Академический Документы

Профессиональный Документы

Культура Документы

Nissan Almera N15 1995-2000 Clutch

Загружено:

Rafael HerputАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Nissan Almera N15 1995-2000 Clutch

Загружено:

Rafael HerputАвторское право:

Доступные форматы

CLUTCH

SECTION

CL

7 8 9 11 11 12 13 13 14

CONTENTS

PRECAUTIONS AND PREPARATION

Precautions Preparation

2

2 2

Operating Clutch

Cylinder

Damper

CLUTCH SYSTEM - Hydraulic Type CLUTCH SYSTEM - Mechanical Type INSPECTION AND ADJUSTMENT

Adjusting Bleeding Clutch Clutch Pedal Hydraulic type Procedure Master

3

4

CLUTCH RELEASE MECHANiSM CLUTCH DISC AND CLUTCH COVER

Clutch Clutch General Inspection Disc Cover and Flywheel

5

5 5 6 6

SERVICE DATA AND SPECIFICATIONS (SDS)

Specifications and Adjustment

HYDRAULIC CLUTCH CONTROL..

Cylinder

PRECAUTIONS AND PREPARATION Precautions

Recommended fluid is brake fluid "DOT 3". Do not reuse drained brake fluid. Be careful not to splash brake fluid on painted areas. When removing and installing clutch piping, use Tool. Use new brake fluid to clean or wash all parts of master cylinder, operating cylinder and clutch damper. Never use mineral oils such as gasoline or kerosene. It will ruin the rubber parts of the hydraulic system.

SBR820B

WARNING: After cleaning clutch disc, wipe it with a dust collector. use compressed air.

Do not

Preparation

SPECIAL SERVICE TOOLS

Tool number Tool name GG94310000 Flare nut torque wrench Description Removing and installing clutch piping

NT406

a: 10 mm (0.39 in) New

KV30101600 (New) KV30101000 (Former) Clutch aligning bar

Installing clutch cover and clutch disc:

a: 15.9 mm (0.626 In) dia. b: 17.9 mm (0.705 in) dia.

NT645

c: 40 mm (1.57 in)

ST20050240 Diaphragm spring adjusting wrench

NT404

Adjusting unevenness of diaphragm spring of clutch cover

a: 150 mm (5.91 in) b: 25 mm (0.98 in)

COMMERCIAL

Tool name Equivalent to GG94310000 CD Flare nut crows foot @ Torque wrench

NT360

SERVICE TOOLS

Description Removing and installing clutch piping

a: 10 mm (0.39 in)

CL-2

CLUTCH SYSTEM -

Hydraulic Type

m (bl : Apply

~ ~

lithium-based grease including molybdenum disulphide.

: N.m (kg-m. ft-Ib) : N.m (kg-m. in-Ib)

SCL667

G) @

Clutch pedal bracket Clutch master cylinder Assist spring Bushing Pin Stopper rubber Operating cylinder Air bleeder screw

@ @J

Withdrawal lever Release bearing Clutch hose Operating cylinder support bracket Clutch lever Spring pin Operating cylinder bracket

@ @

@ @ @ @

(J)

@

@ @

@ @ @

@

Clutch cover Clutch disc Clutch pedal Clevis pin Pedal stopper Fulcrum pin

@

@

CL-3

CLUTCH SYSTEM SEC. 300'307.465

~ \

Mechanical Type

8 - 11 (0.8 - 1.1, 69 - 95)

<D (RHO

model)

r""

