Академический Документы

Профессиональный Документы

Культура Документы

Approved Structural Steel-Welding Procedures - Armor Angle Field Splice

Загружено:

ans44155Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Approved Structural Steel-Welding Procedures - Armor Angle Field Splice

Загружено:

ans44155Авторское право:

Доступные форматы

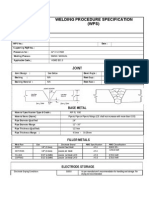

NORTH CAROLINA DEPARTMENT OF TRANSPORTATION ARMOR ANGLE FIELD SPLICE WELDING PROCEDURE SPECIFICATION (WPS) AWS D1.

5

Specifications & Codes: Material Specifications: Welding Process: SMAW NCDOT Standard Specifications/AASHTO/AWS D1.5, Section 2, 5 and 12 ASTM A-36, A572, (A709-36, 50), (M270-GR250, 345) Unlimited Thickness Manual or Semi- Automatic or Automatic: E-7018 Position of Weld Progression: N/A 100 minimum

Welding Current

Manual

Filler Metal Specification: Classification: AWS A5.1 Single or NCDOT Approved Manufacturer: Multiple Pass Electrodes both Welding Current: Root Treatment: Preheat Temp:

Pass Electrode

Flat N/A

DC

Polarity:

Positive

Interpass:

Travel

450 maximum

Post Heat:

N/A Joint Details

Num.

Size

Amperes

Volts

Speed

All

1/8

90-150

20-23

6-9 ipm

SEE ATTACHMENT

PREHEAT Thickness Min. Temp. Up to 3/4" 100 Over 3/4" to 1 1/2" 100 Over 1 1/2" to 2 1/2" 150 Over 2 1/2" 225 WPS Description Armor Angle Field Splice

COMMENTS: Remove all coating, rust, dirt and mill scale within one inch of the area to be welded. Remove all slag, spatter and weld discontinuities between passes. Clean the completed weld of all debris, slag and spatter.

Written By: Signature:

Randy Dempsey, CWI/CWE, TT IV

WPS #: Revision #:

032811028 1

Authorized By: Signature:

Steve Walton, Metals Engineer

NCDOT MATERIALS & TESTS UNIT (STEEL SECTION)

28-1

'WPS

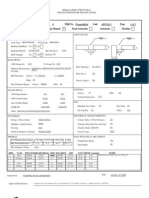

ARMOR ANGLE Fiele! Splice 032811028 JOINT DETAIL ATTACHMENT

Rl

1/4/1

nln

3/8/1

J l.,

1/8

Bevel

MQ.X

to 1/8

Horizonto.l

Leg

of

Angle

Only

ARMOR ANGLE Field Splice JOINT DETAILS

'Wele! SYMbol e!efinitions per A'WS A2.4:2007

FIELD 'WELD SYMBOL

Single V Groove, wi Depth of Groove, Groove Angle o.ne! Grine! Flush SYMbol

28-2

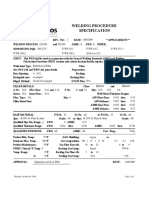

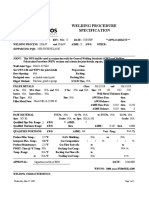

Illustrations Armor Angle Field Splice.

As received

Both pieces beveled and coating next to weld zone removed.

Each pass is cleaned.

NCDOT MATERIALS & TESTS UNIT (STEEL SECTION)

The completed weld is grinded flush

28-3

Вам также может понравиться

- Welding Procedure Specification SampleДокумент2 страницыWelding Procedure Specification Sampleezdi2083% (23)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Wps SawДокумент2 страницыWps Sawdevendrasingh2021100% (6)

- Wps 316L SMAW+GTAW R00Документ2 страницыWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- Metrode WPS SuperduplexДокумент4 страницыMetrode WPS SuperduplexClaudia Mms100% (3)

- Manual Overlay WeldingДокумент8 страницManual Overlay Weldingcarlmac6183% (6)

- WPS - D1.1 - Prequalified Procedures QSSLДокумент26 страницWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedОценок пока нет

