Академический Документы

Профессиональный Документы

Культура Документы

Id 800026 Ultramar Inc Engr Eval Ans 465213-216

Загружено:

api-242947664Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Id 800026 Ultramar Inc Engr Eval Ans 465213-216

Загружено:

api-242947664Авторское право:

Доступные форматы

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Johnny Pan Yee

PAGE 1 DATE October 3, 2012 CHECKED BY

CHANGE OF CONDITION (Permit to Operate) EVALUATION

COMPANY NAME, LOCATION ADDRESS: Ultramar Inc, SCAQMD ID # 800026 2402 E. Anaheim Street Wilmington CA 90744

EQUIPMENT DESCRIPTION: Additions to the equipment description are underlined. Modified conditions are underlined. Deletions to the equipment description and conditions are noted in strikeouts. Section D of Ultramars Facility Permit, ID# 800026

Equipment ID No. Connected To Source Type/ Monitoring Unit Emissions And Requirements Conditions

Process 14 : STORAGE TANKS System 2: EXTERNAL FLOATING ROOF TANKS STORAGE TANK, EXTERNAL FLOATING ROOF, 94-TK-9001, CRUDE OIL, WELDED SHELL, 300,000 BBL; DIAMETER: 221 FT, HEIGHT: 48 FEET WITH A/N: 271656 465213 FLOATING ROOF, PONTOON PRIMARY SEAL, WIPER TYPE, TUBE TYPE, MECHANICAL SHOE SECONDARY SEAL, RIM MOUNTED, WIPER TYPE STORAGE TANK, EXTERNAL FLOATING ROOF, 94-TK-9002, WELDED SHELL, 300,000 BBL; DIAMETER: 221 FT, HEIGHT: 48 FEET WITH A/N: 262831 465214 FLOATING ROOF, PONTOON PRIMARY SEAL, MECHANICAL SHOE, FLEXA-SEAL SECONDARY SEAL, RIM MOUNTED, WIPER TYPE, (B467) (B468) (B464) (B465) D255 HAP: (10) [40CFR 63 SUBPART CC, #2,#3A, 5-252001 6-23-2003]

P13.1 S13.5 C1.2, H23.7

(B466) D256 HAP: (10) [40CFR 63 SUBPART CC, #2,#3A, 6525-2001 6-23-2003] B22.7, C1.2, H23.7

(B469)

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 2 DATE October 3, 2012 CHECKED BY

Equipment

ID No.

Connected To

Source Type/ Monitoring Unit

Emissions And Requirements

Conditions

Process 14 : STORAGE TANKS FLEX-A-SEAL STORAGE TANK, EXTERNAL FLOATING ROOF, 94-TK-9007, CRUDE OIL, WELDED SHELL, 250,000 BBL; DIAMETER: 201 FT 6 IN, HEIGHT: 48 FEET WITH A/N: 483995 465215 FLOATING ROOF, PONTOON PRIMARY SEAL, LIQUID MOUNTED SECONDARY SEAL, RIM MOUNTED, WIPER TYPE GUIDEPOLE, GASKETED COVER, WITH FLOAT, SLEEVE, WIPER, SLOTTED STORAGE TANK, EXTERNAL FLOATING ROOF, 94-TK-9009, CRUDE OIL, WELDED SHELL, 250,000 BBL; DIAMETER: 201 FT 6 IN, HEIGHT: 48 FEET WITH A/N: 229846 465216 FLOATING ROOF, PONTOON PRIMARY SEAL, CATEGORY A, MECHANICAL SHOE SECONDARY SEAL, CATEGORY A, RIM MOUNTED, WIPER TYPE (B488) (B489) (B490) (B482) (B483) (B484) (B1614) D261 HAP: (10) [40CFR 63 SUBPART CC, #2,#3A5-252001 6-23-2003]

P13.1 B22.9, C1.40, H23.7

D263

HAP: (10) [40CFR 63 SUBPART CC, #2,#3A, 5-252001 6-23-2003]

C1.21, H23.7

CONDITIONS: The following permit conditions shall apply to these storage tanks in order to comply with all applicable District, State, and Federal standards. Additions and deletions to the conditions are noted in underlines and strikeouts, respectively. PROCESS CONDITIONS P13.1 All devices under this process are subject to the applicable requirements of the following rules or regulations: Contaminant Benzene Rule 40CFR61, SUBPART Rule/Subpart FF

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 3 DATE October 3, 2012 CHECKED BY

[Processes tied to this condition: P1, P2, P3, P4, P5, P7, P8, P9, P10, P11, P12, P14] [40CFR 61 Subpart FF, 12-04-2003] SYSTEM CONDITIONS S13.5 All devices under this system are subject to the applicable requirements of the following rules or regulations: Contaminant VOC VOC VOC Rule District Rule District Rule District Rule Rule/Subpart 463 1149 1178

[Systems tied to this condition: P14-S1, 2, 7] [RULE 1149, 07-14-1995; RULE 1149, 5-2-2008; RULE 1178, 4-7-2006; RULE 463, 5-6-2005] DEVICE CONDITIONS B. Material/Fuel Type Limits B22.7 The operator shall not use this equipment with materials having a(n) true vapor pressure of 11 psia or greater under actual operating conditions.

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 1303(b)(2)-Offset, 12-6-2002] [Devices subject to this condition: D252, D256, D271, D272, D273]

B22.9

The operator shall not use this equipment with materials having a(n) true vapor pressure of 7.3 psia or greater under actual operating conditions. To verify compliance with this condition, the operator shall sample the materials stored once per month to determine the true vapor pressure. The true vapor pressure shall be determined using ASTM Method D-323 for Reid vapor pressure or other equivalent District-approved method and converted to true vapor pressure using applicable nomographs or equations in EPA AP-42 or District and EPA approved nomographs.

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 1303(b)(2)-Offset, 12-6-2002] [Devices subject to this condition: D261]

C. Throughput or Operating Parameter Limits

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 4 DATE October 3, 2012 CHECKED BY

C1.2

The operator shall limit the number of turnovers to no more than 42 in any one year.

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 1303(b)(2)-Offset, 12-6-2002] [Devices subject to this condition: D255, D256]

C1.21

The operator shall limit the number of turnovers to no more than 475 in any one year.

