Академический Документы

Профессиональный Документы

Культура Документы

Steel Stanchion Design Calcsheet v.0

Загружено:

Olusegun S. AjibolaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Steel Stanchion Design Calcsheet v.0

Загружено:

Olusegun S. AjibolaАвторское право:

Доступные форматы

Project:

segzyajibola@yahoo.com

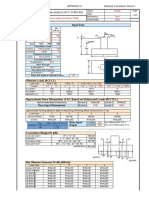

Structure: TYPICAL STANCHION REF BS5950-1 [2000] CALCULATIONS Design Axial load, F = Eccentricity of axial load,e = Moment due to continuity,M= Segment length along x-x = Segment length along y-y = Try: 305 D = B = t = T = b/T = d/t = 55 0 45 7 3 kN mm kNm m m kg/m (Compression) (Min. ecc. for simple connection =

Job Ref: Date: Sheet No: Made by: Checked by:

1 Segun

OUTPUT

253mm)

x 165 x 46 306.6 mm 165.7 mm 6.7 mm 11.8 mm 7.02 39.6

UB rxx = ryy = Zxx = Zyy = Sxx = Syy =

130 mm 39 mm

6.46E+05 mm 1.08E+05 mm 7.20E+05 mm 1.66E+05 mm

3 3 3 3

d = u = x = H = A =

265.2 mm 0.891 27.1 0.195 5870 mm2

Section Classification (for local buckling) (i) Flange Table 9 Table 11 Table 11 With t = 11.8mm , Design strength,Pyf = 1 9 Flange section is Plastic (i) 275 N/mm2 = (275/Py)1/2 = Limiting width-thickness ratio b/t = 7.02 (ii) Web Table 9 Table 11 With t = 6.7mm , Design strength,Pyw = 275 N/mm2 = (275/Py)1/2 = 1 Checking for web 'generally' because of shift in neutral axis due to combined axial and moment, Stress ratio r1 = Fc dtPyw 0.1126 where -1 < r1 1 (ri is -ve for tensile force) Fc AgPyw 89.8828 85.6 = 0.0341 40 71.9063 85.555 112.34 39.6 80/1+r1 Web section is Plastic (ii)

r1 = Stress ratio r2 = r1 d/t = (a) Local Capacity Check F AgFy

Table 11

4.8.3.2.a

Mx Mcx

My Mcy

2

4.2.5.2

4.8.3.2.a

Design strength,Py = 275 Moment due to ecc. Me = 0 Design moment,Mx = 45 Mcx = PySx < = 198 kNm Ignoring minor axis moment (My) F + Mx AgFy Mcx 55 + 45 1614.25 198

N/mm kNm kNm 1.2PyZx 213.2 = 1 0.261

For Plastic Sections

(Low Shear)

<

OK

Project:

segzyajibola@yahoo.com

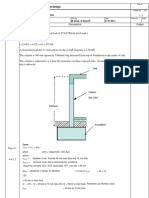

Structure: STANCHIONS REF 4.8.3.3.1 (b) Overall Buckling Check Fc Pc Table 22 + mxMx Mb 0.85 L = = = = 0.85 L = = = = = Ag x pc = + myMy PyZy 5.95 m LEX/rx 45.77 1 CALCULATIONS

Job Ref: Date: Sheet No: Made by: Checked by:

1 Segun

OUTPUT

Effective length,LEX = Slenderness about major axis, x Using strut curve 'a', <110, Compressive strength,pc Effective length,LEY = Slenderness about major axis, y Using strut curve 'b', <110, Compressive strength,pc Design compressive strength,pc Compressive Resistance,Pc=

<

2

180

Table 23 Table 24 Table 22

255 N/mm 2.55 m LEy/ry 65.38

<

180

Table 23 Table 24

212 N/mm2 212 N/mm2 1244 kN m = 45 kNm 0.6

Table 18

4.3.7

Since the column end is pinned, =0 Design moment Mx = For equal flange rolled section, Slenderness ratio for Mb, = W x LE/ry Where W = 1 for plastic section = 65.385 With D/T = 25.9831 Buckling strength,pb = Buckling res. Moment,Mb = Since My = 0, Fc Pc 0.044197 + + mMx Mb 0.1667 = 1

Table 20 4.3.7

225 N/mm2 pb x Sx (Plastic section) = 162 kNm

0.2

<

OK

Вам также может понравиться

- Water Station BOMДокумент3 страницыWater Station BOMrhob24100% (1)

