Академический Документы

Профессиональный Документы

Культура Документы

Column Base Plate (Fixed Type)

Загружено:

Ernest NavarroАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Column Base Plate (Fixed Type)

Загружено:

Ernest NavarroАвторское право:

Доступные форматы

Jurong Aromatics Complex Project

CALCULATION COLUMN BASE PLATE

CALCULATION REPORT FOR COLUMN BASE PLATE

Job No.

JAC0701 Jurong Aromatics Complex Project Jurong Island, in Singapore Jurong Aromatics Corporation Pte Ltd

Project Title : : Location Client :

A REV

03.Jun.2011 DATE

Issued For Approval DESCRIPTION

J.H.Baek PRP'D

W.S.Ham CHK'D

I.Heo APP'D OWNER

Jurong Aromatics Complex Project

CALCULATION COLUMN BASE PLATE

TABLE OF CONTENTS

1. SKETCH OF COLUMN BASE PLATE

2. CALCULATION OF BOLT TENSION AND CONCRETE COMPRESSION

2-1. Moment plus maximum axial force 2-2. Moment plus minimum axial force

3. BASE PLATE THICKNESS

3-1. Compression side bending 3-2. Tension side bending

4. HOLDING DOWN BOLTS AND ANCHORAGE

4-1. Holding down bolts 4-2. Anchorage to concrete

5. SHEAR TRANSFER TO CONCRETE

6. WELDING CHECK

6-1. Tension flange weld 6-2. Compression flange weld 6-3. Web weld

Doc No

: : : :

REFERENCE

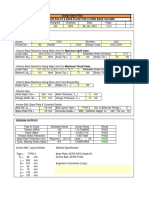

CALCULATION FOR COLUMN BASE PLATE (H-SHAPE)

TITLE: Base Plate for H - Shape Steel Column (Fixed Type A)

Job No Rev Page

07261D

1. SKETCH OF COLUMN BASE PLATE

Design loads Axial force (Fc) Mininum, Fc,min Maximum, Fc,max Shear force (Fv) Moment (M) = = = = 219.2 kN 882.7 kN 65.7 kN 67.9 kNm

60% of shear capa.

Design data Column size Depth Width Flange thickness Web thickness Base plate Depth Width Thickness Flange weld Web weld Anchor bolt Bolt size No. of bolt Bolt to bolt distance Bolt to edge distance Length Gh 20 mm 4 ea 300.0 mm 50.0 mm 450.0 mm Dp Bp Tp sw s' 400.0 mm 300.0 mm 35.0 mm 8.0 mm 8.0 mm H200X100X5.5X8 Dc Bc Tc tc 200.0 mm 100.0 mm 8.0 mm 5.5 mm

Materials Base plate Min. tensile strength Min. yielding strength Fu Fy Fy Anchor bolt DESIGN RESULT SUMMARY 1. Plate thickness 2. Anchor bolt 3. Shear transfer 4. Welds Shear strength Tensile capacity ps SM490A 490.0 MPa 325.0 MPa 315.0 MPa Grade 4.6 160.0 N/mm2 78.4 kN fcu 40.0 N/mm2 refer to JES-43A1 Grade E43 Pw 215.0 N/mm2

t < 16 16 < t < 40 refer to GIS G3106

refer to BS 4190

O.K! O.K! O.K! O.K!

Welding Welding capacity Bedding Concrete

3 / 11

Doc No

: : : :

REFERENCE

CALCULATION FOR COLUMN BASE PLATE (H-SHAPE)

TITLE: Base Plate for H - Shape Steel Column (Fixed Type A)

Job No Rev Page

07261D

2. CALCULATION OF BOLT TENSION AND CONCRETE COMPRESSION

An interface compression force is coupled with a tensile force in the bolts to balance the applied axial compression and bending moment. The moment may act in either direction and symmetrical details are chosen. The distribution of forces gives the equations which must be satisfied simultaneously for a simple base with one row of bolts on each side.

