Академический Документы

Профессиональный Документы

Культура Документы

ABS MooringSPM Guide

Загружено:

CaptIsqanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ABS MooringSPM Guide

Загружено:

CaptIsqanАвторское право:

Доступные форматы

Product Data Sheet / Reference no. OIM-VMS-04 Ver 1.

Spread Mooring Systems

Spread Mooring

Description

Trelleborg Marine Systems designs and manufactures a range of mooring systems for offshore oil and gas F(P) SO & FSRU facilities. This document provides information describing the main components that make up a Spread Mooring System installed onboard an F(P)SO. The mooring system will generally include multiple chain stoppers positioned in the Bow and Stern quarters of the vessel, together with fairleads and chain tensioning facilities. Other enhancements include integrated Load Monitoring and high load warning systems with central monitoring.

Design Note

The basic design criteria for Spread Mooring hardware recommended by Oil Companies International Marine Forum (OCIMF) and Classification Societies is that the mooring chain should be considered the weak link. Chain stoppers, fairleads and their foundations should be designed to withstand the Breaking Load of the mooring chain.

Features

Complete system engineering including design and layout of equipment. Chain stoppers designed to minimize chain bending and wear. Safeguards and optional monitoring to ensure against accidental or inadvertent chain release.

Trelleborg AB 2011

Trelleborg Marine Systems|Takes the pressure off

Product Data Sheet / Reference no. OIM-VMS-04 Ver 1.0

Trelleborg AB 2011

1 DESIGN 1.1 Oil Companies International Marine Forum - Mooring Equipment Guidelines Compliance with Revision 3 (OCIMF MEG3). codes and guidelines Class design requirements, DNV, ABS, BV, Lloyds or RINA as applicable.

2 HAZARDOUS AREA COMPLIANCE 2.1 Area classification The equipment will be supplied with certificates for Hazardous Area Zone 1 or Zone 2 compliance as applicable.

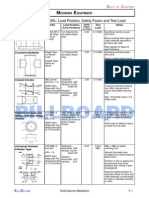

3 CHAIN STOPPERS Based on OCIMF MEG3: 3.1 Design Criteria Chain stoppers are designed to withstand permanent deformation when loaded to the Minimum Breaking Load of the associated chain. Maximum stress at the Design Load will not exceed 85% of the yield of the component material. 3.2 Stud Link Chain Size and Grade Jaw Type Chain Stoppers Quick Release Chain Stoppers Load Monitoring Construction Chain Locking Position Stopper Jaw Operation Up to 127 mm and Grade R4. Vertical or horizontal chain lead with dual jaw and self locking. This type of stopper is not releasable when under load. Refer to Section 7 for quick release stoppers. Not covered in this Data Sheet Refer to Data Sheet OIM-CSH-02. Chain stoppers may incorporate a load cell for measuring the chain tension. Refer to Section 6 for details. Carbon Steel fabrication to ASTM A572 and high strength cast steel to ASTM A148. Chain stoppers will lock any alternate common link. The jaws of the chain stopper are self locking and may be opened manually or optionally hydraulically Jaw locked or open status can be monitored. Jaws can only be opened when load is taken up by a tensioner unit. Bolt down or weld down installation. The design of the foundation plate and underdeck structure is assumed provided by Others unless specified otherwise.

3.3

3.4 3.5 3.6 3.7

3.8

3.9

Installation and Underdeck Stiffening

4 CHAIN CHUTES AND SHEAVES 4.1 4.2 4.3 Design Criteria Chain Size Chain Chutes Designed in accordance to OCIMF MEG 3 and the relevant Class codes for design load and bending radius where applicable. Chain to 127 mm diamter. May be manufactured as an integral part of the chain stopper structure.

2/6

Product Data Sheet / Reference no. OIM-VMS-04 Ver 1.0

Trelleborg AB 2011

4 CHAIN CHUTES AND SHEAVES May be a fixed unit located on the non loaded side of the chain stopper and used to align the chain with a common tensioning winch. 4.4 Chain Sheaves - for Chain Tensioning The chain sheave will be of 5 pocket design and may include a wire groove used in case of back up being required. Unless otherwise specified the Design Load is based on the maximum tensioning capacity of the winch. Chain Sheaves - for Mooring The chain sheave is located on the loaded side of the chain stopper and may be fixed or swiveling type for above or below water application. The Design Load is based on the Minimum Breaking Load of the chain. The chain sheave wheel generally has a 7 pocket design with wire rope groove. 4.6 Sheave Lubrication All sheave units have a lubrication facility and those not accessible are provided with remote grease feed facility. Sheave shaft bearings are generally synthetic.