- Introduction of Detailed Design of Main Bridge (For Project)Документ30 страницIntroduction of Detailed Design of Main Bridge (For Project)taufiqrochmОценок пока нет

- Architects' Perspectives On Construction Waste Reduction by DesignДокумент12 страницArchitects' Perspectives On Construction Waste Reduction by DesignMuhammad NaeemОценок пока нет

- Lifting Lug Weld DesignR1aДокумент1 страницаLifting Lug Weld DesignR1aJohnclaude ChamandiОценок пока нет

- Design Base Plate For I Beam - Bottom BracketДокумент1 страницаDesign Base Plate For I Beam - Bottom BracketCon CanОценок пока нет

- Purlin SoleroДокумент1 страницаPurlin SoleroJoseph Cloyd L. LamberteОценок пока нет

- R D H W FW: Design of Tailing LugДокумент2 страницыR D H W FW: Design of Tailing LugvpjagannaathОценок пока нет

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureДокумент2 страницыWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- Chimney Calculation SheetДокумент14 страницChimney Calculation SheetSrinivasa Rao VenkumahanthiОценок пока нет

- Steel Beam DesignДокумент36 страницSteel Beam DesignTan Choon LengОценок пока нет

- Platform Cleat CalculationДокумент1 страницаPlatform Cleat Calculationmiteshpatel191Оценок пока нет

- Crimp PLTДокумент5 страницCrimp PLTSai SushankОценок пока нет

- Design of Ring Girder SupportДокумент3 страницыDesign of Ring Girder Supportvishal guptaОценок пока нет

- SMHB SDN BHD: Jurutera PerundingДокумент5 страницSMHB SDN BHD: Jurutera PerundingAnonymous D8aZCZ98Оценок пока нет

- Lifting Lug CalculationДокумент2 страницыLifting Lug Calculationmih1Оценок пока нет

- CorbelДокумент5 страницCorbelBharathi ThadigotlaОценок пока нет

- Cdo CalcДокумент3 страницыCdo CalcJeric FarinОценок пока нет

- Rectangular Tanks:: Rectangle Tank DesignДокумент23 страницыRectangular Tanks:: Rectangle Tank Designshna jabarОценок пока нет

- WE-5-2 Fin Plate ConnectionДокумент10 страницWE-5-2 Fin Plate ConnectionPedro AlmeidaОценок пока нет

- Master Foods 12 MДокумент16 страницMaster Foods 12 MSarfarazОценок пока нет

- Isolated Footing 277Документ60 страницIsolated Footing 277Affan Alam100% (1)

- Ldo Storage Tank Calculation 170Документ6 страницLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Calculation Trunion (By Maniacs)Документ5 страницCalculation Trunion (By Maniacs)SyahkullahОценок пока нет

- Slot Expansion CalculationДокумент1 страницаSlot Expansion CalculationSarfaraz KhanОценок пока нет

- Design - of - Steel - Structure-I PDFДокумент54 страницыDesign - of - Steel - Structure-I PDFNi Mesh100% (1)

- Beam Simply SupportedДокумент16 страницBeam Simply SupportedVengatesh HariОценок пока нет

- API650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146Документ11 страницAPI650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146nassmechОценок пока нет

- X - Direction: Seismic Analysis Rectangular TankДокумент11 страницX - Direction: Seismic Analysis Rectangular Tanksubzarbhat87Оценок пока нет

- Design of Floor Plate: Case - I: Blanket Live Load of 5 KN/M + Max. Accln. (Ulsa)Документ31 страницаDesign of Floor Plate: Case - I: Blanket Live Load of 5 KN/M + Max. Accln. (Ulsa)shadab521Оценок пока нет

- Tailing Lug - 173004-05Документ1 страницаTailing Lug - 173004-05shazan100% (1)

- API 650 Tank Nozzle Stand OutДокумент5 страницAPI 650 Tank Nozzle Stand Outtry&try100% (1)

- Shear Design of A Hollow Core SlabДокумент17 страницShear Design of A Hollow Core SlabjrandeepОценок пока нет

- Isoloated Footing DesignДокумент7 страницIsoloated Footing Designvijay moreОценок пока нет

- Design of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)Документ3 страницыDesign of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)sivaОценок пока нет

