Академический Документы

Профессиональный Документы

Культура Документы

Linear Track Knocker Control

Загружено:

Nini FarribasАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Linear Track Knocker Control

Загружено:

Nini FarribasАвторское право:

Доступные форматы

Title:

LINEAR TRACK KNOCKER CONTROL

FARRIBAS

WW2813

Background

Components jamming at the linear track of handlers is one of the most reccurring problems at Test and Finish Area. Handlers are fitted with knockers on its linear track to prevent components to move in piggy back formation which causes jamming during transport of components through the track.

PIGGY BACK FORMATION

Current Situation

Knocking frequency could not be adjusted because it is a built-in parameter in the handler program which is not accessible without the manufacturers assistance.Two types of knockers are being used. The solenoid and the cylinder type. Continuous movement of the knocker produces deterioration on mechanical parts as well as the windings of the solenoid type and reduces its life cycle much faster.

Goal

Provide a method of control for the time interval of knocker actuation to reduce deterioration while still maintaining the most efficient setting.

SOLENOID

CYLINDER

Project Proposal

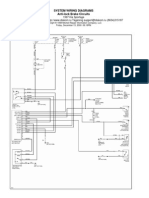

Install an electronic control circuit based on a timer IC whose duty cycle is adjustable to suit the time interval needed for the actuation of the knocker.

Prototype/Installation

CIRCUIT DIAGRAM

PCB

INSTALLATION AT IHS-029

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Nuts and Volts (Nonlinear - Ir) 2006-07Документ108 страницNuts and Volts (Nonlinear - Ir) 2006-07Nini FarribasОценок пока нет

- Saudi Aramco inspection plan for medium voltage cablesДокумент3 страницыSaudi Aramco inspection plan for medium voltage cablesHatemS.MashaGbehОценок пока нет

- Re - 1991-12 PDFДокумент92 страницыRe - 1991-12 PDFAnonymous kdqf49qb100% (1)

- Power System HarmonicsДокумент74 страницыPower System HarmonicsTana AzeezОценок пока нет

- Voltage Regulator Equipment: InstructionsДокумент28 страницVoltage Regulator Equipment: Instructionslxd.hepОценок пока нет

- ABB Technical Application Papers - Vol. 2 MVLV Transformer SubstationsДокумент42 страницыABB Technical Application Papers - Vol. 2 MVLV Transformer SubstationsASM_213Оценок пока нет

- Nikkor LensesДокумент16 страницNikkor LensesIvar VelasquezОценок пока нет

- David W. Thomson III and Jim D. Bourassa - A New Foundation For PhysicsДокумент26 страницDavid W. Thomson III and Jim D. Bourassa - A New Foundation For PhysicsKunma050Оценок пока нет

- Infineon IRS218!4!44 and IR218 4 44 Comparison An v01 00 enДокумент6 страницInfineon IRS218!4!44 and IR218 4 44 Comparison An v01 00 enNini FarribasОценок пока нет

- Ampeg B2 SVT350H Poweramp SchematicДокумент2 страницыAmpeg B2 SVT350H Poweramp SchematicAndres AlegriaОценок пока нет

- Zen and The Art of Radiotelegraphy PDFДокумент108 страницZen and The Art of Radiotelegraphy PDFednspaceОценок пока нет

- 917201B Sinergy SE-0IIДокумент6 страниц917201B Sinergy SE-0IINini FarribasОценок пока нет

- The Versatile 555Документ7 страницThe Versatile 555basmaatjeОценок пока нет

- Poor Mans Spectrum Analyzer PDFДокумент11 страницPoor Mans Spectrum Analyzer PDFNini FarribasОценок пока нет

- Voltage Converters PDFДокумент6 страницVoltage Converters PDFNini Farribas100% (1)

- BangOlufsen Beomaster2000 AmpДокумент4 страницыBangOlufsen Beomaster2000 AmpNini FarribasОценок пока нет

- The Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierДокумент61 страницаThe Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierNini Farribas100% (1)

- 917110c On-Series UPSДокумент2 страницы917110c On-Series UPSNini FarribasОценок пока нет

- System Wiring Diagrams A/C CircuitДокумент1 страницаSystem Wiring Diagrams A/C CircuitEugen BrusićОценок пока нет

- System Wiring Diagrams Anti-Lock Brake CircuitsДокумент1 страницаSystem Wiring Diagrams Anti-Lock Brake CircuitsNini FarribasОценок пока нет

- Carried AwayДокумент2 страницыCarried AwayNini FarribasОценок пока нет

- Fuel GaugeДокумент2 страницыFuel GaugeNini FarribasОценок пока нет

- Digital SLR Photography GuideДокумент29 страницDigital SLR Photography Guidedharmendra_kanthariaОценок пока нет

- System Wiring Diagrams Anti-Lock Brake CircuitsДокумент1 страницаSystem Wiring Diagrams Anti-Lock Brake CircuitsNini FarribasОценок пока нет

