Академический Документы

Профессиональный Документы

Культура Документы

Simulation of Single Phase Inverter Using PSIM for Constant PV Output Voltage

Загружено:

kk_kamalakkannanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Simulation of Single Phase Inverter Using PSIM for Constant PV Output Voltage

Загружено:

kk_kamalakkannanАвторское право:

Доступные форматы

Brijesh M. Patel, Kalpesh J.Chudasma, Hardik A.

Shah

26

Simulation of Single Phase Inverter using PSIM Software for Solar P.V. System give Constant Output Voltage at Different Solar Radiation

Brijesh M. Patel, Kalpesh J.Chudasma, Hardik A.Shah

Abstract:This study investigated the detail function of inverterin small scale distributed power generation, its modelling and related simulation on P-SIM software. This model can be used for photovoltaic application or especially for particular AC module. In this paper work on three basic requirements for Inverter Modelling Amplification, Inversion and Voltage regulation under change in atmospheric condition.

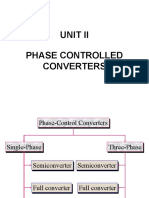

2 Discussion on different possible power conversion topology for PV system or DG system 2.1 Topology of single-phase inverters

DG systems are usually small modular devices close to electricity users, including wind turbines, solar energy systems, fuel cells, micro gas turbines, and small hydro systems, as well as the relevant controlling/ managing and energy storage systems. Such systems commonly need dcac converters or inverters as interfaces between their single-phase loads and sources as shown in Fig. 1[7], which depicts a typical renewable DG system using photovoltaic (PV) as energy source. DG inverters often experience a wide range of input voltage variations due to the fluctuations of energy sources, which impose stringent requirements for inverter topologies and controls. Functions of inverters for small DG systems can be summarized as follow [2, 12].

1. Introduction

The overview of single phase inverters developed for small distributed power generators. The functions of inverters in distributed power generation (DG) systems include dcac conversion, output power quality assurance, various protection mechanisms, and system controls. Unique requirements for small distributed power generation systems include low cost, high efficiency and tolerance for an extremely wide range of input voltage variations. These requirementshavedriven the inverter development toward simpler topologies and structures, lower component counts, and tighter modular design. Both single-stage and multiplestage inverters have been developed for power conversion in DG systems. Single-stage inverters offer simple structure and low cost, but suffer from a limited range of input voltage variations and are often characterized by compromised system performance. On the other hand, multiple-stage inverters accept a wide range of input voltage variations, but suffer from high cost, complicated structure and low efficiency [1]. Various circuit topologies are presented, compared, and evaluated against the requirements of power decoupling and dual-grounding, the capabilities for grid-connected or/and stand-alone operations [2].and the simulation of two stage inverter saw a variation in inverter output power when there is a small variation in input supply or variation in solar panel power output due to change in solar radiation during the day. And result discussion.

Fig. 1. Block diagram of a photovoltaic system. [19] 1) Power conversion from variable dc voltage into fixed ac voltage for stand-alone applications or ac current output following the grid voltage and frequency for grid-connected applications. The variable dc voltage can be higher or lower than the ac voltage in one system, which is observed normally in a wind-turbine energy system. 2) Output power quality assurance with low total harmonic distortion (THD), voltage and frequency deviation, and flickering.

Brijesh M. Patel is working as Assistant Professor, ADIT, New Vallabh Vidyanagar, India, bmp1412@gmail.com, Kalpesh J.Chudasma and Hardik A.Shah are working as Associate Professor, ADIT, New Vallabh Vidyanagar, India,

3) Protections of DG generators and electric power systems from abnormal voltage, current, frequency and temperature conditions, with additional functions such as anti islanding

International Journal of Emerging Trends in Electrical and Electronics (IJETEE ISSN: 2320-9569)

Vol. 4, Issue. 1, June-2013

Brijesh M. Patel, Kalpesh J.Chudasma, Hardik A.Shah

27

protection and electrical isolation if necessary. 4) Control of DG systems and accomplishment of certain objectives such as maximum power extraction from wind energy, maximum power point tracking (MPPT) of PV modules, optimum efficiency for fuel cell systems, optimal energy flow control [5], etc. Based on the electrical isolation between the input and output, inverters can be classified as isolated inverters or non isolated inverters. While electrical isolation is normally achieved using transformers, a choice can be made between using line-frequency transformers as in Fig.2 or high-frequency transformers as in Fig. 3. The dc-link voltage of inverters for DG systems may vary over a wide range. Depending on the input dc voltage range in comparison to the output ac voltage, inverters can be buck inverters, boost inverters, or buck-boost inverters. It should be noted that although the inverters in Fig. 2 and Fig. 3 are buck inverters by themselves, the whole topologies actually represent boost or buck-boost inverters due to PWM operations and voltage step-up in either low frequency or high frequency. Traditional full-bridge buck inverters are used in many existing high power applications with bulky and heavy line-frequency transformers. However, modern power electronic converters tend to use more silicon and less iron. This leads to the pursuance of compact designs with wide input voltage ranges and improved overall efficiency [3]. A multiple-stage inverter is defined as an inverter with more than one stage of power conversion, in which mostly one or more stages accomplish voltage step-up or step-down or electrical isolation, and the last stage performs dcac conversion. 1) dcdcac topologies; 2) dcacdcac topologies; 3) dcacac topologies. These topologies will also be discussed regarding the capabilities to meet certain challenging requirements of DG resource and ac utility [3,8]. Fig. 2. Traditional buck inverter and transformer[17] line-frequency

