Академический Документы

Профессиональный Документы

Культура Документы

Aluminum Design

Загружено:

Umesh ChamaraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aluminum Design

Загружено:

Umesh ChamaraАвторское право:

Доступные форматы

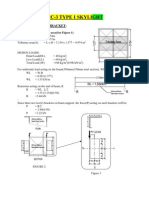

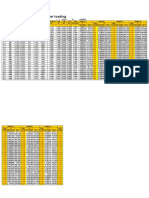

INPUT DATA & DESIGN SUMMARY

MEMBER SIZE 6 OD 0.375 WALL D t A I

x

E

Wt (lbs/ft)

6 0.375 6.63 26.3 10100 7.96

F

tu

= 38 ksi

F

ty

= 35 ksi

F

cy

= 35 ksi

AXIAL COMPRESSION FORCE P = 40 kips, ASD

MAX GEOMETRIC AXIS EFFECTIVE LENGTH kL = 1.5 ft

M

rx

= 13.75 ft-kips, ASD

GEOMETRIC AXIS BENDING UNBRACED LENGTH L

bx

= 2 ft

MAX SHEAR LOAD, ASD V = 30 kips

THE DESIGN IS ADEQUATE.

ANALYSIS

CHECK COMPRESSION STRESS IN AXIAL FORCE

19.05 ksi, (compression in column, AA ADM-IA 3.4.7)

Where r = 1.990 in, (Page VI-28 to VI-33)

kL / r = 9.05

E = 10100 ksi, (Table 3.3-1)

B

c

= F

cy

[1 + (F

cy

/ 2250)

0.5

] = 39.37 , (Table 3.3-4)

D

c

= (B

c

/ 10) (B

c

/ E)

0.5

= 0.25 , (Table 3.3-4)

C

c

= 0.41 (B

c

/ D

c

) = 65.67 , (Table 3.3-4)

n

u

= 1.95 , (Table 3.4-1)

n

y

= 1.65 , (Table 3.4-1)

S

1

= (B

c

- n

u

F

cy

/ n

y

) / D

c

= 0.00 , (Eq. 3.4.7-4)

S

2

= C

c

= 65.67 , (Eq. 3.4.7-5)

19.96 ksi, (compression in curved element, AA ADM-IA 3.4.10)

Where R

b

/ t = 7.500 , (Page I-A-13)

k

1

= 0.35 , (Table 3.3-4)

k

2

= 2.27 , (Table 3.3-4)

B

t

= F

cy

[1 + F

cy

(1/5)

/ 8.7] = 43.19 , (Table 3.3-4)

D

t

= (B

t

/ 4.5) (B

t

/ E)

(1/3)

= 1.56 , (Table 3.3-4)

C

t

= 141 , (Page VII-25)

S

1

= (B

t

- n

u

F

cy

/ n

y

)

2

/ (D

t

)

2

= 1.38 , (Eq. 3.4.10-4)

S

2

= C

t

= 141.00 , (Eq. 3.4.10-5)

GEOMETRIC AXIS BENDING MOMENT

ALUMINUM DESIGN CAPACITY ( PIPE)

TENSILE YIELD STRESS (T5, T6, T7, T8, or T9)

COMPRESSIVE YIELD STRESS (T5 to T9)

TENSILE ULTIMATE STRESS (T5 to T9, Tab 3.3-1)

Project:

Location:

Client:

Consultant:

1

1 2 1

2

2

2

,

,

,

cy

y

c

c

a

u

u

kL F

for S

r n

kL D

B

kL r

for S S F

r n

E kL

for S

r

kL

n

r

t

| |

|

\ .

< < = =

>

| |

|

\ .

1

1 2 2

2

2

2

,

,

,

1

1.6 1

35

cy

b

y

b

t t

b

a

u

b

b

u

F

R

for S

t n

R

B D

t

R

for S S

F

t n

E

R

for S

t

R R b

n

t t

t

| |

\ .

< < = =

>

| |

| |

+ | |

|

\ .

