Академический Документы

Профессиональный Документы

Культура Документы

ASME 31 - 8m

Загружено:

MarcoAlbaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ASME 31 - 8m

Загружено:

MarcoAlbaАвторское право:

Доступные форматы

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

Pipe & Shell

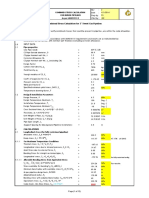

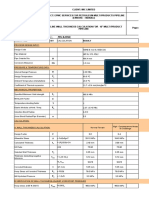

ACCORDING TO ASME/ANSI B31.8 Pipeline 30" Classe I Document Number and Revision Job Number Item Component Tag

Page 3 of 7

Do

Design Data:

321 PSI 87 PSI 82 F 401 PSI 0.236 Inc 0.50 2.21 Mpa 0.60 Mpa 28 C 2.76 Mpa 6.0 mm 0.50 Pv Ph Td Ptest c F Vessel Design Pressure Static Head Pressure Design Temperature Test Pressure Corrosion Allowance Design Factor

t Long Seam

Dimensions:

6.625 Inc 0.280 Inc 1377.953 Inc 1.00 168.3 mm 7.1 mm 35000 mm 1.00 D tn L E Outside Diameter Nominal Wall Thickness Length Weld Efficiency

Calculated Properties:

Weigth Empty Internal Volume Weigth Flooded External Surface 988 Kg 653 dm3 1640 Kg 18.5 m2

Material Properties:

API 5L X52

52,000 PSI 52,000 PSI 358.5 Mpa 358.5 Mpa S St Material Specification Yield strength @ Design temperature Yield strength @ Test temperature

Hot&Corroded

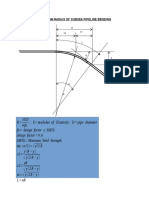

P = Pv + ph Di = Do - 2 * tn + 2 * c According to Table 841.1.8-1 H = tn-c

Geometry / Data

Design Pressure Inside diameter Temperature derating Shell thick P= Di = T= H= 0.043 Inc 408 PSI 6.539 Inc 2.8 Mpa 166.1 mm 1.000 1.1 mm

Stress relieving NOT required per 825.2

ASME/ANSI B31.8 par. 841.1

t = P*D / (2 * S * F * E * T) t + c <= tn MAWP = 2 * S * H / D * F * E * T P to MAWP ratio ASME B31.8 par. 805.233 HS = P * D / ( 2 * H) Hoop stress at des. cond. Hoop stress to Yield strength ratio HS = H.S. / SY = 31174 PSI 214.9 Mpa 60.0% Minimum Nominal thick ERROR t= t+c = MAWP = P / MAWP = 0.052 Inc 0.288 Inc 340 PSI 1.3 mm 7.3 mm 2.3 Mpa 119.9%

New& Cold

Di = Do - 2* tn According to Table 841.1.8-1 H = tn

Geometry / Data

Inside diameter uncorroded Temperature derating Shell thick Design Factor For Test Condition DiUnc = T= H= F= 0.280 Inc 6.066 Inc 154.1 mm 1.000 7.1 mm 0.90

ASME/ANSI B31.8 par. 841.1

MAP = 2 * St * H / D * F * E * T P to MAP ratio ASME B31.8 par. 805.233 HS = Ptest * D / ( 2 * H) Hoop stress at test cond. Hoop stress to Yield strength ratio HS = H.S. / SY = 4748 PSI 32.7 Mpa 9.1% OK MAP = Ptest / MAP = 3949 PSI 27.2 Mpa 10.1%

Length

Вам также может понравиться

- ASME 31 - 4 CalcДокумент1 страницаASME 31 - 4 CalcMarcoAlbaОценок пока нет

- Wall THK Calculation Asme b31.4Документ5 страницWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Thickness Analysis ReportДокумент9 страницThickness Analysis ReportEhtisham AndrAbiОценок пока нет

- Pipe Thickness Calculation PDFДокумент1 страницаPipe Thickness Calculation PDFHeny Martha67% (3)

- Pipe CalculationДокумент2 страницыPipe CalculationWijayantoОценок пока нет

- Pipe Reinforcement Calculation (ASME-B31.3)Документ3 страницыPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Imperial Piping Weight Load Calculation WorkbookДокумент13 страницImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Trunnion Calculation SheetДокумент2 страницыTrunnion Calculation SheetIshu Vohra0% (1)

- Vortex Shedding Load On PipingДокумент1 страницаVortex Shedding Load On Pipingananyo_sengupta100% (1)

- Thickness and Weld Branch Calc To ASME B31 3Документ4 страницыThickness and Weld Branch Calc To ASME B31 3alvinchuan100% (1)

- Asme Viii D Table 2aДокумент9 страницAsme Viii D Table 2aHugoОценок пока нет

- ASME B31.4-Wall Thickness Calc For 6 InchДокумент2 страницыASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoОценок пока нет

- Combined Stress Calc Rev. 2Документ12 страницCombined Stress Calc Rev. 2babu75% (4)

- Reinforcement CheckДокумент2 страницыReinforcement Checkviv0102Оценок пока нет

- Branch Reinforcement Pad Requirement CalculationДокумент2 страницыBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Wall Thickness Calculation ASME B31!8!2007Документ1 страницаWall Thickness Calculation ASME B31!8!2007shafeeqm3086Оценок пока нет

- Sif B31 3Документ24 страницыSif B31 3vuqar0979100% (1)

- Pipe Weight CalculatorДокумент1 страницаPipe Weight Calculatorkenho2Оценок пока нет

