Академический Документы

Профессиональный Документы

Культура Документы

Remote Operated Shutoff Valves Specification

Загружено:

Sharath KrishnanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Remote Operated Shutoff Valves Specification

Загружено:

Sharath KrishnanАвторское право:

Доступные форматы

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 1 of 31

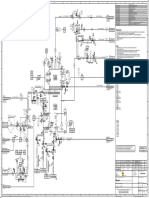

SPECIFICATIONS FOR REMOTE OPERATED SHUTOFF VALVES (ROSOV)

TRIPLE OFFSET, DOUBLE FLANGED , BUTTERFLY VALVES WITH FAIL SAFE PNEUMATIC ACTUATORS

Issue and Revision Record: Revision 0 Date 21.07.2011 BPCL HPCL IOCL Description Issued for Tendering

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 2 of 31

List of Content

Page N o .

Introduction 1.1 Definitions

3 3 3 5 5 5 5 6 6 7 7 8 9 10 10 10 11 11 12 13 14 14 15 16 16 16 19 19

Applicable Codes, Specifications and Standards 2.1 2.2 2.3 2.4 General Deviations to Specification Conflicting Requirements Abbreviations &Terminology

3 4 5 6 7 8

Product Details Plant Environmental Conditions Hazardous Area Classification and Protection Utilities Specification Scope of Supply Specifications & Documents attached Technical 8.1 8.2 Design & Construction Materials &Test Procedures

Pneumatic Actuators for Shutdown Application 9.1 9.2 9.3 General Accessories (all actuators) ROSOV Operation

10.0

Inspection and Tests 10.1 10.2 10.3 General Actuator Test Certificates

11.0 12 13.0 14.0

Spares &Accessories Documentation Guarantee Site Service/Site Visits by Experts.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 3 of 31

15.0

Painting, Marking and Shipment/ / Storage DATA Sheets- Valve, Actuator, Solenoid Valve, PSTD21-28

20

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 4 of 31

Introduction

Hindustan Petroleum Corporation Limited (HPCL), Bharat Petroleum Corporation Limited (BPCL) and Indian Oil Corporation Limited (IOCL) intend to replace existing tank body valves with Remote Operated Shut Off Valve (failsafe) for enhancing operational safety at their various existing petroleum installations.. The purpose of this specification is to define the requirements for pneumatic actuated on/off shut down valves for the following services Tank Overfill Protection Shutdown via Emergency Shutdown System with use of (ROSOVs) pneumatically remotely operated valves from ESD (SIS) System.

Overfill protection system shall be de-energized to trip. Solenoid Valve of ROSOV shall be SIL2 Certified and operate on 230V AC. This specification covers the minimum requirements for the design, manufacture, assembly, Inspection, testing, certification & delivery of On-Off type Triple Offset Butterfly Valves with Pneumatically operated actuator complete with all accessories, for various petroleum installations of HPCL/BPCL/IOCL in India. 1.1 Definitions Owner/s Limited/ Indian Oil Corporation Limited. Bidder / : Manufacture r : Engineer Incharge Shall Should : : Valve Manufacturer Means the Resident Engineer or a person acting on behalf of HPCL/BPCL/IOCL at sites : Hindustan Petroleum Corporation Ltd/ Bharat Petroleum Corporation

This is to be understood as a mandatory in relation to the requirements of this document This is to be understood as a strong recommendation to comply with the requirements of this document.

2

2.1 2.1.1

Applicable Codes, Specifications and Standards

General The items shall be designed and supplied in accordance with this Specification and the codes and standards referenced herein. The design, manufacture, assembly, inspection, testing and certification of P n e u m a t i c Operated on-

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 5 of 31

off type triple offset high performance butterfly valves shall be in accordance with the latest edition of the codes including amendments, specifications and standards (including standards / specifications mentioned therein )listed in this requisition.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 6 of 31

API598 API-6FA API607 API609 ASMEB1.20.1 ASMEB16.5 ASMEB16.10 ASMEB16.34 ASMEB31.3 ASMEB31.4 ANSIB46.1 BSEN12266 Part2 EN50018