\ .

f

a

= P / A = 6.03 ksi < F

a

= Min (F

a 1

, F

a 2

) = 19.05 ksi

[Satisfactory]

CHECK TENSION STRESS IN BENDING MOMENTS

F = Min (1.17F

ty

/n

y

, 1.24F

tu

/ k

t

n

u

) = 24.16 ksi, (tension in bending, AA ADM-IA 3.4.3)

Where k

t

= 1.00 , (Table 3.4-2)

f = M

rx

/ S

x

= 18.79 ksi < F = 24.16 ksi

[Satisfactory]

Where S

x

= 8.78 in, (Page VI-28 to VI-33)

CHECK COMPRESSION STRESS IN BENDING MOMENT

24.82 ksi, (compression in beam, AA ADM-IA 3.4.12)

Where R

b

/ t = 7.500 , (Page I-A-13)

B

tb

= 1.5 F

cy

[1 + F

cy

(1/5)

/ 5.8] = 70.93 , (Table 3.3-4)

D

tb

= (B

tb

/ 2.7) (B

tb

/ E)

(1/3)

= 5.03 , (Table 3.3-4)

S

1

= (B

tb

- 1.17 F

cy

)

2

/ (D

tb

)

2

= 35.51 , (Eq. 3.4.12-3)

S

2

= (n

u

B

tb

/ n

y

- B

t

)

2

/ (n

u

D

tb

/ n

y

- D

t

)

2

= 85.8 , (Eq. 3.4.12-4)

f

bx

= M

rx

/ S

x

= 18.79 ksi < F

bx

= 24.82 ksi

[Satisfactory]

CHECK COMBINED COMPRESSION AND BENDING (AA ADM-IA 4.1.1)

1.07 < 1.33 , (1.33 if IBC/CBC 1605.3.2 apply)

[Satisfactory]

Where C

mx

= 0.85

F

ex

= p

2

E / n

u

(kL

x

/r

x

)

2

= 624.81 ksi

CHECK SHEAR STRESS (AA ADM-IA 3.4.20)

12.25 ksi, (for strong shear)

Where h / t = 16.00 , (for strong shear, Figure 3.4.18-1)

B

s

= (F

cy

/ 3

0.5

) [1 + (F

cy

/ 3

0.5

)

(1/3)

/ 9.3] = 26.13 , (Table 3.3-4)

D

s

= (B

s

/ 10) (B

s

/ E)

0.5

= 0.13 , (Table 3.3-4)

C

s

= 0.41 B

s

/ D

s

= 80.61 , (Table 3.3-4)

S

1

= (B

s

- F

cy

/ 3

0.5

) / (1.25 D

s

) = 35.63 , (Eq. 3.4.20-4)

S

2

= C

s

/ 1.25 = 64.49 , (Eq. 3.4.20-5)

f

s

= V

strong

/ A

w

= 2.50 ksi < F

s

= 12.25 ksi, (for strong shear)

[Satisfactory]

1

1 2

2

2

2

1.17

,

1

,

,

1

1.6 1

35

cy

b

y

b b

tb tb

y

bx

b

b

u

F

R

for

S

t

n

R R

for

S S B D

t t

n

F

E

R

for

S

t

R R b

n

t t

t

| |

< <

|

|

= =

\ .

>

| |

| |

+

|

|

|

\ .

\ .

( ) 1 /

mx a bx

a bx ex

a

a bx

a bx

f f C

f F F F

Max

f f

F F

| |

+

|

|

=

|

| +

|

\ .

1

1 2

2

2

2

/ 3

,

1.25

,

,

1.25

ty

y

s

s

s

y

y

h F

for S

t

n

h

D

B

h t

for

S S F

t n

E h

for S

t

h

n

t

t

| |

|

\ .

< < = =

>

| |

|

\ .

