Академический Документы

Профессиональный Документы

Культура Документы

Design Process

Загружено:

api-2412712690 оценок0% нашли этот документ полезным (0 голосов)

47 просмотров1 страницаОригинальное название

design process

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

47 просмотров1 страницаDesign Process

Загружено:

api-241271269Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

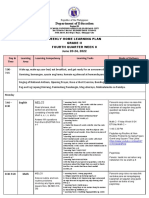

Raegan DuBose 12/02/13 2A

Puzzle Cube Design Process

At the beginning of the school year, my engineering class was given an example design process to use throughout the year. The following is a breakdown of that process in the manner that it applied to the puzzle cube project assigned. 1) Define a Problem The assignment was to create two puzzle cube designs and pick the best design and turn that design into a physical cube. We had to use many different ways of creating the cube. 2) Brainstorm We were given the basic layout of how the project would happen and then thought about the cube designs and what we would like them to look like. Each piece had to be different and still fit together. 3) Research and Generate Ideas The class was given as set of plastic cubes and told to make two separate puzzle cube designs. We were simply supposed to connect the cubes together in random shapes to create cube designs. 4) Identify Criteria and Specify Constraints In addition to the assignment, we were given a specific rubric that gave all the criteria and constraints to be used throughout the project. We also created our own criteria to judge the cube by. 5) Explore Possibilities After the plastic cubes had been created, they were put through a decision matrix to choose the best design. Some criteria were weighted higher than others and a design was chosen. 6) Select an Approach Following that, we were to sketch the cube in isometric layers and oblique cabinet. This helped to remember the cube in its exactitude. 7) Develop a Design Proposal Each piece had to be sketched in multiview, which consisted of the top, front, and right side view in addition to the isometric sketch. All line conventions, including object and hidden lines, had to be present in the multiviews 8) Make a Model or Prototype Immediately following, we designed each piece of the chosen puzzle cube in Autodesk Inventor. Each piece was designed to scale in the program. 9) Test and Evaluate the Design using Specifications The pieces were made into an electronic multiview using Autodesk Inventor to evaluate the correct measurements. Then the multiviews were printed half size and glued into my journal in addition to being posted on our online portfolio. 10) Refine the Design Using an assembly file, the 5 separate pieces of the cube were assembled into a cube and constrained into a cube that was impossible to pull apart. After, we made an animation of all 5 pieces coming together into said cube. 11) Create or Make Solution Nearly finished, a physical cube was created using wooden blocks. Each piece was colored and glued together then sanded down. 12) Communicate Processes and Result A brief summary of the project and a few pictures were uploaded to my online portfolio (raegandubose.weebly.com). Finally, I composed this paper to explain each step of the process.

Вам также может понравиться

- Requirement 1Документ1 страницаRequirement 1api-308825465Оценок пока нет

- Steam Individual UnitДокумент38 страницSteam Individual Unitapi-509967457Оценок пока нет

- Puzzle Cube Project Julia Prien Introduction To Engineering DesignДокумент14 страницPuzzle Cube Project Julia Prien Introduction To Engineering Designapi-302688343Оценок пока нет

- 2 3 A GlassboxДокумент13 страниц2 3 A Glassboxapi-233132806Оценок пока нет

- Puzzle Cube DisplayДокумент1 страницаPuzzle Cube Displayapi-308825465Оценок пока нет

- Spaghetti Earthquake Challenge 1Документ6 страницSpaghetti Earthquake Challenge 1api-428123208100% (1)

- Final PastoralДокумент6 страницFinal Pastoralapi-459207846Оценок пока нет

- Klipstine Kortney Puzzle Cube Write UpДокумент4 страницыKlipstine Kortney Puzzle Cube Write Upapi-302638576Оценок пока нет

- Puzzle Design Challenge BriefДокумент2 страницыPuzzle Design Challenge Briefapi-249926147Оценок пока нет

- Puzzle Cube ProjectДокумент12 страницPuzzle Cube Projectapi-178275861Оценок пока нет

- p4 1 PuzzledesignchallengeДокумент6 страницp4 1 Puzzledesignchallengeapi-180311868Оценок пока нет