STEP 1

2-1. Moment plus maximum axial force

To determine the eccentricity leads to an indication of the necessary base size if no bolt tension was available. Check whether there is tension in the bolts; eccentricity b = M/N = = X/2 = Dp / 2 - b = = Compression = = = 67925 kNmm / 882.7 kN 77.0 400 / 2 - 77 123 mm X= 246.0 mm mm

distance to edge of compressive stress block

(area of compressive stress block) x (cuve strength of concrete) (axial force) (2 x 123 x 300) x (0.6 x 40 N/mm / 10) 1771 kN 882.7 kN

No tension in the bolts!

Projecting portion of base as a cantilever (see Figure 1): required design stress = = = e = (Axial force) / (area of compressive stress block) 882.7 x 10 / (300 x 123 x 2) 11.96 N/mm2 L1 - 0.8sw = = 100 - (0.8 x 8) 93.6 mm Figure 1: Uniform pressure on cantilever Moment per mm width applied to plate from stress block, mc = (required design stress) x e2 2 = 11.96 x 93.6 2 = 52393.6 (per mm width) Nmm

2-2. Moment plus minimum axial force

Substituting defined values into the equilibrium equation M = Ta + Cb becomes: M = 0.6fcubpX(h X 2 ) - N (h hp 2 )

Substituting values results in the quadratic equation: (-3600) X + (2520000) X + (-100798120) = 0 Solving for X gives: X = 42.6 X= or 657.4 42.6 mm Figure 2: Uniform pressure on part of cantilever

4 / 11

Doc No

: : : :

REFERENCE

CALCULATION FOR COLUMN BASE PLATE (H-SHAPE)

TITLE: Base Plate for H - Shape Steel Column (Fixed Type A)

Job No Rev Page

07261D

Substituting into the equations for C and T gives: C = T = 0.6fcuBpX C-N = = 0.6 x 40 x 300 x 42.6 / 10 306.7 - 219.2 = = 306.7 87.6 kN kN

Moment per mm width applied to plate from stress block, mc = = 0.6fcuX (e - X/2) 0.6 x 40 x 42.6 x (93.6 - 42.6/2) = 73919.5 (per mm width) Nmm

3. BASE PLATE THICKNESS

Plate bending on either the tension side or the compression side may govern. Both sides must be investigated and the required plate thickness is the larger value resulting from these checks.

STEP 2

3-1. Compression side bending

Projecting portion of base as a cantilever (see Figure 1): moment per mm width applied to plate from stress block, mc = maximum value of 2-1. and 2-2. above = 4mc Fy 73919.5 Nmm

required base plate thickness:

tp =

4 x 73919.5 315 = 30.6 mm

3-2. Tension side bending

Plate thickness to resist bolt tension is based on a calculation for a pure cantilever, with no prying assumed. Plate bending across the corners may only be avoided by ensuring bolts are positioned within lines 45 from the corner of the column flange. (see Figure 3)

mr = T x m

= =

87.6 x 43.6 x 10 3817871.8 Nmm

Figure 3: Plate bending on tension side

m = L1 - k - 0.8 sw = =

100 - 50 - 0.8 x 8 43.6 mm 4mr Fybp 4 x 3817871.8 315 x 300 mm = 12.7 mm

required base plate thickness: tp =

Larger plate thickness tp =

30.6 mm

35

O.K! Plate thickness is sufficient!

5 / 11

Doc No

: : : :

REFERENCE

CALCULATION FOR COLUMN BASE PLATE (H-SHAPE)

TITLE: Base Plate for H - Shape Steel Column (Fixed Type A)

Job No Rev Page

07261D

4. HOLDING DOWN BOLTS AND ANCHORAGE

4-1. Holding down bolts

Force T is assumed to be shared equally between all the bolts in the tension row: T (number of bolts in tension) 43.8 kN 78.4 kN 87.6 2

STEP 3

force per bolt = =

O.K!

4-2. Anchorage to concrete

Assume an effective depth of the holding down bolts, L = = 450 - 50 (cover to reinforcement) 400 mm

Using anchor plate and check the concrete base for punching shear in accordance with BS 8110. Anchor plate size (for Grade 4.6 bolts) = 5d x 5d x 0.6d thk. Perimeter for punching shear P= = (12 x L) + (total perimeter of anchor plate) (12 x 400) + (50 x 2 + 300 x 1) x 2 + (100 x 2) fv vc = 5800.0 mm = 100 x 100 x 12 mm

Basic requirement, Average shear stress fv = T PxL =

87.6 x 10 5800 x 400 = 0.038 N/mm2

Obtaining design concrete shear stress, v c in accordance with table 3.8 of BS 8110, an area of tension reinforcement is assumed to its minimum value of 0.15% at the effective depth of 400 mm. vc = 0.34 N/mm2 > 0.038 N/mm2

O.K! Anchor bolts are sufficient!

