Академический Документы

Профессиональный Документы

Культура Документы

Hitachi Tool - ASR Pico

Загружено:

junior_radaicИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hitachi Tool - ASR Pico

Загружено:

junior_radaicАвторское право:

Доступные форматы

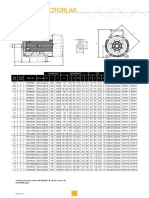

No. 320.

Q max

HRC

High Efcient

Roughing

Semi Finishing

54 (62)

No. of

Teeth

2~8

Type B

Type A

D D1

Type B

Type A

ID Code

FH 529

FH 530

FH 531

FH 532

FH 533

FH 537

FH 538

FH 539

d2

d2

d1

d1

D1

Item Code

Stock Flutes D

ASRM-2016R-2

2

16

ASRM-2020R-3

3

20

ASRM-2025R-4

4

25

ASRM-2032R-5

5

32

ASRM-2040R-6

6

40

ASR-2042RM-6

6

42

ASR-2052RM-7

7

52

ASR-2066RM-8

8

66

D

D1

6.2

10.2

15.2

22.2

30.2

32.2

42.2

56.2

H

25

30

35

40

40

40

50

50

d1

8.5

10.5

12.5

17

17

16

22

27

M

M8

M10

M12

M16

M16

d2

13

18

21

29

29

32

47

60

A

5.5

6

7

7

7

B

17

19

22

23

23

C

10

10

10

12

12

E

10

15

17

22

22

0 / -0.2

Inserts

One Insert-size for all diameters

16 mm ~ 66 mm

EPNW0603TN-8

= Stock | Germany

INSERTS

ID Code

WF 641

WF 642

WF 643

Item No.

Stock Grade NEW Coating

TB6005 PVD Hybrid Coating

EPNW0603TN-8

TB6020 PVD Hybrid Coating

EPNW0603TN-8

TB6045 PVD Hybrid Coating

EPNW0603TN-8

= Stock | Germany

Programming Radius

R

2

2

2

Clamp Screw

Wrench

ID-Code Item-Code ID-Code Item-Code

ET175

250-141(A) ET13

104-T8

Recommended Cutting Conditions

I

II

Insert

Grade

Carbon-Steel

TB 6020

Alloy-Steel

TB 6045

<30HRC

Alloy-Steel

III Tool-Steel

30~40HRC

TB 6020

TB 6045

Pre-Hardened

TB 6005

Steel

IV

TB 6020

Tool-Steel

40~50HRC

Pre-Hardened

TB 6005

Steel

TB 6020

Tool steel

(50-62HRC)

Cast-Iron

VIII GG

GGG

TB 6020

TB 6045

Work piece

material

Insert

Grade

I

II

Carbon-Steel

TB 6020

Alloy-Steel

TB 6045

<30HRC

Alloy-Steel

III Tool-Steel

30~40HRC

TB 6020

TB 6045

Pre-Hardened

TB 6005

Steel

IV

TB 6020

Tool-Steel

40~50HRC

Pre-Hardened

TB 6005

Steel

TB 6020

Tool steel

(50-62HRC)

Cast-Iron

VIII GG

GGG

TB 6020

TB 6045

Cutting

Condition

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

Cutting

Condition

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

n (min-1)

Vc (m/min)

Vf (mm/min)

fz feed/tooth

ap (mm)

ae (mm)

Volume cm3

16 (z2)

< 3D

General High 3D5D 5D7D

Speed

1,800 3,590

90

180

2,880 10,060

0.8

1.4

0.8

0.6

12

12

28

72

1,800 3,590

90

180

2,880 10,060

0.8

1.4

0.6

0.4

12

12

21

48

1,800 2,590

90

130

2,160 6,220

0.6

1.2

0.5

0.35

12

12

13

26

1,600 2,390

80

120

1,600 4,780

0.5

1.0

0.4

0.25

12

12

8

14

1,800 3,590

90

180

4,320 11,490

1.2

1.6

1.0

0.8

12

12

52

110

2,590

130

4,150

0.8

0.6

12

30

2,590

130

4,150

0.8

0.5

12

25

1,800

90

2,880

0.8

0.4

12

14

1,600

80

1,920

0.6

0.35

12

8

2,590

130

6,220

1.2

0.8

12

60

2,590

130

4,150

0.8

0.5

12

25

2,590

130

4,150

0.8

0.4

12

20

1,800

90

2,880

0.8

0.3

12

10

1,600

80

1,920

0.6

0.25

12

6

2,590

130

6,220

1.2

0.6

12

45

32 (z5)