4.5

5 CHAIN TENSIONING 5.1 Chain Jacks and Tensioning winches Chain tensioning for spread mooring applications require either chain jack or a winch to apply the tensioning of the mooring chain. After the chain is tensioned it is secured by the chain stopper. Chain jacks may be either individual units mounted behind each chain stopper or a common unit shared between several chain stoppers. Operational and handling considerations will generally dictate the suitability of using a transferable chain jack. Features include: Designed specifically for Trelleborg range of jaw and quick release chain stoppers. 5.2 Chain Tensioning Jack Tension forces to 200t. Stroke length (typically) 2.5 chain links. Stroke rate (typically) 0.75m/min. Operation by pushbutton or pendant. Incorporates load monitoring via a pressure sensor with local readout. HPU can be integrally mounted to the chain jack. Suitable for Zone 1 or 2 hazardous area where applicable. A jack handling system can be provided to suit the deck layout.

3/6

Product Data Sheet / Reference no. OIM-VMS-04 Ver 1.0

Trelleborg AB 2011

5 CHAIN TENSIONING A tensioning winch may be considered where: One common winch mounted to the Bow and Stern deck is used to accommodate Port and Starboard side chains. Adequate deck space and a clear route is available to run the winch wire to each stopper. A common wire rope deflector Sheave (or snatch block) in conjunction with fixed deck sheaves can be installed to lead the wire to each chain. Features: 5.3 Chain Tensioning Winch Chain tensioning winches range in capacities to 200t pulling force. Fitted with a wire rope spooling system. Winch speed (typically) 6m/min. Operation by local flow control lever. Incorporates load monitoring via a pressure sensor with local readout. Suitable for Zone 1 or 2 hazardous area where applicable. Hydraulic consumption (typical) 100kW; 60 litres/min; 200 Bar. It may be a dedicated HPU or hydraulics supplied from vessels own system where available. 5.4 Winch Sheaves Fixed, deflector or snatch block sheaves used to direct the winch wire to the chain have a design load based on the maximum static load capacity of the winch.

6 LOAD MONITORING SYSTEM (OPTIONAL) Trelleborg manufactured load cells may be fitted to dual jaw chain stoppers. Features include: Redundantly strain gauged load cell. 6.1 Load Cells Stainless steel construction. Calibrated from zero to rated Safe Working Load (SWL). Accuracy +/-2% BSL. Ingress IP rating 66/68. 6.2 Local Load Display Unit Panel mounted display of loads and alarms for multiple chain stoppers. Refer to Data Sheet LMS-LSMH-03.

4/6

Product Data Sheet / Reference no. OIM-VMS-04 Ver 1.0

Trelleborg AB 2011

6 LOAD MONITORING SYSTEM The Remote Display Unit is generally located within the Cargo Control Room (CCR) to monitor, display and record load and alarm history for each stopper. Unless otherwise specified CCR is assumed a non hazardous area and an air conditioned room. Central Monitoring System The Remote Display Unit consists of a 15 inch LCD touch screen workstation suitable for mounting to a 19 inch rack cabinet. Cabinet assumed by Others unless otherwise specified. Functionality: Setting load alarm levels High and Very High for each chain stopper. Load display and warning. Load history and alarm trail recording for each stopper. 6.4 Load Alarm Station Is an optional deck mounted visible and audible alarm station mounted adjacent to each group of stoppers to provide High and Very High load warnings. Is an optional pager sized portable monitor used to receive and display load and alarm information. Refer Data Sheet DAS-IHDU-04. 6.6 Distributed Control System - Interface The DCS interface allows transfer of data such as loads and alarms from the Load Monitoring System to the vessel based Distributed Control System (DCS) and is offered as an option. Electro Hydraulic Power Units require three phase 380 - 440 V 60 Hz. Local and Remote Display panels require 110 V or 220 60 Hz. All ship deck run cable are assumed to be supplied by Others unless otherwise specified. Each Chain Stopper is load tested to 100% Safe Working Load (SWL). Each load cell is calibration tested from 0 to 100% SWL. Testing performed under witness of an independent third party or Class representative. Unless otherwise noted load testing is not performed on chain chutes and fairleads. The verification of structural capacity is by Class approval of the structural calculations. The Factory Acceptance Test (FAT) covers the end to end testing of the instrumentation package, system interfaces and software.