5. SHEAR TRANSFER TO CONCRETE

Most moment connections are able to rely on friction. However, if high shear is combined with low moment and low axial compression, or if there is axial tension, it is the safest to provide a direct shear connection, either by setting the base plate in a shallow pocket which is filled with concrete or by providing a shear key welded to the underside of the plate. Check if the horizontal shear is transferred by friction, assuming available resistance to 0.3 of axial compression where axial tension is not applied. available shear resistance = 0.3 x Fc,min = 65.7 kN Fv = 65.7 kN

STEP 4

O.K!

The horizontal shear is transferred by friction!

6 / 11

Doc No

: : : :

REFERENCE

CALCULATION FOR COLUMN BASE PLATE (H-SHAPE)

TITLE: Base Plate for H - Shape Steel Column (Fixed Type A)

Job No Rev Page

07261D

6. WELDING CHECK

6-1. Tension flange weld

For most small and medium sized columns, the tension flange welds will be symmetrical, full strength fillet welds. Once the leg length of the required fillet weld exceeds 12mm then a partial penetration butt welds with superimposed fillet welds, or full penetration butt welds will probably be a more economical solution. tension capacity of the flange = = = force in the tension flange Bc x Tc x Fy 100 x 8 x 325 / 10 260 kN M D c - Tc Af Ac - 219.2 x 800 2716

STEP 5

= = =

-Nx

67.9 x 10 200 - 8 289.2 kN

where, Af : area of the column flange = Bc x Tc ,mm2 Ac : column cross-sectional area, mm2 Therefore, weld force per mm = 289.2 / (2 x 100 - 5.5) = 1.487 x 10 / 215 6.9 mm 1.487 6.9 kN/mm mm

weld throat required at 215 N/mm flange weld thickness = 8.0 mm

O.K!

8mm full strength fillet weld is required!

6-2. Compression flange weld

Assuming bearing contact, nominal welds only are required. However, since the moment is reversible, the tension weld must be made to both flanges.

6-3. Web weld

The capacity of the column web welds for horizontal shear forces should be taken as: Psw = = = 2 x 0.7 x s' x Pw x Lws 2 x 0.7 x 8 x 215 x (200 - 8 x 2) / 10 443.1 kN 65.7 kN

O.K! 8mm fillet weld is required!

where, Lws : length of web welds between fillets, mm

7 / 11

AVAILABLE SECTION LIST & PROPERTY for JAC

NO Name H (mm) Bf (mm) Tw (mm) Tf (mm) r (mm) A (cm2) Ix (cm4) Iy (cm4)

1 H194X150X6X9 2 H200X100X5.5X8 3 H244X175X7X11 4 H250X125X6X9 5 H294X200X8X12 6 H300X150X6.5X9 7 H340X250X9X14 8 H350X175X7X11 9 H390X300X10X16 10 H400X200X8X13 11 H440X300X11X18 12 H450X200X9X14 13 H488X300X11X18 14 H500X200X10X16 15 H588X300X12X20 16 H600X200X11X17 17 H700X300X13X24 18 H800X300X14X26 19 H100X100X6X8 20 H125X125X6.5X9 21 H150X150X7X10 22 H200X200X8X12 23 H250X250X9X14 24 H300X300X10X15 25 H350X350X12X19 26 H400X400X13X21

194 200 244 250 294 300 340 350 390 400 440 450 488 500 588 600 700 800 100 125 150 200 250 300 350 400

150 100 175 125 200 150 250 175 300 200 300 200 300 200 300 200 300 300 100 125 150 200 250 300 350 400

6 5.5 7 6 8 6.5 9 7 10 8 11 9 11 10 12 11 13 14 6 6.5 7 8 9 10 12 13

9 8 11 9 12 9 14 11 16 13 18 14 18 16 20 17 24 26 8 9 10 12 14 15 19 21

13 11 16 12 18 13 20 14 22 16 24 18 26 20 28 22 28 28 10 10 11 13 16 18 20 22

39.01 27.16 56.24 37.66 72.38 46.78 101.5 63.14 135 84.12 157.4 96.76 163.5 114.2 192.5 134.4 235.5 267.4 21.9 30.31 40.14 63.53 92.18 119.8 173.9 218.7