Вам также может понравиться

- Design of Aluminum Structure 1Документ3 страницыDesign of Aluminum Structure 1Ray Coello100% (2)

- Design Calculations For Aluminium Profile-13795Документ8 страницDesign Calculations For Aluminium Profile-13795msiddiq1100% (1)

- Aluminium Design Manual 2010 - The Aluminium AssociationДокумент440 страницAluminium Design Manual 2010 - The Aluminium AssociationQuang Hoành Lê100% (15)

- ADM 2015 Aluminum Design Manual - Tables 2-19Документ2 страницыADM 2015 Aluminum Design Manual - Tables 2-19Louis Liu100% (1)

- Section Classification BS 8118-1-1991Документ1 страницаSection Classification BS 8118-1-1991AthumizОценок пока нет

- Load CalculationДокумент108 страницLoad Calculationvpshreekanth71% (14)

- DESIGN CALCULATION Report PDFДокумент61 страницаDESIGN CALCULATION Report PDFShaikh Muhammad Ateeq100% (1)

- Structural GlassДокумент1 страницаStructural Glasssamgivp2869100% (4)

- Alum SampleДокумент2 страницыAlum Samplewaweng22Оценок пока нет

- Steel Bracket DesignДокумент3 страницыSteel Bracket Designrandy_pabilona50% (4)

- Aluminium DesignДокумент9 страницAluminium Designikanyu79Оценок пока нет

- ASCE7-10 Example Wind Chapter 5Документ12 страницASCE7-10 Example Wind Chapter 5Ahmed Ben Hmida100% (1)

- Aluminum Design Manual Frequently Asked Questions: Structures Section 4.7.7, What Inside Radius RДокумент3 страницыAluminum Design Manual Frequently Asked Questions: Structures Section 4.7.7, What Inside Radius RMeet SatheyОценок пока нет

- Glass PanelДокумент2 страницыGlass PanelEIWAA50% (2)

- Design Calculation-Glass BalustradeДокумент8 страницDesign Calculation-Glass Balustrademsiddiq1100% (2)

- Wind Load Arched RoofДокумент97 страницWind Load Arched Roofjeanfat100% (1)

- Design Guide 31 - Castellated and Cellular Beam DesignДокумент117 страницDesign Guide 31 - Castellated and Cellular Beam DesignLCS100% (18)

- Wind Calculation BS 6399Документ1 страницаWind Calculation BS 6399Alden CayagaОценок пока нет

- Structural Glass Design-UBCДокумент6 страницStructural Glass Design-UBCmsiddiq1100% (1)

- Composite Beam Simply Supported DesignДокумент21 страницаComposite Beam Simply Supported DesignTharanga Pradeep100% (1)

- Glass Fin Calculation in LTBДокумент7 страницGlass Fin Calculation in LTBAmro Ahmad Ali100% (2)

- AAMA TIR-A9-14 - Design Guide For Metal Cladding Fasteners - CommentedДокумент99 страницAAMA TIR-A9-14 - Design Guide For Metal Cladding Fasteners - CommentedMarco BenedettiОценок пока нет

- Design of Steel BeamДокумент19 страницDesign of Steel BeamAnonymous tBhJoH5wgMОценок пока нет

- Base Plate Design - HiltiДокумент38 страницBase Plate Design - HiltiVictor IkeОценок пока нет

- Design Model For Bolted Moment End Plate With RhsДокумент63 страницыDesign Model For Bolted Moment End Plate With Rhsfirter100% (1)

- Wind Calculation For CanopyДокумент11 страницWind Calculation For Canopyamitkukna100% (3)

- ConnectionДокумент2 страницыConnectionEIWAAОценок пока нет

- Glass Chart ASTM E1300Документ15 страницGlass Chart ASTM E1300mercab15Оценок пока нет

- Hilti Calculation ExamplesДокумент10 страницHilti Calculation ExamplesNgoc TruongОценок пока нет

- 5 Design of StiffnersДокумент30 страниц5 Design of StiffnersHazza JumaaОценок пока нет

- ASCE 7-22 CH 32 - For PC - SouДокумент49 страницASCE 7-22 CH 32 - For PC - SousharethefilesОценок пока нет

- Shelf Angle DesignДокумент16 страницShelf Angle Designaku94Оценок пока нет

- Column Base Plates DesignДокумент19 страницColumn Base Plates Designccbserialk80% (5)

- Ebf CBCДокумент6 страницEbf CBCNikki RobertsОценок пока нет

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-08Документ3 страницыBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-08yanu13Оценок пока нет