- Wall THK Calculation Asme b31.4Документ7 страницWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Weldstrength Calc ProgДокумент10 страницWeldstrength Calc ProgSajal KulshresthaОценок пока нет

- Pipeline Calculations - ASAB Gas Lift LinesДокумент11 страницPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqОценок пока нет

- Section VIII CalДокумент19 страницSection VIII CalPradeep Kothapalli100% (1)

- Plate CalculationДокумент7 страницPlate CalculationminhthanhmosОценок пока нет

- New - Reinforcement of NozzleДокумент31 страницаNew - Reinforcement of NozzleNithin ZsОценок пока нет

- Asme b31 3 03 PDFДокумент3 страницыAsme b31 3 03 PDFAtallah BoufatahОценок пока нет

- AS4041 ASME B31 - 3 Pipe Wall ThicknessДокумент8 страницAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthДокумент3 страницыASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyОценок пока нет

- Gas Line - 20 BargДокумент22 страницыGas Line - 20 Bargsaravanakkumar boominahtan100% (1)

- Calculation Minimum Required Thickness For Bending Pipe r2Документ11 страницCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanОценок пока нет

- Underground Pipe THK CalДокумент12 страницUnderground Pipe THK Calmkchy12100% (3)

- Upheaval Buckling CalculationДокумент10 страницUpheaval Buckling CalculationMoustafa Fares100% (1)

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Документ1 страницаWall Thickness Calculation - ASME B31.8 2007 (Template)LU1228100% (3)

- Area Reinforcement CalculatorДокумент5 страницArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Calculation For Reinforced PadДокумент4 страницыCalculation For Reinforced Padjsridhar_34750% (2)

- PIPECALC ASME B31.4 - Rev 2Документ24 страницыPIPECALC ASME B31.4 - Rev 2Mohsin RazaОценок пока нет

- Asme B31.8Документ14 страницAsme B31.8omar equihua100% (1)

- YoussefДокумент1 страницаYoussefhhgjdfОценок пока нет

- Pressure Vessel Calculations ASME SectioДокумент11 страницPressure Vessel Calculations ASME Sectioivan chirinosОценок пока нет

- ASME B31.8 Riser CalcДокумент12 страницASME B31.8 Riser CalcSalz EngineeringОценок пока нет

- Dummy Leg JacobsДокумент1 страницаDummy Leg Jacobsananyo_sengupta0% (1)

- ASME B31.3.4.8 Wall Thickness CalculatorДокумент26 страницASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- New Storage Tanks Design GuidelinesДокумент6 страницNew Storage Tanks Design GuidelinespaaryОценок пока нет

- Annexure - Bolt Torque CalculationДокумент4 страницыAnnexure - Bolt Torque CalculationDarshan PanchalОценок пока нет

- Area Reinforcement CalculatorДокумент5 страницArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Minimum Radius Pipe Bending-R1Документ4 страницыMinimum Radius Pipe Bending-R1AdvisОценок пока нет

- Design of Flanges - Full-Face Gasket 2010Документ29 страницDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Trunnion CalculationДокумент92 страницыTrunnion CalculationkarunaОценок пока нет

- Pd5500 Flange CalculationДокумент6 страницPd5500 Flange CalculationMakrand SakpalОценок пока нет

- Structural AnalysisДокумент12 страницStructural Analysisabhishek5810Оценок пока нет

- Welded Beam CalculationДокумент2 страницыWelded Beam CalculationVeenoyОценок пока нет

- Wall Thickness 2Документ18 страницWall Thickness 2Imam Zulfir RamandhaОценок пока нет

- Internal CoilДокумент2 страницыInternal CoilwhngomjОценок пока нет

- Pressure Vessel THCK CalcДокумент8 страницPressure Vessel THCK Calcmkchy12100% (1)

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Документ8 страницPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalОценок пока нет

- Design of Pressure Vessel NewДокумент511 страницDesign of Pressure Vessel NewneelОценок пока нет

- Design Calculations For Pressure VesselsДокумент30 страницDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- Asme - Shell External Pressure REV AДокумент1 страницаAsme - Shell External Pressure REV APohn Myint HanОценок пока нет

- Calculo de Recipientes A PresionДокумент2 страницыCalculo de Recipientes A PresionCesar Augusto Castellar OrtegaОценок пока нет

- Pipe Thickness Calculations - : ClassДокумент1 страницаPipe Thickness Calculations - : ClassOluwachidiОценок пока нет

- Design Calculations For Pressure VesselsДокумент24 страницыDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Corrosion Coupon SystemДокумент1 страницаCorrosion Coupon SystemMarcoAlbaОценок пока нет

- Welcome To Pipe Fitting IndiaДокумент2 страницыWelcome To Pipe Fitting IndiaMarcoAlbaОценок пока нет

- Quality of Care of Reproductive Health in China TodayДокумент2 страницыQuality of Care of Reproductive Health in China TodayMarcoAlbaОценок пока нет

- VISTAR Sour Service Oil ProductionДокумент1 страницаVISTAR Sour Service Oil ProductionMarcoAlbaОценок пока нет

- Hydrolink General Product CatalogueДокумент17 страницHydrolink General Product CatalogueMarcoAlbaОценок пока нет

- Rosemount 3051 Revision 5 Configuration Data SheetДокумент2 страницыRosemount 3051 Revision 5 Configuration Data SheetMarcoAlbaОценок пока нет

- ACS Montz BrochureДокумент11 страницACS Montz BrochureMarcoAlbaОценок пока нет