Академический Документы

Профессиональный Документы

Культура Документы

Flange Leakage

Загружено:

RUDHRA DHANASEKAR0 оценок0% нашли этот документ полезным (0 голосов)

82 просмотров3 страницыD

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документD

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

82 просмотров3 страницыFlange Leakage

Загружено:

RUDHRA DHANASEKARD

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

FLANGE LEAKAGE/STRESS CALCULATIONS

Flange Inside Diameter [B] (User to verify) ......(mm.)

102.362

Flange Thickness [t]..............................(mm.)

22.352

Flange Rating (Optional) ..............................

150.000

Bolt Circle Diameter .............................(mm.)

190.500

Number of Bolts .......................................

8.000

Bolt Diameter ....................................(mm.)

19.050

Bolt Initial Tightening Stress ............( KPa )

Uncompressed Gasket Thickness ....................(mm.)

4.500

Grade of Attached B16_5 ANSI Flange....................

1.100

Leak Pressure Ratio [m] ...............................

3.000

Effective Gasket Modulus ..................( KPa ) 3016456.000

Externally Applied Moment ..... (optional) ....( N.m. )

1144.000

Externally Applied Force ...... (optional) .......( N.)

3156.000

Pressure [P]...............................( KPa )

7.500

Disable Stress Calculations (Y/N) .....................

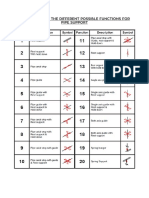

Flange Type (1-8, see ?-Help or Alt-P to plot) ........

1.000

Flange Outside Diameter [A].......................(mm.)

230.000

Design Temperature ................................ C

100.000

Small End Hub Thickness [g0]......................(mm.)

12.300

Large End Hub Thickness [g1]......................(mm.)

33.000

Hub Length [h]....................................(mm.)

52.324

Flange Allowable @Design Temperature ......( KPa ) 137895.141

Flange Allowable @Ambient Temperature .....( KPa ) 137895.141

Flange Modulus of Elasticity @Design ......( KPa ) 196000.000

Flange Modulus of Elasticity @Ambient .....( KPa ) 198400.000

Bolt Allowable @Design Temperature ......( KPa ) 158579.406

Bolt Allowable @Ambient Temperature .....( KPa ) 158579.406

Gasket Seating Stress [y] .................( KPa ) 68948.000

Flange Allowable Stress Multiplier ....................

1.000

Bolt Allowable Stress Multiplier (VIII Div 2 4-141) ...

1.000

Disable Leakage Calculations (Y/N) ....................

N

Disable ANSI B16.5 Checks (Y/N) .......................

N

Flange Face OD or Lapjt Cnt OD....................(mm.)

157.200

Flange Face ID or Lapjt Cnt ID....................(mm.)

102.362

Gasket Outer Diameter ............................(mm.)

149.230

Gasket Inner Diameter ............................(mm.)

127.000

Nubbin Width .....................................(mm.)

Facing Sketch .........................................

1.000

Facing Column .........................................

2.000

Flange Type: (Integral Weld Neck)

Effective gasket width parameters:

Effective gasket seating width, b......(mm.) 5.5575

Diameter of gasket load reaction, G....(mm.) 138.1150

SAFETY FACTOR SUMMARY for the different Flange Models

analyzed. (SAFETY FACTOR = Allowed/Actual)

SAFETY

FACTOR

Flexibility/Gasket Compression Model (Leakage).. 40.10

ANSI B16.5/Equivalent Pressure (Stress).........

0.73

ASME Model Operating (Stress)...................

3.74

ASME Model Seating (Stress).....................

0.88

FLANGE FLEXIBILITY MODEL --------------------------------BOLTED FLANGE CHARACTERISTICS:

Initial Tightening Stress in the Bolt (Not the seating

stress):

358262 KPa

Approximate Torque required to induce the above initial

stress:

199 N.m.

GASKET COMPRESSION:

COMPRESSION

(mm.)

After Initial Boltup (Ci)........... 0.2526887953

Loss-of due to Pressure (Cp)........ 0.0000194460

Loss-of due to Applied Moment (Cm).. 0.0057338094

Loss-of due to Applied Force (Cf)... 0.0005461788

Loss-of due to all loads (CL)....... 0.0062994342

Initial minus all Losses (Ci-CL).... 0.2463893443

For Leak-Proof Joint (Creq)......... 0.0000671318

Excess available (Ci-Creq) ......... 0.2526216507

LEAKAGE SAFETY FACTOR: (If less than one then joint

leakage is predicted.) (Allowed/Actual)

Pressure Only (Ci-Creq)/Cp ............. 12990.92

Force Only (Ci-Creq)/Cf ................ 462.53

Moment Only (Ci-Creq)/Cm ............... 44.06

Pressure+Force+Moment (Ci-Creq)/CL .....

40.10

EQUIVALENT PRESSURE MODEL ---------------------------Equivalent Pressure ( KPa ) ............

2429.58

ANSI B16.5 Flange Allowable Pressure Rating .