f

@m

~~~

to.J 16 - 22 ,

77'\ -j,

~

,/

/

.

fA'l

~ {l

(1.6.2.2,

<D (LHD

,-0

12 - 16)~ model)

Of ~

':,

~'

/~

r ';,

~~

I'

@ to.J 16

@m

~

<

@

to.J 16 - 22

,/'

~,

~JO

~

01Q'?0'J:l'e..-----~;,

~

'~d'

a , be

i,:

',@/

c

_1 L~---~

1r

I

a!',~~

be \.\~':~

22 (1.6 - 2.2, 12 16)

,

~

:' ~'

d ~~ v,~

..--.......

~m

~

.Jl

to.J13-16 (1.3 1.6, 9 - 12)

.~

(1.6 - 2.2, 12 - 16)

C1J.~,

(

~

@m

'm

@

to.J 13 - 16 (1.3 1.6, 9 12) to.J 16 - 22 (1.6 - 2.2, 12 - 16) .~.

@

@ ~ ~

, I

m(Q ~~@

-m~. ~

m(Q

~h (7\I~ ~ \ ~J;i::::;~

l"J" - 29 (2.2 - 3.0, 1. - 22)1> 0~~

@-..........t>'"l(0.8-1.1,69-95)

<:.~

'I

' ApplV Ilth'"m-",,'

molybdenum (kg-m, ft-lb) (kg-m, in-Ib)

SCL668

<bl ~'"

/l~~

:11)

<bl

.

m (Q

~I!C!

Iiii\

I!C! <bl

om,,, '001""00

disulphide.

[OJ ; N.m IjJ ; N'm

G) @

Clutch pedal bracket Insulator Assist spring Withdrawal lever Clutch cover Clutch disc

(1)

@ @ @J @

Return spring Clutch lever Spring pin Release bearing Stopper rubber

@

@ @ @ @

@

@ @ @

Clutch pedal Bushing Pedal stopper Lock nut Fulcrum pin

CL-4

INSPECTION AND ADJUSTMENT Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper. Pedal height "H": Refer to 50S, CL-14.

Pedal stopper

Dash lower panel (except CD20 engine model) / /

L Floor car-pet

(CD20 engine model)

SCL625

L Dash reinforcement panel

2.

Lock nut

For mechanical

type -

a. b.

Adjusting nut

SCL423

Adjust withdrawal lever play "8" according to the following procedure_ Push withdrawal lever by hand until resistance is felt, and then tighten adjusting nut. Turn back adjusting nut 2.5 to 3.5 turns, and then tighten lock nut. Withdrawal lever play "B": 2.5 - 3.5 mm (0.098 - 0.138 in) lock nut: ~: 3 - 4 N'm (0.3 - 0.4 kg-m, 26 - 35 in-Ib)

3.

For hydraulic type and mechanical

type at center of

As a final check, measure pedal free travel "A" pedal pad. Pedal free travel "A": Refer to 50S, CL-14.

SCL341-A

Bleeding Procedure -

Hydraulic type

SCL613

Bleed air according to the following procedure. Carefully monitor fluid level at master cylinder during bleeding operation. 1. Top up reservoir with recommended brake fluid. 2. Connect a transparent vinyl tube to air bleeder valve. 3. Fully depress clutch pedal several times. 4. With clutch pedal depressed, open bleeder valve to release air, then close bleeder valve. 5. Repeat steps 3 through 5 above until clear brake fluid comes out of air bleeder valve.

CL-5

HYDRAULIC CLUTCH CONTROL Clutch Master Cylinder

SEC. 305

~ 2.9 5.9 (0.30 0.60, 26.0 52.2)

/

@LHD models

CD

(j) ~

2.5 - 3.9 (0.25 - 0.40, 21.7 - 34.7)

(1),

1'.

@m

CD Rubbing

surface to piston assembly

~'.

,<

@. Apply

brake fluid when assembling.

~f

@

m

~ I'

".

@liJa-

11

(08. '.1,

/@O@I1I!@(A':o'::"'1

m@(LHD models) Rubbing surface to push rod

(jJ) m

@ (RHD models) @ (LHD models)

* Take care

m@ m m @

of the bolt direction ~

Contact surface to piston assembly

: Apply rubber grease. : Apply silicone grease, Apply rubber lubricant. (kg-m. in-Ib)

@~

1.5 - 2.9 (0.15 - 0.30, 13.0 - 26.0) Remove this stopper, when removing piston and return spring.

SCL669

CD :

Iil : N.m

(1)

@ Piston assembly Piston cup Return spring Reservoir tank Reservoir hose

@ (])

@

@

@

@ @)

Reservoir cap Reservoir band Cylinder body Packing Valve stopper

@ @ @ @

Push rod Stopper Stopper ring Dust cover Lock nut