2004 1999 2005 2009 1983 2003 2000 2004 2004 2004 1995 2002 2000 2006 2004 1991

Valve Inspection and Testing. Specification for Fire test for Valves. Fire test for soft-seated quarter-turn valves Butterfly Valve Design Pipe Threads, General Purpose(inch) Steel Pipe Flanges and Flanged Fittings Face-to-Face and End-to-End Dimensions of Valves ValvesFlanged, Threaded, and Welding End Chemical Plant and Petroleum Refinery Piping Liquid transportation systems for hydrocarbons and other liquids Surface Texture(Surface Roughness, Waviness & Lay) Industrial Valves, Testing of valves, test procedures & Acceptance criteria. Electrical Apparatus for Potentially Explosive Atmosphere [EEx(d)] Electrical apparatus to explosive gas atmosphere. Classification of degrees of protection provided by Enclosures (IPcodes). Electromagnetic compatibility of IndustrialProcess management and control equipment Functional Safety of Electrical/Electronic/ Programmable Electronic Safety Related Systems Functional safetySafety Instrumented Systems for the Process Industry Sector Pressure Testing of Steel Valves Steel structures painting council-visual standard

IEC60079 IEC60529 IEC60801

IEC61508

2010

IEC61511 MSS-SP-61 SSPC-VIS-1

2010 2003 2002

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 7 of 31

National Codes

IS-2148 2004 Flame-proof enclosures for electric apparatus, etc: Methods for determining thermal classification of electric insulation.

IS-1271

1985

2.2 2.2.1

Deviations to Specification The Bidder shall provide an itemized list of any deviations to this specification. These shall be listed on the Compliance sheet with seal & duly signed by authorized signatory & shall be submitted along with offer by the Bidder. Where conflict between standards occurs then the Bidder shall seek a clarification ruling from the Owner. Where a deviation from the standard is required, then the Bidder shall make a formal request with full supporting information. Only those deviations that are agreed between the Owner and the Bidder will be incorporated in to the requisition at the time of order. Conflicting Requirements In case of conflict between the requirements of this specification, API609 and the Codes, Standards and Specifications referred in clause 2.1 above, the requirements of this specification shall govern. Order of precedence shall be as follows: First priority Second priority Third priority Fourth priority Fifth priority Data Sheets This Specification API607 Other Referred Codes &Standards Manufacturers Standard

2.2.2

2.2.3

2.3

Note: Should any conflict arise either before or after order placement the Bidder shall immediately inform the Owner for technical resolution of the conflict. 2.4 Abbreviations &Terminology

CE DVC ESDV valve FAT FB FC FMEDA

Carbon Equivalent Digital Valve Controller Emergency Shutdown Factory Acceptance Test Full Bore Fail Safe Close Failure Modes Effects and Diagnostic

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 8 of 31

Analysis. FO GUI

Fail Safe Open Graphical User Interface

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 9 of 31

HFT MOV IEC Commission IS ISA JB LO Open LC Close/ Full Long Standing Still MOS MOV MSBT Torque MTBF MTTR PFD PST PSTD QAP RC ROSOV SAT SFF SET SIL SIS Systems SOV SRT SST TAS TFMS TOBV Valves. VAC VDC CCOE CMRI

Hardware Fault Tolerance Motor Operated/ Actuated On-Off Valve International Electro-technical Intrinsic Safety Instruments Society of America Junction Box Lock Open/ Full Lock Close LSS Manual Override Switch Motor Operated Valves Maximum Spring Break Mean Time Between Failures Mean Time To Repair Probability of Failure on Demand Partial Stroke Testing Partial Stroke Testing Device Quality assurance Plan Regular Cycling Remote OperatedESDV Site Acceptance Test Safe Failure Fraction Spring End Torque Safety Integrity Level Safety Integrated Solenoid Operated Valve Spring Return Torque Spring Standing Torque Terminal Automation System Tank Farm Management System Triple Offset High Performance Butterfly Volts alternating current Volts direct current Chief Controller Of Explosives Central Mining Research Institute

White Oil product details

In the table below, Product Characteristics of the products are mentioned as general guidelines to bidders

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 10 of 31

Product

Flash point (OC) > 35 (-) 30 (-) 20 > 35 101 > 35 33 (-) 23.3 16.6

Specific gravity gm/cc 0.82-0.86 0.73 0.69- 0.78 0.8 0.8 0.82 0.66 0.79

HSD - High Speed Diesel MS Motor Spirit Naphtha ATF Aviation Turbine Fuel SKO - Super Kerosene Oil MTO Mineral Turpentine Oil Hexane Ethanol

Vapour pressur e kg/cm2a < 0.4 0.7 < 0.7 < 0.4 < 0.05 0.01 0.37 0.08

Viscosity (cSt)

Pumping Temp. (OC) Ambient Ambient Ambient Ambient Ambient Ambient Ambient Ambient

2-5 @ 40OC < 0.7 < 0.7 2.56 1.97 14.92 0.277 1.2

The above product specifications are indicative and may vary.