- Wireless Power Transmission Using Magnetic Resonance by Mandip Jung Sibakoti and Joey HambletonДокумент13 страницWireless Power Transmission Using Magnetic Resonance by Mandip Jung Sibakoti and Joey HambletonRakesh RtОценок пока нет

- Nt116 Tower Lamp Control CircuitДокумент1 страницаNt116 Tower Lamp Control CircuitNini FarribasОценок пока нет

- Nt116 Tower Lamp Control CircuitДокумент1 страницаNt116 Tower Lamp Control CircuitNini FarribasОценок пока нет

- 3572-PK SNo.28 Instruction ManualДокумент348 страниц3572-PK SNo.28 Instruction ManualNini FarribasОценок пока нет

- Delta Tester 9424 Training ModuleДокумент35 страницDelta Tester 9424 Training ModuleNini FarribasОценок пока нет

- Drmos Pizza Board Ets Revb1 SCH 20121115Документ3 страницыDrmos Pizza Board Ets Revb1 SCH 20121115Nini FarribasОценок пока нет

- Delta Tester 9424 Training ModuleДокумент35 страницDelta Tester 9424 Training ModuleNini FarribasОценок пока нет

- Admin Instruction - EmailДокумент5 страницAdmin Instruction - EmailMuhammad MuzammilОценок пока нет

- 5A Symmetrical Power SupplyДокумент1 страница5A Symmetrical Power SupplyBaskoro SutrisnoОценок пока нет

- Detuned ReactorДокумент2 страницыDetuned ReactorGanesh KumarОценок пока нет

- Meegahapola L. Hybrid AC-DC Power Grids. Stability..Control 2022Документ285 страницMeegahapola L. Hybrid AC-DC Power Grids. Stability..Control 2022GomolemoGumzNtlailaneОценок пока нет

- Flaura Parts List V1 0Документ4 страницыFlaura Parts List V1 0Alessandro CardelliОценок пока нет

- Manual Mas345Документ31 страницаManual Mas345Eibar016Оценок пока нет

- Lectures List T-A: Office Hours: Anytime by AppointmentДокумент28 страницLectures List T-A: Office Hours: Anytime by AppointmentggsddfОценок пока нет

- Price List - February 2020.: Scoop BinsДокумент3 страницыPrice List - February 2020.: Scoop BinsGeorge HaskellОценок пока нет

- BF1556 For 5V1A Charger DesignДокумент20 страницBF1556 For 5V1A Charger Design5a DOHCОценок пока нет

- Technical Data: NPN Power Silicon Switching TransistorДокумент3 страницыTechnical Data: NPN Power Silicon Switching TransistorJuan RamírezОценок пока нет

- Refresher Day 18Документ3 страницыRefresher Day 18Jevan A. CalaqueОценок пока нет

- Telescopic PDFДокумент8 страницTelescopic PDFdemodemo321123Оценок пока нет

- NBCDO MC - 02 - s2015 PDFДокумент4 страницыNBCDO MC - 02 - s2015 PDFEli NaguitОценок пока нет

- Termostto S101Документ16 страницTermostto S101FiedrichОценок пока нет

- Fcas 50 SN 60Документ16 страницFcas 50 SN 60Sung Ryoung LimОценок пока нет

- 220 110kV Substation at KAVOOR Design Instruction SheetДокумент2 страницы220 110kV Substation at KAVOOR Design Instruction SheetRubesh KumarОценок пока нет

- Pre-Action/Deluge/Agent Releasing Control Unit Fr-320 SeriesДокумент2 страницыPre-Action/Deluge/Agent Releasing Control Unit Fr-320 SeriesQuynhОценок пока нет

- Assignment 2 Prestressed Concrete DesignДокумент1 страницаAssignment 2 Prestressed Concrete DesignPippen DialaОценок пока нет

- Lesson 8 Final Control ElementДокумент9 страницLesson 8 Final Control ElementRachel Renti CruzОценок пока нет

- Eocrss-30S: Product DatasheetДокумент2 страницыEocrss-30S: Product DatasheetAbdulSattarОценок пока нет

- NSCR-ROW-Elevated-StructuresДокумент1 страницаNSCR-ROW-Elevated-Structuresftma borjaОценок пока нет

- STP 120 PDFДокумент3 страницыSTP 120 PDFhamza shahОценок пока нет

- Gate Ec: Q. 1-30 Carry One Mark EachДокумент44 страницыGate Ec: Q. 1-30 Carry One Mark EachSuraj KumarОценок пока нет

- BAT49Документ4 страницыBAT49roekanОценок пока нет

- FAQ Apply Permit To FlyДокумент3 страницыFAQ Apply Permit To FlyArchipelago Travel ToursОценок пока нет

- User Manual For Infrared Thermometer WBS T007Документ11 страницUser Manual For Infrared Thermometer WBS T007Daniel Tomuta0% (1)