Fig. 3 Multiple-stage inverter with a high frequency transformer.

2.2 Two-Level PWM Control technique for H bridge inverter control

The H-bridge topology inverter is the most popular singlephase converter in various applications, especially in higher power rating applications. It consists of two arms fig4 and outputs a single-phase AC output voltage, V out to the load. Pulse Width Modulation (PWM) techniques are used to control the switching devices on and off. During last few years, PWM technique has been the subject of intensive research and a large variety of PWM control schemes have been discussed. Sinusoidal PWM (SPWM) approach is often used in single-phase applications.

Fig.4 single-phase H-bridge inverter Three different sinusoidal PWM switching schemes are used commonly for two-level single-phase inverter. They are bipolar PWM scheme, unipolar PWM scheme and modified unipolar PWM scheme [3] Figure 5 below shows the bipolar PWM modulation scheme. In

International Journal of Emerging Trends in Electrical and Electronics (IJETEE ISSN: 2320-9569)

Vol. 4, Issue. 1, June-2013

Brijesh M. Patel, Kalpesh J.Chudasma, Hardik A.Shah

28

order to generate a sinusoidal AC output with desired amplitude Vm and frequency f, a sinusoidal control signal Vcontrol at a desired frequency f1 is compared with a continuous triangular waveform Vcarrier as shown in Figure 5[13,16]

Fig. 6 unipolar PWM modulation scheme

Fig.5 bipolar PWM modulation scheme When Vcontrol is greater than Vcarrier, the PWM output is positive; otherwise the PWM output is negative. The frequency of carrier waveform Vcarrier establishes the switching frequency s f of the inverter. The modulation index i m is defined as

2.3 Overview of Solar Power Conversion System

The power conversion subsystem for a solar power system has two main tasks: one is to control the input terminal conditions to make photovoltaic (PV) modules operate at a maximum power point (MPP) and to capture the maximum power for the sun [7]. The other is to convert the output dc voltage from solar modules to a suitable ac voltage and meet the utility requirements [5] Therefore, most of the solar power conversion systems apply two-stage topology. The most common two-stage systems [6] consist of a dc-dc solar module-connected converter and dc-ac PWM inverters as shown in Figure 7 [9,15].

where Vcm is the peak amplitude of the control signal, while Vcrp is the peak amplitude of the triangle signal (carrier). the modulation ratio is defined as:

where f carrier is the carrier frequency. A unipolar PWM modulation scheme is shown in Figure 6 where the two switch pairs in H-bridge inverter are not always switched simultaneously as in the bipolar scheme. Instead, the switching of the two arms is controlled by two control signals. Therefore, the output voltage changes between 0 and +Vd or between 0 and - Vd in half fundamental period. Two control reference signals are used in this scheme. The output voltage from the bipolar PWM scheme does not have zero state, which means the output voltage of the inverter only changes between +Vd and - Vd. This scheme requires only one control reference signal, but the performance is poor[14]

Fig 7 two-stage solar power conversion system [11]

2.4 topology

Simulation of single phase inverter

Linear regulator often plays important role in implementing power supply capable of constant voltage/current control. It always provides lost of advantage such as low ripple noise, low EMI, good regulation, easy control strategy. However due to bulky size, low efficiency switch mode technique has become inevitable development trend for raising the power density, power efficiency and dynamic

International Journal of Emerging Trends in Electrical and Electronics (IJETEE ISSN: 2320-9569)

Vol. 4, Issue. 1, June-2013

Brijesh M. Patel, Kalpesh J.Chudasma, Hardik A.Shah

29

performance. The full bridge converter is one of the isolated converter topology that use in high power rating. The block diagram of it is shown in fig 8. The feedback signal of voltage is given to control circuit using PI-controller block for control and protection purpose.

