Академический Документы

Профессиональный Документы

Культура Документы

Centrifugal Pump Assignment

Загружено:

cderin2000Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Centrifugal Pump Assignment

Загружено:

cderin2000Авторское право:

Доступные форматы

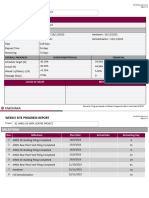

PROJECT

RUMAITHA-SHANAYEL PHASE III Assignment Module 2 DEVELOPMENT PROJECT FEED DATASHEET FOR OIL EXPORT PUMPS

PROJECT NO DOCUMENT NO PAGE NO. REVISION

DOCUMENT DOC. SUB-TITLE MANUFACTURER

1 Note APPLICABLE TO: 2 3 4 5 6 7 8 9 10 11 12 FOR

DS FOR CENTRIFUGAL PUMPS (API 610, 11TH ED)

Author: Guillermo Hauke OIL EXPORT PUMP SERVICE

MRQ NO.

PROPOSAL APPLICABLE NTL/INTNTL STANDARD: UNIT API-610

ABU DHABI CO. FOR ONSHORE OIL OPERATIONS (ADCO)

1. Using on-line catalogues or any data you may have, find the most adequate pump to provide the following service. Justify your choice. RUMAITHA (44) SITE

NO. REQ FOUR (4) (Note 20) PUMP SIZE MANUFACTURER LIQUID CHARACTERISTICS Units Maximum Minimum STABILISED CRUDE OIL Note 23 Bar Abs. 0.82 0.7820.799 Note Max & min values refer only to the property listed SERVICE TYPE MODEL

OI BB5

No

SE

SERVICE :

LIQUID TYPE OR NAME : VAPOR PRESSURE : RELATIVE DENSITY : SPECIFIC HEAT : VISCOSITY :

IF INTERMIT

PUMPS OPER

CORROSION D

EROSION DUE cSt 1.71-2.75

H2S CONCEN

13 14 15 16 17 18 19 20

OPERATING CONDITIONS (6.1.2)

Units NPSHa Datum: PUMPING TEMPERATURE : FLOW : DISCHARGE PRESSURE : (6.3.2) SUCTION PRESSURE : DIFFERENTIAL PRESSURE :

0

CHLORIDE CO Rated Normal Minimum

Maximum

PARTICULATE S

C.L. Impeller C 65 275 93.25

4.5

PARTICULATE C

40 Note 4

m /hr Bar g Bar g Bar

* At grade level

88.75 1158.1 (Note 21)

>10

21 22 23

DIFFERENTIAL HEAD : NPSHA : HYDRAULIC POWER :

m m kW

24 25 26 27 28 29 30 31 MOUNTED AT : LOCATION: OUTDOOR GRADE

SITE AND UTILITY DATA (Refer Machinery Design Basis Doc No.: 30.99.91.06 COOLING WATER : UNHEATED UNDER ROOF TROPICALISATION REQD 6.1.22 Zone 2 T3 TEMP PRESS. SOURCE N/A

INLET

ELECTRIC AREA CLASSIFICATION: GROUP IIB

Rotating Machinery MSc. University of Zaragoza. Mod. 2. Pumps and applications

TEMP CLASS

1

MAX

MAX MIN

SITE DATA : ELEVATION (MSL) : BAROMETER :

COOLING WATER CHLORIDE CON INSTRUMENT AIR :

2. Calculate the power of the required electric motor. Indicate the global pump efficiency and the electrical motor efficiency.

3. Select a mechanical seal for this pump according to API682 third edition, ISO 21049 code. Indicate the API plan recommended.

4. If the NPSHA is reduced below the required for the pump selected in 1), propose and justify a solution. Is there another API pump type that could be selected?

