Академический Документы

Профессиональный Документы

Культура Документы

ANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195

Загружено:

Alessio BarboneИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195

Загружено:

Alessio BarboneАвторское право:

Доступные форматы

182

Pressure Vessel Design Manual

Anchor Bolts

Anchor bolts are governed by one of the three following load cases: 1. Longitudinal load: If Qo > QL, then no uplift occurs, and the minimum number and size of anchor bolts should be used. If Qo < Q L , then uplift does occur:

QL - Qo

. N

= load per bolt

2. Shear: Assume the fNed saddle takes the entire shear load.

FL = shear per bolt

3. Transverse load: This method of determining uplift and overturning is determined from Ref. 21 (see Figure 3-57).

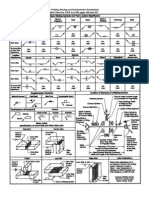

Figure 3-57. Dimensions and loading for base plate and anchor bolt analysis.

M = (0.5Fe or F w ) B M e=Qo

Y3

+ K,Y2 + KzY + K3 = 0

If e < "/6, then there is no uplift. If e 3 %, then proceed with the following steps. This is an iterative procedure for finding the tension force, T, in the outermost bolt. Step 1: Find the effective bearing length, Y. Start by calculating factors K 1 a ,

K i = 3(e - 0.5A) 6nlat Kz = F (f + e)

If not equal to 0, then proceed with Step 3. Step 3: Assume a new value of Y and recalculate the equation in Step 2 until the equation balances out to approximately 0. Once Y is determined, proceed to Step 4. Step 4: Calculate the tension force, T, in the outermost bolt or bolts. I A Y 1

Step 5: From Table 3-28, select an appropriate bolt material and size corresponding to tension-force, T. Step 6: Analyze the bending in the base plate. Distance, x = 0.5A +f - Y Moment, M = Tx 6M Bending stress,fb = -

Step 2: Substitute values of K1-3 into the following equation and assume a value of Y = %A as a first trial.

t"b

Allowable Tension Load on Bolts, Kips, per AlSC

~

Nom. Bolt Dia., in.

Cross-sectional Area, ab, in.' A-307 A-325 Ft=20ksi Ft=44ksi

%

0.3068 6.1 13.5

t

0.4418 8.8 19.4

2 l

0.6013 12.0 26.5

1%

1%

1%

1.485 29.7 65.3

1'h

0.7854 15.7 34.6

0.994 19.9 43.7

1.227 24.5 54.0

1.767 35.3 77.7

Вам также может понравиться

- Zick Analysis For Saddle SupportДокумент8 страницZick Analysis For Saddle Supportfuransu777100% (1)

- Hinge Calculation FormulasДокумент2 страницыHinge Calculation FormulasamaОценок пока нет

- SEISMIC ANALYSIS KazzincДокумент14 страницSEISMIC ANALYSIS KazzincArees KhambattaОценок пока нет

- Steel Design Notes CSAДокумент73 страницыSteel Design Notes CSAAntoine LetendreОценок пока нет

- Studding Outlet Calculation - PV Elite 2016Документ8 страницStudding Outlet Calculation - PV Elite 2016Liu YangtzeОценок пока нет

- PFS FWKO Tank EvaluationДокумент12 страницPFS FWKO Tank EvaluationkoyahassanОценок пока нет

- PV Elite ResultДокумент239 страницPV Elite ResultChaitanya Sai TОценок пока нет

- Baffle Thickness CalculationДокумент22 страницыBaffle Thickness CalculationAdrian Stoicescu100% (1)

- Tailing Lug - 173004-05Документ1 страницаTailing Lug - 173004-05shazan100% (1)

- Horizontal Vessel Stress AnalysisДокумент12 страницHorizontal Vessel Stress AnalysissridharОценок пока нет

- Saddle 1Документ3 страницыSaddle 1RUDHRA DHANASEKARОценок пока нет

- New Storage Tanks Design GuidelinesДокумент6 страницNew Storage Tanks Design GuidelineschrisevabОценок пока нет

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Документ35 страницDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainОценок пока нет