DISASSEMBLY

AND ASSEMBLY

screwdriver when

Push piston into cylinder body with removing and installing valve stopper. Align groove of piston assembly installing valve stopper. Check direction of piston cups.

and valve stopper

when

c;D.=: =.J3@

Groove

SCL214

CL-6

HYDRAULIC CLUTCH CONTROL Clutch Master Cylinder (Cont'd)

INSPECTION

Check the following items, and replace if necessary. Rubbing surface of cylinder and piston, for uneven wear, rust or damage Piston with piston cup, for wear or damage Return spring, for wear or damage Dust cover, for cracks, deformation or damage Reservoir, for deformation or damage

Operating Cylinder

SEC. 306

Operating cylinder

m@

/ Piston spring Piston cup

7:\ I

{

'c Bleeder screw

/ I ~d /

~ti)

m~;}

~,""d

Always replace after every disassembly as a set.

~Q

/Piston

IiIS.9 - 9.8 N.m . (0.6 - 1.0 kg-m, 52.2 - 86.7 In-Ib)

(il@

Dust cover /

m lR): Apply rubber grease.

SCL607-B

INSPECTION

Check the following items, and replace if necessary. Rubbing surface of cylinder and piston, for uneven wear, rust or damage Piston with piston cup, for wear or damage Piston spring, for wear or damage Dust cover, for cracks, deformation or damage

CL-7

HYDRAULIC CLUTCH CONTROL Clutch Damper

SEC. 306

Bleeder screw 1i15.9 - 9.8 (0.60 - 1.00, 52.2 . 86.7) Cylinder body (LHD model) 11]5.1 - 6.5 (0.52 - 0.66, 45.1 - 57.5)

m @ Rubbing

surface to piston assembly

Piston cup

m @ J'

- Damper cover (RHD model)

Piston assembly

m @ Contact

surface to piston assembly Damper rubber ~

II] 2.9

- 5.9 (0.30 - 0.60, 25.7 - 52.2)

m@

Apply rubber grease. (kg-m. in-Ib)

SCL672

II] : N'm

INSPECTION

Check cylinder and piston rubbing surface for uneven wear, rust or damage. Replace if necessary. Check damper rubber and piston cup for cracks, deformation or damage. Replace if necessary.

CL-8

CLUTCH RELEASE MECHANISM

SEC. 321

Withdrawal lever (Hydraulic clutch control)

* : Pay attention

m (Q:

to direction of bearing retainer. grease including molybdenum disulphide.

Spring pin

SCL670

Apply lithium-based

REMOVAL AND INSTAllATION

Remove release ward. bearing by pulling bearing retainers out-

Align spring spring pin.

pin with cavity of clutch housing

and tap out

INSPECTION

Check the following items, and replace if necessary. Release bearing, to see that it rolls freely and is free from noise, cracks, pitting or wear Release sleeve and withdrawal lever rubbing surface, for wear, rust or damage

CL-9

CLUTCH RELEASE MECHANISM

LUBRICATION

Lithium-based grease including molybdenum disulphide

Apply recommended grease to contact surface and rubbing surface. Too much lubricant might damage clutch disc facing.

ACL020

CL-10

CLUTCH DISC AND CLUTCH COVER

SEC. 300

~1st: 10-20(1.0-2.0,7.2-14) 2nd: 22 - 29 (2.2 - 3.0 , 16 - 22)

Clutch disc Do not clean in solvent. When installing, be careful that grease from main drive shaft does not adhere to clutch disc.

Clutch cover

m (iJ:

~

Apply lithium-based grease including molybdenum disulphide. : N'm (Kg-m, ft-Ib).

ACL019

Clutch Disc

INSPECTION

Check the following items, and replace if necessary. Clutch disc, for burns, discoloration, oil or grease leakage Clutch disc, for wear of facing Wear limit of facing surface to rivet head: 0.3 mm (0.012 in)

SCL221