- WPS FormatДокумент1 страницаWPS FormatAbdullah AnsariОценок пока нет

- Welding Procedure Specification For 24'' PipeДокумент2 страницыWelding Procedure Specification For 24'' Pipeenels77100% (1)

- PQR-WPS-WPQR XXX Rev 0Документ6 страницPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WPS P91Документ6 страницWPS P91JoseAlbertoNeyraОценок пока нет

- P91 WPSДокумент6 страницP91 WPSPepe SagitarioОценок пока нет

- WPS MigДокумент3 страницыWPS MigAJOJOY00960% (5)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Iso 8501Документ4 страницыIso 8501cisar0007100% (2)

- Stainless Steels & Nickel AlloysДокумент108 страницStainless Steels & Nickel AlloysAhmad Aloudah50% (8)

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Документ30 страницLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Navneet Singh100% (2)

- Approved Structural Steel-Welding Procedures - Stud WeldingДокумент3 страницыApproved Structural Steel-Welding Procedures - Stud Weldingans44155100% (2)

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleДокумент8 страницApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12Оценок пока нет

- WPSДокумент1 страницаWPSNidhinkorothОценок пока нет

- WPS GTAW Stainless SteelДокумент4 страницыWPS GTAW Stainless SteelAnand NarayananОценок пока нет

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Документ2 страницыWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyОценок пока нет

- WPS - 012Документ11 страницWPS - 012MAT-LIONОценок пока нет

- WPS SiloДокумент1 страницаWPS SiloNidhinkorothОценок пока нет

- Aluminium WPSДокумент2 страницыAluminium WPSAnonymous yCpjZF1rF100% (1)

- WPS - 008Документ11 страницWPS - 008MAT-LIONОценок пока нет

- Manual Structural WeldingДокумент12 страницManual Structural WeldingwalitedisonОценок пока нет

- WPS - D1.1Документ1 страницаWPS - D1.1Nam_HitechОценок пока нет

- WPS - 014Документ11 страницWPS - 014MAT-LIONОценок пока нет

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectДокумент4 страницыWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremОценок пока нет

- WPS - 015Документ11 страницWPS - 015MAT-LIONОценок пока нет

- WPS - 018Документ12 страницWPS - 018MAT-LIONОценок пока нет

- WPS - 017Документ12 страницWPS - 017MAT-LIONОценок пока нет

- Attached WpsДокумент6 страницAttached WpsnourfarmajidОценок пока нет

- Welding Procedure Specification For 24'' PipeДокумент2 страницыWelding Procedure Specification For 24'' Pipeenels77100% (2)

- PQR For 32 MM PlateДокумент1 страницаPQR For 32 MM PlateMuhammed MubeenОценок пока нет

- Aluminim WPSДокумент2 страницыAluminim WPSKarthikeyan ShanmugavelОценок пока нет

- Wps p91 - BhelДокумент2 страницыWps p91 - BhelAshish Gupta100% (4)

- Aluminim WPSДокумент2 страницыAluminim WPSmahmoud_allam3Оценок пока нет

- WPS - Merd-01Документ3 страницыWPS - Merd-01Phuong NguyenОценок пока нет

- PQR SAW ProcessДокумент1 страницаPQR SAW Processdevendrasingh202133% (3)

- P91 Profile WpsДокумент6 страницP91 Profile WpsManzar KhanОценок пока нет

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsДокумент3 страницыEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Welding Procedure Specification: Page 1 of 1Документ2 страницыWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- WPS - 010Документ12 страницWPS - 010MAT-LIONОценок пока нет

- Welding Procedure Specification: Monday, April 27, 2009 Page 1 of 2Документ2 страницыWelding Procedure Specification: Monday, April 27, 2009 Page 1 of 2srb metallurgОценок пока нет

- WPS - 007Документ11 страницWPS - 007MAT-LIONОценок пока нет

- WPS Sa 517Документ2 страницыWPS Sa 517DHANANNJAI SINGH -Оценок пока нет

- 2G & 5GДокумент2 страницы2G & 5GRahul MoottolikandyОценок пока нет

- 1000 XXXX HY80 HSLA100Документ2 страницы1000 XXXX HY80 HSLA100srb metallurgОценок пока нет