Rotating Machinery MSc. University of Zaragoza. Mod. 2. Pumps and applications

Вам также может понравиться

- Apc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsДокумент9 страницApc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsdexiОценок пока нет

- Industry Application Guide Micro Data Center Meets Edge Computing Attom TechnologyДокумент7 страницIndustry Application Guide Micro Data Center Meets Edge Computing Attom TechnologyMeОценок пока нет

- Data Communication Between Programmable Logic S7-300 PDFДокумент7 страницData Communication Between Programmable Logic S7-300 PDFcarlosmarciosfreitasОценок пока нет

- Hvac Report 20140604Документ198 страницHvac Report 20140604Muhammad Yusuf FirdausОценок пока нет

- Annex 4 - Tier Certification of Operational Sustainability - PresentationДокумент12 страницAnnex 4 - Tier Certification of Operational Sustainability - PresentationKamran SiddiquiОценок пока нет

- CLB-1000B Spec SheetДокумент1 страницаCLB-1000B Spec Sheetdiegoh_silvaОценок пока нет

- Fulltext01 PDFДокумент64 страницыFulltext01 PDFdexiОценок пока нет

- Electrical Works For Data Centre-01Oct10Документ60 страницElectrical Works For Data Centre-01Oct10sainiksenthil100% (1)

- Practical Considerations For Implementing Prefabricated Data CentersДокумент14 страницPractical Considerations For Implementing Prefabricated Data CentersJesús MendivelОценок пока нет

- Fault Tolerant Power Compliance Specification - v2Документ3 страницыFault Tolerant Power Compliance Specification - v2Doruk BakırОценок пока нет

- Autodesk Simulation CFD Datacenters Whitepaper enДокумент7 страницAutodesk Simulation CFD Datacenters Whitepaper enben_splОценок пока нет

- Certified Data Centre Design Professional CDCDPДокумент2 страницыCertified Data Centre Design Professional CDCDPY Rajesh KumarОценок пока нет

- Data Center Power and Cooling: White PaperДокумент25 страницData Center Power and Cooling: White PaperarmasciaОценок пока нет

- Normal ChecklistДокумент2 страницыNormal ChecklistNacho ConsolaniОценок пока нет

- UPTIME Report New FormatДокумент1 страницаUPTIME Report New Formatapi-3760134Оценок пока нет

- Standards UpdateДокумент4 страницыStandards Updatescrane@Оценок пока нет

- Pressurization For Staircase (SG Code)Документ4 страницыPressurization For Staircase (SG Code)Zaw Moe KhineОценок пока нет

- DC Air ManagementДокумент83 страницыDC Air ManagementSargurusivaОценок пока нет

- ALL Manday RateДокумент53 страницыALL Manday RateEngFaisal AlraiОценок пока нет

- Desigo CC V4.2 BIM ViewerДокумент11 страницDesigo CC V4.2 BIM ViewerDogan KarabulutОценок пока нет

- Green Buildings Lessons Learnt IGBCДокумент21 страницаGreen Buildings Lessons Learnt IGBCvabsОценок пока нет

- Cabling Standard Standards OverviewДокумент6 страницCabling Standard Standards Overview6989wyОценок пока нет

- (Lexe0599-01) Uptime Tier III and IV Data CenterДокумент1 страница(Lexe0599-01) Uptime Tier III and IV Data Centervictor.ciprianiОценок пока нет

- TECHPAPER ATD ContCooling PDFДокумент3 страницыTECHPAPER ATD ContCooling PDFA.K.A. HajiОценок пока нет

- 11 808 417 01 PDFДокумент20 страниц11 808 417 01 PDFManuel Alejandro Espinosa FarfanОценок пока нет

- The Uptime Institute Tier Classification System: Comparisons With TIA-942Документ2 страницыThe Uptime Institute Tier Classification System: Comparisons With TIA-942Doruk BakırОценок пока нет

- VP Director Facilities Engineering in United States Resume Kenneth PoynterДокумент2 страницыVP Director Facilities Engineering in United States Resume Kenneth PoynterKennethPoynterОценок пока нет

- Organic Waste Converter: Presentation OnДокумент8 страницOrganic Waste Converter: Presentation OnLeo VictorОценок пока нет

- V-300 ImirДокумент1 страницаV-300 ImirprathameshОценок пока нет

- Effective Job Analysis: Fundamentals of Human Resource Management, 10/E, Decenzo/RobbinsДокумент24 страницыEffective Job Analysis: Fundamentals of Human Resource Management, 10/E, Decenzo/RobbinsFarhana MituОценок пока нет

- As Plan Drawing (Gambar Perencanaan) : Kendari Int - Kendari BMH (Segment Kendari - Wawoni)Документ1 страницаAs Plan Drawing (Gambar Perencanaan) : Kendari Int - Kendari BMH (Segment Kendari - Wawoni)setiawan jodiОценок пока нет