Clutch disc, for backlash of spline and runout of facing. Maximum backlash of spline (at outer edge of disc): Model 180 0.7 mm (0.028 in) Model 190 and 200 0.8 mm (0.031 in) Model 215 0.9mm (0.035 in) Runout limit: 1.0 mm (0.039 in) Distance of runout check point (from hub center): Model 180 85 mm (3.35 in) Model 190 90 mm (3.54 in) Model 200 95 mm (3.74 in) Model 215 102.5mm (4.04 in)

CL-11

CLUTCH DISC AND CLUTCH COVER Clutch Disc (Cont'd)

INSTALLATION

Apply recommended grease to contact surface of splines.

Too much lubricant may damage clutch disc facing.

Clutch Cover and Flywheel

INSPECTION AND ADJUSTMENT Check clutch cover, installed on vehicle, for uneven diaphragm spring toe height.

Uneven limit: Model 180 Model 190, 200 and 215 1.0 mm (0.039 in) 0.7 mm (0.028 in)

SCL466-A

If out of limit, adjust the height with Tool.

FLYWHEEL INSPECTION

Dial gauge

CAUTION: Do not allow any magnetic teeth.

materials

to contact the ring gear

Inspect contact surface of flywheel for slight burns or discoloration. Clean flywheel with emery paper. Check flywheel runout.

Maximum allowable runout: Refer to EM section ("Inspection", "CYLINDER

BLOCK").

AEM100

INSTALLATION Insert Tool into clutch disc hub when installing clutch cover and disc. Be careful not to allow grease to contaminate clutch facing. Tighten bolts in numerical order, in two steps.

First step: ~: 10 20 N'm '(1.0 2.0 kg-m, 7 - 14 ft-Ib) Final step: ~: 22 29 N'm (2.2 3.0 kg-m, 16 22 ft-Ib)

SCL616-A

CL-12

SERVICE DATA AND SPECIFICATIONS General Specifications

CLUTCH CONTROL SYSTEM

Engine Type of clutch control Except for CD20 Mechanical CD20 Hydraulic

(SOS)

CLUTCH MASTER CYLINDER

Inner diameter

mm (in) 15.87 (5/8)

CLUTCH OPERATING CLUTCH DAMPER

Inner diameter

mm (in)

CYLINDER

17.46 (11/16)

Inner diameter

mm (in)

19.05 (3/4)

CLUTCH DISC

Unit: mm (in)

Engine Model Facing size (Outer dia. x inner dia. x thickness) Thickness of disc assembly with load

GA14DE 180 180 x 125 x 3.5 (7.09 x 4.92 x 0.138)

GA15DE, GA16DE 190 190 x 132 x 3.5 (7.48 x 5.20 x 0.138)

CD20 200 200 x 130 x 3.5 (7.87 x 5.12 x 0.138)

SR20DE 215 215 x 140 x 3.5 (8.46 x 5.51 x 0.138) 7.6 - 8.0 (0.299 - 0.315) with 3,923 N (400 kg, 882 Ib)

8.0 - 8.4 (0.315 - 0331) with 3,923 N (400 kg, A2 Ib)

CLUTCH COVER

Engine Model Full-load N (kg, Ib) GA14DE 180 3,236 (330, 728) 3,432 (350, 772) GA15DE

I

190

GA16DE

CD20 200

SR20DE 215 4,413 (450, 992)

3,825 (390, 860)

3,481 (355, 783)

CL-13

SERVICE DATA AND SPECIFICATIONS

(SOS)

Inspection and Adjustment

CLUTCH PEDAL

Unit: mm (in) Except for CD20 engine models Applied model RHO Pedal height "H" Pedal free travel "A" (at pedal pad) Withdrawal lever play "8" 159 - 169 (6.26 - 6.65)'1 LHD 153 - 163 (6.02 - 6.42)*2 RHO 156 - 166 (6.14 - 6.54)'1 LHD 149 - 159 (5.87 - 6.26)'2 CD20 engine models

11 - 15 (0.43 - 0.59) 2.5 - 3.5 (0.098 - 0.138)

9 - 16 (0.35 - 0.63)

'1: Measured from surface of dash reinforcement panel to surface of pedal pad. '2: Measured from surface of dash lower panel to surface of pedal pad.

CLUTCH DISC

Unit: mm (in) Disc model Wear limit of facing surface to rivet head Runout limit of facing Distance of runout check point (from hub center) Maximum backlash of spline (at outer edge of disc) 85 (3.35) 90 (3.54) 180 190

I

0.3 (0.012) 1.0 (0.039)

200

215

I

0.8 (0.031)

95 (3.74)

102.5 (4.04)

0.7 (0.028)

0.9 (0.035)

CLUTCH COVER

Unit: mm (in) Cover model Uneven limit of diaphragm spring toe height 180 1.0 (0.039) 190