- Bridge ProjectДокумент15 страницBridge Projectapi-254543483Оценок пока нет

- Design Challenge: Oscar's Cubes: Puzzle Pieces (4x4 Inch Cubes)Документ5 страницDesign Challenge: Oscar's Cubes: Puzzle Pieces (4x4 Inch Cubes)Brandon Edward Leo PoulinОценок пока нет

- 2.4 Puzzle Cube Lesson Plan: Manufacturing ClusterДокумент5 страниц2.4 Puzzle Cube Lesson Plan: Manufacturing Clusterapi-344263170Оценок пока нет

- Lake Travis High School Principles of Engineering 3A Marble SorterДокумент6 страницLake Travis High School Principles of Engineering 3A Marble Sorterapi-336931682Оценок пока нет

- 2.3.A Glass BoxДокумент14 страниц2.3.A Glass BoxMarealz MoresaОценок пока нет

- CLC 12-Combined Final Capstone Proposal Ref 1Документ4 страницыCLC 12-Combined Final Capstone Proposal Ref 1api-692368800Оценок пока нет

- 2010 Puzzle Cube ProjectДокумент6 страниц2010 Puzzle Cube Projectapi-106613477Оценок пока нет

- Puzzle Cube Design Challenge Final PortfolioДокумент19 страницPuzzle Cube Design Challenge Final Portfolioapi-260940948Оценок пока нет

- RaconsolacionlessonplanДокумент5 страницRaconsolacionlessonplanBelinda tolentinoОценок пока нет

- CardboardchallengecurriculumkitДокумент9 страницCardboardchallengecurriculumkitapi-340001112Оценок пока нет

- Final Course Document:: Fabricación Digital Maria Sofia Jassir Acosta 201819963Документ11 страницFinal Course Document:: Fabricación Digital Maria Sofia Jassir Acosta 201819963jassir jassirОценок пока нет

- Project Taking Shape Student GuideДокумент7 страницProject Taking Shape Student GuideKishore S100% (1)

- Design Portfolio Mohammad Monem 2020Документ19 страницDesign Portfolio Mohammad Monem 2020api-528176673Оценок пока нет

- Puzzledesignchallenge SheetДокумент5 страницPuzzledesignchallenge Sheetapi-275475101Оценок пока нет

- AutoCAD in 7 Days - SampleДокумент36 страницAutoCAD in 7 Days - SampleHaji AliОценок пока нет

- Empowering Students with Image Manipulation SkillsДокумент14 страницEmpowering Students with Image Manipulation SkillsRexchel Nicole P. AlvarezОценок пока нет

- 4 1 Puzzle Design ChallengeДокумент5 страниц4 1 Puzzle Design Challengeapi-306792106Оценок пока нет

- Lessonplan1102 1104Документ6 страницLessonplan1102 1104api-300454762Оценок пока нет

- Name: Jesabell Omagap Sambile Yr/Course/Section: 2BSABE-BДокумент6 страницName: Jesabell Omagap Sambile Yr/Course/Section: 2BSABE-BMizpah DuculanОценок пока нет

- Unit: Christmas Creativity: Duration: 2 Weeks (4 Class Periods)Документ6 страницUnit: Christmas Creativity: Duration: 2 Weeks (4 Class Periods)JLBVIОценок пока нет

- Design BriefДокумент9 страницDesign Briefapi-251159104Оценок пока нет

- Binder 1Документ12 страницBinder 1api-211956215Оценок пока нет

- Mini Project FAQ - DetailsДокумент3 страницыMini Project FAQ - DetailsTusanita MapuolaОценок пока нет

- Rubik GradeДокумент2 страницыRubik GradejudaswashereОценок пока нет

- Science LessonДокумент8 страницScience Lessonapi-351183547Оценок пока нет

- Portfolio Phase 2 TemplateДокумент2 страницыPortfolio Phase 2 TemplatemurtazaОценок пока нет

- Kami Export - Daniel Ford - Online 20-21 Senior Project OutlineДокумент2 страницыKami Export - Daniel Ford - Online 20-21 Senior Project Outlineapi-376944994Оценок пока нет