- The Girder Design Is Adequate.: DL LLДокумент9 страницThe Girder Design Is Adequate.: DL LLangkutanОценок пока нет

- Double TeeДокумент3 страницыDouble Teeyanu13Оценок пока нет

- Edificios SMRF ACIДокумент5 страницEdificios SMRF ACIJorge AlbertoОценок пока нет

- Diseño de Vigas A FlexionДокумент12 страницDiseño de Vigas A FlexionDaniel Peña FarfanОценок пока нет

- Basement Column Supporting Lateral Resisting Frame Based On ACI 318-08Документ2 страницыBasement Column Supporting Lateral Resisting Frame Based On ACI 318-08yanu13Оценок пока нет

- Borrador A MomentoДокумент16 страницBorrador A MomentoDaniel Peña FarfanОценок пока нет

- Ocbf IbcДокумент3 страницыOcbf IbcNikki RobertsОценок пока нет

- Basement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryДокумент46 страницBasement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryHizbar ArsjadОценок пока нет

- Wave On StringДокумент13 страницWave On StringManish TakОценок пока нет

- Columna de SotanoДокумент38 страницColumna de SotanoLivian TeddyОценок пока нет

- AISC 13.0 Properties ViewerДокумент18 страницAISC 13.0 Properties ViewerramilianОценок пока нет

- Bolted Moment ConnectionДокумент18 страницBolted Moment ConnectionHugo EzequielОценок пока нет

- EC2 Flowcharts - DimensionamentoДокумент5 страницEC2 Flowcharts - DimensionamentoTiago Valente100% (1)

- The Design Is Adequate.: 6 OD × 0.375 WALLДокумент3 страницыThe Design Is Adequate.: 6 OD × 0.375 WALLGreatОценок пока нет

- LRFD TablasДокумент3 страницыLRFD TablasFlorencio SandovalОценок пока нет

- Aceros - AISCДокумент4 страницыAceros - AISCFreddy Gallo SanchezОценок пока нет

- Concrete Pool Design Based On ACI 318-05: Input Data & Design SummaryДокумент13 страницConcrete Pool Design Based On ACI 318-05: Input Data & Design SummaryRicardo Vega ZamoraОценок пока нет

- Torsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionДокумент26 страницTorsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionHafiezul HassanОценок пока нет

- Testbeams For Ver Pile CapacityДокумент13 страницTestbeams For Ver Pile CapacitytmssorinОценок пока нет

- Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryДокумент3 страницыConcrete Column Design Based On ACI 318-11: Input Data & Design Summaryjaimeleoxxx0% (1)

- Exam 2 F10 SolДокумент8 страницExam 2 F10 SolAlejandro AguirreОценок пока нет

- Intake WellДокумент97 страницIntake WellHiren PatelОценок пока нет

- Side Runner DesignДокумент8 страницSide Runner Designvijaystructural100% (1)

- Section 4 PDFДокумент70 страницSection 4 PDFherrerafaridОценок пока нет

- Analytic Geometry: Graphic Solutions Using Matlab LanguageОт EverandAnalytic Geometry: Graphic Solutions Using Matlab LanguageОценок пока нет

- Sounds of Silence WebДокумент3 страницыSounds of Silence WebUmesh ChamaraОценок пока нет

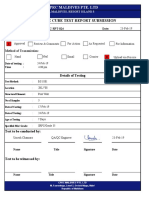

- Concrete Cube Test Report Submission: CPRC Maldives Pte. LTDДокумент1 страницаConcrete Cube Test Report Submission: CPRC Maldives Pte. LTDUmesh ChamaraОценок пока нет

- Concrete Cube Test Report Submission: CPRC Maldives Pte. LTDДокумент2 страницыConcrete Cube Test Report Submission: CPRC Maldives Pte. LTDUmesh ChamaraОценок пока нет

- Concrete Cube Test Report Submission: CPRC Maldives Pte. LTDДокумент1 страницаConcrete Cube Test Report Submission: CPRC Maldives Pte. LTDUmesh ChamaraОценок пока нет