200 0.7 (0.028)

215

CL-14

Вам также может понравиться

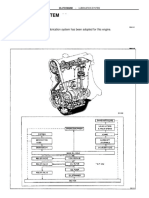

- Nissan Almera N15 1995-2000 GA, SR Series Engine Librication and Cooling SystemsДокумент41 страницаNissan Almera N15 1995-2000 GA, SR Series Engine Librication and Cooling SystemsSebastian AgudeloОценок пока нет

- Nissan Almera N15 1995-2000 Steering SystemДокумент35 страницNissan Almera N15 1995-2000 Steering SystemSebastian AgudeloОценок пока нет

- Nissan Almera N15 1995-2000 Rear SuspensionДокумент12 страницNissan Almera N15 1995-2000 Rear SuspensionSebastian AgudeloОценок пока нет

- Nissan Almera N15 1995-2000 Front SuspensionДокумент30 страницNissan Almera N15 1995-2000 Front SuspensionŽilvinas-Jonas Lukas MateikisОценок пока нет

- Nissan Almera N15 1995-2000 Manual TransaxleДокумент66 страницNissan Almera N15 1995-2000 Manual TransaxleSebastian AgudeloОценок пока нет

- Nissan Almera N15 1995-2000 MaintenanceДокумент56 страницNissan Almera N15 1995-2000 MaintenanceSebastian AgudeloОценок пока нет

- Nissan Almera N15 1995-2000 Heater and Air ConditionerДокумент84 страницыNissan Almera N15 1995-2000 Heater and Air ConditionerWattana Tengcharonchai100% (1)

- Instrument Panel Analog - Nissan Sentra 1993Документ8 страницInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaОценок пока нет

- Aygo MMT ResetДокумент3 страницыAygo MMT ResetAlan Ghon100% (2)

- Ec QG16Документ320 страницEc QG16Mahmoud El-MeghenyОценок пока нет

- B10a8 Air Bag PDFДокумент6 страницB10a8 Air Bag PDFDaniel Garcia100% (1)

- Nissan Almera N15 1995-2000 SRS AirbagДокумент46 страницNissan Almera N15 1995-2000 SRS AirbagSebastian AgudeloОценок пока нет

- Engine Mechanical : Group 11CДокумент36 страницEngine Mechanical : Group 11CRomaОценок пока нет

- Y61 CRD X Sm7e-Y61kg1 emДокумент22 страницыY61 CRD X Sm7e-Y61kg1 emDaniel BruceОценок пока нет

- Aeon NEW SPORTY 125-180 Repair ManualДокумент93 страницыAeon NEW SPORTY 125-180 Repair ManualGassmeОценок пока нет

- 2006 Nissan AltimaДокумент304 страницы2006 Nissan AltimaMuhammad Ali BhuttoОценок пока нет

- Body Electrical SystemДокумент104 страницыBody Electrical SystemСергейУ-У100% (1)

- 13 Re Russia-Kd 6B3 WM PDFДокумент636 страниц13 Re Russia-Kd 6B3 WM PDFIgor LukОценок пока нет

- SECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresДокумент3 страницыSECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresPriscilla Kelly Freitas dos SantosОценок пока нет

- Diesel+code+toyota+ PDFДокумент10 страницDiesel+code+toyota+ PDFKumar HemrajОценок пока нет

- 1999 Nissan Altima 2.4L Charging Systems Generators & Regulators HitachiДокумент18 страниц1999 Nissan Altima 2.4L Charging Systems Generators & Regulators HitachiRubenОценок пока нет

- Distributor Installation: Crankshaft Position Sensor RemovalДокумент2 страницыDistributor Installation: Crankshaft Position Sensor RemovalKeyboardMan1960Оценок пока нет

- In This Issue: Brake System Service Toyota's Hybrid Vehicle Continuously Variable Transmission Power Steering ServiceДокумент40 страницIn This Issue: Brake System Service Toyota's Hybrid Vehicle Continuously Variable Transmission Power Steering ServiceDilan SenarathneОценок пока нет

- A32 GiДокумент49 страницA32 GiLevin Tan HtОценок пока нет

- CX-5 - HvacДокумент334 страницыCX-5 - HvacCata LinОценок пока нет