2630 1810 6040 3960 11100 7210 21200 13500 37900 23500 54700 32900 68900 46800 114000 75600 197000 286000 378 839 1620 4720 10700 20200 39800 66600

507 134 984 294 1600 508 3650 984 7200 1740 8110 1870 8110 2140 9010 2270 10800 11700 134 293 563 1600 3650 6750 13600 22400

Where, Zx, Zy Modulus of Section Sx, Sy Plastic Modulus of Section Sv Plastic Modulus of Web, means Plastic Modulus of Shear Area Av For Calculation of Section Capacity, Refer BS5950-1:2000, Section 4

SM490A py

t < 16 t < 40 t > 40 325 315 295 Mpa

Zx (cm3)

Zy (cm3)

Sx (cm3)

Sy (cm3)

Sv (cm3)

BCI CLASS

Shear Capacity (KN) =0.6*Av*py

Moment Capacity (KN.m) Low Shear

271 181 495 317 756 481 1250 771 1940 1170 2490 1460 2820 1870 3890 2520 5640 7160 75.6 134 216 472 860 1350 2280 3330

67.6 26.7 112 47 160 67.7 292 112 480 174 540 187 540 214 601 227 721 781 26.7 46.9 75.1 160 292 450 776 1120

309 209 558 366 859 542 1410 868 2190 1330 2820 1680 3230 2180 4490 2980 6460 8240 87.6 154 246 525 960 1500 2550 3670

104 41.9 173 73.1 247 105 447 174 733 268 828 291 830 335 928 361 1120 1220 41.2 71.9 115 244 444 684 1180 1700

46.5 46.6 86.2 80.7 145.8 129.2 219.0 188.3 320.4 279.8 448.8 400.7 561.8 547.6 900.9 881.0 1381.6 1958.3 10.6 18.6 29.6 62.0 110.9 182.3 292.0 416.5

2 1 1 1 2 3 2 3 3 3 1 3 1 3 3 3 3 3 1 1 1 2 2 3 2 3

227.0 214.5 333.1 292.5 458.6 380.3 596.7 477.8 760.5 624.0 943.8 789.8 1046.8 975.0 1375.9 1287.0 1774.5 2184.0 117.0 158.4 204.8 312.0 438.8 585.0 819.0 1014.0

100.4 67.9 181.4 119.0 279.2 156.3 458.3 250.6 630.5 380.3 916.5 474.5 1049.8 607.8 1264.3 819.0 1833.0 2327.0 28.5 50.1 80.0 170.6 312.0 438.8 828.8 1082.3

refer BS5950-1:2000, Section 4

Moment Capacity (KN.m) High Shear

85.3 52.8 153.3 92.7 231.8 128.3 387.1 209.8 543.8 319.6 746.9 387.7 840.5 474.1 1036.2 608.8 1486.5 1844.2 25.0 44.0 70.3 150.5 276.0 399.3 711.3 961.5

assume Fv/Pv=1, =[2(Fv/Pv)-1]2 = 1, which is about 20% consevative than Fv/Pv=0.6

BASE PLATE SCHEDULE (H-PLATE)

No. Colume Size 1 H194X150X6X9 2 H200X100X5.5X8 3 H244X175X7X11 4 H250X125X6X9 5 H294X200X8X12 6 H300X150X6.5X9 7 H340X250X9X14 8 H350X175X7X11 9 H390X300X10X16 10 H400X200X8X13 11 H440X300X11X18 12 H450X200X9X14 13 H488X300X11X18 14 H500X200X10X16 15 H588X300X12X20 16 H600X200X11X17 17 H700X300X13X24 18 H800X300X14X26 19 H100X100X6X8 20 H125X125X6.5X9 21 H150X150X7X10 22 H200X200X8X12 23 H250X250X9X14 24 H300X300X10X15 25 H350X350X12X19 26 H400X400X13X21

Вам также может понравиться

- Base Plate Design - BS CodeДокумент3 страницыBase Plate Design - BS Codemicheleling669667% (3)