4

4.1 4.2

Hazardous Area Classification and Protection

Instruments located in hazardous area shall be certified to meet or exceed the electrical hazardous area defined by Area classification The actuator accessories used shall be flame proof and suitable for hazardous area of Zone1,Group IIA/IIB,T3 or better for applications. Additionally all valve associated instruments shall be weather proof to IP65 as minimum. Instruments certified for use in the specified hazardous area classification shall have certifications/ approvals from accredited international agencies like FM, ENELEC, PTB, BASSEFA, ATEX, etc. All enclosures for electrical equipment shall be suitable for use in Hazardous are as per Haz. Area Classification and vendor shall submit valid test certificate issued by CIMFR & PESO. Flameproof enclosures and instruments which are manufactures outside India and certified by accredited international authorities shall also have approval of PESO, India.

5

5.1

Utilities Specification

Instrument Air Supply pressure may range between 4.5kg/cm(g) to 6.5kg/cm(g). However Actuator shall be sized for instrument air supply pressure of 4.0kg/cm2 (g) & shall withstand the design pressure 10kg/cm2(g).

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 11 of 31

5.2

Electric Supply of 230 V (+/- 10%) AC, 50 HZ (+/- 5%)

6

6.1

Scope of Supply

The scope of this tender covers the design, manufacture, testing and supply of pneumatically actuated, failsafe to close valves to be installed on the tank body of petroleum storage tanks as per the specifications and data sheets attached. These valves are part of SIS for tank overfill protection & functioning as ROSOVs(ESDVs). Complete actuated valve assembly shall have capability for use in SIL 3 application having certification from TUV / Exida as per IEC 61508. However the designed SIS loop has one ROSOV & as per IEC 61508, the architectural constraint limits overall loop SI to SIL2.

6.2

This specification covers the minimum requirements for design, manufacture and supply of fire safe, triple offset ,metal to metal seated, high performance, bidirectional- zero leak tight shutoff, non-rubbing, torque seated, antistatic, antiblow out stem arrangement, quarter turn, double flange end butterfly valves of size equal& more than DN 100 mm (4") to DN 700 mm (28) as a complete assembly of valve & actuator unit with all accessories. The materials, design and workmanship shall satisfy the relevant standards, specifications & codes referred in this document. Where the specifications stipulate requirements in addition to those contained in the standard, codes and specifications, these additional requirements shall also be satisfied. The Bidder shall supply the complete assembled and tested valve with actuator & related accessories. The designed, engineered and supplied equipment/ system shall be suitable for the site conditions specified. All components/consumables used shall be new, state of the art and of current manufacture. Bidder shall include in the bid, list of specific deviations, separately, if any, to this specification and all attachment thereof, otherwise, the offer will be deemed to be in compliance with complete tender and its attachments and subsequent claims for extra scope will not be considered. This specification does not relieve the Bidder from final guarantee as to materials, apparatus, workmanship and performance of the valve supplied. The Bidder shall, in respect of this tender, procure material from approved makes/vendors listed in the datasheet notes, unless the particular type of material is not covered by the list, or a special dispensation to deviate from the list has been granted in writing by the Owner. Vendor / Bidder to include the startup & commissioning spares for valves, actuators and other accessories in the quoted price and the list of such spares shall be provided in the technical bid.

6.3

6.4

6.5

6.6 6.7

6.8

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 12 of 31

6.9

SPARES & SPECIAL TOOLS :

6.9.1 Vendor shall submit list of standard spares of Actuators along with unit rates with validity for 2 years. 6.9.2 Vendor shall submit list of special tools, if required for maintenance of Actuators along with unit rates with validity of 2 years. The above shall be submitted in a separate sealed envelope as mentioned in the price-bid formats

6.10 Approved vendor/ makes are provided in this tender is for the manufacturer name only, and not for any specific model. For all items/components the offered model must meet the relevant specification and proven track record (PTR) requirements as specified in this tender document. . The Bidder shall provide the related necessary evidence for use of their valves in similar application (reference lists with installation dates and run hours accumulated by date, etc.). Only equipment of proven reliability in similar service conditions, shall be included in the Bidders proposal (prototypes shall not be proposed). Bidder shall prepare and submit all necessary documents during various stages of the project as listed in this tender document.

6.11

6.12 Inspection and testing of all components, sub-assemblies and complete assemblies of items manufactured at Bidders works, and other sub-Vendors/Suppliers Bidders works shall be in accordance with approved QA/QC procedure. 6.13 Factory Acceptance Test (FAT) shall be performed in line with tender requirements & as per approved post PO FAT procedure . Providing necessary manpower & equipment support during FAT/ testing is in bidders scope.