6.3

6.5

Hand Held Monitor

7 POWER AND CABLE REQUIREMENTS 7.1 7.2 Voltage Supply Ship Wiring - Control Cable Chain Stoppers Load Cells Chain Chutes and Fairleads Instrumentation

8 TESTING 8.1 8.2 8.3 8.4

5/6

Product Data Sheet / Reference no. OIM-VMS-04 Ver 1.0

Trelleborg AB 2011

9 QUALITY 9.1 9.2 9.3 Accreditation Material Traceability Inspection and Test Plan (ITP) Trelleborg Marine Systems Melbourne ISO 9001 2008 by Lloyds Register. Structural materials are Class approved and material certificates are supplied with final documentation. Provided with Vendor Post Award documentation package and submitted for client approval.

10 DOCUMENTATION 10.1 10.2 Post Award Vendor Technical Package Manufacturing Data Record (MDR) Submitted for Client approval following contract award. Manufacturing Data Record (MDR) provided at completion of the project covering fabrication, mechanical, materials, electrical certifications, NDT and testing. A full set of manuals are provided.

Installation Operation 10.3 and Maintenance Manuals

Trelleborg Marine Systems commitment to continuous product improvement means that we reserve the right to upgrade and modify equipment and systems without notice as technological and operational parameters demand.

For Further information, please contact:

Trelleborg Marine Systems Melbourne Pty Ltd Virginia Park, 9 South Drive, 236-262 East Boundary Road East Bentleigh, Victoria 3165 Australia Tel: +61 (0) 3 9575 9999, Fax: +61 (0) 3 9575 9900 Website: www.trelleborg.com/marine Email: mooring@trelleborg.com

6/6

Вам также может понравиться

- Rafaqat Ali NotesДокумент155 страницRafaqat Ali Notesyogesh pandeyОценок пока нет

- Propulsion of Offshore Support VesselsДокумент8 страницPropulsion of Offshore Support VesselsPatrick Araujo RamalhoОценок пока нет

- Appendix B - Equipment BrochureДокумент24 страницыAppendix B - Equipment BrochureAllissa SuwondoОценок пока нет

- Light and Smoke Signal: Warning DisposalДокумент1 страницаLight and Smoke Signal: Warning Disposalariesyiha100% (1)

- Stability For Offshore VesselsДокумент2 страницыStability For Offshore VesselsilgarОценок пока нет

- LECTURE No.6: Anchor Handlers or Anchor Handling Vessels (AHV) Is Very Powerful Ships ThatДокумент12 страницLECTURE No.6: Anchor Handlers or Anchor Handling Vessels (AHV) Is Very Powerful Ships ThatMiruna ClinciuОценок пока нет

- AnchoringДокумент12 страницAnchoringDryanmОценок пока нет

- Steering Gear Rules: Conventions and Regulations. Classification Society Requirements Are As FollowsДокумент26 страницSteering Gear Rules: Conventions and Regulations. Classification Society Requirements Are As FollowsBhupender Ramchandani100% (1)

- NR 595 - 2014-08 PDFДокумент24 страницыNR 595 - 2014-08 PDFSimen EllingsenОценок пока нет

- Seakeeping LectureДокумент30 страницSeakeeping Lectureknowme73100% (1)

- Deltamarin Eedi Study For Emsa Final ReportДокумент159 страницDeltamarin Eedi Study For Emsa Final ReportPipolo PippoОценок пока нет

- Anchor & MooringДокумент20 страницAnchor & MooringMahmud HasanОценок пока нет

- OCIMF Hot Work PDFДокумент9 страницOCIMF Hot Work PDFiomerko100% (1)