1767.82

STRESS SAFETY FACTOR: (If less than one then joint

failure is predicted.) (Allowed/Actual)

ANSI B16.5/Equivalent Pressure .................

0.73

ASME SECT VIII DIV 1 STRESS MODEL -----------------------ACCORDING TO A05 APP 2-14, THE FOLLOWING RIGIDITY

FACTORS SHOULD BE LESS THAN 1.0

ASME Rigidity Factor "J", Operating Case ....... 15.0006

ASME Rigidity Factor "J", Seating Case ......... 62.6304

CALCULATED STRESSES ( KPa

OPERATING ALLOW SEATING

--------- ----- ------- -----

ALLOW

Longitudinal Hub .. 11004 206843 46505 206843

Radial Flange ..... 36913 137895 156006 137895 *

Tangential Flange .

8637 137895 36503 137895

Maximum Average ... 23958 137895 101255 137895

Bolting ........... 23422 158579 106666 158579

"*" Indicates Failure for an item.

STRESS SAFETY FACTOR: (If less than one then joint

failure is predicted.) (Allowed/Actual)

OPERATING

SEATING

--------------Longitudinal Hub ....

18.80

4.45

Radial Flange .......

3.74

0.88

Tangential Flange ...

15.97

3.78

Maximum Average .....

5.76

1.36

Bolting .............

6.77

1.49

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Welcome To Presentation On: Pipe Support Systems & Piping FlexibilityДокумент67 страницWelcome To Presentation On: Pipe Support Systems & Piping Flexibilitysids8292% (24)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- HVAC Ducting - Principles and FundamentalsДокумент56 страницHVAC Ducting - Principles and FundamentalsRiddhi Patel100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 12 Marking Scheme: Worksheet (AS) : R I V RДокумент1 страница12 Marking Scheme: Worksheet (AS) : R I V RRuby ChongОценок пока нет

- ACI 336.2R-88 R02 Suggested Analysis and Design Procedures For Combined Footings and Mats - MyCivil - IrДокумент11 страницACI 336.2R-88 R02 Suggested Analysis and Design Procedures For Combined Footings and Mats - MyCivil - IrRenjith S AnandОценок пока нет

- Anti Termite TreatmentДокумент99 страницAnti Termite TreatmentPja ShanthaОценок пока нет

- Hvac Formulas PDFДокумент25 страницHvac Formulas PDFSaraswatapalit0% (1)

- Parents' Handbook of Careers After SchoolДокумент32 страницыParents' Handbook of Careers After Schoolraj50% (4)

- AutoPipe Vessel PresentationДокумент32 страницыAutoPipe Vessel PresentationRUDHRA DHANASEKARОценок пока нет

- Modern Construction TechniquesДокумент19 страницModern Construction TechniquesLizle Len BanciloОценок пока нет

- Stiffness Coefficients For Nozzles in API 650 Tanks PDFДокумент8 страницStiffness Coefficients For Nozzles in API 650 Tanks PDFvijay10484100% (1)

- Fatigue Damage Models For Laminated Composite StructuresДокумент100 страницFatigue Damage Models For Laminated Composite StructuresBaşar ZamanОценок пока нет

- 1-Piping Manual-Pdms12Документ413 страниц1-Piping Manual-Pdms12MOHSEN2005IBОценок пока нет

- Man Cage Check SheetДокумент1 страницаMan Cage Check SheetRUDHRA DHANASEKAR100% (1)

- Design and Study of Floating Roof For Oil Storage TanksДокумент20 страницDesign and Study of Floating Roof For Oil Storage TanksswaminathanОценок пока нет

- Api 610Документ11 страницApi 610prakasharmyОценок пока нет

- Kill Your Limiting Beliefs PDFДокумент8 страницKill Your Limiting Beliefs PDFBhupesh PatelОценок пока нет

- Power Capacity HVAC CalculationДокумент12 страницPower Capacity HVAC CalculationEdОценок пока нет

- Cygnus Surface Brochure Iss7Документ12 страницCygnus Surface Brochure Iss7RUDHRA DHANASEKARОценок пока нет

- PE FeestructДокумент1 страницаPE FeestructRUDHRA DHANASEKARОценок пока нет

- Gc-27 (West Kuwait) : Arabi Enertech K.S.CДокумент1 страницаGc-27 (West Kuwait) : Arabi Enertech K.S.CRUDHRA DHANASEKARОценок пока нет

- Diploma in Industrial Safety 1 Yr. HAZARDS IN WORK PLACES (DIS-1) (4031504)Документ2 страницыDiploma in Industrial Safety 1 Yr. HAZARDS IN WORK PLACES (DIS-1) (4031504)RUDHRA DHANASEKARОценок пока нет

- M-2214 - SHT 2 PDFДокумент1 страницаM-2214 - SHT 2 PDFRUDHRA DHANASEKARОценок пока нет