- 1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulДокумент29 страниц1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulRubenОценок пока нет

- SB 10044035 5193 PDFДокумент5 страницSB 10044035 5193 PDFferran_alfonsoОценок пока нет

- SQR372 Engine: Maintenance Manual Chery Automobile Co., LTDДокумент46 страницSQR372 Engine: Maintenance Manual Chery Automobile Co., LTDAngel Pulido UrreaОценок пока нет

- Engine MechanicallДокумент119 страницEngine MechanicallGabriel BalcazarОценок пока нет

- Actyon A0 A06005Документ10 страницActyon A0 A06005Arimbi GembiekОценок пока нет

- P1012-Fuel Pump Delivery Pressure Too High: Theory of OperationДокумент2 страницыP1012-Fuel Pump Delivery Pressure Too High: Theory of OperationYovani AcevedoОценок пока нет

- Em PDFДокумент188 страницEm PDFRoberto BravoОценок пока нет

- TATA Minibus 407 MaintainanceДокумент13 страницTATA Minibus 407 MaintainancePraveen Kumar ReddyОценок пока нет

- Transfer: Workshop ManualДокумент92 страницыTransfer: Workshop ManualmailforspamОценок пока нет

- CX-5 - Mitsubishi 1 PDFДокумент334 страницыCX-5 - Mitsubishi 1 PDFJULIAN VALDERRAMA100% (1)

- Musso Owner Manual SmallДокумент482 страницыMusso Owner Manual Smallbogdanxp2000Оценок пока нет

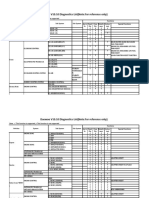

- Daewoo V10.10 Diagnostics List (Note:For Reference Only)Документ9 страницDaewoo V10.10 Diagnostics List (Note:For Reference Only)Ismael ZerpaОценок пока нет

- Automatic Transaxle Manual PDFДокумент429 страницAutomatic Transaxle Manual PDFJeff UptagrafftОценок пока нет

- Timing Belt Mazda Millenia S 2002Документ5 страницTiming Belt Mazda Millenia S 2002Carlos MendozaОценок пока нет

- Mitsubishi Rosa SpecificationsДокумент2 страницыMitsubishi Rosa Specificationsjamshed khan0% (1)

- 2012-2013 Ssang Yong Rexton Y290 Service ManualДокумент1 395 страниц2012-2013 Ssang Yong Rexton Y290 Service Manualbogdanxp2000Оценок пока нет

- Lower Control Arm Assy LH: ReplacementДокумент30 страницLower Control Arm Assy LH: ReplacementMusat Catalin-Marian100% (1)

- Almera N16 TechДокумент4 страницыAlmera N16 TechSpiros FousasОценок пока нет

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXДокумент11 страницAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeОценок пока нет

- Maintenance Checklist: Macan/S/GTS/Turbo (2015-On)Документ2 страницыMaintenance Checklist: Macan/S/GTS/Turbo (2015-On)edk34100% (1)

- Mitsubishi Engine F9Q Series Workshop ManualДокумент48 страницMitsubishi Engine F9Q Series Workshop ManualAlexandru sОценок пока нет

- Em2008 PDFДокумент407 страницEm2008 PDFBeto GarciaОценок пока нет

- Ssang Young Rex TonДокумент14 страницSsang Young Rex TonHri Vitalion100% (2)

- SsangYong Back in Actio (May 25, 2011)Документ6 страницSsangYong Back in Actio (May 25, 2011)ChangKwon ChungОценок пока нет

- Toyota Land Cruiser 1998-2007 - Air+ConditioningДокумент113 страницToyota Land Cruiser 1998-2007 - Air+ConditioningseowshengОценок пока нет

- LSD Manual PDFДокумент13 страницLSD Manual PDFHector Muñoz SepulvedaОценок пока нет

- Engine 3 0l Turbo Diesel - Specifications - TorqueДокумент3 страницыEngine 3 0l Turbo Diesel - Specifications - TorqueAlex Sirgiovanni0% (1)

- ToyotaДокумент12 страницToyotaZarate CruzОценок пока нет

- p5 5S-FE+ENGINE+REPAIR+MANUALДокумент23 страницыp5 5S-FE+ENGINE+REPAIR+MANUALkavindaОценок пока нет

- 13C PDFДокумент81 страница13C PDFKyaw Kyaw LinnОценок пока нет