- 3D Modeling Course - OutlineДокумент5 страниц3D Modeling Course - OutlineNika BellosilloОценок пока нет

- Christmas Creativity Project DescriptionДокумент7 страницChristmas Creativity Project DescriptiontennisbeastОценок пока нет

- Guide - UE4 Modular Pipes Project Breakdown v1Документ68 страницGuide - UE4 Modular Pipes Project Breakdown v1fardeenrezakhan1Оценок пока нет

- FolioДокумент38 страницFoliocameron_h_gordonОценок пока нет

- Transformation ProjectДокумент3 страницыTransformation Projectjaxonbuszan34Оценок пока нет

- 3 3 1reportДокумент12 страниц3 3 1reportapi-302334715Оценок пока нет

- Puzzle Design Challenge Brief R Molfetta WeeblyДокумент4 страницыPuzzle Design Challenge Brief R Molfetta Weeblyapi-274367128Оценок пока нет

- Puzzle Design Challenge: Define The ProblemДокумент12 страницPuzzle Design Challenge: Define The Problemapi-306079911Оценок пока нет

- Building Things UnitДокумент10 страницBuilding Things Unitapi-535157829Оценок пока нет

- Engineering Notebook 2023Документ8 страницEngineering Notebook 2023estanton629Оценок пока нет

- Puzzle Cube DB and DeliverablesДокумент2 страницыPuzzle Cube DB and Deliverablesapi-392680519Оценок пока нет

- Bottling The FurnitureДокумент3 страницыBottling The Furniturerobinsonje1Оценок пока нет

- Nuke VFX Compositing Course With Steve WrightДокумент3 страницыNuke VFX Compositing Course With Steve WrightAlthaf VA100% (1)

- Capstone Finalized Draft Details WorksheetДокумент3 страницыCapstone Finalized Draft Details Worksheetapi-649456679Оценок пока нет

- Science Worksheet For Class XДокумент15 страницScience Worksheet For Class XTejas Shreyas SrivastavaОценок пока нет

- Solar Oven 1Документ2 страницыSolar Oven 1api-359445793Оценок пока нет

- Bridge ProjectДокумент17 страницBridge Projectapi-397497149100% (1)

- Module 16 For Grade 10 PDFДокумент22 страницыModule 16 For Grade 10 PDFAARON CABINTAОценок пока нет

- Let's Practise: Maths Workbook Coursebook 4От EverandLet's Practise: Maths Workbook Coursebook 4Оценок пока нет

- Learn Autodesk Inventor 2018 Basics: 3D Modeling, 2D Graphics, and Assembly DesignОт EverandLearn Autodesk Inventor 2018 Basics: 3D Modeling, 2D Graphics, and Assembly DesignОценок пока нет

- Wolf Architects 2013Документ7 страницWolf Architects 2013api-241194406Оценок пока нет

- Habit Project Design Brief 2016Документ3 страницыHabit Project Design Brief 2016api-241271269Оценок пока нет

- Habitat2 SheetsДокумент5 страницHabitat2 Sheetsapi-241271269Оценок пока нет

- Welcome To YatesylvaniaДокумент13 страницWelcome To Yatesylvaniaapi-241271269Оценок пока нет

- Nanotechnology CarДокумент11 страницNanotechnology Carapi-241271269Оценок пока нет

- Behind Your WallsДокумент3 страницыBehind Your Wallsapi-241271269Оценок пока нет

- Manufacturing MiniДокумент2 страницыManufacturing Miniapi-241271269Оценок пока нет

- Evolution of Cancer Detection TreatmentДокумент8 страницEvolution of Cancer Detection Treatmentapi-241271269Оценок пока нет

- Principles and Elements of DesignДокумент9 страницPrinciples and Elements of Designapi-241271269Оценок пока нет

- Nanotechnology Project - Rubric 2014 BДокумент4 страницыNanotechnology Project - Rubric 2014 Bapi-253572636Оценок пока нет

- 2012 Puzzle Cube ProjectДокумент4 страницы2012 Puzzle Cube Projectapi-241194406Оценок пока нет

- Newtons Laws EssayДокумент1 страницаNewtons Laws Essayapi-241271269Оценок пока нет

