500 supplied by

Augusta) ,

- Potentiometer (Cockpit Panel - 10 K ),

- Thermal Switch DOTS,

- Cockpit Control Panel (ventilation/air-conditioning selected/available),

- Modular Avionic Unit ( MAU for failure triggering),

- Temperature Control Valve control via Cockpit Control Panel .

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Helicopter harness Maintenance connector

using Test box 92599A010000:

- memorised failure/s is/are sent on the maintenance bus and can be

indicated on the Test Box,

Heating Failure read

out box Flow chart

Heating Failure read

out box cont.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating Control Box HCB general view:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating Control Box Pin Location:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Heating Control Box Pin Location:

TWO TW From EATS

To

Maintenance

Connector

PIN ITEM TYPE NOM. / MAX

CURRENT

WIRE FROM / TO

2 EATS- SIG Analog Input 5 / 10 mA

3 EATS- REF Analog Input 5 / 10 mA SH CORE

17 ADTS-FAULT 5v / OC 2 / 10 mA SINGLE CORE

18 CTL1-FAULT 5v / OC 2 / 10 mA SINGLE CORE

26 TS-FAULT 5v / OC 2 / 10 mA SINGLE CORE

10 EATS-FAULT 5v / OC 2 / 10 mA SINGLE CORE

37 FAULT-RESET 5v / OC 2 / 10 mA SINGLE CORE

50 FAULT-TEST 5v / OC 2 / 10 mA SINGLE CORE

38 FAULT-READ 5v / OC 2 / 10 mA SINGLE CORE

39 ENABLE 5v / OC 2 / 10 mA SINGLE CORE

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Shut Off Valve SOV 6916A020000:

Function:

The valve shuts off the engine hot air supply of the high pressure bleed ducting

when heating is not selected by the pilot or forbidden for safety reasons.

The valve is a fail safe component (in close position).

Description:

The shut-off valve is a solenoid operated in-line valve. A piston acting as a valve

displaces inside a cylinder, machined in a 1inch diameter body.

The piston is kept at rest against its seat by a spring.

When energized, the solenoid vents air from the valve servo-chamber, thus

causing piston to open. Valve remains open as long as solenoid is energized.

When solenoid is de-energized, puppet valve shuts vent port and opens pressure

port, compressed air through a filter pushes piston against the seat to close

position.

Piston rings avoid too large internal leakages.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Shut Off Valve - SOV

Characteristics:

Nominal power supply: 28 Vdc

Current consumption: 0,4 A

Opening /closing time 3 s / 4 s

Operating pressure min/max: 0,7 bar/15 bar

Normal operating temperature: 403 C up to max. 436C for a short time

Surrounding temperature: -40C to +150C up to max. 180C

Storage temperature: -55C to + 85C

Weight: 1100 g

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Shut Off Valve - SOV Pin Location (idem for SOV2):

Overall view:

(GND)

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

High Pressure Check Valve 2298A020000:

It prevents the potential one engine discharge towards the other in case of

strong pressure misbalance (one engine off, lower engine rate) between

the 2 engines.

The check valve with a 1 inch diameter, is a non return valve connected to

the bleed ducting branch close to the engine port. This is a double flap

stainless steel check valve.

Similar check valves are already used on J aguar, Tornado and Eurofighter

Aircraft.

Characteristics:

Normal operating temperature (short time): 231C (270C) up to 403C (436C)

max.

Ambient temperature: -40C to +130C

Storage temperature: -55C to +85C

Weight: 50g

Internal leakage closed in non return position: <1 g/mn at 8 bar

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HP - Check Valve general view:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Temperature Control Valve TCV 14422A030001:

Function:

The temperature control valve is driven either by the pilot in Manual or by the

HCB in Automode.

It modulates the amount of hot air to be injected in the jet pump to control the

heatingtemperature for the cockpit and cabin zone.

Description:

The temperature control valve body, is a cylindrical carbon plug valve with stainless

"1" inch steel body.

It is driven by an electric actuator mounted on an insulated base to limit the thermal

conductiontowards the actuator.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Temperature Control Valve TCV:

Description cont'd:

The valve is composed of :

a stainless steel body with machined female ports,

a cylindrical carbon plug,

a shaft which transmits the rotational movement of the plug by a tenon-

mortise type drive,

a spring washer which pushes the plug and the shaft onto the seal,

a cap to maintain the spring.