- Totota AygoДокумент318 страницTotota AygoOlsi QinamiОценок пока нет

- Engine Mechanical PDFДокумент115 страницEngine Mechanical PDFAndrey GladyshevОценок пока нет

- RB 25 HeadДокумент9 страницRB 25 HeadAlexander Dominguez0% (1)

- Em - Engine Mechanical PDFДокумент24 страницыEm - Engine Mechanical PDFMoaed Kanbar86% (21)

- 78 Dt400e DT250E ManualДокумент18 страниц78 Dt400e DT250E Manualdisgustipate0% (1)

- Cata R5 Moteurs GB PDFДокумент11 страницCata R5 Moteurs GB PDFRafael HerputОценок пока нет

- Em PDFДокумент175 страницEm PDFRafael HerputОценок пока нет

- Em PDFДокумент175 страницEm PDFRafael HerputОценок пока нет

- Nissan Almera N15 1995-2000 ClutchДокумент14 страницNissan Almera N15 1995-2000 ClutchRafael HerputОценок пока нет

- MaintenanceДокумент28 страницMaintenanceRafael HerputОценок пока нет

- Stiinta Si Ingineria MaterialelorДокумент300 страницStiinta Si Ingineria Materialeloribol8306100% (10)

- 11 Best V10 Engines Ever MadeДокумент22 страницы11 Best V10 Engines Ever Madelollie9832Оценок пока нет

- Brochure enДокумент40 страницBrochure enJunanda Pandapotan Manik100% (1)

- TWLL-Screw Conveyer FeederДокумент8 страницTWLL-Screw Conveyer FeederVictor Julio Torres DazaОценок пока нет

- Specification For Fire Pump - Part 7Документ5 страницSpecification For Fire Pump - Part 7Melisa MackОценок пока нет

- Technical Datasheet Briton 2003V DC - 011Документ2 страницыTechnical Datasheet Briton 2003V DC - 011Peter van WykОценок пока нет

- Full Blasting Licence SyllabusДокумент1 страницаFull Blasting Licence Syllabustmadzi0% (1)

- Fyp ReportДокумент41 страницаFyp Reportramish javedОценок пока нет

- General Motor's Strategies: SectionДокумент17 страницGeneral Motor's Strategies: SectionSaurabh VermaОценок пока нет

- AURTTC003Документ8 страницAURTTC003CHANDRASIRI K.H.M.C. (BETA16009)Оценок пока нет

- Komatsu Wa470 6 Operation Maintenance ManualДокумент20 страницKomatsu Wa470 6 Operation Maintenance Manualtanna100% (22)

- Parts List FAS-SC7 37Документ45 страницParts List FAS-SC7 37Magoga MagoutОценок пока нет

- TDC SeminarДокумент6 страницTDC Seminarkim cheОценок пока нет

- Fanning Friction (F) and Colburn (J) Factors of A Louvered Fin and Flat Tube Compact Heat ExchangerДокумент10 страницFanning Friction (F) and Colburn (J) Factors of A Louvered Fin and Flat Tube Compact Heat ExchangerLiu YangtzeОценок пока нет

- The Audi A7 and S7 Sportback: Pricing and Specification GuideДокумент84 страницыThe Audi A7 and S7 Sportback: Pricing and Specification GuideT33kОценок пока нет

- List of Companies Havin G SAP at NagpurДокумент3 страницыList of Companies Havin G SAP at NagpurPallavi ChawlaОценок пока нет

- DKT - 001-6 14 22-IndictmentДокумент18 страницDKT - 001-6 14 22-IndictmentSimon AlvarezОценок пока нет

- Camshaft Opel Zafira-BДокумент3 страницыCamshaft Opel Zafira-Bmr & mrsОценок пока нет

- Engine Kit 466102-001Документ2 страницыEngine Kit 466102-001Rosalba AcuñaОценок пока нет

- 5 HP 19 FLДокумент246 страниц5 HP 19 FLAngel Barrera100% (1)

- Imagine Living in A World Where Cars Could TalkДокумент27 страницImagine Living in A World Where Cars Could TalkMd. Rashed RahmanОценок пока нет

- Firestone OTR Databook 10 27 2017Документ68 страницFirestone OTR Databook 10 27 2017Rodrigo CatotaОценок пока нет

- MD 2020Документ2 страницыMD 2020gjdgraafОценок пока нет