- Base Plate DesignДокумент118 страницBase Plate Designsanjay singhОценок пока нет

- End Plate DesignДокумент4 страницыEnd Plate DesignAgnon Fung100% (4)

- Design of Shear KeyДокумент13 страницDesign of Shear Keynhulugalla100% (1)

- 5 - Moment-Area MethodДокумент103 страницы5 - Moment-Area MethodAkela Richard100% (1)

- Escorts TractorsДокумент65 страницEscorts TractorsAnonymous RQcJ8yM100% (2)

- SCP BangaloreДокумент21 страницаSCP BangaloreSahana asmiОценок пока нет

- System Analysis and DesignДокумент24 страницыSystem Analysis and DesignKundan KumarОценок пока нет

- Combined Gusset Plate DesignДокумент3 страницыCombined Gusset Plate Designkalpanaadhi100% (3)

- Design of Headed Concrete AnchorДокумент121 страницаDesign of Headed Concrete AnchorkalpanaadhiОценок пока нет

- 2.column Base Plate (Fixed Type)Документ15 страниц2.column Base Plate (Fixed Type)ZevanyaRolandTualakaОценок пока нет

- Base Plate DesignДокумент32 страницыBase Plate DesignGautam Sharma50% (2)

- Bolt Capacity CalculationsДокумент4 страницыBolt Capacity CalculationskalpanaadhiОценок пока нет

- Moment Connection - Flush End Plate-19.01.06Документ48 страницMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Design of Embeded Plate (INDIAN STANDARD)Документ3 страницыDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- Base Plate Design (Fixed Base)Документ3 страницыBase Plate Design (Fixed Base)Saravana NОценок пока нет

- Base Plate Design Fixed RevisedДокумент8 страницBase Plate Design Fixed RevisedEngDbt80% (5)

- Connection Design SheetДокумент47 страницConnection Design SheetStephen James100% (1)

- Base PlateДокумент45 страницBase PlateMuhammed Ali60% (5)

- Circular Base PlateДокумент4 страницыCircular Base PlateErnesto Feliciano Basurto Galvez100% (1)

- Design Sample of Base Plate and Anchor BoltДокумент5 страницDesign Sample of Base Plate and Anchor BoltSunil NepalОценок пока нет

- Steel Column Base PlateДокумент17 страницSteel Column Base PlateVAN HUNG TRANОценок пока нет

- Beam To Beam Connection (Bending & Shear)Документ15 страницBeam To Beam Connection (Bending & Shear)ChangHangWingОценок пока нет

- Beam To Beam ConnectionДокумент47 страницBeam To Beam Connectionamitkumar8946Оценок пока нет

- MOMENT EndplateДокумент10 страницMOMENT EndplateALPHYL BALASABASОценок пока нет

- Base Plate CalculationДокумент6 страницBase Plate CalculationbuildconОценок пока нет

- Base Plate Design - 8m Span - Max Vertical LoadДокумент7 страницBase Plate Design - 8m Span - Max Vertical Loadnitin400Оценок пока нет

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryДокумент25 страницRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Calculation For Rafter-Column ConnectionДокумент6 страницCalculation For Rafter-Column ConnectionpriantomoОценок пока нет

- Design of Base PlateДокумент166 страницDesign of Base PlateAnonymous ciKyr0t86% (7)

- Beam-Column Using Double Angle CleatДокумент7 страницBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Anchor Bolt CHKДокумент17 страницAnchor Bolt CHKPriya GОценок пока нет

- Bolted Cover Plate Splice Connection B1Документ4 страницыBolted Cover Plate Splice Connection B1ikanyu79Оценок пока нет

- Shear Connection - Beam - Steel Column - Fin PlateДокумент30 страницShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Base Plate - FixedДокумент4 страницыBase Plate - Fixedbhaskardharani80% (5)

- Moment Connection Portal FrameДокумент18 страницMoment Connection Portal Frametmssorin100% (1)

- Base Plate Design-1 - J BoltДокумент41 страницаBase Plate Design-1 - J BoltGautam PaulОценок пока нет

- Splice 03Документ15 страницSplice 03LexОценок пока нет

- Moment ConnectionДокумент39 страницMoment ConnectionRitwick MishraОценок пока нет