< 3D

General High 3D5D 5D7D

Speed

900 1,800

90

180

4,500 14,400

1.0

1.6

1.0

0.5

24

24

108

173

900 1,800

90

180

4,500 14,400

1.0

1.6

0.8

0.4

24

24

86

138

900 1,300

90

130

3,600 9,100

0.8

1.4

0.6

0.35

24

24

52

76

800 1,200

80

120

2,400 6,000

0.6

1.0

0.4

0.25

24

24

23

36

900 1,800

90

180

6,300 16,200

1.4

1.8

1.25

1.0

24

24

189

389

1,300

130

6,500

1.0

0.8

24

125

1,300

130

6,500

1.0

0.6

24

94

900

90

3,600

0.8

0.5

24

43

800

80

2,400

0.6

0.35

24

20

1,300

130

9,100

1.4

0.8

24

175

1,300

130

6,500

1.0

0.6

24

94

1,300

130

6,500

1.0

0.5

24

78

900

90

3,600

0.8

0.4

24

35

800

80

2,400

0.6

0.25

24

14

1,300

130

9,100

1.4

0.6

24

131

> 7D

1,800

90

2,880

0.8

0.4

12

14

1,800

90

2,880

0.8

0.3

12

10

1,800

90

2,880

0.8

0.2

12

7

1,600

80

1,920

0.6

0.15

12

3

1,800

90

4,320

1.2

0.5

12

26

> 7D

900

90

4,500

1.0

0.4

24

43

900

90

4,500

1.0

0.35

24

38

900

90

3,600

0.8

0.25

24

22

800

80

2,400

0.6

0.15

24

9

900

90

6,300

1.4

0.4

24

60

20 (z3)

< 3D

General High 3D5D 5D7D

Speed

1,440 2,870

90

180

4,320 13,780

1.0

1.6

1.0

0.5

15

15

65

103

1,440 2,870

90

180

4,320 13,780

1.0

1.6

0.8

0.4

15

15

52

83

1,440 2,080

90

130

3,460 8,740

0.8

1.4

0.6

0.35

15

15

31

46

1,280 1,920

80

120

2,310 5,760

0.6

1.0

0.4

0.25

15

15

14

22

1,440 2,870

90

180

6,050 15,500

1.4

1.8

1.25

1.0

15

15

113

233

2,080

130

6,240

1.0

0.8

15

75

2,080

130

6,240

1.0

0.6

15

56

1,440

90

3,460

0.8

0.5

15

26

1,280

80

2,310

0.6

0.35

15

12

2,080

130

8,740

1.4

0.8

15

105

2,080

130

6,240

1.0

0.6

15

56

2,080

130

6,240

1.0

0.5

15

47

1,440

90

3,460

0.8

0.4

15

21

1,280

80

2,310

0.6

0.25

15

9

2,080

130

8,740

1.4

0.6

15

79

40 (z6), 42 (z6)