- Sea KeepingДокумент55 страницSea KeepingsiswoutОценок пока нет

- Ballast Free ShipsДокумент18 страницBallast Free ShipsassddfОценок пока нет

- Effect of Pretension On Moored Ship RespДокумент13 страницEffect of Pretension On Moored Ship RespIvandito HerdayandityaОценок пока нет

- 2009 MODU Code A.1023Документ148 страниц2009 MODU Code A.1023Praveen BalachandranОценок пока нет

- MSC 216 (82) AmendedДокумент4 страницыMSC 216 (82) AmendedTymur BadzhykovОценок пока нет

- LECTURE No.8 Pipe Laying Vessels: Fig.1. Types of Pipe Lay Vessel Submarine PipelinesДокумент14 страницLECTURE No.8 Pipe Laying Vessels: Fig.1. Types of Pipe Lay Vessel Submarine PipelinesMiruna Clinciu100% (1)

- 4 Point Mooring SystemДокумент3 страницы4 Point Mooring SystemCapt. shashi jha100% (1)

- Group 4 Procedures in AnchoringДокумент30 страницGroup 4 Procedures in AnchoringJP Perdez100% (1)

- 8 Point Mooring - Attachment XxxiiДокумент5 страниц8 Point Mooring - Attachment XxxiiFaiqah AzmirОценок пока нет

- This IS IT!!!!!!!!!!!!!!!!!Документ48 страницThis IS IT!!!!!!!!!!!!!!!!!g k azadОценок пока нет

- White Paper: Computer Simulation of Buoy Mooring SystemsДокумент12 страницWhite Paper: Computer Simulation of Buoy Mooring Systemssmithwork100% (1)

- In Water SurveyДокумент33 страницыIn Water SurveyZin Maung Tun100% (1)

- 01 0002Документ7 страниц01 0002opytnymoryakОценок пока нет

- Phase 1 Stability - CompressedДокумент16 страницPhase 1 Stability - CompressedSam UelОценок пока нет

- Ship Classification and TypesДокумент15 страницShip Classification and TypesPandu Prayoga HoppusОценок пока нет

- Engine Room CraneДокумент22 страницыEngine Room CraneNarendra KatdareОценок пока нет

- Structural Damage On Unloading: Hatch Coamings and CoversДокумент194 страницыStructural Damage On Unloading: Hatch Coamings and Coversjosecarlos180177100% (2)

- Sample Offshore Vessel: Inspected at Cardiff, United Kingdom & Northern Ireland 1 JANUARY 2018Документ56 страницSample Offshore Vessel: Inspected at Cardiff, United Kingdom & Northern Ireland 1 JANUARY 2018seluarbolaОценок пока нет

- Comissionamento Do Sistema de Pull in PDFДокумент65 страницComissionamento Do Sistema de Pull in PDFrfelippe8733Оценок пока нет

- Navigational Safety in The Straits of Malacca: Current and Future ConcernДокумент32 страницыNavigational Safety in The Straits of Malacca: Current and Future Concernamirsyawal87100% (1)

- An FSO-FPSO Providers View On Station Keeping OptionsДокумент42 страницыAn FSO-FPSO Providers View On Station Keeping Optionsfairuz1012100% (2)

- Classification SocietyДокумент9 страницClassification SocietyIbrahim AdalıОценок пока нет

- 337TO 003 World's Largest FLNG PreludeДокумент9 страниц337TO 003 World's Largest FLNG PreludeRamОценок пока нет

- NWEA GuidelinesДокумент145 страницNWEA GuidelinesdanianishОценок пока нет

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDДокумент10 страницITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDcataiceОценок пока нет

- What Makes Mooring Operation Dangerous?Документ4 страницыWhat Makes Mooring Operation Dangerous?Mayura RanatungaОценок пока нет

- Full Scale Meas Sea TrialДокумент30 страницFull Scale Meas Sea TrialLukman Tarigan Sumatra100% (1)

- OCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atДокумент4 страницыOCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atRobson PaixãoОценок пока нет

- Azimuth Thruster Control System (ACS) PDFДокумент4 страницыAzimuth Thruster Control System (ACS) PDFdavid artantoОценок пока нет

- Sales Number: IA811E: This Electronic Edition Is Licensed To Master Marine For 1Документ142 страницыSales Number: IA811E: This Electronic Edition Is Licensed To Master Marine For 1mozca1Оценок пока нет