- Lug SupportДокумент2 страницыLug SupportSachin5586Оценок пока нет

- Saddle Road Transportation Analysis 1Документ2 страницыSaddle Road Transportation Analysis 1vpjagannaathОценок пока нет

- Lifting Lug Analysis DesignДокумент5 страницLifting Lug Analysis DesignAlessio BarboneОценок пока нет

- Tema ChecklistДокумент2 страницыTema ChecklistAdrian Stoicescu100% (1)

- Base Ring Fillet Size CalculationДокумент4 страницыBase Ring Fillet Size Calculationmiteshpatel191Оценок пока нет

- Rectangular Tanks:: Rectangle Tank DesignДокумент23 страницыRectangular Tanks:: Rectangle Tank Designshna jabarОценок пока нет

- Skirt Support Analysis Per en 13445Документ13 страницSkirt Support Analysis Per en 13445karthik1amarОценок пока нет

- Sample Design Calculation - Vessel Supported On LugsДокумент11 страницSample Design Calculation - Vessel Supported On LugsSiva baalan100% (2)

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFДокумент4 страницыBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiОценок пока нет

- Platform Cleat CalculationДокумент1 страницаPlatform Cleat Calculationmiteshpatel191Оценок пока нет

- Solid Mechanics (Bending of A T Beam Lab Report)Документ12 страницSolid Mechanics (Bending of A T Beam Lab Report)rajesh yadavОценок пока нет

- Ldo Storage Tank Calculation 170Документ6 страницLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Tank DesignДокумент89 страницTank Designpatrickandreas77Оценок пока нет

- Pressure Vessel Lifting Lug CalculationДокумент2 страницыPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Etank Full ReportДокумент108 страницEtank Full ReportFaizal SattuОценок пока нет

- 2400 Tema DCДокумент7 страниц2400 Tema DCMasoodMiyanОценок пока нет

- Cs & Las Impact Req - Asme Sec Viii Div 2Документ16 страницCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareОценок пока нет

- Standard Size Trap - Taylor ForgeДокумент1 страницаStandard Size Trap - Taylor ForgeAlessio BarboneОценок пока нет

- Mechanical Engineering Design 8thДокумент12 страницMechanical Engineering Design 8thStipendijeVlaОценок пока нет

- Saddle CalculationДокумент10 страницSaddle Calculationpharis_chrisОценок пока нет

- Design of Reinforced Concrete RING BEAM FOUNDATIONДокумент2 страницыDesign of Reinforced Concrete RING BEAM FOUNDATIONnirmal suthar100% (1)

- EJMA 8th Edition - 2003Документ212 страницEJMA 8th Edition - 2003Alessio Barbone100% (4)

- Internal Pipe Distributor Design ProcedureДокумент5 страницInternal Pipe Distributor Design Proceduresenthil kumarОценок пока нет

- Nozzle Load AnalysisДокумент2 страницыNozzle Load Analysisvm153748763Оценок пока нет

- WF, Unp, Angle, Pipe Steel Profile CalculationДокумент24 страницыWF, Unp, Angle, Pipe Steel Profile CalculationFian ArdiyanaОценок пока нет

- Prying Action A General TreatmentДокумент9 страницPrying Action A General TreatmentFWICIP100% (1)

- SP-2069 Specification For Pressure VesselsДокумент68 страницSP-2069 Specification For Pressure Vesselsarjunprasannan7Оценок пока нет

- Anchor Bolt CalculationДокумент8 страницAnchor Bolt CalculationRajput Pratiksingh100% (1)

- Analysis of a rectangular pressure vesselДокумент7 страницAnalysis of a rectangular pressure vesselPressure VesselОценок пока нет

- 28 Roark Flat PlatesДокумент14 страниц28 Roark Flat Platesgutmont0% (1)

- Cdo CalcДокумент3 страницыCdo CalcJeric FarinОценок пока нет

- Tailing Lug Design FormulaДокумент2 страницыTailing Lug Design FormulaRajeshОценок пока нет

- Jn1399 - 71t Lifting LugДокумент5 страницJn1399 - 71t Lifting LugRiyan EsapermanaОценок пока нет

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselДокумент36 страницBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungОценок пока нет