2.6 Converter control scheme using PI-controller

The control scheme essentially consisting of only one sensor with simple structure when compared with classical boost converter which requires both voltage and current sensors. Here, DC voltage of load is fed back and compared with Vdc reference voltage. If, there is reduced dc voltage then there is difference between ref. voltage & O/P voltage. This difference is in the form of error, which is given to PI-Controller. PI- controller stabilizes this error and give the modulated single output for PWM scheme. Signals from PI- controller is compared with high frequency signal reference signal as shown in fig9[2]

F

Fig 9 Comparison between Pi Output Signal and Carrier signal Fig. 8 Single Phase Inverter Topology with p-sim software

2.5 Closed loop converter control system

Control system should be able to adjust duty cycle in time in order to regulate the output voltage with input voltage and load variation. Voltage mode and current control mode control technique adapted to design switching power supply. As the speed of the processors increase and large load changes frequently encountered in system transition from one sleep mode to active mode, the faster transient response of DC-DC power supply has been more important. The transient response of voltage mode control technique, when the input voltage is changing because it has only one feedback loop. The input voltage varying after the variation of output voltage occurs. In fact, the transient response of voltage mode control is slow for any variation of power stage. The basic principle of following circuits in the boosting up the voltage are, charging & discharging reactive component into a load, controlling the level of charge & consequently output voltage by switching the DC supply in & out of the circuit at very high frequencies. They include a freewheeling diode to protect the switch from inductors very reverse current and this also ensures that the generated inductor energy is applied to load capacitor are connected in parallel with load, to filter the voltage ripple & to maintain constant output voltage. Inductor is used in series with the load to filter the current ripple.

Fig 10 Converter output 230v DC

To set the gain and time-constant there are three methods given below: (i) Analytical method (ii) Empirical method (iii) Trial and error method

PI-controller is designed by trial and error method for line and load regulation. Most of industries used this method for tuning of PI-controller. PI-proportional integral, where integral term yields zero steady- state error in tracing constant set point & proportional term yields output is proportional to input. Integral control filters higher frequency sensor noise; it is slow in response to current error. On the other hand, the proportional term responds immediately to the current error, yet it cannot achieve without an unacceptably large gain. PI controller reduces very high transient error. PWM technique is used

International Journal of Emerging Trends in Electrical and Electronics (IJETEE ISSN: 2320-9569)

Vol. 4, Issue. 1, June-2013

Brijesh M. Patel, Kalpesh J.Chudasma, Hardik A.Shah

30

for generating gate pulses of IGBTs. The duty cycle is varied according to output voltage. To increase the output voltage increases the duty ratio. Main drawback of this system is slow transient response of output voltage. If input voltage changes from 20v to 17v due to solar radiation as shown in table, the output voltage of the converter will also changes and error will generated accordingly the control circuit and this error signal after comparing with triangular wave is used for triggering the four IGBT and it will maintain the output voltage of converter to 230v dc constant. Now this 230v dc is converted to 230v AC with A unipolar PWM modulation scheme is shown in Figure6.4 where the two switch pairs in H-bridge inverter are not always switched simultaneously as in the bipolar scheme. Instead, the switching of the two arms in Fig.12 is controlled by two control signals. Therefore, the output voltage changes between 0 and +230 or between 0 and 230 in half fundamental period as shown in fig13. Two control reference signals are used in this scheme as shown in fig11. and also in table show the variation in output voltage and power using this control topology when the input supply voltage changes due to variation in solar radiation.

Vin D.C Volt 22 21.5 21 20.5 19.5 19 18.5 18

Delta Vin Volt 10 % 7.5 % 5% 2.5 % 2.5 % 5% 7.5% 10 %

Vinverter

IL

Power (watt)

Delta Vinverter %

Delta P % 25 19 12 5.6 0.26 0.73 1.06 0.06

A.C Volt Amp

259.7 252 245 237.08 230.39 229.7 229.35 230.45

1.29 1.26 1.22 1.18 1.15 1.148 1.146 1.152

335.01 317.52 298.9 280.72 264.94 263.69 262.83 265.48

12.09 8.87 5.8 2.8 0.0462 0.39 0.54 0.43

Fig 11 switching of the two arms using unipolar PWM modulation scheme

Fig 12 output current and voltage waveform of sim software

inverter in p-

2.7 Simulation result and discussion

In fig 12 and table 1 show the simulation result of inverter with above topology so we can see the variation in inverter output power when there is a small variation in input supply or variation in solar panel power output due to change in solar radiation during the day.

3. Conclusion

Fig. 11 Switching signal of the two arms of PWM modulation scheme

Table 1 variation in inverter o/p power when there is a Small variation in input supply

These inverter topologies can be used for photovoltaic applications and particular inverters for the AC-Module. The task for such an inverter is to amplify the photovoltaic-module low voltage up to the higher-level voltage of the grid and to convert it from DC into AC. and maintain it constant as there is a variation in atmospheric

International Journal of Emerging Trends in Electrical and Electronics (IJETEE ISSN: 2320-9569)

Vol. 4, Issue. 1, June-2013

Brijesh M. Patel, Kalpesh J.Chudasma, Hardik A.Shah

31

condition or in solar radiation during the whole day.