- Strickland ProjectДокумент2 страницыStrickland Projectapi-241271269Оценок пока нет

- Computer Portfolio (Aashi Singh)Документ18 страницComputer Portfolio (Aashi Singh)aashisingh9315Оценок пока нет

- Newcomers Guide To The Canadian Job MarketДокумент47 страницNewcomers Guide To The Canadian Job MarketSS NairОценок пока нет

- Periodic ClassificationДокумент4 страницыPeriodic ClassificationtusharОценок пока нет

- Ecole Polytechnique Federale de LausanneДокумент44 страницыEcole Polytechnique Federale de LausanneSyed Yahya HussainОценок пока нет

- 10 Slides For A Perfect Startup Pitch DeckДокумент6 страниц10 Slides For A Perfect Startup Pitch DeckZakky AzhariОценок пока нет

- April 2017 Jacksonville ReviewДокумент40 страницApril 2017 Jacksonville ReviewThe Jacksonville ReviewОценок пока нет

- Installation Instruction XALM IndoorДокумент37 страницInstallation Instruction XALM IndoorVanek505Оценок пока нет

- Mechanics of Deformable BodiesДокумент21 страницаMechanics of Deformable BodiesVarun. hrОценок пока нет

- Module - No. 3 CGP G12. - Subong - BalucaДокумент21 страницаModule - No. 3 CGP G12. - Subong - BalucaVoome Lurche100% (2)

- PC November 2012Документ50 страницPC November 2012bartekdidОценок пока нет

- FALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFДокумент3 страницыFALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFJISHNU TKОценок пока нет

- PW CДокумент4 страницыPW CAnonymous DduElf20OОценок пока нет

- Colour Ring Labels for Wireless BTS IdentificationДокумент3 страницыColour Ring Labels for Wireless BTS Identificationehab-engОценок пока нет

- WassiДокумент12 страницWassiwaseem0808Оценок пока нет

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinДокумент36 страницTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)

- The Changing Face of War - Into The Fourth GenerationДокумент5 страницThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozОценок пока нет

- Ks3 Science 2008 Level 5 7 Paper 1Документ28 страницKs3 Science 2008 Level 5 7 Paper 1Saima Usman - 41700/TCHR/MGBОценок пока нет

- LON-Company-ENG 07 11 16Документ28 страницLON-Company-ENG 07 11 16Zarko DramicaninОценок пока нет

- Course Tutorial ASP - Net TrainingДокумент67 страницCourse Tutorial ASP - Net Traininglanka.rkОценок пока нет

- Injection Timing (5L) : InspectionДокумент2 страницыInjection Timing (5L) : InspectionaliОценок пока нет

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Документ8 страницDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIOОценок пока нет

- Investigatory Project Pesticide From RadishДокумент4 страницыInvestigatory Project Pesticide From Radishmax314100% (1)

- Bluetooth Home Automation Using ArduinoДокумент25 страницBluetooth Home Automation Using ArduinoRabiОценок пока нет

- Deep Groove Ball Bearings PDFДокумент11 страницDeep Groove Ball Bearings PDFArpit VermaОценок пока нет

- JD - Software Developer - Thesqua - Re GroupДокумент2 страницыJD - Software Developer - Thesqua - Re GroupPrateek GahlanОценок пока нет

- SEMICONDUCTORS AssignmentДокумент8 страницSEMICONDUCTORS AssignmentMaryam MuneebОценок пока нет

- Weekly Choice - Section B - February 16, 2012Документ10 страницWeekly Choice - Section B - February 16, 2012Baragrey DaveОценок пока нет

- Put The Items From Exercise 1 in The Correct ColumnДокумент8 страницPut The Items From Exercise 1 in The Correct ColumnDylan Alejandro Guzman Gomez100% (1)

- Numerical Methods: Jeffrey R. ChasnovДокумент60 страницNumerical Methods: Jeffrey R. Chasnov2120 sanika GaikwadОценок пока нет

- USA V BRACKLEY Jan6th Criminal ComplaintДокумент11 страницUSA V BRACKLEY Jan6th Criminal ComplaintFile 411Оценок пока нет