- Syllabus - : Week 1 2: Simulation Tool TrainingДокумент16 страницSyllabus - : Week 1 2: Simulation Tool TrainingRUDHRA DHANASEKARОценок пока нет

- Symbols Pipe SupportДокумент1 страницаSymbols Pipe SupportRUDHRA DHANASEKARОценок пока нет

- Pipe SupportДокумент5 страницPipe SupportRUDHRA DHANASEKARОценок пока нет

- Ga-Key PlanДокумент1 страницаGa-Key PlanRUDHRA DHANASEKARОценок пока нет

- Li Cad 10 SettingsДокумент2 страницыLi Cad 10 SettingsRUDHRA DHANASEKARОценок пока нет

- Bottle SupportsДокумент2 страницыBottle SupportsRUDHRA DHANASEKARОценок пока нет

- Trigonometry Formulas PDFДокумент2 страницыTrigonometry Formulas PDFsasi15augОценок пока нет

- What's New - PV Elite 2018Документ36 страницWhat's New - PV Elite 2018RUDHRA DHANASEKARОценок пока нет

- Series FormulasДокумент3 страницыSeries FormulasBachchan MishraОценок пока нет

- Lifting DetailДокумент1 страницаLifting DetailRUDHRA DHANASEKARОценок пока нет

- Internal & DetailДокумент1 страницаInternal & DetailRUDHRA DHANASEKARОценок пока нет

- Algebra FormulasДокумент3 страницыAlgebra Formulasyuvarajr30Оценок пока нет

- What S New - PV Elite 2018Документ5 страницWhat S New - PV Elite 2018NirmalОценок пока нет

- Lecture 36 - Lacing SystemsДокумент16 страницLecture 36 - Lacing SystemsGajendra JoshiОценок пока нет

- ABLOY Fire Door Closing Systems - 2018Документ16 страницABLOY Fire Door Closing Systems - 2018eaglebrdОценок пока нет

- S700 - APA Simple Solutions LVL Beams & Headers PDFДокумент2 страницыS700 - APA Simple Solutions LVL Beams & Headers PDFAbdurrahman CinarОценок пока нет

- Plasticity of StructuresДокумент1 страницаPlasticity of StructuresNambiyanna DavanagereОценок пока нет

- Guias PDFДокумент116 страницGuias PDFAndres PuertaОценок пока нет

- Plumbing Questionnaires PDFДокумент53 страницыPlumbing Questionnaires PDFEmilySisnerosMenoriasОценок пока нет

- Vitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenДокумент50 страницVitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenAnca IscruОценок пока нет

- Vortex Shear Mixer Product Leaflet enДокумент4 страницыVortex Shear Mixer Product Leaflet enJARABA - Jean Luis ReyesОценок пока нет

- Material ScienceДокумент810 страницMaterial ScienceNikhil Batham67% (3)

- Orthotropic Structural Analysis of Short Fiber FilledДокумент12 страницOrthotropic Structural Analysis of Short Fiber Filledjossiab100% (1)

- UNILAB SHARK - Shell&Tube Database (October 2015)Документ66 страницUNILAB SHARK - Shell&Tube Database (October 2015)Unilab100% (1)

- Plate Girders With Corrugated Steel Webs PDFДокумент13 страницPlate Girders With Corrugated Steel Webs PDFMarcelo Albe100% (1)

- Slabs in Midas GenДокумент50 страницSlabs in Midas Genmarkespino100% (1)

- A Review of One-Dimensional Unsteady Friction Models For Transient Pipe FlowДокумент11 страницA Review of One-Dimensional Unsteady Friction Models For Transient Pipe FlowBhuvanaОценок пока нет

- Keep Your Facility Fully Operational.: Chemetall Maintenance ProductsДокумент8 страницKeep Your Facility Fully Operational.: Chemetall Maintenance Productseggy mushadiОценок пока нет

- LIBRO3Документ43 страницыLIBRO3Camilo LacoutureОценок пока нет

- 10.0 Innovative Turbulence Modeling - SST Model in ANSYS CFXДокумент2 страницы10.0 Innovative Turbulence Modeling - SST Model in ANSYS CFXกี้ บางพระОценок пока нет

- Steel Rod, Bars and Wire For Cold Heading and Cold ExtrusionДокумент22 страницыSteel Rod, Bars and Wire For Cold Heading and Cold ExtrusionReginaldo SantosОценок пока нет

- ME8391-Engineering Thermodynamics PDFДокумент20 страницME8391-Engineering Thermodynamics PDFbharathОценок пока нет

- T650 RevA7-12-06Документ1 страницаT650 RevA7-12-06manickam81Оценок пока нет

- Ball Valve QAPДокумент2 страницыBall Valve QAPAnant RubadeОценок пока нет

- NDT PDFДокумент4 страницыNDT PDFBHARANIОценок пока нет

- Basement ExcavationДокумент4 страницыBasement ExcavationAnonymous U6pIEKQghОценок пока нет

- Lubrication and LubricantsДокумент17 страницLubrication and LubricantsSamatha Farai ZviuyaОценок пока нет