< 3D

General High 3D5D 5D7D

Speed

720 1,440

90

180

4,320 13,830

1.0

1.6

1.0

0.5

30

30

130

207

720 1,440

90

180

4,320 13,830

1.0

1.6

0.8

0.4

30

30

104

166

720 1,040

90

130

3,460 8,740

0.8

1.4

0.6

0.35

30

30

62

92

640

960

80

120

2,310 5,760

0.6

1.0

0.4

0.25

30

30

28

43

720 1,440

90

180

6,050 15,560

1.4

1.8

1.25

1.0

30

30

227

467

1,040

130

6,240

1.0

0.8

30

150

1,040

130

6,240

1.0

0.6

30

112

720

90

3,460

0.8

0.5

30

52

640

80

2,310

0.6

0.35

30

24

1,040

130

8,740

1.4

0.8

30

210

1,040

130

6,240

1.0

0.6

30

112

1,040

130

6,240

1.0

0.5

30

94

720

90

3,460

0.8

0.4

30

42

640

80

2,310

0.6

0.25

30

17

1,040

130

8,740

1.4

0.6

30

157

> 7D

1,440

90

4,320

1.0

0.4

15

26

1,440

90

4,320

1.0

0.35

15

23

1,440

90

3,460

0.8

0.25

15

13

1,280

80

2,310

0.6

0.15

15

5

1,440

90

6,050

1.4

0.4

15

36

> 7D

720

90

4,320

1.0

0.4

30

52

720

90

4,320

1.0

0.35

30

45

720

90

3,460

0.8

0.25

30

26

640

80

2,310

0.6

0.15

30

10

720

90

6,050

1.4

0.4

30

73

Hitachi Tool Engineering Europe GmbH

Itterpark 12 40724 Hilden Germany Phone +49 (0) 21 03 24 82-0 Fax +49 (0) 21 03 24 82-30

e-Mail info@hitachitool-eu.com Internet www.hitachitool-eu.com

2006 by Hitachi Tool Engineering Europe GmbH 3rd Edition Printed in Germany

25 (z4)

< 3D

General High 3D5D 5D7D

Speed

1,150 2,300

90

180

4,600 14,720

1.0

1.6

1.0

0.5

20

20

92

147

1,150 2,300

90

180

4,600 14,720

1.0

1.6

0.8

0.4

20

20

74

118

1,150 1,660

90

130

3,680 9,300

0.8

1.4

0.6

0.35

20

20

44

65

1,020 1,530

80

120

2,450 6,120

0.6

1.0

0.4

0.25

20

20

20

31

1,150 2,300

90

180

6,440 16,560

1.4

1.8

1.25

1.0

20

20

161

331

1,660

130

6,640

1.0

0.8

20

106

1,660

130

6,640

1.0

0.6

20

80

1,150

90

3,680

0.8

0.5

20

37

1,020

80

2,450

0.6

0.35

20

17

1,660

130

9,300

1.4

0.8

20

149

52 (z7)

< 3D

General

High

Speed

551

90

3,858

1

1

40

154

551

90

3,858

1

0.8

40

123

551

90

3,087

0.8

0.6

40

74

490

80

2,058

0.6

0.4

40

33

551

90

5,402

1.4

1.25

40

270

1,102

180

12,347

1.6

0.5

40

247

1,102

180

12,347

1.6

0.4

40

198

796

130

7,803

1.4

0.35

40

109

735

120

5,145

1

0.25

40

51

1,102

180

13,890

1.8

1

40

556

1,660

130

6,640

1.0

0.6

20

80

1,660

130

6,640

1.0

0.5

20

66

1,150

90

3,680

0.8

0.4

20

29

1,020

80

2,450

0.6

0.25

20

12

1,660

130

9,300

1.4

0.6

20

112

> 7D

1,150

90

4,600

1.0

0.4

20

37

1,150

90

4,600

1.0

0.35

20

32

1,150

90

3,680

0.8

0.25

20

18

1,020

80

2,450

0.6

0.15

20

7

1,150

90

6,440

1.4

0.4

20

52

66 (z8)

< 3D

General

High

Speed

434

90

3,474

1

1

50

174

434

90

3,474

1

0.8

50

139

434

90

2,779

0.8

0.6

50

83

386

80

1,853

0.6

0.4

50

37

434

90

4,864

1.4

1.25

50

304

869

180

11,118

1.6

0.5

50

278

869

180

11,118

1.6

0.4

50

222

627

130

7,026

1.4

0.35

50

123

579

120

4,632

1

0.25

50

58

869

180

12,507

1.8

1

50

625

HTT204 0610 ASR-Pico-5.0 BW

Work piece

material

Вам также может понравиться

- Пазовые фрезы PDFДокумент72 страницыПазовые фрезы PDFstctoolОценок пока нет

- Catalog Series RTC Aventics en 6912350Документ150 страницCatalog Series RTC Aventics en 6912350Omar Jasid LaraОценок пока нет