- Welding Procedure SpecificationДокумент2 страницыWelding Procedure SpecificationSAKDA MAPRADITKULОценок пока нет

- Wps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International AirportДокумент5 страницWps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International Airportamit rajputОценок пока нет

- WPS 856110.016 Rev 3Документ1 страницаWPS 856110.016 Rev 3laz_kОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesОт EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesОценок пока нет

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsОт EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsРейтинг: 3.5 из 5 звезд3.5/5 (6)

- American SpeechДокумент2 страницыAmerican Speechans44155Оценок пока нет

- Acceptancecriteriaofwelddefectsasperdifferentcodes 170522043214Документ17 страницAcceptancecriteriaofwelddefectsasperdifferentcodes 170522043214ans44155Оценок пока нет

- Passive-To Be ConcentratedДокумент11 страницPassive-To Be Concentratedans44155Оценок пока нет

- Preposition AboardДокумент170 страницPreposition Aboardans44155Оценок пока нет

- Orange LevelДокумент66 страницOrange Levelans44155Оценок пока нет

- Coating For Steelwork PDFДокумент16 страницCoating For Steelwork PDFquiron2014Оценок пока нет

- Hajj Vazhikatty by Kader MohideenДокумент12 страницHajj Vazhikatty by Kader Mohideenans44155Оценок пока нет

- Violet LevelДокумент116 страницViolet Levelans44155Оценок пока нет

- Surface & Tandem - ScanДокумент1 страницаSurface & Tandem - Scanans44155Оценок пока нет

- Approved Structural Steel-Welding Procedures - Armor Angle Field SpliceДокумент3 страницыApproved Structural Steel-Welding Procedures - Armor Angle Field Spliceans44155Оценок пока нет

- Materialscience8 To 16Документ44 страницыMaterialscience8 To 16ans44155Оценок пока нет

- Flux Certificate - 234-ELİFLUX BBR-AG-Sample PDFДокумент1 страницаFlux Certificate - 234-ELİFLUX BBR-AG-Sample PDFans44155Оценок пока нет

- Nutrition and Exercise During Pregnancy VoiceOver PresentationДокумент26 страницNutrition and Exercise During Pregnancy VoiceOver Presentationans44155Оценок пока нет

- Engg MaterialsДокумент20 страницEngg MaterialsVimin PrakashОценок пока нет

- A Thoughtful InquiryДокумент8 страницA Thoughtful Inquiryans44155Оценок пока нет

- American Speech: Popular Expressions Used in The United States A B C D E F G H I J K L M N O P Q R S T U V W X Y ZДокумент2 страницыAmerican Speech: Popular Expressions Used in The United States A B C D E F G H I J K L M N O P Q R S T U V W X Y Zans44155Оценок пока нет

- Shiyakkalum Avartham KolhaiyyumДокумент59 страницShiyakkalum Avartham Kolhaiyyumans44155Оценок пока нет

- 700-S2Si-Sample-3.20 MM PDFДокумент1 страница700-S2Si-Sample-3.20 MM PDFans44155Оценок пока нет

- Industrial Radiography Image Forming TechniquesДокумент99 страницIndustrial Radiography Image Forming TechniquesAnonymous gFcnQ4goОценок пока нет

- Qcb1019 - Radiation Safety Procedure PDFДокумент3 страницыQcb1019 - Radiation Safety Procedure PDFans44155Оценок пока нет

- Yello Level LessonsДокумент87 страницYello Level Lessonsans44155Оценок пока нет

- Engg Materials PDFДокумент20 страницEngg Materials PDFans44155Оценок пока нет

- Wali in IslamДокумент10 страницWali in IslamKiran KachhawahaОценок пока нет

- Thermit WeldingДокумент2 страницыThermit Weldingans44155Оценок пока нет

- Structural Steel Bolted Joints by Megdad - NAPISДокумент35 страницStructural Steel Bolted Joints by Megdad - NAPISans44155Оценок пока нет

- Blue Level LessonsДокумент501 страницаBlue Level Lessonsans44155Оценок пока нет