- (Catalogue 2011) CanalisДокумент107 страниц(Catalogue 2011) CanalisAgus YohanesОценок пока нет

- Cable Landing Station: Gargi Choudhury 8/29/2015Документ16 страницCable Landing Station: Gargi Choudhury 8/29/2015Hanza KH100% (1)

- Does Your Data Center Follow ASHRAE TC 9.9 Thermal Guidelines For Data Processing Environments - Sunbird DCIMДокумент2 страницыDoes Your Data Center Follow ASHRAE TC 9.9 Thermal Guidelines For Data Processing Environments - Sunbird DCIMGeorgiaОценок пока нет

- Data Center Infrastructure Providers A Complete Guide - 2019 EditionОт EverandData Center Infrastructure Providers A Complete Guide - 2019 EditionОценок пока нет

- M4864P6B Module Specification: Revision History Date Prepared by DetailsДокумент5 страницM4864P6B Module Specification: Revision History Date Prepared by DetailsSatheesh Kumar NatarajanОценок пока нет

- 02 - Introduction To Data Center Tiers and StandardsДокумент54 страницы02 - Introduction To Data Center Tiers and Standardsturturkeykey24Оценок пока нет

- Evaporative Cooling SystemДокумент8 страницEvaporative Cooling SystemAshok KumarОценок пока нет

- Dunhm-Bush PRODUCT GUIDEDB Global Product GuideДокумент19 страницDunhm-Bush PRODUCT GUIDEDB Global Product GuideFalak KhanОценок пока нет

- Power+ A Parallel Redundant UPS - Uninterruptible Power SupplyДокумент8 страницPower+ A Parallel Redundant UPS - Uninterruptible Power SupplyGamatronicОценок пока нет

- IT Best Practices Data Center Site Selection PDFДокумент11 страницIT Best Practices Data Center Site Selection PDFUgur UnluakinОценок пока нет

- Power Infrastructure Solutions - Products Catalogue 2016 LRДокумент91 страницаPower Infrastructure Solutions - Products Catalogue 2016 LRJerry MarshalОценок пока нет

- Cent Bank Home Finance LTD (CBHFL) : Tender DocumentДокумент51 страницаCent Bank Home Finance LTD (CBHFL) : Tender Documentrahul1512Оценок пока нет

- Data Center Operations Index BenchmarkДокумент23 страницыData Center Operations Index BenchmarkCarlos AguileraОценок пока нет

- CommissioningДокумент18 страницCommissioningmonarch_007Оценок пока нет

- 08-100923 K2 JHR01-03 Data CentreДокумент44 страницы08-100923 K2 JHR01-03 Data CentreHanitha (Digital & Technology)100% (1)

- Hotel BMS BrochureДокумент8 страницHotel BMS BrochureRares OpricaОценок пока нет

- Condenser Product ManualДокумент24 страницыCondenser Product ManualAdnanОценок пока нет

- TIERSTANDARD Topology 120801 PDFДокумент12 страницTIERSTANDARD Topology 120801 PDFSomyot Songsalee100% (1)

- User Guide For Implementing ECBC in Data Centers - CII-IGBC and LBNL (DOE) USA - May 2021Документ69 страницUser Guide For Implementing ECBC in Data Centers - CII-IGBC and LBNL (DOE) USA - May 2021Pavan Kumar SОценок пока нет

- Building Management System: CharacteristicsДокумент14 страницBuilding Management System: CharacteristicsshaikamirulhasanОценок пока нет

- Air Cooled Chiller Operation and InstallationДокумент87 страницAir Cooled Chiller Operation and InstallationOmar Lutfi100% (2)

- Application Guide: Reserve PowerДокумент4 страницыApplication Guide: Reserve PowermiljenkopОценок пока нет

- Energy Recovery WheelДокумент8 страницEnergy Recovery WheelRawan Alwan ZarifОценок пока нет

- Hot Aisle Cold Aisle ContainmentДокумент8 страницHot Aisle Cold Aisle ContainmentdhansbeОценок пока нет

- Tube Fitters ManualДокумент320 страницTube Fitters Manualcderin2000100% (1)