- Ball Bearings CatalogueДокумент40 страницBall Bearings CatalogueCorneliu TocanОценок пока нет

- 1 Cutting Tools KДокумент358 страниц1 Cutting Tools Kchitzulanu100% (1)

- Serie 523 - ISO 15552Документ69 страницSerie 523 - ISO 15552NixiusОценок пока нет

- Catalogue Esconylescoflex PDFДокумент8 страницCatalogue Esconylescoflex PDFTEIUSANUОценок пока нет

- W22 Mechanical Data - Frames 63 To 132: Drive End (D.E.) Shaft DimensionsДокумент1 страницаW22 Mechanical Data - Frames 63 To 132: Drive End (D.E.) Shaft DimensionsingenieuredwinОценок пока нет

- FL6003 PDFДокумент4 страницыFL6003 PDFMauricio Barrios CastellanosОценок пока нет

- Spidex OperatingДокумент10 страницSpidex Operatingwalk001Оценок пока нет

- Hydraulic Cylinders CHДокумент8 страницHydraulic Cylinders CHStoianovici CristianОценок пока нет

- Servo Part ListДокумент2 страницыServo Part ListahmetОценок пока нет

- Vdi ShanksДокумент15 страницVdi ShanksmachineCanОценок пока нет

- Taper LockДокумент5 страницTaper Lockhexapodo2Оценок пока нет

- Caracteristicas Motores PDFДокумент60 страницCaracteristicas Motores PDF0ZKRCITHOОценок пока нет

- DatasheetДокумент16 страницDatasheetErick MauricioОценок пока нет

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesДокумент17 страницMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasОценок пока нет

- Symbols Outer Ring: 1) DMP 2) DP DMP Bs B1s Bs IaДокумент1 страницаSymbols Outer Ring: 1) DMP 2) DP DMP Bs B1s Bs IaMiftakhu ZaimОценок пока нет

- Mitubishi AJX PDFДокумент20 страницMitubishi AJX PDFZeljko StamatovicОценок пока нет

- Gafco Carbon FilterДокумент4 страницыGafco Carbon Filtermzmakba1Оценок пока нет

- Natsteel RebarsДокумент12 страницNatsteel RebarsjoebriffaОценок пока нет

- Natsteel - Reinforcement BarsДокумент12 страницNatsteel - Reinforcement BarsJianhua WuОценок пока нет

- VHM 106 161 PDFДокумент56 страницVHM 106 161 PDFGeronimo PrincipeОценок пока нет

- CC936AДокумент4 страницыCC936AKen Lau Boun KongОценок пока нет

- HTD Pulleys For Plain Boring: Optibelt ZRS HTD - Zahnscheiben Für Zylindrische BohrungДокумент14 страницHTD Pulleys For Plain Boring: Optibelt ZRS HTD - Zahnscheiben Für Zylindrische BohrungAbdessamad AyadОценок пока нет

- Process Machine Consumption +tol 20% Per Pce Per PceДокумент3 страницыProcess Machine Consumption +tol 20% Per Pce Per PceBumi AzarakhОценок пока нет

- Socitec Wirerope Iso Load Deflection PDFДокумент0 страницSocitec Wirerope Iso Load Deflection PDFraju3685Оценок пока нет

- VAT-Endustriyel Motor SF34Документ1 страницаVAT-Endustriyel Motor SF34Can AtunОценок пока нет

- LG Multi Split AC Catalogue 2019Документ5 страницLG Multi Split AC Catalogue 2019Ravi SankarОценок пока нет

- Cable Size and Tighting TorqueДокумент6 страницCable Size and Tighting TorqueAN.ADAMMSОценок пока нет

- Stihl ms-210 ms-230 Ms-250.iplДокумент17 страницStihl ms-210 ms-230 Ms-250.iplRosario SimbariОценок пока нет

- Threading Tools (SST Series)Документ8 страницThreading Tools (SST Series)Gilberto ManhattanОценок пока нет

- Quantity EstimateДокумент64 страницыQuantity Estimatefrancis sebastian lagamayoОценок пока нет