- Steel Staircase DesignДокумент6 страницSteel Staircase DesignMario FeghaliОценок пока нет

- End-Plate-Design BS CodeДокумент15 страницEnd-Plate-Design BS CodeRaymond SabadoОценок пока нет

- Base Plate DesignДокумент9 страницBase Plate DesignbuildconОценок пока нет

- Vessel Foundation 1 CalcДокумент7 страницVessel Foundation 1 CalcmakcodetechОценок пока нет

- Wind PDFДокумент24 страницыWind PDFnagarajhebbarОценок пока нет

- Design of Grating For PlatformДокумент5 страницDesign of Grating For Platformvj8584100% (2)

- Calculation Sheet: Design PhilosophyДокумент36 страницCalculation Sheet: Design Philosophyrammohan100% (1)

- Column Base Plate (Hinge Type)Документ14 страницColumn Base Plate (Hinge Type)Tengku Nizarul AslamiОценок пока нет

- 1.0 Rectangular Column-BIAXIALДокумент31 страница1.0 Rectangular Column-BIAXIALFranklyn P. Genove100% (1)

- Knee ConnectionsДокумент13 страницKnee ConnectionsNag RajОценок пока нет

- Column Base Plate (Hinge Type)Документ11 страницColumn Base Plate (Hinge Type)ZevanyaRolandTualakaОценок пока нет

- Embed Design - Core WallДокумент39 страницEmbed Design - Core Wallkalpanaadhi100% (1)

- Ba Culvertf TestДокумент16 страницBa Culvertf TestsanjuktaacharyyaОценок пока нет

- Column Base Plate (Hinge Type)Документ7 страницColumn Base Plate (Hinge Type)Ernest NavarroОценок пока нет

- M2-CV-RC-D-005 (R1)Документ22 страницыM2-CV-RC-D-005 (R1)ksshashidharОценок пока нет

- Connections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)Документ5 страницConnections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)travis8zimmermannОценок пока нет

- Composite Steel GirderДокумент10 страницComposite Steel GirdersorowareОценок пока нет

- OHSRДокумент48 страницOHSRsachingadage100% (2)

- Design of Base Plate As Per IS800Документ180 страницDesign of Base Plate As Per IS800buildcon62% (13)

- PF2Документ4 страницыPF2nhulugallaОценок пока нет

- Base PlateДокумент32 страницыBase PlateSunil SinghОценок пока нет

- Abut DesignДокумент32 страницыAbut DesignSubir Kunda100% (2)

- CVX7640 32Документ14 страницCVX7640 32malingauomОценок пока нет

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDДокумент4 страницыDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghОценок пока нет

- Shop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Документ129 страницShop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Ernest NavarroОценок пока нет

- Structural Design Calculation Sheet For Aluminum PergolaДокумент58 страницStructural Design Calculation Sheet For Aluminum PergolaErnest Navarro100% (2)

- Parameters:: 32.0 Mpa 460.0 Mpa 3000.0 MM 300.0 MM 502.0 MM 2700.0 KN-M 450.0 KN 30 MMДокумент6 страницParameters:: 32.0 Mpa 460.0 Mpa 3000.0 MM 300.0 MM 502.0 MM 2700.0 KN-M 450.0 KN 30 MMErnest NavarroОценок пока нет

- Asi09-048 Site Investigation Report PDFДокумент68 страницAsi09-048 Site Investigation Report PDFErnest NavarroОценок пока нет

- Technocast Precast L.L.C.: Design Calculation SheetДокумент5 страницTechnocast Precast L.L.C.: Design Calculation SheetErnest NavarroОценок пока нет

- Soil Investigation Report PDFДокумент174 страницыSoil Investigation Report PDFErnest NavarroОценок пока нет

- Masonry Blocks: ProductsДокумент5 страницMasonry Blocks: ProductsErnest NavarroОценок пока нет

- CT-631. Design Calculation Sheet. Rev.01 PDFДокумент136 страницCT-631. Design Calculation Sheet. Rev.01 PDFErnest Navarro100% (1)

- Aci318m-11code Requirements For Beams Under Combined Shear and TorsionДокумент11 страницAci318m-11code Requirements For Beams Under Combined Shear and TorsionErnest NavarroОценок пока нет

