Академический Документы

Профессиональный Документы

Культура Документы

Datums For Positional Tolerancing (GD&T)

Загружено:

Kishor kumar BhatiaОригинальное название

Авторское право

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Datums For Positional Tolerancing (GD&T)

Загружено:

Kishor kumar BhatiaАвторское право:

DATUMS FOR POSITIONAL TOLERANCING

DATUMS FOR POSITIONAL TOLERANCING

LINES FROM WHICH MEASUREMENTS ARE MADE.

DATUMS FOR POSITIONAL TOLERANCING

RESULT WHEN SIDES ARE OFF-SQUARE.

3

PART WITH ONE DATUM FEATURE SPECIFIED.

GAUGE

4

Part with three datum features specified

Gauge

Part with angular hole referred to a datum system

6

Gauge for part with angular hole with datums

7

DATUMS FOR THIN PARTS

Drawing of thin part

DATUMS FOR THIN PARTS - RFS

GAUGE FOR THIN PARTS - RFS

10

DATUMS FOR THIN PARTS - MMC

11

GAUGE FOR THIN PARTS - MMC

12

DATUMS & CHECKING LONG HOLES

DATUM SYSTEM FOR A LONG HOLE

GAUGE FOR ABOVE PART

13

CIRCULAR DATUMS

If position of small hole is established from the axis of large hole, not necessary to specify one of the holes as datum.

14

CIRCULAR DATUMS

It is essential to specify the datum in order to be more clear as two cylindrical surfaces are involved i.e, OD & ID . It is also essential to determine whether the true position to be established perpendicular to the face or parallel to the datum axis. If it is parallel to the datum axis datum A would not be specified.

15

MULTIPLE HOLE DATUMS

GROUP OF HOLE FORMING A SINGLE DATUM

16

MULTIPLE HOLE DATUMS

Axes of two holes is not advisable to specify as datum MMC.

without

Difficult to arrive at a setup for measuring purpose due to variation in hole sizes, centre distance between holes, parallelism of the hole axes and perpendicularity with the part surface. On MMC basis all holes may be specified as a single datum. Then the gauge pin size of all four holes shall be 6.18mm.

17

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Class 6 Level 1 Imo 2022 Set BДокумент8 страницClass 6 Level 1 Imo 2022 Set BKishor kumar BhatiaОценок пока нет

- Asset 2022-23 Class 5 MathsДокумент19 страницAsset 2022-23 Class 5 MathsKishor kumar Bhatia100% (1)

- Class 6 Level 1 Imo 2020 Set AДокумент7 страницClass 6 Level 1 Imo 2020 Set AKishor kumar BhatiaОценок пока нет

- Class 6 Level 1 Imo 2018 Set AДокумент7 страницClass 6 Level 1 Imo 2018 Set AKishor kumar BhatiaОценок пока нет

- Class 6 Level 1 Imo 2021 Set BДокумент8 страницClass 6 Level 1 Imo 2021 Set BKishor kumar BhatiaОценок пока нет

- Class 2 Imo Paper 2014 Set AДокумент8 страницClass 2 Imo Paper 2014 Set AKishor kumar BhatiaОценок пока нет

- Imo Class 5 2022-23 Set-B Level-1Документ8 страницImo Class 5 2022-23 Set-B Level-1Kishor kumar BhatiaОценок пока нет

- IMO Class 6 - 2023-24 Set AДокумент8 страницIMO Class 6 - 2023-24 Set AKishor kumar Bhatia100% (1)

- Class 6 Level 1 Imo 2022 Set BДокумент8 страницClass 6 Level 1 Imo 2022 Set BKishor kumar BhatiaОценок пока нет

- Chemistry Class 11th and 12th For School, Mains Level, IIT Advance & NEETДокумент3 страницыChemistry Class 11th and 12th For School, Mains Level, IIT Advance & NEETKishor kumar BhatiaОценок пока нет

- Geometrical Dimensioning & Tolerancing - Review of Indian StandardsДокумент43 страницыGeometrical Dimensioning & Tolerancing - Review of Indian StandardsKishor kumar Bhatia100% (3)

- DMRCДокумент1 страницаDMRCKishor kumar BhatiaОценок пока нет

- Suggestion To PM of India 32 Post OfficeДокумент4 страницыSuggestion To PM of India 32 Post OfficeKishor kumar BhatiaОценок пока нет

- Solution IMT-120 3Документ8 страницSolution IMT-120 3Kishor kumar BhatiaОценок пока нет

- Suggestion To PM of India - Banking SectorДокумент1 страницаSuggestion To PM of India - Banking SectorKishor kumar BhatiaОценок пока нет

- Suggestion To PM of India 23-Banking-SectorДокумент2 страницыSuggestion To PM of India 23-Banking-SectorKishor kumar BhatiaОценок пока нет

- Suggestion To PM of India 27 Personal-Information-PrivacyДокумент3 страницыSuggestion To PM of India 27 Personal-Information-PrivacyKishor kumar BhatiaОценок пока нет

- Advance English Language - LearningДокумент114 страницAdvance English Language - LearningKishor kumar Bhatia100% (1)

- Coplanarity & Symmetry - GD&TДокумент9 страницCoplanarity & Symmetry - GD&TKishor kumar BhatiaОценок пока нет

- Pattern CastingДокумент17 страницPattern CastingKishor kumar Bhatia100% (1)

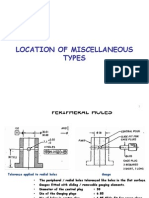

- Location of Miscellaneous Types - GD&TДокумент9 страницLocation of Miscellaneous Types - GD&TKishor kumar Bhatia100% (1)

- Geometrical Tolerancing (GD&T)Документ12 страницGeometrical Tolerancing (GD&T)Kishor kumar BhatiaОценок пока нет

- Projected Tolerance Zone Concept-GD&TДокумент24 страницыProjected Tolerance Zone Concept-GD&TKishor kumar Bhatia100% (6)

- Tolerance Accumulation and Analysis (GD&T)Документ80 страницTolerance Accumulation and Analysis (GD&T)Kishor kumar Bhatia50% (4)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)