The tightness at the bearing is ensured by a seal.

The tightness on the cap is ensured by the lip which is an integral part of the cap.

An electrical heating muff covers the valve body and is automatically supplied by

28Vdc in case of sub-zero temperatures.

Two thermo switches control the electrical supply of the heater.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Temperature Control Valve - TCV:

Characteristics:

Nominal supply voltage : 28 VDC (limit 17 Vdc to 32 Vdc)

Current consumption : < 0.6 Amp (1.8 Amp with heating)

Maximum operating pressure : 12.7 bar

Maximum operating temperature : 436 C

Ambient operation temperature : - 40 C to + 130 C

Opening, closing time : 4 s

Internal leakage under 12 bar rel. pressure: < 12 l/mn

Weight: 700 g

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Temperature Control Valve 14422A030001 TCV

general view:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Temperature Control Valve Pin Location :

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Jet Pump 428B010000:

Function:

The jet pump is the heating systemhot air generator.

It produces a hot air flowusing temperature and pressure of engine bleed air.

The expansion of bleed air at high pressure and temperature through the injector

sucks and warms up a large amount of outside fresh air.

The generated hot air flowis therefore a mixture of extremely hot engine bleed air

and external fresh air.

Bleed flow

Outside fresh air Mixed air

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Jet Pump:

Description :

A Composite Mixing Unit (a venturi and a mixing chamber in one

assy)

A twin stainless steel Injector

An insulation plate installed between Mixing unit and Injector

The main components of the J et Pump are:

The jet pump provides sufficient heat to cockpit and cabin using HP engine

bleed air (maximum2%of each engine).

A tube directly connected to the injector of the J et Pump, by-passes the TCV

if failed closed. This ensures a minimumtemperature of 18 C and provides

comfort to the cockpit and cabin within the full flight envelop:

Altitude [0-20000ft] , External temperature [-40,+50 C]

The calculated heat power of the jet pump is 13 kW.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Jet Pump:

Characteristics:

Maximum operating pressure - Mixing Unit: 0,1 bar above atmosphere

Maximum operating pressure - Injector: 12.0 bar

Maximum operating temperature - Mixing Unit: 85 C (short time 120 C)

Maximum operating temperature - Injector: 403

Max. short time operation temperature: 436 C

Mixing Unit flow rate: 500 g/s

Injector flow rate: 170 g/s

Ambient operation temperature : - 40 C to + 85 C

Weight: 0,9 Kg

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

Jet Pump general view:

Mixing Unit

Injector

By-pass tube

ADTS location

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HP Ducts & Insulation Jackets:

- the engine compartment for P/N 12758A010000and 12759A010000

- the tail rotor compartment for P/N 12760A010001and 12761A010001

Functions:

The high-pressure ducting is used to supply air fromthe two engines bleed

ports to the jet pump.

It interfaces with the shut off valves, the check valves and the temperature

control valve.

The ducting crosses the upper deck firewall and 2 different parts of the

helicopter:

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HP Ducts & Insulation Jackets:

Description:

P/N 12758A010000 & 12579A010000

Flexible hoses located in the engine compartment. The hose will

compensate engine displacement and vibration.

The duct is connected

- to the engine ports with an orifice plate to limit the bleed flow to 2% of

the total engine flow

- to the shut off valves

P/N 12760A010001

Rigid duct located underneath the engine department connected to the shut off

valves through a SM coupling and including the support flange of the check valve.

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HP Ducts & Insulation Jackets cont'd:

Description:

P/N 12761A010001

Rigid duct located underneath the engine compartment including a Tee

junction and a flexible hose to compensate thermal growth and pressure

loads. The duct is connected to the Temperature control valve and

includes the check valves supporting flanges.

Maximum operating condition: 12 bar at 230 C or short time 11,7 bar at

436 C

HP Duct

12761A010001

HP Duct

12758A010000

HP Duct

12760A010001

HP Duct 12759A010000

AB 139

LIEBHERR-AEROSPACE Toulouse Dez. 2003 TECHNICAL SERVICES

Training DOCTR 039

Heating system

HP Ducts & Insulation Jackets:

The ducts located underneath the engine compartment (P/N 12760A01 &