- IIT Hyderabad Faculty Housing Design CalculationsДокумент33 страницыIIT Hyderabad Faculty Housing Design CalculationssmijusОценок пока нет

- Ccsviiid1 2260Документ2 страницыCcsviiid1 2260DieguitoOmarMoralesОценок пока нет

- 7-12-0024 Rev 7Документ1 страница7-12-0024 Rev 7cynideОценок пока нет

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearДокумент4 страницыConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalОценок пока нет

- Trunnion 6 TonДокумент3 страницыTrunnion 6 TonEngr Khurram Jaan RamayОценок пока нет

- Skirt Design - For Small VesselsДокумент7 страницSkirt Design - For Small VesselsSakthi VelОценок пока нет

- Blind ThicknessДокумент1 страницаBlind ThicknessRizwan Waheed KhanОценок пока нет

- Tailing LugДокумент3 страницыTailing LugSajad AbdulОценок пока нет

- Solution Tutorial - 1Документ2 страницыSolution Tutorial - 1Akash FuryОценок пока нет

- Stress Concentrations - Lab ReportДокумент6 страницStress Concentrations - Lab ReportArunodha HettiarachchiОценок пока нет

- PHN001_Unit1st_Assisgnment1st_2022 2Документ12 страницPHN001_Unit1st_Assisgnment1st_2022 2harshitaОценок пока нет

- Home Work 5 - Chapter 5: SolutionsДокумент6 страницHome Work 5 - Chapter 5: SolutionssarahhОценок пока нет

- Hw1 Sol Fall 2015Документ8 страницHw1 Sol Fall 2015Ong Kok Meng100% (1)

- Circular Shaft em 327: Mechanics of Materials Laboratory: ObjectivesДокумент4 страницыCircular Shaft em 327: Mechanics of Materials Laboratory: ObjectivesSumit SharmaОценок пока нет

- RC Beam Torsion DesignДокумент33 страницыRC Beam Torsion Design2011kumarОценок пока нет

- Exercises On Stress StateДокумент4 страницыExercises On Stress StatecusanhОценок пока нет

- Double Bottom Petroleum Storage Tanks ExplainedДокумент10 страницDouble Bottom Petroleum Storage Tanks ExplainedAlessio BarboneОценок пока нет

- Typical SupportДокумент9 страницTypical SupportAlessio BarboneОценок пока нет

- Uniform Building Code Volume 21997Документ545 страницUniform Building Code Volume 21997raymond100% (1)

- PEG Property Document Copy RestrictionsДокумент1 страницаPEG Property Document Copy RestrictionsAlessio BarboneОценок пока нет

- AutoPIPE Vessel FundamentalsДокумент172 страницыAutoPIPE Vessel FundamentalsAlessio BarboneОценок пока нет

- Fouling and Plate Heat ExchangerДокумент3 страницыFouling and Plate Heat ExchangerAlessio BarboneОценок пока нет

- Soil InvestigationДокумент23 страницыSoil InvestigationAlessio BarboneОценок пока нет

- Pagine Da De-Mystifying AutoCAD Plant 3D IsometricsДокумент10 страницPagine Da De-Mystifying AutoCAD Plant 3D IsometricsAlessio BarboneОценок пока нет

- Terminations For Steel Wire Ropes Safety: ÖnormДокумент5 страницTerminations For Steel Wire Ropes Safety: ÖnormAlessio BarboneОценок пока нет

- Aws Welding SymbolsДокумент2 страницыAws Welding SymbolsAlessio BarboneОценок пока нет

- Terminations For Steel Wire Ropes Safety: ÖnormДокумент5 страницTerminations For Steel Wire Ropes Safety: ÖnormAlessio BarboneОценок пока нет

- Terminations For Steel Wire Ropes Safety: ÖnormДокумент5 страницTerminations For Steel Wire Ropes Safety: ÖnormAlessio BarboneОценок пока нет

- Pagine Da NAYYAR M. L. - Piping HandbookДокумент5 страницPagine Da NAYYAR M. L. - Piping HandbookAlessio BarboneОценок пока нет

- AppuntiДокумент2 страницыAppuntiAlessio BarboneОценок пока нет