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 1303(b)(2)-Offset, 12-6-2002] [Devices subject to this condition: D263]

C1.40

The operator shall limit the throughput to no more than 620,000 barrel(s) in any one calendar month. The operator shall comply with the following throughput measurement practices. The operator shall calculate the throughput, in barrels, by the following equation: 0. 14 x D x D x L, where D is the diameter of the tank in feet based on the tank strapping chart and L is the total vertical one-way roof travel in feet per month. The operator shall install and maintain an automatic tank level gauge (ATLG) and recorder to continuously record the vertical movement of the roof. For the purpose of this condition, continuous recording is defined as once per hour. The operator shall calculate the total one-way roof movement, in feet, on a daily and monthly basis. The ATLG installed shall be verified once per quarter by comparing against a manual tank level measurement. If the ATLG differs from the manual tank level measurement by more than 1.0 inch or 0. 8%, whichever is greater, the ATLG shall be repaired and put back into service within 10 days. While the ATLG is being repaired, the throughput shall be determined by the hourly tank level data averaged from the previous 30 days prior to the discovery of the discrepancy. In the event of a failure or routine maintenance of the ATLG, the ATLG shall be repaired (if necessary) and put back into service within 10 days of the time that the ATLG failed or was removed from service for maintenance. While the ATLG is being repaired or maintained, the throughput shall be determined by the hourly tank level data averaged from the previous 30 days prior to time that the ATLG went out of service. [RULE 1303(b)(2)-Offset, 5-10-1996; RULE 1303(b)(2)-Offset, 12-6-2002]

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 5 DATE October 3, 2012 CHECKED BY

[Devices subject to this condition: D261]

D. D90.10

Monitoring/Testing Requirements The operator shall periodically monitor the vapor pressure of the material stored in this storage tank according to the following specifications: The operator shall determine the true vapor pressure by one of the following methods: 1) record the tank contents and temperature once per month and use the organic liquid storage tank figure 7.1 series in AP-42; 2) sample and test the material stored, 3) derive the vapor pressure using engineering calculations, or 4) maintain on file a copy of the Material Safety Data Sheet (MSDS) of the material stored. Records of materials stored and vapor pressure of the material stored, and their MSDS if applicable, shall be retained for a period of five years and made available to the Executive Officer upon request. [RULE 1303(b)(2)-Offset, 5-10-1996; RULE 1303(b)(2)-Offset, 12-6-2002] [Devices subject to this condition: D217, D218, D221, D252, D256, D259, D260, D262, D264, D272, D273, D274, D307, D309]

H. Applicable Rules H23.7 This equipment is subject to the applicable requirements of the following rules or regulations: Contaminant VOC Rule 40CFR60, SUBPART Rule/Subpart K

[Devices tied to this condition: D255, D256, D257, D258, D259, D260, D261, D262, D263, D264, D265, D266] [40CFR 60 Subpart K, 05-05-1989]

COMPLIANCE WITH PERMIT CONDITIONS - RECORDS: Device [D255] - Storage Tank 94-TK-9001 Conditions S13.5: The Rule 463 and Rule 1178 tank inspection report dated 5-2-12 is included in Attachment 2. No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 1.50 to 4.97 psia) are included in Attachment 1.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 6 DATE October 3, 2012 CHECKED BY

Condition C1.2:

The throughput limit is 42 turnovers (12,600,000 bbl) in any one calendar year. Ultramar submitted throughput records showing 27.32 turnovers (8,196,368 bbl) from July 2011 to June 2012. Throughput records are included in Attachment 1.

Condition H23.7: The tank inspection and reporting requirements for 40CFR Part 60 Subpart K and 40CFR Part 63 Subpart CC are met by the Rule 463 and Rule 1178 tank inspection report dated 52-12 (included in Attachment 2). No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 1.50 to 4.97 psia) are included in Attachment 1. Device [D256] - Storage Tank 94-TK-9002 Conditions S13.5: The Rule 463 and Rule 1178 tank inspection report dated 6-11-2012 is included in Attachment 2. No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 1.68 to 4.49 psia) are included in Attachment 1. Condition B22.7: The true vapor pressure (TVP) limit is 11 psia. Ultramar submitted monthly TVP records showing a maximum TVP of 4.49 psia for July 2011 through June 2012. TVP records are included in Attachment 1. Condition C1.2: The throughput limit is 42 turnovers (12,600,000 bbl) in any one calendar year. Ultramar submitted throughput records showing 27.78 turnovers (8,332,770 bbl) from July 2011 to June 2012. Throughput records are included in Attachment 1.

Condition H23.7: The tank inspection and reporting requirements for 40CFR Part 60 Subpart K and 40CFR Part 63 Subpart CC are met by the Rule 463 and Rule 1178 tank inspection report dated 611-2012 (included in Attachment 2). No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 1.68 to 4.49 psia) are included in Attachment 1. Device [D261] - Storage Tank 94-TK-9007 Conditions S13.5: The Rule 463 and Rule 1178 tank inspection report dated 5-1-12 is included in Attachment 2. No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 1.13 to 5.33 psia) are included in Attachment 1. Condition B22.9: The true vapor pressure (TVP) limit is 7.3 psia. Ultramar submitted monthly TVP records showing a maximum TVP of 5.33 psia for July 2011 through June 2012. TVP records are included in Attachment 1. Condition C1.40: The throughput limit is 620,000 bbl in any one calendar month. Ultramar submitted throughput records showing the maximum throughput was 552,610 bbl/month (May 2012). Throughput records are included in Attachment 1. The automatic level gauge (ATLG) must be verified once per quarter against a manual tank level measurement. Ultramar submitted monthly manual tank level measurements. The

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 7 DATE October 3, 2012 CHECKED BY

maximum error was 1/2, which is less than the maximum error of 1 allowed. The manual tank level measurements are included in Attachment 4. Condition H23.7: The tank inspection and reporting requirements for 40CFR Part 60 Subpart K and 40CFR Part 63 Subpart CC are met by the Rule 463 and Rule 1178 tank inspection report dated 5/5/08 (included in Attachment 2). No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 1.13 to 4.91 psia) are included in Attachment 1. Device [D263] - Storage Tank 94-TK-9009 Conditions S13.5: The Rule 463 and Rule 1178 tank inspection report dated 5-8-2012 is included in Attachment 2. No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 0.85 to 6.24 psia) are included in Attachment 1. Condition C1.2: The throughput limit is 475 turnovers (118,750,000 bbl) in any one calendar year. Ultramar submitted throughput records showing 16.82 turnovers (4,205,544 bbl) from July 2011 to June 2012. Throughput records are included in Attachment 1.