- LSA CodeДокумент77 страницLSA CodecallmeirfanОценок пока нет

- Illc 66Документ35 страницIllc 66faizan100% (1)

- Life Raft Release System and Launching Procedure Marine InsightДокумент8 страницLife Raft Release System and Launching Procedure Marine Insightmavericksailor100% (1)

- AMSA36Документ66 страницAMSA36Btwins123100% (2)

- NWEA GuidelinesДокумент160 страницNWEA GuidelinesMorten Monika MosbergОценок пока нет

- Liferaft - General RequirementsДокумент8 страницLiferaft - General Requirementsstamatis100% (1)

- 85 Inf 4Документ3 страницы85 Inf 4Erwin Paulian SihombingОценок пока нет

- SAFETY NAVIGATION MANAGEMENT at MALACCA STRAIT PDFДокумент18 страницSAFETY NAVIGATION MANAGEMENT at MALACCA STRAIT PDFAditama Dirga100% (1)

- Avoiding "Death Traps On Ships" - Understanding Dangers of Mooring OperationДокумент9 страницAvoiding "Death Traps On Ships" - Understanding Dangers of Mooring OperationSubbu JsrОценок пока нет

- Hawser Hooks For Tandem or Single Point Mooring PDFДокумент6 страницHawser Hooks For Tandem or Single Point Mooring PDFSrinivasan RajenderanОценок пока нет

- Specification For Belt Speed Relays and Transducers (First Revision) IPSS:1-04-018-06Документ5 страницSpecification For Belt Speed Relays and Transducers (First Revision) IPSS:1-04-018-06GopalMahantaОценок пока нет

- Quick Release Hooks and CapstansДокумент8 страницQuick Release Hooks and CapstansRaul Strugar100% (1)

- Treleborg MS-OIM Offshore BrochureДокумент8 страницTreleborg MS-OIM Offshore BrochureAdrianBuzamatОценок пока нет

- Damper Testing: The World of Damper Test MachinesДокумент11 страницDamper Testing: The World of Damper Test MachinesFajarОценок пока нет

- TECHNILДокумент40 страницTECHNILCaptIsqanОценок пока нет

- NTK Sensor Catalogue 2015 PDFДокумент226 страницNTK Sensor Catalogue 2015 PDFCaptIsqan60% (5)

- SAMPLE Crane CatalogДокумент12 страницSAMPLE Crane CatalogCaptIsqanОценок пока нет

- Manta Rig Move 1 - Songkhla - E. PlatformДокумент22 страницыManta Rig Move 1 - Songkhla - E. PlatformCaptIsqan100% (1)

- Stability Information ManualДокумент381 страницаStability Information ManualBharath Kumar Vasamsetty100% (2)

- Analysis of Barge Transport and Launching PDFДокумент27 страницAnalysis of Barge Transport and Launching PDFCaptIsqanОценок пока нет

- Sea Fastening Master PDFДокумент164 страницыSea Fastening Master PDFe_taubОценок пока нет

- Offshor Mooring SystemДокумент6 страницOffshor Mooring SystemcudalbgeoОценок пока нет

- Mono BuoyДокумент40 страницMono BuoyCaptIsqan100% (4)

- Marine Breakaway Couplings Information PaperДокумент20 страницMarine Breakaway Couplings Information Paperjamolina9093100% (5)

- MV Pacific D - ClassДокумент9 страницMV Pacific D - ClassCaptIsqanОценок пока нет

- Bollard RequirementДокумент2 страницыBollard RequirementCaptIsqan100% (1)

- Wire Rope, Rigging, & Mooring For Offshore Construction by KTL Offshore - CatalogueДокумент106 страницWire Rope, Rigging, & Mooring For Offshore Construction by KTL Offshore - CatalogueJogi Oscar SinagaОценок пока нет

- Brake Holding Power TestДокумент6 страницBrake Holding Power TestCaptIsqanОценок пока нет

- IACS Mooring Chain InspectionДокумент9 страницIACS Mooring Chain InspectionCaptIsqanОценок пока нет

- IHC FPSO BrochureДокумент12 страницIHC FPSO BrochureCaptIsqanОценок пока нет

- Jack Up Rig Design PDFДокумент91 страницаJack Up Rig Design PDFAhmed Rehim50% (2)