- Water Tank Load CalculationДокумент2 страницыWater Tank Load CalculationyarmeenaОценок пока нет

- Output Calculation & Formulas: Done byДокумент6 страницOutput Calculation & Formulas: Done byAddrien Daniel100% (1)

- Atasehir Gardens Podium OF: Member: LocationДокумент7 страницAtasehir Gardens Podium OF: Member: LocationklynchelleОценок пока нет

- Seismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameДокумент34 страницыSeismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameEmmanuel LazoОценок пока нет

- Wind Speed Calculation As Per SP-1275Документ7 страницWind Speed Calculation As Per SP-1275Siva baalanОценок пока нет

- Calculation Sheet: Form ESTD/F/0036C of Job/ Work Order No. DateДокумент21 страницаCalculation Sheet: Form ESTD/F/0036C of Job/ Work Order No. Datesinu_emailОценок пока нет

- Heat ExchangersДокумент30 страницHeat ExchangersvpjagannaathОценок пока нет

- Steel Column DesignДокумент4 страницыSteel Column DesignEly Jane DimaculanganОценок пока нет

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Документ2 страницыEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingОценок пока нет

- 4 - PFC To Hanging Plate ConnДокумент13 страниц4 - PFC To Hanging Plate Connabdul khaderОценок пока нет

- Steel Connections v1.3Документ83 страницыSteel Connections v1.3Mateus GehlenОценок пока нет

- Design of Wind Pressure of SiloДокумент1 страницаDesign of Wind Pressure of SilosrinivasОценок пока нет

- Sfex Pad Eyes Calculations 35T - 32MMДокумент1 страницаSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaОценок пока нет

- SteelSpan MADДокумент6 страницSteelSpan MADAnonymous pD2ymRUguОценок пока нет

- Stability CritariaДокумент9 страницStability CritariaAbu Bakar Siddke RumiОценок пока нет

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Документ9 страницDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KОценок пока нет

- Design Calculations of Storage Tank: According To API 650 Code, 11 EditionДокумент3 страницыDesign Calculations of Storage Tank: According To API 650 Code, 11 EditionAkash Kazama100% (1)

- Welded Connection 1Документ2 страницыWelded Connection 1engineeringyusufОценок пока нет

- Isolated FootingsДокумент12 страницIsolated FootingsGovendan GopalakrishnanОценок пока нет

- Design of Plate GirdersДокумент30 страницDesign of Plate GirdersTHULASI MОценок пока нет

- API 650 Pipe Column DesignДокумент4 страницыAPI 650 Pipe Column DesignJoselito CalagosОценок пока нет

- Moment Baseplate Design Rev. 0Документ3 страницыMoment Baseplate Design Rev. 0Bok MortegaОценок пока нет

- Concrete DesignДокумент169 страницConcrete DesignabuzahrauОценок пока нет

- Baseplate Biaxial MZДокумент26 страницBaseplate Biaxial MZD SRINIVAS100% (1)

- Column and Foundation DesignДокумент12 страницColumn and Foundation DesignMohafisto SofistoОценок пока нет

- Steel Beam Design Calcsheet v.0Документ4 страницыSteel Beam Design Calcsheet v.0Olusegun S. Ajibola100% (1)

- Combined FDN ColumnДокумент21 страницаCombined FDN ColumnGautam SharmaОценок пока нет

- Durabilty and Fire ResistanceДокумент6 страницDurabilty and Fire ResistanceMohafisto SofistoОценок пока нет

- Base Plate DesignДокумент1 страницаBase Plate DesignOlusegun S. AjibolaОценок пока нет

- Base Plate DesignДокумент1 страницаBase Plate DesignOlusegun S. AjibolaОценок пока нет

- Base Plate DesignДокумент1 страницаBase Plate DesignOlusegun S. AjibolaОценок пока нет

- Steel Beam Design Calcsheet v.0Документ4 страницыSteel Beam Design Calcsheet v.0Olusegun S. Ajibola100% (1)

- Design of Flexural MembersДокумент10 страницDesign of Flexural MembersOlusegun S. Ajibola100% (1)

- Index For Safe Work Method Statements (CIVIL/FIT-OUT WORK)Документ2 страницыIndex For Safe Work Method Statements (CIVIL/FIT-OUT WORK)Ranjan KumarОценок пока нет