- Concrete Cube Test Report Submission: CPRC Maldives Pte. LTDДокумент1 страницаConcrete Cube Test Report Submission: CPRC Maldives Pte. LTDUmesh ChamaraОценок пока нет

- Concrete Cube Test Report Submission: CPRC Maldives Pte. LTDДокумент1 страницаConcrete Cube Test Report Submission: CPRC Maldives Pte. LTDUmesh ChamaraОценок пока нет

- Regulatory Guide 1.92Документ27 страницRegulatory Guide 1.92tmax33Оценок пока нет

- Extracted Pages From RFHISL3-SOC-MES-ID-001.2-MS FOR DRY WALL PARTITION BY ZINTAДокумент1 страницаExtracted Pages From RFHISL3-SOC-MES-ID-001.2-MS FOR DRY WALL PARTITION BY ZINTAUmesh ChamaraОценок пока нет

- Sound Insulation Prediction-Method 2Документ1 страницаSound Insulation Prediction-Method 2Umesh ChamaraОценок пока нет

- STC Calculation For XCOM Bedroom - Living Room Floor & CeilingДокумент3 страницыSTC Calculation For XCOM Bedroom - Living Room Floor & CeilingUmesh ChamaraОценок пока нет

- Section CeilingДокумент1 страницаSection CeilingUmesh ChamaraОценок пока нет

- Bolt TorqueДокумент2 страницыBolt TorqueUmesh Chamara100% (1)

- Sound Insulation Prediction-Method 1Документ1 страницаSound Insulation Prediction-Method 1Umesh ChamaraОценок пока нет

- Assignment 01-UmeshДокумент19 страницAssignment 01-UmeshUmesh ChamaraОценок пока нет

- Steel Purlin C ChannelДокумент12 страницSteel Purlin C ChannelUmesh ChamaraОценок пока нет

- Staircase NewДокумент10 страницStaircase NewUmesh ChamaraОценок пока нет

- Structural Design Brief - Rev 0Документ6 страницStructural Design Brief - Rev 0Umesh ChamaraОценок пока нет

- Calculation of Fire Tender LoadingДокумент4 страницыCalculation of Fire Tender LoadingUmesh ChamaraОценок пока нет

- Fir Engine LoadДокумент2 страницыFir Engine LoadgurvinderОценок пока нет

- Food Diary With Example A4Документ6 страницFood Diary With Example A4Umesh ChamaraОценок пока нет

- Suspended Sump SlabДокумент12 страницSuspended Sump SlabUmesh ChamaraОценок пока нет

- Steel Purlin C ChannelДокумент15 страницSteel Purlin C ChannelUmesh ChamaraОценок пока нет

- Plate DesignДокумент6 страницPlate DesignUmesh ChamaraОценок пока нет

- Ijgi 03 00130Документ13 страницIjgi 03 00130Umesh ChamaraОценок пока нет

- Design of Doble Angle For TrussДокумент10 страницDesign of Doble Angle For TrussUmesh ChamaraОценок пока нет

- Stair Hand Rail Connection Design Calculation-WPCДокумент12 страницStair Hand Rail Connection Design Calculation-WPCUmesh ChamaraОценок пока нет

- New LONG Beam Design SheetДокумент20 страницNew LONG Beam Design SheetUmesh ChamaraОценок пока нет

- Pass Pass Pass Pass Pass Pass Pass Pass Pass: (KN) (N/mm2)Документ1 страницаPass Pass Pass Pass Pass Pass Pass Pass Pass: (KN) (N/mm2)Umesh ChamaraОценок пока нет

- Barrier Design GuidanceДокумент75 страницBarrier Design GuidancearchpavlovicОценок пока нет

- WallДокумент44 страницыWallUmesh ChamaraОценок пока нет

- Flexural Design of Reinforced Concrete Beam SectionsДокумент15 страницFlexural Design of Reinforced Concrete Beam SectionsAamir HaideriОценок пока нет

- Seminar Report On Electro Active Polymers Done by Manojkumar Mahadevan, IndiaДокумент26 страницSeminar Report On Electro Active Polymers Done by Manojkumar Mahadevan, Indianikhil_prasanthОценок пока нет