Condition H23.7: The tank inspection and reporting requirements for 40CFR Part 60 Subpart K and 40CFR Part 63 Subpart CC are met by the Rule 463 and Rule 1178 tank inspection report dated 58-2012 (included in Attachment 2). No compliance issues are noted. Monthly records of the commodity stored in this tank (crude oil) and the true vapor pressure (TVP = 0.85 to 6.24 psia) are included in Attachment 1.

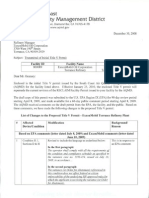

COMPLIANCE RECORD REVIEW: A check of the AQMD Compliance Database shows that the facility has received three Notices to Comply and 21 Notices of Violation since January 1, 2010. None of the NCs or NOVs apply to the storage tanks submitted for a change of condition. BACKGROUND: Ultramar, Inc. is a refinery in the city of Wilmington. The facility is a NOx and SOx RECLAIM facility. These four applications apply to external floating roof storage tanks located at the refinery. Table 1 lists the four change of condition applications received from Ultramar to change the tank classification from the Group 2 category to the Group 1 category under 40CFR 63 Subpart CC for four existing external floating roof storage tanks containing crude oil: 94-TK-9001, 94-TK-9002, 94-TK-9007, 94-TK-9009. Table 1 AQMD Applications Submitted A/N

Date Submitted

Equipment

Device ID

Requested Action

Previous A/N Permit # Status

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee Requested Action

PAGE 8 DATE October 3, 2012 CHECKED BY

A/N

Date Submitted

February 6, 2007

Equipment

Device ID

D255

Previous A/N Permit # Status

271656 D89016 Active 262831 D72453 Active 483995 G1914 Active 229846 D35008 Active n/a

465213

MASTER APPLICATION

Storage Tank, 94-TK-9001 with External Floating Roof

Change from Group 2 to Group 1 category under 40CFR 63 Subpart CC Change from Group 2 to Group 1 category under 40CFR 63 Subpart CC Change from Group 2 to Group 1 category under 40CFR 63 Subpart CC Change from Group 2 to Group 1 category under 40CFR 63 Subpart CC

RECLAIM Facility Permit Amendment

465214

February 6, 2007

Storage Tank, 94-TK-9002 with External Floating Roof

D256

465215

February 6, 2007

Storage Tank, 94-TK-9007 with External Floating Roof

D261

465216

February 6, 2007 January 22, 2009

Storage Tank, 94-TK-9009 with External Floating Roof RECLAIM Facility Permit Amendment

D263

495049

n/a

FEE EVALUTION: The fees paid for the applications are as follows: Table 2 Application Fees Paid A/N

465213 465214 465215 465216 495049

Equipment

Storage Tank, 94-TK-9001 with External Floating Roof Storage Tank, 94-TK-9002 with External Floating Roof Storage Tank, 94-TK-9007 with External Floating Roof Storage Tank, 94-TK-9009 with External Floating Roof RECLAIM Facility Permit Amendment

BCAT 231904 231904 231904 231904 555010

Type 66 66 66 66 85

Status 21 21 21 21 21

Fee Schedule

C C C C n/a

Fees Required, $ 1,453.64 726.82 1,453.64 726.82 843.80 $5,204.72

Fees Paid, $ 1,453.64 726.82 1,453.64 726.82 843.80 $5,204.72

Total

PERMIT CHANGES REQUESTED: Ultramar submitted application 465213 listed in Table 1 to: Change crude oil storage tank 94-TK-9001 from Group 2 to Group 1 category under 40CFR 63 Subpart CC. As a matter of corporate policy, Ultramar wishes to permit all their crude oil storage tanks as Group 1 to simplify their permit compliance requirements. In addition, the quantity of HAPs emitted

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 9 DATE October 3, 2012 CHECKED BY

from the tanks is directly related to the composition of the constituents in the crude oil and crude vapor. Ultramar has noted that a wider range of crude oils are now available for refining. To provide flexibility in the variety of crude oils stored, Ultramar has chosen to reclassify the tank to a Group 1 designation. Remove the reference to Tube-type primary seal. This is apparently a typographical error in the permit. The primary seal was changed from tube-type to wiper-type in 1992 (see A/N 271656), but both types were listed on the equipment description. The equipment description should only list a wiper-type primary seal.

There are no physical changes in the equipment, nor any change in the method of operation. Ultramar submitted application 465214 listed in Table 1 to: Change crude oil storage tank 94-TK-9002 from Group 2 to Group 1 category under 40CFR 63 Subpart CC. As a matter of corporate policy, Ultramar wishes to permit all their crude oil storage tanks as Group 1 to simplify their permit compliance requirements. In addition, the quantity of HAPs emitted from the tanks is directly related to the composition of the constituents in the crude oil and crude vapor. Ultramar has noted that a wider range of crude oils are now available for refining. To provide flexibility in the variety of crude oils stored, Ultramar has chosen to reclassify the tank to a Group 1 designation. Change the primary and secondary seal description from Flex-a-seal to Wiper Type. Flex-a-seal is a specific brand name for a wiper type seal from one manufacturer. Wiper Type is the generic description for this type of seal. Description change only; not an equipment modification.

There are no physical changes in the equipment, nor any change in the method of operation. Ultramar submitted application 465215 listed in Table 1 to: Change crude oil storage tank 94-TK-9007 from Group 2 to Group 1 category under 40CFR 63 Subpart CC. As a matter of corporate policy, Ultramar wishes to permit all their crude oil storage tanks as Group 1 to simplify their permit compliance requirements. In addition, the quantity of HAPs emitted from the tanks is directly related to the composition of the constituents in the crude oil and crude vapor. Ultramar has noted that a wider range of crude oils are now available for refining. To provide flexibility in the variety of crude oils stored, Ultramar has chosen to reclassify the tank to a Group 1 designation.