4. References

[1] Inverters for Single-phase Grid Connected Photovoltaic Systems - An Overview, Martina Calais, Johanna Myrzik, Vassilios G, School of Engineering, Murdoch University, Murdoch WA 6150, Australia Technical University of Eindhoven, The Netherlands [2] Muhammad h. Rashid, power electronics handbook, academic press, USA [3] Billy M. T. Ho and Henry Shu-Hung Chung, An Integrated Inverter with Maximum Power Tracking for Grid- Connected PV Systems, IEEE, china [4] Liuchen Chang, Design Of A 400w Single-Phase BuckBoost Inveter for PV Applications, Liuchen Chang, Canada [4] Martina Calais, Johanna Myrzik, Vassilios G, Inverters for Single-phase Grid Connected Photovoltaic Systems , Netherlands [5] Sangmin Jung, Youngsang Bae, Sewan Choi Hyosung Kim Seoul, A Low Cost Utility Interactive Inverter for Residential Power Generation Korea [6] Mihai Ciobotaru, Remus Teodorescu and Frede Blaabjerg, Control of single-stage single-phase PV inverter, Denmark. [7] A Low Cost Utility Interactive Inverter for Residential Power Generation Sangmin Jung, Youngsang Bae, Sewan Choi Hyosung Kim Seoul National University of Technology,Dept.of Control and Instrumentation Eng. 172 Kongneung-Dong, Nowon-Ku, Seoul 139-743, Korea [8] Topologies of Single-Phase Inverters for Small Distributed Power Generators: An Overview Yaosuo Xue, Student Member, IEEE, Liuchen Chang, Senior Member, IEEE, Sren Bkhj Kjr, Member, IEEE, IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 19, NO. 5, SEPTEMBER 2004 [9] A Review of Single-Phase Grid-Connected Inverters for Photovoltaic Modules Soeren Baekhoej Kjaer, Member, IEEE, John K. Pedersen, Senior Member, IEEE, and Frede Blaabjerg, Fellow, IEEE [10] Control of single-stage single-phase PV inverter Mihai Ciobotaru, Remus Teodorescu and Frede Blaabjerg, Institute of Energy Technology, Aalborg University, Pontoppidanstraede 101 DK-9220, Aalborg, Denmarkh. http://www.Jet.aau.dK [11] Design Of A 400w Single-Phase Buck-Boost Inveter For Pv Applications 2nd Canadian Solar Buildings Conference Calgary, June 10 14, 2007 by Liuchen Chang Dept. of Elec. & Comp. Eng., University of New Brunswick, Fredericton, NB, Canada [12] An Integrated Inverter With Maximum Power Tracking for Grid-Connected PV Systems by Billy M. T. Ho, Student Member, IEEE, and Henry Shu-Hung Chung, Senior Member, ieee, ieee transactions on power electronics, vol. 20, no. 4, july 2005 [13] Liling Zhou, Evaluation and DSP Based Implementation of PWM Approach for Single-Phase DC-AC ConvertersMaster Thesis, Department of Electrical and Computer Engineering, Florida State University, 2005. [14] Richard A. Cullen, What is Maximum Power Point Tracking (MPPT) and How Does It Work? www.blueskyenergyic.com [15] Frede Blaabjerg, Zhe Chen, Soeren Baekhoej Kjaer, Power Electronics as Efficient Interface in Dispersed Power Generation Systems- Power Electronics, IEEE Transactions on, Volume 19, No. 5, 2004, pp.1184-1194. [16] J. M. Chang, W. N. Chang, S. J. Chiang, Single-Phase GridConnected PV System Using Three-Arm Rectifier-InverterAerospace and Electronic System, IEEE Transaction on, Volume 42, No.1, 2006, pp. 211-219.