- CMAA MovementДокумент9 страницCMAA MovementalbertoxinaОценок пока нет

- Fourier Transform Infrared (FT-IR) Spectrometers Coupled To Thermal AnalysisДокумент24 страницыFourier Transform Infrared (FT-IR) Spectrometers Coupled To Thermal Analysisc_passerino6572Оценок пока нет

- Loc Corr SS Weldments SummaryДокумент52 страницыLoc Corr SS Weldments SummarySatheesh KumarОценок пока нет

- Solved Problems in PhysicsДокумент22 страницыSolved Problems in Physicsvasudevan m.vОценок пока нет

- 2nd Final 2020Документ7 страниц2nd Final 2020Mira VeranoОценок пока нет

- Spring 07 - EE 221 Problem Set 4 SolutionДокумент3 страницыSpring 07 - EE 221 Problem Set 4 SolutionSerkan AkbulutОценок пока нет

- Ta-Compact-P: - With NPT and SWT ConnectionsДокумент8 страницTa-Compact-P: - With NPT and SWT ConnectionsPablo CastroОценок пока нет

- 7 ASNT - Q&A - Book - D - Liquid - PenetrantДокумент40 страниц7 ASNT - Q&A - Book - D - Liquid - Penetrantangel507p90% (10)

- 2 - SANFIELD-Quality Manual For Elastomeric BearingsДокумент34 страницы2 - SANFIELD-Quality Manual For Elastomeric Bearingsghaghra bridge100% (5)

- Design Optimization of A Solenoid-Based Electromagnetic Soft Actuator With Permanent Magnet CoreДокумент5 страницDesign Optimization of A Solenoid-Based Electromagnetic Soft Actuator With Permanent Magnet CoreVinit MhatreОценок пока нет

- CE765 - Advanced Steel DesignДокумент3 страницыCE765 - Advanced Steel DesignatklingerОценок пока нет

- Blaine Number - Average Particle SizeДокумент2 страницыBlaine Number - Average Particle Sizedondo1004Оценок пока нет

- Electo Stream DrillingДокумент3 страницыElecto Stream DrillingShubhamОценок пока нет

- Me Trology 8Документ25 страницMe Trology 8HARIMETLYОценок пока нет

- Piping Design and Plant LayoutДокумент44 страницыPiping Design and Plant LayoutVp Singh RawatОценок пока нет

- Electrochemistry: Voltaic Cells: Rezzan Hekmat AP Chemistry - 3 Pd. Lab Write UpДокумент3 страницыElectrochemistry: Voltaic Cells: Rezzan Hekmat AP Chemistry - 3 Pd. Lab Write UpRezzan HekmatОценок пока нет

- SteamДокумент2 страницыSteamChiОценок пока нет

- Md1 Module 2Документ17 страницMd1 Module 2Daniel MillanoОценок пока нет

- Waves and Sound WorksheetДокумент12 страницWaves and Sound WorksheetprosenОценок пока нет

- Level Switch Msi 96003421Документ6 страницLevel Switch Msi 96003421Sanyi48Оценок пока нет

- Imaging Techniques in Biomedical Engineering (Thermal Imaging)Документ67 страницImaging Techniques in Biomedical Engineering (Thermal Imaging)Karminder SinghОценок пока нет

- Nadca - Overview of Defets in Die CastingДокумент197 страницNadca - Overview of Defets in Die CastingJayabharath Rajadurai100% (8)

- Cold Drawn PDFДокумент1 страницаCold Drawn PDFAna Emily PrentissОценок пока нет

- Final ResearchДокумент29 страницFinal Researchshubham dhakulkarОценок пока нет

- Indian Standard: Methods of Test For CablesДокумент3 страницыIndian Standard: Methods of Test For CablesVatsalОценок пока нет

- QC Radiologic TechnologyДокумент20 страницQC Radiologic TechnologyMa. Charlotte CabaleОценок пока нет

- A Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystДокумент17 страницA Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystFrank LordОценок пока нет