- CT-631. Design Calculation Sheet. Rev.0 PDFДокумент101 страницаCT-631. Design Calculation Sheet. Rev.0 PDFErnest Navarro100% (1)

- Menaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFДокумент176 страницMenaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFErnest NavarroОценок пока нет

- Partial Fixity in ETABSДокумент3 страницыPartial Fixity in ETABSErnest NavarroОценок пока нет

- Loadbearing Architectural PrecastДокумент24 страницыLoadbearing Architectural PrecastErnest NavarroОценок пока нет

- ConneCtor PDA 2001 Data (Segmentation)Документ24 страницыConneCtor PDA 2001 Data (Segmentation)Vivek AnandanОценок пока нет

- Eaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsДокумент24 страницыEaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsGeorge BuitragoОценок пока нет

- Hands On ExerciseДокумент6 страницHands On ExerciseTakeaslynn Khalia GardnerОценок пока нет

- 4th Class - Alberto LARA PDFДокумент4 страницы4th Class - Alberto LARA PDFalara-731450Оценок пока нет

- (检验室)计算机化系统验证核心文件(中英文对照)Документ18 страниц(检验室)计算机化系统验证核心文件(中英文对照)JasonОценок пока нет

- Quiz QuestionsДокумент8 страницQuiz QuestionsSai NathОценок пока нет

- SLM Configuration Step by StepДокумент54 страницыSLM Configuration Step by StepHubert MandukuОценок пока нет

- Is 17406 - 2020 Transportation, Storage, Installation and Tensioning of Wire Ropes For Passenger Ropeway - Code of PracticeДокумент12 страницIs 17406 - 2020 Transportation, Storage, Installation and Tensioning of Wire Ropes For Passenger Ropeway - Code of PracticeSandeep Kumar JaiswalОценок пока нет

- Article ReviewДокумент2 страницыArticle ReviewPravin Shinde100% (2)

- BIM ModelingДокумент51 страницаBIM ModelingTony NguyenОценок пока нет

- Glotut 01 AnsДокумент2 страницыGlotut 01 AnsJean LawОценок пока нет

- Dir. Master File-NewДокумент436 страницDir. Master File-NewassmexellenceОценок пока нет

- Bearing TolerancesДокумент5 страницBearing Tolerancesstavros stergiopoulosОценок пока нет

- D) Access Information Stored On Computer Files While Having A Limited Understanding of The Client's Hardware and Software FeaturesДокумент6 страницD) Access Information Stored On Computer Files While Having A Limited Understanding of The Client's Hardware and Software FeaturesShanygane Delos SantosОценок пока нет

- What Is Free/Open-Source Software (FOSS) ?Документ24 страницыWhat Is Free/Open-Source Software (FOSS) ?Marko SchuetzОценок пока нет

- Snap728 enДокумент8 страницSnap728 enRajОценок пока нет

- CS230Документ464 страницыCS230JFPacОценок пока нет

- Std-145 General Safety Audit GuidlinesДокумент123 страницыStd-145 General Safety Audit Guidlinespanduranganraghurama100% (1)

- How To Use Transaction SOST & SCOT For Chec..Документ2 страницыHow To Use Transaction SOST & SCOT For Chec..ghenno18Оценок пока нет

- Inside TT44 ManualДокумент64 страницыInside TT44 Manualkaesar100% (1)

- Aviation InsuranceДокумент30 страницAviation Insurancelaxmi sambreОценок пока нет

- XO CookbookДокумент47 страницXO CookbookDavid CarballidoОценок пока нет

- 2017 CacДокумент70 страниц2017 CacHorațiu FerchiuОценок пока нет

- Report For Action: Date: April 16, 2019 To: City Council From: City Manager Wards: AllДокумент20 страницReport For Action: Date: April 16, 2019 To: City Council From: City Manager Wards: AllToronto StarОценок пока нет

- A33CEДокумент4 страницыA33CEfausstrollОценок пока нет

- Shielding RF Components at The Package LeveДокумент12 страницShielding RF Components at The Package LeveSebastian ReguanОценок пока нет

- Windows Azure Overview TechEd v03Документ23 страницыWindows Azure Overview TechEd v03mobile_hasmadi_othmanОценок пока нет