There are no physical changes in the equipment, nor any change in the method of operation. Ultramar submitted application 465216 listed in Table 1 to: Change crude oil storage tank 94-TK-9009 from Group 2 to Group 1 category under 40CFR 63 Subpart CC. As a matter of corporate policy, Ultramar wishes to permit all their crude oil storage tanks as Group 1 to simplify their permit compliance requirements. In addition, the quantity of HAPs emitted from the tanks is directly related to the composition of the constituents in the crude oil and crude vapor. Ultramar has noted that a wider range of crude oils are now available for refining. To provide flexibility in the variety of crude oils stored, Ultramar has chosen to reclassify the tank to a Group 1

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 10 DATE October 3, 2012 CHECKED BY

designation. There are no physical changes in the equipment, nor any change in the method of operation. Table 3 Storage Tank Specifications

External Floating Roof Tank 94-TK-9001 (D255) A/N 465213 Tank Dimensions Diameter, feet Volume, gallons (barrels) Throughput, barrels per year Turnovers Paint Characteristics Internal Shell Condition Shell Color/Shade Shell Condition Tank Construction and RimSeal System Construction: Primary Seal: Secondary Seal: Liquid Contents Mixture/Component Roof Characteristics Type Deck Fittings/Status 221.0 12,600,000 (300,000) 12,600,000 42 Light Rust White/White Good External Floating Roof Tank 94-TK-9002 (D256) A/N 465214 221.0 12,600,000 (300,000) 12,600,000 42 Light Rust White/White Good

Welded Mechanical Shoe Wiper Type, Rim-mounted Crude Oil

Welded Mechanical Shoe Wiper Type, Rim-Mounted Crude Oil, max vapor pressure: 11 psia Pontoon

1-Access Hatch (24-in Dia.)/Bolted Cover, Gasketed 1-Gauge-Hatch/Sample Well (8-in Dia.)/Weighted Mech. Actuation, Gasketed 64-Roof Leg (3-in Dia.)/Adjustable, Pontoon Area, Sock 105-Roof Leg (3-in Dia.)/Adjustable, Center Area, Sock 1-Unslotted Guidepole Well/Gasketed Sliding Cover with Wiper 2-Vacuum Breaker (10 in Dia.)/ Weighted Mech. Actuation, Gasketed

Pontoon

1-Access Hatch (24-in Dia.)/Bolted Cover, Gasketed 1-Gauge-Hatch/Sample Well (8-in Dia.)/Weighted Mech. Actuation, Gasketed 64-Roof Leg (3-in Dia.)/Adjustable, Pontoon Area, Sock 105-Roof Leg (3-in Dia.)/Adjustable, Center Area, Sock 1-Unslotted Guidepole Well/Gasketed Sliding Cover 2-Vacuum Breaker (10 in Dia.)/ Weighted Mech. Actuation, Gasketed

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 11 DATE October 3, 2012 CHECKED BY

Table 3 Storage Tank Specifications

External Floating Roof Tank 94-TK-9007 (D261) A/N 465215 Tank Dimensions Diameter, feet Volume, gallons (barrels) Throughput, barrels per year Turnovers Paint Characteristics Internal Shell Condition Shell Color/Shade Shell Condition Tank Construction and RimSeal System Construction: Primary Seal: Secondary Seal: Liquid Contents Mixture/Component Roof Characteristics Type Deck Fittings/Status 201.5 10,500,000 (250,000) 7,440,000 29.76 Light Rust White/White Good External Floating Roof Tank 94-TK-9009 (D263) A/N 465216 201.5 10,500,000 (250,000) 118,750,000 475 Light Rust White/White Good

Welded Liquid Mounted Rim Mounted, Wiper Type Crude Oil, max vapor pressure: 7.3 psia Pontoon

1-Access Hatch (24-in Dia.)/Bolted Cover, Gasketed 1-Gauge-Hatch/Sample Well (8-in Dia.)/Weighted Mech. Actuation, Gasketed 30-Roof Leg (3-in Dia.)/Adjustable, Pontoon Area, Sock 105-Roof Leg (3-in Dia.)/Adjustable, Center Area, Sock 1-Slotted Guidepole /Gasketed Cover, Float, Sleeve, Wiper 2-Vacuum Breaker (10 in Dia.)/ Weighted Mech. Actuation, Gasketed

Welded Mechanical Shoe Rim Mounted, Wiper Type Crude Oil

Pontoon

1-Access Hatch (24-in Dia.)/Bolted Cover, Gasketed 1-Gauge-Hatch/Sample Well (8-in Dia.)/Weighted Mech. Actuation, Gasketed 30-Roof Leg (3-in Dia.)/Adjustable, Pontoon Area, Sock 105-Roof Leg (3-in Dia.)/Adjustable, Center Area, Sock 1-Unslotted Guidepole Well/Gasketed Sliding Cover 2-Vacuum Breaker (10 in Dia.)/ Weighted Mech. Actuation, Gasketed

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 12 DATE October 3, 2012 CHECKED BY

EMISSIONS: There are no physical changes in the equipment, nor any change in the method of operation. No change in emissions is expected. RULES EVALUATION: PART 1 Rule 212 SCAQMD REGULATIONS November 14, 1997

Standards for Approving Permits

The proposed change of condition meets all criteria in Rule 212 for permit approval. The change of conditions is expected to allow operation of this storage tank without emitting air contaminants in violation of Division 26 of the State Health and Safety Code or in violation of AQMDs rules and regulations. The change of conditions for this storage tank does not constitute a significant project because (1) the modified permit unit are not located within 1000 feet of a school; (2) the emissions increase does not exceed the daily maximum specified in subdivision (g) of this rule (30 lbs/day); and (3) the modified permit unit does not have an increased cancer risk greater than, or equal to, one in a million (1x 10-6) during a lifetime of 70 years or pose a risk of nuisance.

Rule 402

Nuisance Nuisance complaints are not expected under normal operating conditions.

May 7, 1976

Rule 463

Organic Liquid Storage

May 6, 2005

This rule applies to any above-ground tank with capacity 19,815 gallons or greater for storing organic liquids. 463(c) Tank Roof Requirements. Tanks 94-TK-9001 & 94-TK-9002 are 300,000 bbl external floating roof tanks storing crude oil with a true vapor pressure greater than 0.5 psia. Tanks 94-TK-9007 & 94-TK-9009 are 250,000 bbl external floating roof tanks storing crude oil with a true vapor pressure greater than 0.5 psia. All four tanks are subject to the vapor controls requirements of Rule 463(c)(1) . External Floating Roof. All four external floating roof tanks are required to be equipped with the vapor control devices specified Rule 463(c)(1). These tanks are equipped with a pontoon type cover that rests on the surface of the organic liquid stored and are equipped with both a primary and a secondary seal between the tank shell and roof edge. Compliance is expected with proper inspection and maintenance practices. Other Performance Requirements.