- 24 Vibration IsolatorДокумент22 страницы24 Vibration IsolatorNon Etabas Gadnatam100% (1)

- Schiffstechnik Eng 2007Документ16 страницSchiffstechnik Eng 2007Ardhan FauzanОценок пока нет

- GR5290 Fabrications 8pp Brochure - Updated Feb 2020Документ8 страницGR5290 Fabrications 8pp Brochure - Updated Feb 2020designsОценок пока нет

- Tech SpecificationsДокумент47 страницTech Specificationssureshn829Оценок пока нет

- Steelwise PDFДокумент4 страницыSteelwise PDFBilal RasheedОценок пока нет

- Steel Beams Astm A36Документ4 страницыSteel Beams Astm A36Wala LangОценок пока нет

- White Sika Paper Strengthening ConcreteДокумент12 страницWhite Sika Paper Strengthening ConcreteRaed alkronz Raed alkronzОценок пока нет

- Reference - Comflor 80 Brochure PDFДокумент24 страницыReference - Comflor 80 Brochure PDFgks6043Оценок пока нет

- BIA - Steel Lintel DesignДокумент7 страницBIA - Steel Lintel Designgpax42Оценок пока нет

- 20-SDMS-01 REV. 02: Saudi Electricity CompanyДокумент39 страниц20-SDMS-01 REV. 02: Saudi Electricity CompanyMendu Prashanth100% (1)

- Pharmacy Block e TenderДокумент78 страницPharmacy Block e TenderDevidas JaijarОценок пока нет

- COMMON SSR 2011-12 and Basic Input Data For Irrigation Work ItemsДокумент143 страницыCOMMON SSR 2011-12 and Basic Input Data For Irrigation Work ItemsGuru Prasad100% (4)

- W01 358 7609Документ29 страницW01 358 7609MROstop.comОценок пока нет

- Steelwise AISCДокумент6 страницSteelwise AISCAruna Kumari GОценок пока нет

- Design BasisДокумент55 страницDesign BasisAnonymous fLgaidVBhz100% (1)

- Anchor Bolt TolerancesДокумент1 страницаAnchor Bolt TolerancesskkongОценок пока нет

- Schedule of Rates - RCD-Bihar-11th Edition-2016Документ568 страницSchedule of Rates - RCD-Bihar-11th Edition-2016sarsij81% (27)

- 20 TMSS 01 R0Документ0 страниц20 TMSS 01 R0renjithas2005Оценок пока нет

- General Specification For Welding and Weld Inspection (EIL)Документ19 страницGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- WBS For Dry Cargo Semi-TrailerДокумент115 страницWBS For Dry Cargo Semi-TrailerDanudear DanielОценок пока нет

- Q Q345 345E (China / GB) E (China / GB) : Les Propriétés Des Matériels Les Propriétés Des MatérielsДокумент2 страницыQ Q345 345E (China / GB) E (China / GB) : Les Propriétés Des Matériels Les Propriétés Des MatérielsAbdelkader DraïОценок пока нет

- MasterSpec 034900 GFRC 2012Документ12 страницMasterSpec 034900 GFRC 2012Taurai ChiwanzaОценок пока нет

- Aisc Seismic Design Module1 IntroductionДокумент107 страницAisc Seismic Design Module1 IntroductionFreddy Mauricio LucayОценок пока нет

- Astm A992mДокумент3 страницыAstm A992mPriyam KmОценок пока нет

- Arcelormittal Clad PDFДокумент7 страницArcelormittal Clad PDFbookppОценок пока нет

- Evaluation of Iron and Steel in Historic BridgesДокумент8 страницEvaluation of Iron and Steel in Historic BridgesjayaramanrathnamОценок пока нет

- Tolerances For Precast Concrete Structures PDFДокумент14 страницTolerances For Precast Concrete Structures PDFHari HaranОценок пока нет

- Guideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire StructДокумент92 страницыGuideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire StructLeung LiangОценок пока нет

- Hangers and Supports For Hvac Piping and EquipmentДокумент10 страницHangers and Supports For Hvac Piping and EquipmentAmeen Mohamed Ali SanadОценок пока нет