- Masonry Support Systems & Lintels: For The Construction IndustryДокумент36 страницMasonry Support Systems & Lintels: For The Construction IndustryTarun SebastianОценок пока нет

- Equivalents of Carbon Steel QualitiesДокумент10 страницEquivalents of Carbon Steel Qualitiesibson045001256Оценок пока нет

- Shell Flintkote 3: Product Technical Data SheetДокумент3 страницыShell Flintkote 3: Product Technical Data SheetAhmed TahsinОценок пока нет

- Knauf Cinema BrochureДокумент30 страницKnauf Cinema BrochureLujain YousefОценок пока нет

- 11 - Concrete Flexural DesignДокумент20 страниц11 - Concrete Flexural Designleona Grace MendozaОценок пока нет

- Project Presentation With GUETДокумент22 страницыProject Presentation With GUEThavel keysanОценок пока нет

- DCS Ii PDFДокумент7 страницDCS Ii PDFDinesh PatilОценок пока нет

- Waffle Slab - WikipediaДокумент15 страницWaffle Slab - WikipediaBryan PongaoОценок пока нет

- Important TopicsДокумент20 страницImportant TopicswweretОценок пока нет

- Conversion CycleДокумент40 страницConversion CycleKelvin CaldinoОценок пока нет

- ICE UK Specification For Ground Investigation - IntroДокумент13 страницICE UK Specification For Ground Investigation - IntroWhiskoОценок пока нет

- Building Technology 01: Steel Mesh Hexaflumuron Hexaflumuron TermiticideДокумент27 страницBuilding Technology 01: Steel Mesh Hexaflumuron Hexaflumuron TermiticideCollado Noel DivinaОценок пока нет

- Bordo Steel ConstructionДокумент9 страницBordo Steel ConstructionEngineering ComillaОценок пока нет

- GB 50204-2002 Code For Acceptance of Construction Quality of Concrete Structuress. Part 2Документ46 страницGB 50204-2002 Code For Acceptance of Construction Quality of Concrete Structuress. Part 2Dilnesa EjiguОценок пока нет

- 175X175 RC Piles PDFДокумент2 страницы175X175 RC Piles PDFSiva JaseОценок пока нет

- 10 Advantages of Precast Structures - Steel Construction DetailingДокумент12 страниц10 Advantages of Precast Structures - Steel Construction Detailingsarre mamoudouОценок пока нет

- SOUR WATER STRIPPER & DISPOSAL SYSTEM AT BERRI GAS PLANT PROGRESS MEASUREMENT SYSTEM REPORT Project ID BI-10-01628Документ2 страницыSOUR WATER STRIPPER & DISPOSAL SYSTEM AT BERRI GAS PLANT PROGRESS MEASUREMENT SYSTEM REPORT Project ID BI-10-01628Er Md AamirОценок пока нет

- Footing Chart: FOOTING SUMMARY: Soil Bearing Pressure 2000 PSFДокумент1 страницаFooting Chart: FOOTING SUMMARY: Soil Bearing Pressure 2000 PSFChristian LlorcaОценок пока нет

- Slab Bridge Design For WorkДокумент27 страницSlab Bridge Design For WorkEngineeri TadiyosОценок пока нет

- Hythrust Jacking and Micro Tunnelling Pipe SystemДокумент4 страницыHythrust Jacking and Micro Tunnelling Pipe SystemSaran KlОценок пока нет

- Research Design Final ManuscriptДокумент38 страницResearch Design Final ManuscriptWealey MendozaОценок пока нет

- Volume Blasting Weekly Februari 2019Документ26 страницVolume Blasting Weekly Februari 2019didi setiawanОценок пока нет

- Prelim Exam: CE 502 Concrete Design 1/1Документ1 страницаPrelim Exam: CE 502 Concrete Design 1/1Joy lauriaОценок пока нет

- MEGAWRAP-200: Unidirectional Carbon Fabric For Structural StrengtheningДокумент2 страницыMEGAWRAP-200: Unidirectional Carbon Fabric For Structural StrengtheningMarli MaksutiОценок пока нет

- Wak CV (Updated)Документ10 страницWak CV (Updated)Waheed AhmadОценок пока нет

- CementaidДокумент3 страницыCementaidGuntherОценок пока нет

- Ktherm Project Specification FINALДокумент26 страницKtherm Project Specification FINALhenryОценок пока нет