463(c)(1)

463(d)

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 13 DATE October 3, 2012 CHECKED BY

Rule 463 463(d)(1) 463(d)(2)

Organic Liquid Storage

May 6, 2005

The tanks are greater than 19,815 gallons and do not store gasoline. Therefore, this paragraph does not apply. The external floating roof shall float on the organic liquid at all times (i.e., free of the roof leg supports) except when the tanks are being completely emptied for cleaning, or repair. These external floating roof tanks do not store gasoline. Therefore, this paragraph does not apply. These tanks will not store organic liquids having a true vapor pressure of 11 psia (569 mm Hg) or greater under actual storage conditions. These tanks have stored crude oil for the past 10 years and records show TVP < 11 psia. Replacement seals on the tank will only be chosen from the current list of seals approved by District. The crude oil stored in this tank should continue to be in compliance with the vapor pressure limit. Compliance with Rule 463 is expected with proper recordkeeping and inspections.

463(d)(3) 463(d)(4)

463(d)(5) 463(d)(6)

Rule 1149

Storage Tank Cleaning and Degassing

July 14, 1995

The tanks will continue to be subject to the tank cleaning and degassing requirements of this rule. Compliance is expected.

Rule 1178 1178(b)

Further Reduction of VOC Emissions from Storage Tanks at Petroleum Facilities

April 7, 2006

Applicability. This rule applies to all aboveground storage tanks with capacity greater than 19,818 gallons and used to store organic liquids with true vapor pressure greater than 0.1 psi and located at any petroleum facility emitting more than 20 tons per year of VOC in any emission inventory year starting with emission inventory year 2000. These four tanks store crude oil with a TVP greater than 0.1 psia and are therefore subject to Rule 1178. External Floating Roof Tanks. For tanks containing organic liquids with a true vapor pressure less than 3 psia for the emission inventory year 2000, the tank shall be equipped with the fittings specified in this paragraph. These four tanks store crude oil with a TVP which may exceed 3 psia. Since the tank stores liquids greater than 3 psia (crude oil), the tank is not subject to the fittings requirements of Rule 1178(d)(1).

1178(d)(1)

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 14 DATE October 3, 2012 CHECKED BY

Rule 1178

Further Reduction of VOC Emissions from Storage Tanks at Petroleum Facilities

April 7, 2006

1178(d)(2)

Domed External Floating Roof Tanks. For tanks containing organic liquids greater than 3 psia for the emission inventory year 2000, a dome roof is required to be installed. Rule 1178(j)(7) provides an exemption from the doming requirements of paragraph (d)(2)(A) and (d)(2)(B) if the tank is permitted to contain more than 97% by volume crude oil and complies with all the remaining applicable requirements of this rule.

Specifications: Contains more than 97%vol crude oil? Maximum vapor pressure: psia

1178(d)(2)(D)

94-TK-9001 [D255]

94-TK-9002 [D256]

94-TK-9007 [D261]

94-TK-2009 [D263]

Yes 11.0

Yes 11.0

Yes 7.3

Yes 11.0

The external floating roof tank has been equipped with all roof openings in accordance with the specifications listed in subparagraph (d)(1)(A):

94-TK-9001 [D255] 94-TK-9002 [D256] 94-TK-9007 [D261] 94-TK-2009 [D263]

Specifications: (i) Equip each access hatch and gauge float well with a cover that is gasketed and bolted. The cover shall be closed at all times, with no visible gaps, except when the hatch or well must be opened for access. (ii) Equip each gauge hatch/sample well with a cover that is gasketed. The cover shall be closed at all times, with no visible gaps, except when the hatch or well must be opened for access. (iii) Gasket or cover each adjustable roof leg with a VOC impervious sock at all times when the roof is floating. (iv) Gasket each rim vent. Rim vents shall be closed at all times, with no visible gaps, when the roof is floating; and shall be set to open only when the roof is being floated off the roof leg supports or when the pressure beneath the rim seal exceeds the manufacturer's recommended setting

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

N/A; No Rim Vent

N/A; No Rim Vent

N/A; No Rim Vent

N/A; No Rim Vent

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 15 DATE October 3, 2012 CHECKED BY

Rule 1178

Further Reduction of VOC Emissions from Storage Tanks at Petroleum Facilities

94-TK-9001 [D255] 94-TK-9002 [D256] 94-TK-9007 [D261]

April 7, 2006

94-TK-2009 [D263]

Specifications: (v) Gasket each vacuum breaker. Vacuum breakers shall be closed at all times, with no visible gaps, when the roof is floating; and shall be set to open only when the roof is being floated off or is being landed on the roof leg supports. (vi) Equip each open floating roof drain with a slotted membrane fabric cover or other device with an equivalent control efficiency that covers at least 90 percent of the area of the opening. (vii) Equip each unslotted guidepole well with a gasketed sliding cover and a flexible fabric sleeve or wiper (viii) Equip each unslotted guidepole with a gasketed cover at the end of the pole. The cover shall be closed at all times, with no visible gaps, except when gauging or sampling. (ix) Equip each slotted guidepole with a gasketed cover, a pole wiper and a pole sleeve. The pole sleeve shall be extended into the stored liquid (x) Equip each slotted guidepole having a pole float with a gasketed cover, a pole wiper, and a pole float wiper. The wiper or seal of the pole float shall be at or above the height of the pole wiper. (xi) Cover each slotted guidepole opening with a gasketed cover at all times, with no visible gaps, except when the cover must be opened for access.

Yes

Yes

Yes

Yes

N/A No roof drain

N/A No roof drain

N/A No roof drain

N/A No roof drain

Yes

Yes

N/A

Yes

Yes

Yes

N/A

Yes

N/A

N/A

Yes

N/A

N/A

N/A

Yes

N/A

N/A

N/A

Yes

N/A

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 16 DATE October 3, 2012 CHECKED BY

Rule 1178

Further Reduction of VOC Emissions from Storage Tanks at Petroleum Facilities

94-TK-9001 [D255] 94-TK-9002 [D256] 94-TK-9007 [D261]

April 7, 2006

94-TK-2009 [D263]

Specifications: (xii) Maintain the pole float in a condition such that it floats within the guidepole at all times except when it must be removed for sampling or when the tank is empty. (xiii) Except for vacuum breakers and rim vents, ensure that each opening in the external floating roof shall provide a projection below the liquid surface. (xiv) Except for vacuum breakers, rim vents, roof drains, and leg sleeves, equip all other openings in the roof with a gasketed cover or seal which is closed at all times, with no visible gaps, except when the cover or seal must be opened for access. Subparagraph (d)(1)(B) Specifications: (i) The primary seal shall be a mechanical shoe or liquid mounted. (ii) The secondary seal shall be rim mounted and shall not be attached to the primary seal.