- Alcad Vantex Io 4.4.E.1016Документ2 страницыAlcad Vantex Io 4.4.E.1016cderin2000Оценок пока нет

- IOM Horizontal Bandlock 2 Closure - ManualДокумент22 страницыIOM Horizontal Bandlock 2 Closure - Manualcderin2000Оценок пока нет

- 40 Things The Word of God Does For You - Joyce MeyerДокумент3 страницы40 Things The Word of God Does For You - Joyce Meyercderin2000100% (1)

- TViX HD M6600 EnglishДокумент80 страницTViX HD M6600 Englishcderin2000Оценок пока нет

- Scaffolding PDFДокумент80 страницScaffolding PDFLeo Richmond75% (4)

- JC International Training Calendar 2019 2Документ13 страницJC International Training Calendar 2019 2cderin2000Оценок пока нет

- 15 Easy Ways To Lower Blood Sugar Levels NaturallyДокумент9 страниц15 Easy Ways To Lower Blood Sugar Levels Naturallycderin2000Оценок пока нет

- Crane Wire Changing ProcedureДокумент2 страницыCrane Wire Changing ProcedureSasan Abbasi83% (24)

- Equipment Criticality White PaperДокумент6 страницEquipment Criticality White Papercderin2000Оценок пока нет

- Operational Readiness - Bridging The Gap Between Construction and Operations For New Capital AssetsДокумент15 страницOperational Readiness - Bridging The Gap Between Construction and Operations For New Capital Assetscderin2000100% (1)

- Web Enabled Selection Method For Key Performance Indicators For ManufacturingДокумент9 страницWeb Enabled Selection Method For Key Performance Indicators For Manufacturingcderin2000Оценок пока нет

- Operation and Maintenance of Electrochlorination PlantДокумент5 страницOperation and Maintenance of Electrochlorination Plantمروه وهيب100% (1)

- Explorer 710 User ManualДокумент144 страницыExplorer 710 User Manualcderin2000Оценок пока нет

- A Bible Study of Ephesians - Joyce MeyerДокумент60 страницA Bible Study of Ephesians - Joyce Meyercderin200096% (27)

- Advanced CMMS MetricsДокумент17 страницAdvanced CMMS Metricscderin2000Оценок пока нет

- Critical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyДокумент182 страницыCritical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyAustin Higgins97% (61)

- Vibration Dignostic ChartДокумент5 страницVibration Dignostic ChartIbrahim Sammour92% (12)

- Our God of Promise - Dr. Charles StanleyДокумент2 страницыOur God of Promise - Dr. Charles Stanleycderin2000Оценок пока нет

- Electrolyser-Operating Manual PDFДокумент6 страницElectrolyser-Operating Manual PDFcderin20000% (1)

- Believer's Voice of Victory - December 2016Документ32 страницыBeliever's Voice of Victory - December 2016cderin2000Оценок пока нет

- 40 Things The Word of God Does For You - Joyce MeyerДокумент3 страницы40 Things The Word of God Does For You - Joyce Meyercderin2000100% (1)

- 40 Things The Word of God Does For You - Joyce MeyerДокумент3 страницы40 Things The Word of God Does For You - Joyce Meyercderin2000100% (1)

- Optimizing Maintenance Efficiencies With An Effective Greasing ProgramДокумент6 страницOptimizing Maintenance Efficiencies With An Effective Greasing Programcderin2000Оценок пока нет

- Visibility Sensor - User GuideДокумент98 страницVisibility Sensor - User Guidecderin2000100% (1)

- Answer The Call To PublishДокумент8 страницAnswer The Call To Publishcderin2000Оценок пока нет

- Electrolyser Operating ManualДокумент6 страницElectrolyser Operating Manualcderin2000Оценок пока нет

- Live Healed - Gloria CopelandДокумент32 страницыLive Healed - Gloria Copelandcderin2000100% (3)

- Understanding Crude Oil and Product Markets Primer Low PDFДокумент39 страницUnderstanding Crude Oil and Product Markets Primer Low PDFrohanpujari100% (1)

- Asset Integrity Management in The North Amfrica Oil and GasДокумент5 страницAsset Integrity Management in The North Amfrica Oil and Gascderin2000Оценок пока нет