[17] R. O. Cceres and I. Barbi, A boost dc-ac converter: analysis, design, and experimentation, IEEE Trans. Power Electron., vol. 14, pp. 134141, Jan. 1999. [18] N. Vzquez, J. Almazan, J. lvarez, C. Aguilar, and J. Arau, Analysis and experimental study of the buck, boost and buck-boost inverters, in Proc. IEEE PESC99, Charleston, SC, June 27July 1 1999, pp. 801806. [19] A. Beristin, J. Bordonau, A. Gilabert, and G. Velasco, Synthesis and modulation of a single phase dc/ac converter with high frequency isolation in photovoltaic energy applications, in Proc. IEEE PESC03, Acapulco, Mxico, June 1519, 2003, pp. 11911196. [20] CN Bhende, S Mishra, Siva Ganesh Malla, Permanent magnet synchronous generator-based standalone wind energy supply system, IEEE Transactions on Sustainable Energy, Vol. 2, Issue. 4, 2011. [21] SG Malla, CN Bhende, S Mishra, Photovoltaic based water pumping system, International Conference on Energy, Automation, and Signal (ICEAS), 2011 [22] Jagan Mohana Rao Malla, Siva Ganesh Malla, Three level diode clamped inverter for DTC-SVM of induction motor, International Conference on Power Electronics, Drives and Energy Systems (PEDES), 2010. [23] Jagan Mohana Rao Malla, Siva Ganesh Malla, Five level parallel inverter for DTC SVM of induction motor, WSEAS TRANSACTIONS on POWER SYSTEMS, 2010 [24] Mr. Sandeep N Panchal, Mr. Vishal S Sheth, Mr. Akshay A Pandya, Simulation Analysis of SVPWM Inverter Fed Induction Motor Drives, International Journal of Emerging Trends in Electrical and Electronics (IJETEE) Vol. 2, Issue. 4, pp. 18-22, April-2013. [25] Dhana Prasad Duggapu, Satya Venkata Kishore Pulavarthi and Swathi Nulakajod, Comparison between Diode Clamped and HBridge Multilevel Inverter (5 to 15 odd levels), International Journal of Emerging Trends in Electrical and Electronics (IJETEE) Vol. 1, Issue. 4, pp. 6678, March-2013. [26] Mr. Ambadas. S. Mane and Mr. Vijay. B. Suryawanshi, Analysis of Five Level Inverter, International Journal of Emerging Trends in Electrical and Electronics (IJETEE) Vol. 1, Issue. 1,pp. 98-101, March-2013. [27] A Mallikarjuna Prasad, S Thirumalaiah, U chaithanya and P Nagarjuna, Simulation of New Multilevel Inverter Topology, International Journal of Emerging Trends in Electrical and Electronics (IJETEE) Vol. 1, Issue. 1, pp. 6873, , March-2013. [28] J.M.R.MALLA AND S.G.MALLA, LOW COST MULTILEVEL INVERTER (PARALLEL INVERTER), International J.of Multidispl.Research & Advcs. in Engg.(IJMRAE), Vol. 2, No. I, April 2010, pp 271-289

[1]Mr. B.M. Patel was born in visnagar, India, in 1986. He received his B. E. degree from L.C.I.T. Bhandu, and M.E. from B.V.M College V.V. Nagar under S.P. University. Presently he is working asAssistant Professor in A.D. Patel institute of technology New V.V Nagar [2]Mr.H.A.Shah was born in umreth, India, in 1979. He received his B. E. degree from B.V.M, V.V. Nagar, and M.E. from M.S. University,baroda. Presently he is working as Associate Professor in A.D. Patel institute of technology New V.V Nagar [3] Mr.K.J Chudasma was born in umreth, India, in 1974. He received his B. E. degree from B.V.M, V.V. Nagar, and M.E. from B.V.M. College V.V.Nagar under S.P. University. Presently he is working as Associate Professor in A.D. Patel institute of technology New V.V Nagar

International Journal of Emerging Trends in Electrical and Electronics (IJETEE ISSN: 2320-9569)

Vol. 4, Issue. 1, June-2013

Вам также может понравиться

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОт EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОценок пока нет

- Microcontroller Based Three Phase InverterДокумент4 страницыMicrocontroller Based Three Phase InverterEditor IJRITCCОценок пока нет

- Power BJTДокумент14 страницPower BJTJahangeer SoomroОценок пока нет

- Simplified Analysis of Graetz CircuitДокумент42 страницыSimplified Analysis of Graetz CircuitKaran Singhania100% (3)

- Measurement of VelocityДокумент59 страницMeasurement of VelocityYogeshBhatt100% (1)

- EE2203-Electronic Device and Circuits Question BankДокумент11 страницEE2203-Electronic Device and Circuits Question BankAnbarasan Annamalai100% (1)

- Induction Motor Drive Control MethodsДокумент8 страницInduction Motor Drive Control MethodsRudra Kumar MishraОценок пока нет

- Voltage Control of Single-Phase InvertersДокумент17 страницVoltage Control of Single-Phase Invertersmailmanugs100% (1)

- Design of Single Phase H-Bridge Multilevel Inverter Using Microcontroller Atmel 89c51Документ52 страницыDesign of Single Phase H-Bridge Multilevel Inverter Using Microcontroller Atmel 89c51Sabir VeОценок пока нет

- On IgbtДокумент19 страницOn IgbtSayanta Saha100% (1)

- Ac DrivesДокумент36 страницAc Drivesaswardi50% (2)

- Design Calculations For Buck-Boost Converters: Michael Green Advanced Low Power SolutionsДокумент12 страницDesign Calculations For Buck-Boost Converters: Michael Green Advanced Low Power SolutionsnandhakumarmeОценок пока нет