N/A

N/A

Yes

N/A

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Mechanical Shoe

Yes

Mechanical Shoe

Yes

Liquid mounted

Yes

Mechanical Shoe

Yes

Yes

Yes

Yes

Compliance with Rule 1178 is expected.

REG XIII

New Source Review (NSR)

December 6, 2002 Application Deem Complete Year: 2007

These tanks were subject to New Source Review when they were constructed. These applications propose no increase in crude oil throughput or vapor pressure; therefore, no increase in emissions. 1303(a) Best Available Control Technology (BACT). No increase in emissions; therefore, no BACT requirements. The tanks are all already equipped with primary and secondary seals. The storage tanks have only stored crude oil for over 10 years now.

1303(b)

Modified source which results in a net emission increase. There is no increase in

emissions; therefore, no modeling, emission offset, sensitive zone, facility compliance, or major polluting facilities requirements apply.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 17 DATE October 3, 2012 CHECKED BY

Rule 1401

New Source Review of Toxic Air Contaminants

March 4, 2005

These applications propose no increase in crude oil throughput or vapor pressure; therefore, no increase in emissions and no increase in the MICR and HIA and HIC for both off-site worker and residential receptors. Federal NSR for toxics does not apply since this is not considered a reconstruction per 40CFR63, Subpart A, 63.2.

Regulation XX

RECLAIM

May 6, 2005

Ultramar has been designated as a RECLAIM facility. These crude oil storage tanks do not emit NOx or SOx; therefore, RECLAIM requirements do not apply to these applications.

Regulation XXX

Title V

March 16, 2001

Ultramar is a designated as a Title V facility. Ultramars Title V permit became effective on May 29, 2009. Therefore, the facility is now subject to the requirements of Regulation XXX. This application is considered a Minor Permit Revision as defined in Rule 3000 and subject to 45 day review by EPA. PART 2 STATE REGULATIONS

California Environmental Quality Act (CEQA) This proposed change of condition is not a significant project.

PART 3

FEDERAL REGULATIONS

40CFR Part 60 Subpart K

Standards of Performance for Volatile Organic Liquid Storage Vessels (Including Petroleum Liquid Storage Vessels) for Which Construction, Reconstruction, or Modification Commenced After June 11, 1973, and Prior to May 19, 1978

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 18 DATE October 3, 2012 CHECKED BY

40CFR Part 60 Subpart K

Standards of Performance for Volatile Organic Liquid Storage Vessels (Including Petroleum Liquid Storage Vessels) for Which Construction, Reconstruction, or Modification Commenced After June 11, 1973, and Prior to May 19, 1978 This tank is currently subject to 40 CFR 60 Subpart K. This tank currently complies with tank design/control requirements of Subpart K. 40CFR Part 60 Subpart Kb applies to storage vessels for which construction, reconstruction, or modification commenced after July 23, 1984. In order for a modification to occur under NSPS, there must be a pound per hour (lb/hr) increase in emissions to the atmosphere as a result of physical or operational changes. There is no increase in emissions; this tank is not subject to Subpart Kb. These applications for change of condition will subject the storage tanks to 40CFR Part 63 Subpart CC as Group 1 storage vessels. Per 63.640(n)(5), a Subpart CC Group 1 storage vessel that is also subject to the provisions of 40CFR Part 60 Subpart K is required to comply only with the provisions of Subpart CC.

40CFR Part 63 Subpart CC

National Emission Standards for Hazardous Air Pollutants from Petroleum Refineries

In accordance with 63.641 Definitions. of 40CFR Part 63 Subpart CC, a Group 1 storage vessel means a storage vessel at an existing source that has a design capacity > 46,758 gallons (1,113 barrels) and stored-liquid maximum true vapor pressure > 1.5 psia and stored-liquid annual average true vapor > 1.2 psia and annual average HAP liquid concentration > 4 percent by weight total organic HAP. A Group 2 storage vessel means a storage vessel that does not meet the definition of a Group 1 storage vessel. In Ultramars case, the Subpart CC storage vessel group designation is based on the stored-liquid annual average HAP liquid concentration. Crude oil storage tanks 94-TK9001, 94-TK-9002, 94-TK-9007, and 94-TK-9009 are currently tagged as Subpart CC Group 2 storage vessels because the crude oil stored is < 4 % by weight total organic HAP. Ultramar requested a change of condition to tag these four tanks as 40CFR Part 63 Subpart CC Group 1 storage vessels, based on their concern that the weight percent of total organic HAP may exceed the Group 2 limitation of 4%wt HAP maximum at some point in the future since there are a variety of crude oils now available for refining. Section J of the current facility permit specifies that the operator shall not reclassify a Group 2 emission point to a Group 1 emission point without first obtaining a valid permit from the AQMD. Since the average annual HAP liquid concentration can only be determined after the fact, and the control, inspection, recordkeeping and reporting requirements are more restrictive for Group 1 storage vessels than Group 2 storage vessels, imposing the Group1 storage vessel requirements is the more conservative designation for air quality purposes.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 19 DATE October 3, 2012 CHECKED BY

40CFR Part 63 Subpart CC

National Emission Standards for Hazardous Air Pollutants from Petroleum Refineries

These four tanks currently comply with the 40CFR Part 63 Subpart CC Group 1 storage vessel requirements for VOC emission control (mechanical shoe primary seal plus a rim mounted, double weld wiper secondary seal) and the inspection, recordkeeping and reporting requirements through compliance with District Rules 463, 1149 and 1178. Ultramar included these four tanks as 40CFR 63.464 Storage Vessels, Group 1 in their Periodic Monitoring and Exception Reports to the EPA since 2007. See Attachment 2. Continued compliance with the requirements of 40CFR Part 63 Subpart CC for Group 1 storage vessels is expected.