- 4HP20 Repair ManualДокумент140 страниц4HP20 Repair ManualautomaticosbrasilОценок пока нет

- GM 6T70/75 and Ford 6F50/55: 2007 6T70 (MH2) FWD 2007 6T75 (MY9) FWD/ (MH6) AWD Six Speed Automatic TransaxleДокумент60 страницGM 6T70/75 and Ford 6F50/55: 2007 6T70 (MH2) FWD 2007 6T75 (MY9) FWD/ (MH6) AWD Six Speed Automatic TransaxleRepuestos Maceira100% (3)

- Weber CarburatorДокумент2 страницыWeber CarburatorLaurence ZahraОценок пока нет

- Property of American Airlines: LektroДокумент146 страницProperty of American Airlines: Lektrofernando echavarria 7Оценок пока нет

- Riddhi Polymers: Date: 06-12-2016 ToДокумент3 страницыRiddhi Polymers: Date: 06-12-2016 ToVasoya ManojОценок пока нет

- Bauer BG 15 H: Rotary Drilling RigДокумент16 страницBauer BG 15 H: Rotary Drilling RigDilhara WickramaarachchiОценок пока нет

- F01 Sliding Tilting SunroofДокумент21 страницаF01 Sliding Tilting SunroofPhan VănОценок пока нет

- Key Catalogue Complete PDFДокумент72 страницыKey Catalogue Complete PDFInderpreet Singh100% (1)

- Japanese Death Poems: Written by Zen Monks and Haiku Poets on the Verge of DeathОт EverandJapanese Death Poems: Written by Zen Monks and Haiku Poets on the Verge of DeathРейтинг: 4 из 5 звезд4/5 (72)

- Japanese Proverbs: Wit and Wisdom: 200 Classic Japanese Sayings and Expressions in English and Japanese textОт EverandJapanese Proverbs: Wit and Wisdom: 200 Classic Japanese Sayings and Expressions in English and Japanese textРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Writing Haiku: A Beginner's Guide to Composing Japanese Poetry - Includes Tanka, Renga, Haiga, Senryu and HaibunОт EverandWriting Haiku: A Beginner's Guide to Composing Japanese Poetry - Includes Tanka, Renga, Haiga, Senryu and HaibunОценок пока нет

- Classic Haiku: An Anthology of Poems by Basho and His FollowersОт EverandClassic Haiku: An Anthology of Poems by Basho and His FollowersРейтинг: 3.5 из 5 звезд3.5/5 (4)

- 15 Japanese Short Stories for Beginners: Listen to Entertaining Japanese Stories to Improve Your Vocabulary And Learn Japanese While Having FunОт Everand15 Japanese Short Stories for Beginners: Listen to Entertaining Japanese Stories to Improve Your Vocabulary And Learn Japanese While Having FunОценок пока нет

- Beginner's Guide to Japanese Haiku: Major Works by Japan's Best-Loved Poets - From Basho and Issa to Ryokan and Santoka, with Works by Six Women Poets (Free Online Audio)От EverandBeginner's Guide to Japanese Haiku: Major Works by Japan's Best-Loved Poets - From Basho and Issa to Ryokan and Santoka, with Works by Six Women Poets (Free Online Audio)Оценок пока нет

- Even Monkeys Fall from Trees: The Wit and Wisdom of Japanese ProverbsОт EverandEven Monkeys Fall from Trees: The Wit and Wisdom of Japanese ProverbsРейтинг: 5 из 5 звезд5/5 (1)

- I Wait for the Moon: 100 Haiku of Momoko KurodaОт EverandI Wait for the Moon: 100 Haiku of Momoko KurodaРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Japanese Haiku: Its Essential Nature and HistoryОт EverandJapanese Haiku: Its Essential Nature and HistoryРейтинг: 3.5 из 5 звезд3.5/5 (14)

- Life and Zen Haiku Poetry of Santoka Taneda: Japan's Beloved Modern Haiku Poet (Includes a Translation of Santoka's "Diary of the One-Grass Hut")От EverandLife and Zen Haiku Poetry of Santoka Taneda: Japan's Beloved Modern Haiku Poet (Includes a Translation of Santoka's "Diary of the One-Grass Hut")Рейтинг: 4.5 из 5 звезд4.5/5 (3)