- Pro 787426Документ5 страницPro 787426Mohamed ElmakkyОценок пока нет

- SN430-2 2006-12 SAP eДокумент3 страницыSN430-2 2006-12 SAP eChristopher LloydОценок пока нет

- Suportes HiltДокумент52 страницыSuportes HiltAdilson GabuОценок пока нет

- Especificaciones Tecnicas Solmax Hdpe Metric EspanolДокумент3 страницыEspecificaciones Tecnicas Solmax Hdpe Metric EspanolAlfredo OvandoОценок пока нет

- Ap 02007Документ12 страницAp 02007Diana Laura Gallegos VasquezОценок пока нет

- Series 2412 - BSL Dimensional Fittings DrawingsДокумент10 страницSeries 2412 - BSL Dimensional Fittings DrawingsNabil RamehОценок пока нет

- Suction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsДокумент2 страницыSuction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsZMCONTROLОценок пока нет

- Pulleys TechДокумент8 страницPulleys TechashkansoheylОценок пока нет

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyДокумент4 страницыTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69Оценок пока нет

- Hilti DD 120Документ9 страницHilti DD 120Rickesh NunkooОценок пока нет

- Induction Motors: Single-PhaseДокумент3 страницыInduction Motors: Single-Phasemayito12093120Оценок пока нет

- Ceratizit U DrillДокумент8 страницCeratizit U DrillJitendra BagalОценок пока нет

- S 2332 Æ32 MM, Graphite Brushes, 15 Watt, Approved: Order NumberДокумент1 страницаS 2332 Æ32 MM, Graphite Brushes, 15 Watt, Approved: Order NumberChristophe BaurandОценок пока нет

- Cutter GuideДокумент1 страницаCutter GuideCarlos RamirezОценок пока нет

- Gy2g0200d020n-Mf VP10RTДокумент6 страницGy2g0200d020n-Mf VP10RTTungstenCarbideОценок пока нет

- Stihl MS 362 M-Tronic Parts List - Chainsaw Workshop ManualsДокумент57 страницStihl MS 362 M-Tronic Parts List - Chainsaw Workshop ManualsMaxiice DrafterОценок пока нет

- Catalogue Mennekes ReceptaclesДокумент30 страницCatalogue Mennekes Receptaclesbhaveshbhoi100% (1)

- Placute Filetare Taegu TecДокумент16 страницPlacute Filetare Taegu TecVladislav VatamaniucОценок пока нет

- CM Petroleum Rating Guide - 01.4A - OffshoreДокумент4 страницыCM Petroleum Rating Guide - 01.4A - OffshorecalixtohenriquezОценок пока нет

- SAE-J1926 Port Reference DimensionsДокумент1 страницаSAE-J1926 Port Reference DimensionsSamuel RochetteОценок пока нет

- Aluminum™ GafcoДокумент4 страницыAluminum™ GafcoBoanerges MalazarteОценок пока нет

- External Cyilindrical Grinding Surface Grinding and Thread Center GrindingДокумент2 страницыExternal Cyilindrical Grinding Surface Grinding and Thread Center GrindingpetroviccaaОценок пока нет

- OMRONДокумент14 страницOMRONwirawansatriaОценок пока нет

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryОт EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Programming Guide Cycles 840D PDFДокумент416 страницProgramming Guide Cycles 840D PDFjunior_radaicОценок пока нет

- Milling ManualДокумент137 страницMilling Manualyarth88Оценок пока нет

- Ampco Machining RecommendationsДокумент9 страницAmpco Machining Recommendationsjunior_radaicОценок пока нет

- MB0420120104 HS-450i Mechanical ManualДокумент72 страницыMB0420120104 HS-450i Mechanical Manualjunior_radaicОценок пока нет

- Milling ManualДокумент137 страницMilling Manualyarth88Оценок пока нет

- MB0120120108 HS-450i Operator's ManualДокумент152 страницыMB0120120108 HS-450i Operator's Manualjunior_radaicОценок пока нет

- M70 ProgramaçãoДокумент587 страницM70 Programaçãojunior_radaicОценок пока нет

- Manual Parámetros FanucДокумент507 страницManual Parámetros Fanucjunior_radaic50% (2)