CONCLUSION: Based on the above evaluation, it recommended that the following be issued: A/N 465213

MASTER APPLICATION

Recommendation Issue Permits to Operate Revise Ultramar facility permit (ID 800026) to show the administrative changes to the tank seal descriptions and the change in conditions from 40CFR Part 63 Subpart CC Group 2 storage vessels to Group 1 storage vessels. Approve Revision Application

465214 465215 465216 495049

List of Attachments

1. Tank throughput and vapor pressure records, July 2011 to June 2012 2. MACT Semi-Annual Report for Period January 1 through June 30, 2012 Rule 463 & Rule 1178 Tank Inspection Report , May/June 2012

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 20 DATE October 3, 2012 CHECKED BY

Attachment 1. Tank throughput and vapor pressure records, July 2011 to June 2012

Tank Capacity Limit Monthly Throughput Month-Year Jul-11 Aug-11 Sep-11 Oct-11 Nov-11 Dec-11 Jan-12 Feb-12 Mar-12 Apr-12 May-12 Jun-12 Total

94-TK-9001 300,000 42

D255 bbl turnovers/year

94-TK-9002 300,000 42

D256 bbl turnovers/year

94-TK-9007 250,000 620,000

D261 bbl bbl/ month

94-TK-9009 250,000 475

D263 bbl turnovers/year

bbls 830,940 869,820 634,024 758,145 681,211 577,265 277,858 453,123 841,511 691,212 797,385 783,874 8,196,368

turnovers 2.77 2.90 2.11 2.53 2.27 1.92 0.93 1.51 2.81 2.30 2.66 2.61 27.32

bbls 900,873 745,914 740,236 789,358 687,126 691,122 294,676 353,172 762,957 822,007 784,732 760,597 8,332,770

turnovers 3.00 2.49 2.47 2.63 2.29 2.30 0.98 1.18 2.54 2.74 2.62 2.54 27.78

bbls 374,078 274,041 265,648 379,303 418,860 302,330 77,871 144,342 486,505 528,818 552,610 362,579 4,166,985

turnovers 1.50 1.10 1.06 1.52 1.68 1.21 0.31 0.58 1.95 2.12 2.21 1.45 16.67

bbls 269,409 425,709 348,033 262,432 291,901 481,499 173,773 138,691 425,104 402,835 425,465 560,693 4,205,544

turnovers 1.08 1.70 1.39 1.05 1.17 1.93 0.70 0.55 1.70 1.61 1.70 2.24 16.82

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 21 DATE October 3, 2012 CHECKED BY

Monthly Vapor Pressure and Contents, July 2011 to June 2012

Tank Number

Vapor Pressure Limit TVP<11 psia

Monthly Vapor Pressure, psia, and Contents July 2011 4.18 Crude Aug 2011 4.31 Crude 4.49 Crude 1.73 Crude 1.71 Crude

Sept 2011

Oct 2011 3.18 Crude 2.88 Crude 3.98 Crude 4.60 Crude

Nov 2011 2.74 Crude 3.28 Crude 3.97 Crude 4.55 Crude

Dec 2011 3.85 Crude 3.58 Crude 3.78 Crude 4.04 Crude

Jan 2012 2.20 Crude 2.14 Crude 4.91 Crude 4.41 Crude

Feb 2012 2.15 Crude 2.17 Crude 3.40 Crude 1.94 Crude

Mar 2012 4.97 Crude 3.08 Crude 3.25 Crude 6.24 Crude

Apr 2012 1.87 Crude 2.28 Crude 1.53 Crude 3.33 Crude

May 2012

June 2012

94-TK9001

3.04 Crude 3.68 Crude 2.70 Crude 2.28 Crude

2.47 Crude 1.68 Crude 5.33 Crude 4.43 Crude

1.50 Crude 1.79 Crude 4.91 Crude 4.43 Crude

94-TK9002

TVP<11 psia

3.70 Crude

94-TK9007

TVP<7.3 psia

1.13 Crude

94-TK9009

TVP<11 psia

0.85 Crude

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 22 APPL. NO. 465213 - 465216 PROCESSED BY: Jon Uhl/Connie Yee

PAGE 22 DATE October 3, 2012 CHECKED BY

Attachment 2. MACT Semi-Annual Report for Period January 1 through June 30, 2012 Rule 463 & Rule 1178 Tank Inspection Report, May/June 2012

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Transmix PermitДокумент3 страницыTransmix Permitapi-242947664Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- New and Current ResumeДокумент3 страницыNew and Current Resumeapi-242947664Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Denatured Ethanol Storage TankДокумент2 страницыDenatured Ethanol Storage Tankapi-242947664Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- HBD - Hearing Board Cases - 6-16-2004 - HB Case 5425-3 - Fac Id 107042 - Name Kinder Morgan Li-1Документ94 страницыHBD - Hearing Board Cases - 6-16-2004 - HB Case 5425-3 - Fac Id 107042 - Name Kinder Morgan Li-1api-242947664Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- HBD - Hearing Board Cases - 7-7-2004 - HB Case 5425-3 Kinder Morgan Tank Inventory-EditedДокумент10 страницHBD - Hearing Board Cases - 7-7-2004 - HB Case 5425-3 Kinder Morgan Tank Inventory-Editedapi-242947664Оценок пока нет

- HBD - Hearing Board Cases - 12-10-2004 - HB Case 5425-3 Kinder Morgan Final DispositionДокумент6 страницHBD - Hearing Board Cases - 12-10-2004 - HB Case 5425-3 Kinder Morgan Final Dispositionapi-242947664Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- HBD - Hearing Board Cases - 5-21-2004 - HB Case 5425-3 Kinder Morgan PetitionДокумент9 страницHBD - Hearing Board Cases - 5-21-2004 - HB Case 5425-3 Kinder Morgan Petitionapi-242947664Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Id 800183 Paramount Petroleum Corp - Engr Eval Ans 515155 515312Документ20 страницId 800183 Paramount Petroleum Corp - Engr Eval Ans 515155 515312api-242947664Оценок пока нет

- Id 800436 Tesoro Refining and Marketing Co - Engr Eval An 474150 EditedДокумент9 страницId 800436 Tesoro Refining and Marketing Co - Engr Eval An 474150 Editedapi-242947664Оценок пока нет

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan NoticeДокумент3 страницыHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Noticeapi-242947664Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Facility Plot 1Документ1 страницаHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Facility Plot 1api-242947664Оценок пока нет

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan NovДокумент1 страницаHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Novapi-242947664Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Aerial Photo 1Документ1 страницаHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Aerial Photo 1api-242947664Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Map 1Документ2 страницыHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Map 1api-242947664Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Id 131003 BP West Coast Products - Carson - Eng Eval An 462618-2Документ10 страницId 131003 BP West Coast Products - Carson - Eng Eval An 462618-2api-242947664Оценок пока нет

- Edgington Oil Id 800264 An 477953 Eng EvalДокумент7 страницEdgington Oil Id 800264 An 477953 Eng Evalapi-242947664Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Id 800264 Edgington Oil - Engr Eval An 471110 471112 AДокумент12 страницId 800264 Edgington Oil - Engr Eval An 471110 471112 Aapi-242947664Оценок пока нет