- 10 kW Inverter Design for Fuel Cell SystemДокумент52 страницы10 kW Inverter Design for Fuel Cell Systemguddu13481Оценок пока нет

- Oscillator PDFДокумент4 страницыOscillator PDFJoshua DuffyОценок пока нет

- Power Electronics Lab Manual-withoutreadingsandprepostlab-EE0314Документ69 страницPower Electronics Lab Manual-withoutreadingsandprepostlab-EE0314Sankaran Nampoothiri KrishnanОценок пока нет

- 21 Toma EmanoilДокумент6 страниц21 Toma EmanoilFredy Peñafiel PazОценок пока нет

- BJT Frequency Responce PDFДокумент57 страницBJT Frequency Responce PDFAlpha RomeoОценок пока нет

- Class 27 - Modeling of Servo MotorsДокумент25 страницClass 27 - Modeling of Servo Motorsapi-26676616100% (1)

- Introduction to Power Electronics ChapterДокумент9 страницIntroduction to Power Electronics ChapterSouvik GanguliОценок пока нет

- Emeng 3131 Electrical Power Systems: Fundamentals of Power System Yoseph MekonnenДокумент36 страницEmeng 3131 Electrical Power Systems: Fundamentals of Power System Yoseph MekonnenmichaelОценок пока нет

- DC-DC Buck Converter: Principles and EvolutionДокумент36 страницDC-DC Buck Converter: Principles and EvolutionAnas RajputОценок пока нет

- Digital Voltmeters Can Be Classified in To The Following Broad CategoriesДокумент22 страницыDigital Voltmeters Can Be Classified in To The Following Broad CategoriesSysu KumarОценок пока нет

- Gain, Phase margins, compensatorsДокумент10 страницGain, Phase margins, compensatorszakiannuarОценок пока нет

- DC - Ac Inv.Документ82 страницыDC - Ac Inv.Jegadeeswari GОценок пока нет

- MTDC System PDFДокумент17 страницMTDC System PDFAshok Kumar67% (3)

- Merz Price Differential Protection For TransformerДокумент2 страницыMerz Price Differential Protection For TransformerapjbalamuruganОценок пока нет

- Exp 11 Single Phase Inverter Part IДокумент7 страницExp 11 Single Phase Inverter Part Iusmpowerlab0% (1)

- Control Systems IMP QUESTIONSДокумент8 страницControl Systems IMP QUESTIONSHarika HarikaОценок пока нет

- Full-Wave RectifierДокумент7 страницFull-Wave Rectifiermohdshujaat100% (2)

- Simulation of Buck Converter with Synchronous RectifierДокумент7 страницSimulation of Buck Converter with Synchronous RectifierThinh NguyenОценок пока нет

- SPWM V/HZ InverterДокумент51 страницаSPWM V/HZ InverterLabi BajracharyaОценок пока нет

- Block Diagram of Chopper Fed-Dc MotorДокумент1 страницаBlock Diagram of Chopper Fed-Dc MotorMohammed Saad100% (1)

- Pspice Lab ManualДокумент30 страницPspice Lab ManualSrinivasarao ThumatiОценок пока нет

- Unit Ii Phase Controlled ConvertersДокумент102 страницыUnit Ii Phase Controlled ConverterscoolrajeeeОценок пока нет

- Simulation of a Voltage-Mode PWM Boost ConverterДокумент103 страницыSimulation of a Voltage-Mode PWM Boost ConverterAshok KumarОценок пока нет

- ARDUINO SPWM SINE INVERTER PROJECT GUIDEДокумент5 страницARDUINO SPWM SINE INVERTER PROJECT GUIDEmaurilioctbaОценок пока нет

- Single Phase AC Voltage ControllerДокумент6 страницSingle Phase AC Voltage Controllermozaher1Оценок пока нет

- L9 Single Phase VSIДокумент114 страницL9 Single Phase VSIPrashant Surana100% (1)

- Unit Vii Fet AmplifiersДокумент14 страницUnit Vii Fet AmplifiersAadarsha timilsinaОценок пока нет

- DSP Lab Sample Viva QuestionsДокумент7 страницDSP Lab Sample Viva QuestionsNikoBellicОценок пока нет

- Single Phase InverterДокумент7 страницSingle Phase InverterBHALAJI BIRLAОценок пока нет

- Industrial Electronics and Robotics Semiconductor Devices, Switches, Time Delay CircuitsДокумент2 страницыIndustrial Electronics and Robotics Semiconductor Devices, Switches, Time Delay Circuitssaqib_maqboolОценок пока нет

- Unit-3::Half Wave Rectifier, Ripple Factor, Full WaveДокумент12 страницUnit-3::Half Wave Rectifier, Ripple Factor, Full WaveHemant TulsaniОценок пока нет