- Manual Iso Torno FanucДокумент174 страницыManual Iso Torno Fanucjunior_radaicОценок пока нет

- I ConsoleДокумент56 страницI Consolejunior_radaicОценок пока нет

- Optimal Bracing System For Steel TowersДокумент4 страницыOptimal Bracing System For Steel TowersSaravanan Silamban100% (1)

- Catalogue FX03 enДокумент2 страницыCatalogue FX03 enonur_guzel6403100% (1)

- Specification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Документ2 страницыSpecification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Rahul KhoslaОценок пока нет

- Cromato AmarilloДокумент3 страницыCromato Amarillohumbertotorresr100% (1)

- Tofflon Service Engineer JD - IndonesiaДокумент4 страницыTofflon Service Engineer JD - IndonesiaTamilОценок пока нет

- Alfa Laval Sanitary Fittings and Basic ValvesДокумент91 страницаAlfa Laval Sanitary Fittings and Basic ValvesDobrovolschi ConstantinОценок пока нет

- Calculation of Duct SizingДокумент7 страницCalculation of Duct SizingPhyu Mar Thein KyawОценок пока нет

- IRIS IR Inline SeparatorДокумент6 страницIRIS IR Inline SeparatorNistha ChakrabortyОценок пока нет

- Dhir 1988Документ11 страницDhir 1988AhmadrazatahirОценок пока нет

- Secure QualityДокумент15 страницSecure QualityAnonymous e2wolbeFsОценок пока нет

- A Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Документ9 страницA Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Shreya Giri0% (1)

- Accelerating Admixtures For ShotcreteДокумент7 страницAccelerating Admixtures For Shotcreteneen61Оценок пока нет

- CPP MSDSДокумент4 страницыCPP MSDSevyОценок пока нет

- Manufacturing ProcessesДокумент17 страницManufacturing ProcessesTh GmОценок пока нет

- Separator 01dyДокумент44 страницыSeparator 01dyFadhil KhalidОценок пока нет

- Farrat Plate BrochureДокумент12 страницFarrat Plate BrochureShaneLinehanОценок пока нет

- Materiales de Construcción CanaletasДокумент40 страницMateriales de Construcción CanaletasErick Joel OcampoОценок пока нет

- PLEM Pile DrivabilityДокумент49 страницPLEM Pile Drivabilityarturom100% (1)

- EKT Mech 2014 2Документ9 страницEKT Mech 2014 2Ravinder ReddyОценок пока нет

- Specification For PVC Door & UPVC - WindowДокумент16 страницSpecification For PVC Door & UPVC - Windowsurbhi aggarwalОценок пока нет

- KAAP Technology Description and BenfitsДокумент4 страницыKAAP Technology Description and BenfitsTalha Jamil100% (1)

- TALAT Lecture 3501: Alloys and PropertiesДокумент8 страницTALAT Lecture 3501: Alloys and PropertiesCORE MaterialsОценок пока нет

- Novolac Vinyl Ester Resin: Asecorr 970Документ2 страницыNovolac Vinyl Ester Resin: Asecorr 970Mohammed SafwanОценок пока нет

- Help CarlosДокумент141 страницаHelp Carloszarzosa rabanalОценок пока нет

- Improved Chulhas - Final-1Документ60 страницImproved Chulhas - Final-1erkiruthirajОценок пока нет

- Level Based Training OutlineДокумент11 страницLevel Based Training OutlinesureshchitraОценок пока нет

- Aalborg HeaterДокумент2 страницыAalborg HeaterRokhmatuSivaОценок пока нет

- DIY HHO Torch Water Torch For Only 4Документ11 страницDIY HHO Torch Water Torch For Only 4martin ongОценок пока нет

- Easypure Ii Reservoir Feed Water Purification System: Operating Manual and Parts List Lt1305X1 Rev. 0Документ42 страницыEasypure Ii Reservoir Feed Water Purification System: Operating Manual and Parts List Lt1305X1 Rev. 0Anonymous 7qn4qmОценок пока нет

- Fuel Oil SystemДокумент11 страницFuel Oil SystemNawin Kumar100% (2)