- Id 800026 Ultramar Inc - Engr Eval Ans 526586 526261Документ71 страницаId 800026 Ultramar Inc - Engr Eval Ans 526586 526261api-242947664Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Id 800183 Paramount Petroleum Corp - Engr Eval An 526347Документ14 страницId 800183 Paramount Petroleum Corp - Engr Eval An 526347api-242947664Оценок пока нет

- Id 800264 Edgington Oil Company - Epa Cover Letter An 471226-232Документ2 страницыId 800264 Edgington Oil Company - Epa Cover Letter An 471226-232api-242947664Оценок пока нет

- Id 800436 Tesoro Refining Marketing Co-La Refinery - Engr Eval An 470285 470286Документ15 страницId 800436 Tesoro Refining Marketing Co-La Refinery - Engr Eval An 470285 470286api-242947664Оценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Id 800026 Ultramar Inc Engr EvalДокумент14 страницId 800026 Ultramar Inc Engr Evalapi-242947664Оценок пока нет

- Reg Review of Eng Eval For Application No 475623 475624 FCC Bypass SCR - Waste Heat Boiler 2f-7Документ11 страницReg Review of Eng Eval For Application No 475623 475624 FCC Bypass SCR - Waste Heat Boiler 2f-7api-242947664Оценок пока нет

- Exxonmobil 800089 340343 040909 Public Notice EnglishДокумент2 страницыExxonmobil 800089 340343 040909 Public Notice Englishapi-242947664Оценок пока нет

- Exxonmobil Statement of BasisДокумент49 страницExxonmobil Statement of Basisapi-242947664Оценок пока нет

- Edgington Oil Id 800264 An 471225 Eng EvalДокумент14 страницEdgington Oil Id 800264 An 471225 Eng Evalapi-242947664Оценок пока нет

- Id 800264 Edgington Oil - Engr Eval An 471105 471107 471109Документ12 страницId 800264 Edgington Oil - Engr Eval An 471105 471107 471109api-242947664Оценок пока нет

- Edgington Public NoticeДокумент2 страницыEdgington Public Noticeapi-242947664Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Id Exxonmobil Oil Corp - Facility Letter - Final Initial Title VДокумент6 страницId Exxonmobil Oil Corp - Facility Letter - Final Initial Title Vapi-242947664Оценок пока нет

- Jurnal Kasus Etikolegal Dalam Praktik KebidananДокумент13 страницJurnal Kasus Etikolegal Dalam Praktik KebidananErni AnggieОценок пока нет

- Dingenen 2017Документ14 страницDingenen 2017pedro.coleffОценок пока нет

- Arma 2018 047Документ7 страницArma 2018 047Lígia BrumОценок пока нет

- Juri Ferrer - Ws - WeatherДокумент4 страницыJuri Ferrer - Ws - WeathersJIqsОценок пока нет

- Human Sociobiology: A Holistic Approach (Dan Freedman)Документ126 страницHuman Sociobiology: A Holistic Approach (Dan Freedman)Cynthia AndrewsОценок пока нет

- Cocktails For A CrowdДокумент117 страницCocktails For A CrowdΓιώργης Δημητρίου100% (2)

- Dialysis and ElectrodialysisДокумент32 страницыDialysis and ElectrodialysisJuan CarvajalОценок пока нет

- Scala: Service InstructionsДокумент16 страницScala: Service Instructionsmario_turbinadoОценок пока нет

- VEIKK A15PRO Instruction Manual 0714Документ20 страницVEIKK A15PRO Instruction Manual 0714Corny777 UwUОценок пока нет

- Lesson 5: Prejudice and StereotypesДокумент31 страницаLesson 5: Prejudice and StereotypesZeynep SulaimankulovaОценок пока нет

- BIS Ventilation Brochure enДокумент16 страницBIS Ventilation Brochure enBruno SantosОценок пока нет

- Tibia Bone Segmentation in X-Ray Images - A Comparative AnalysisДокумент8 страницTibia Bone Segmentation in X-Ray Images - A Comparative AnalysisSuzanaPetrovicОценок пока нет

- PQPДокумент60 страницPQPlee100% (4)

- Gardobond 24d Imu Sds Ver1Документ6 страницGardobond 24d Imu Sds Ver1stuart3962Оценок пока нет

- Effects of Various Liquid Organic Solvents On Solvent-Induced Crystallization of Amorphous Poly (Lactic Acid) FilmДокумент11 страницEffects of Various Liquid Organic Solvents On Solvent-Induced Crystallization of Amorphous Poly (Lactic Acid) FilmqueteimportaОценок пока нет

- Lipoma in Submandibular Region - A Case ReportДокумент4 страницыLipoma in Submandibular Region - A Case Reportmaxfac2010Оценок пока нет

- Liquid Fertilizer PresentationДокумент17 страницLiquid Fertilizer PresentationAnna RothОценок пока нет

- ST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCДокумент3 страницыST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCjodelle11Оценок пока нет

- Bars Performance AppraisalДокумент6 страницBars Performance AppraisalPhillip Miler0% (1)

- V. Aa. Gram A/S: DescriptionДокумент2 страницыV. Aa. Gram A/S: Descriptioncontango O&GОценок пока нет

- Reishi MushroomДокумент5 страницReishi Mushroomjunver100% (4)

- CS1 Epoxy Curing AgentsДокумент21 страницаCS1 Epoxy Curing AgentsAlptekin100% (1)

- Psicologia BuenisimoДокумент6 страницPsicologia BuenisimoSophieОценок пока нет

- Electric Vehicle in IndonesiaДокумент49 страницElectric Vehicle in IndonesiaGabriella Devina Tirta100% (1)

- Savage Inequalities Reading ReflectionДокумент2 страницыSavage Inequalities Reading Reflectionapi-367127133Оценок пока нет

- Vice President Quality Operations in Greater Chicago IL Resume Kevin FredrichДокумент2 страницыVice President Quality Operations in Greater Chicago IL Resume Kevin FredrichKevin Fredrich1Оценок пока нет

- Chapter 4 - Medical Aspects of Food SafetyДокумент17 страницChapter 4 - Medical Aspects of Food SafetyasushkОценок пока нет

- According To India International Coffee Festival in The TitledДокумент4 страницыAccording To India International Coffee Festival in The Titledsalman vavaОценок пока нет

- Neicchi 270 ManualДокумент33 страницыNeicchi 270 Manualmits2004Оценок пока нет

- NABARD Grade A 2020 Phase 2 ESI ARDДокумент6 страницNABARD Grade A 2020 Phase 2 ESI ARDrohit bhosadОценок пока нет