- Frequency Response of Two Stage RC Coupled AmplifierДокумент38 страницFrequency Response of Two Stage RC Coupled AmplifierAyesha Gupta100% (2)

- Instrument Transformers TutorialДокумент5 страницInstrument Transformers TutorialEzeldeen AgoryОценок пока нет

- Power Electronics Lab Manual1Документ72 страницыPower Electronics Lab Manual1Harish SvОценок пока нет

- HVDC Unit IIIДокумент22 страницыHVDC Unit IIISreenivas Reddy BodimallaОценок пока нет

- MALVINO & BATES Chapter 08Документ29 страницMALVINO & BATES Chapter 08Reece RevosaОценок пока нет

- Comparison of AC and DC TransmissionДокумент2 страницыComparison of AC and DC TransmissionFahad Yousaf KhanОценок пока нет

- EMI Lecture Notes Week 5: Measurement of Inductance and Capacitance Using AC BridgesДокумент34 страницыEMI Lecture Notes Week 5: Measurement of Inductance and Capacitance Using AC BridgesPavan KumarОценок пока нет

- Control of Single Phase To Three Phase AcДокумент10 страницControl of Single Phase To Three Phase Acpriya dharshiniОценок пока нет

- 2 Lecture 2 Diode B Stad - CH - 01Документ66 страниц2 Lecture 2 Diode B Stad - CH - 01peter brownОценок пока нет

- Chapter 2 - OscillatorsДокумент31 страницаChapter 2 - OscillatorsAbdul Qawie Jumaan100% (1)

- Direct Energy Conversion Lecture I PDFДокумент11 страницDirect Energy Conversion Lecture I PDFAftab Ali Afridi33% (3)

- Pe Final Ex SS 2010-2011Документ8 страницPe Final Ex SS 2010-2011Saif Uddin100% (1)

- +ayurveda LessonsДокумент91 страница+ayurveda LessonsFelipe TrovãoОценок пока нет

- Child Psychology EducationДокумент96 страницChild Psychology Educationராஜா MVSОценок пока нет

- Siemens G120Документ26 страницSiemens G120kk_kamalakkannanОценок пока нет

- 29 06 2014 GeneralTamilДокумент25 страниц29 06 2014 GeneralTamilRajaganapathi ShanmugasundaramОценок пока нет

- Robotic Assistance For Ultrasound Guided Prostate BrachytherapyДокумент9 страницRobotic Assistance For Ultrasound Guided Prostate Brachytherapykk_kamalakkannanОценок пока нет

- TNPSC Group Exam-I - 2013 Answer SheetsДокумент75 страницTNPSC Group Exam-I - 2013 Answer Sheetsnagarathinam82Оценок пока нет

- Python 3 Hands OnДокумент139 страницPython 3 Hands OnusersupreethОценок пока нет

- Vasthu Sastra in TamilДокумент44 страницыVasthu Sastra in Tamilkailasasundaram85% (47)

- A Short Introduction To UNIX Operating SystemДокумент34 страницыA Short Introduction To UNIX Operating SystemAli AhmedОценок пока нет

- CNC Technology WorkshopДокумент2 страницыCNC Technology Workshopkk_kamalakkannanОценок пока нет

- Std12 AdvTamilДокумент320 страницStd12 AdvTamilkk_kamalakkannanОценок пока нет

- Tamil SSLC Certificate PSTM DetailsДокумент1 страницаTamil SSLC Certificate PSTM Detailskk_kamalakkannanОценок пока нет

- TNPC Question Papers WebsiteДокумент113 страницTNPC Question Papers Websitekk_kamalakkannan100% (1)

- Std10 Tamil 1 PDFДокумент125 страницStd10 Tamil 1 PDFsasikumar rОценок пока нет

- Linuxcnc GcodeДокумент1 страницаLinuxcnc Gcodekk_kamalakkannanОценок пока нет

- Open SourceДокумент6 страницOpen Sourcekk_kamalakkannanОценок пока нет

- Linuxcnc GcodeДокумент1 страницаLinuxcnc Gcodekk_kamalakkannanОценок пока нет

- Galil DMC 2143 Controller ManualДокумент118 страницGalil DMC 2143 Controller Manualkk_kamalakkannanОценок пока нет

- Joy Stick ConfigurationДокумент12 страницJoy Stick Configurationkk_kamalakkannanОценок пока нет

- Model ResumeДокумент2 страницыModel Resumekk_kamalakkannanОценок пока нет

- Linux CNC ArchitectureДокумент1 страницаLinux CNC Architecturekk_kamalakkannanОценок пока нет

- SsДокумент1 страницаSskk_kamalakkannanОценок пока нет

- Department of Robotics and Automation EngineeringДокумент1 страницаDepartment of Robotics and Automation Engineeringkk_kamalakkannanОценок пока нет

- Flow ChartДокумент1 страницаFlow Chartkk_kamalakkannanОценок пока нет

- Types of RamsДокумент2 страницыTypes of Ramskk_kamalakkannanОценок пока нет

- Driving High-Current Loads With MicrocontrollersДокумент12 страницDriving High-Current Loads With Microcontrollerschintu333Оценок пока нет

- RC Car Side ViewДокумент111 страницRC Car Side ViewSanjeev TarigopulaОценок пока нет

- AN907 Stepping Motor FundamentalsДокумент36 страницAN907 Stepping Motor Fundamentalswalker84Оценок пока нет

- AMCI - Stepper Motor Control - Stepper Motor Drivers - SD17060E Ethernet - IP Stepper Motor Indexer - DriveДокумент5 страницAMCI - Stepper Motor Control - Stepper Motor Drivers - SD17060E Ethernet - IP Stepper Motor Indexer - DrivePedro Cu AguirreОценок пока нет

- 11 EE462L H Bridge InverterДокумент5 страниц11 EE462L H Bridge Invertertt_aljobory3911Оценок пока нет

- Proposal ProjectДокумент15 страницProposal Projectsm shamilОценок пока нет

- Qdr4500 Technical ManualДокумент250 страницQdr4500 Technical Manualcrisbar80% (5)

- Fire FightingДокумент78 страницFire FightingsadashivthotaОценок пока нет

- Govindu Sai Anirudh Thesis 2018Документ73 страницыGovindu Sai Anirudh Thesis 2018Mehul ShahОценок пока нет

- Automatic Gun Targeting SystemДокумент19 страницAutomatic Gun Targeting SystemManam Nobal100% (1)

- Ir2110 H Bridge SchematicДокумент3 страницыIr2110 H Bridge SchematicКети Таневска33% (3)

- New Final Project Report of CNC PlotterДокумент52 страницыNew Final Project Report of CNC PlotterSiddesh Sanju86% (7)

- HIP4080A, 80V High Frequency H-Bridge Driver: Application Note December 11, 2007 AN9404.3Документ13 страницHIP4080A, 80V High Frequency H-Bridge Driver: Application Note December 11, 2007 AN9404.3Natalia González RoggetОценок пока нет

- Me 223 Lab 9 H-Bridge Motor Control L293D S16Документ5 страницMe 223 Lab 9 H-Bridge Motor Control L293D S1611103212Оценок пока нет

- Automotive Power Electronics GuideДокумент100 страницAutomotive Power Electronics GuidesrgubiliОценок пока нет

- PWM DC Motor Controller Using MOSFETs and IR2110 HДокумент3 страницыPWM DC Motor Controller Using MOSFETs and IR2110 HdragoblaztrОценок пока нет

- Tidr 393Документ9 страницTidr 393bazoka fransiskusОценок пока нет

- DIODES - Total Solutions For NB Application 20100304 PDFДокумент36 страницDIODES - Total Solutions For NB Application 20100304 PDFsorintvrОценок пока нет

- PROJECT Mislestone 1Документ8 страницPROJECT Mislestone 1Kirankumar ReddyОценок пока нет

- Joystick Controlled WheelchairДокумент3 страницыJoystick Controlled WheelchairAnonymous kw8Yrp0R5rОценок пока нет

- Where Do You Start?: 27Mhz Door Knob AlarmДокумент72 страницыWhere Do You Start?: 27Mhz Door Knob AlarmsergioОценок пока нет

- VsiДокумент34 страницыVsiSudhakar Reddy100% (1)

- MC33186 NissanДокумент24 страницыMC33186 NissanAgustin100% (1)

- Disturbance Observer Based Current Controller For A Brushed DC MotorДокумент6 страницDisturbance Observer Based Current Controller For A Brushed DC MotorAji Brahma NugrohoОценок пока нет

- Project Presentation PDFДокумент22 страницыProject Presentation PDFARIF KANONОценок пока нет

- Arduino Modules L298NДокумент4 страницыArduino Modules L298NNermin FejzicОценок пока нет

- Abstracts TotalДокумент232 страницыAbstracts TotalhaleemforyouОценок пока нет

- Prototype CNC Machine Design Article Analyzes Modular SystemДокумент6 страницPrototype CNC Machine Design Article Analyzes Modular SystemTheng ChanntholОценок пока нет

- Design and Implementation of Secure Electronic Passport SystemДокумент8 страницDesign and Implementation of Secure Electronic Passport SystemManish Kumar Reddy NangiОценок пока нет

- Interfacing DC motor to 8051 microcontroller using AT89S51Документ4 страницыInterfacing DC motor to 8051 microcontroller using AT89S51Pranjal MethiОценок пока нет