Specifications& Documents attached

7.1 Specification, datasheets, schedule of quantities for valves are appended to the specification.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 13 of 31

Technical

8.1 8.1.1. 8.1.2. 8.1.3. 8.1.4. Design & Construction of Triple Offset High Performance Butter fly Valves Metal seated butterfly valve shall be supplied with anti-static devices. Butterfly valves shall be as per API 609 with double flange ends construction. Dimensions shall be as per API 609 long pattern. Flanged end shall have dimensions as per ASME B16.5 . Flange face shall be raised face. Flange face finish shall be serrated or smooth as indicated in Valve Data Sheet. Smooth finish when specified shall be 63125AARH smooth finish. When specified in the valve data sheet, valves shall be designed to withstand a sustained internal one mille bar vacuum in both open and closed position. Valves shall be provided with position indicator and stops at the fully open and fully closed positions. Manufacture unit shall be in possession of valid ISO 9001 certificate Valve should meet ISO 15848 standard for fugitive emissions Vendor will indicate closing torque required for each size of the valve for their closing. Valve will be pressure tested at closing torque and should achieve zero leak . Valve shall be manufactured with close tolerance and should employ robotic welding and 3D measurement of seat and disc . Valve body to be in single piece and valve seat should not protrude out side the valve body upto 20 size. Valves of size DN 200 mm (8) and above shall be equipped with lifting lugs. Tapped holes and eye bolts shall not be used for lifting lugs. Incase lifting lugs are not provided on the valve then vendor shall provide detailed instruction set for handling the valves for installation without need of lifting lugs. Valves shall be of fire safe design as per BS EN 12266 Part2 /API6FA/ API607,as indicated in Valve Data Sheet. As a special requirement one valve for each size selected randomly by TPI shall be fire tested as per the specifications at the manufacturers place over and above the requirements specified in the API standards. Valves shall be suitable for above ground installation as indicated in the Valve Data Materials & Test Procedures Material for major components of the valves shall be as indicated in Valve Data Sheet.

8.1.5. 8.1.6. 8.1.7 8.1.8 8.1.9

8.1.10 8.1.11 8.1.12.

8.1.13

8.1.14 Sheet. 8.2 8.2.1

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 14 of 31

8.2.2 8.2.3

Carbon steel used for the manufacture of valves shall be fully kilned. The Carbon Equivalent (CE)of valve end connections, shall not exceed 0.45% (as calculated by the following formula) on check analysis for each heat of steel used:

8.2.4

Charpy V Notch test on each heat of base material shall be conducted as per API609, for all pressure containing parts such as body, end flanges and welding ends as well as bolting material for pressure containing parts. Unless specified otherwise, the Charpy impact test shall be conducted at 0C. The Charpy impact test specimen shall be taken in the direction of principal grain flow and notched perpendicular to the original surface of plate or forging. The minimum average absorbed energy per set of three specimens shall be 27J with an individual minimum per specimen of 22J. No specimen shall exhibit less than 80 per cent shear area. The hardness of base material of body and principal parts of the valve such as disc & body etc. shall not exceed 22RC. Shaft/ Stem can be with higher hardness based on the shaft material & applicable relevant standard.

8.2.5

8.2.6

9

9.1 9.1.1

Pneumatic Actuators for Shutdown Application

General Single actingspring return pneumatic piston actuators of scotch & yoke type as specified in data sheet shall be used for shutdown services and where the valve design dictates. Rack & Pinion & Pressure balance actuators shall not be used. These ROSOVs shall be equipped with spring return single acting piston actuators. The required position of the valve when the controlling medium is lost s h a l l b e Fail Closed as indicated on the datasheets. The actuator shall be sized using a factor of 1.25times the maximum shut-in head pressure to ensure that the actuator has sufficient built-in power to operate the valve from a closed in system or to ensure seating against such a condition. The actuator-valve stem connection shall be a bolt-threaded split clamp. Piston actuators shall be sized to provide the required force at supply pressure of 4.0 kg/cm(g) but must be suitable for pressures up to 10.0kg/cm(g). Where requested on data sheet the actuator shall be supplemented with air capacity tanks (with non-return valves, pressure gauges, drains etc.). Air capacity tanks shall be sized to provide adequate air storage such that three valve operations may be obtained between 4.0 and 6.5 kg/cm. The tanks shall be manufactured from carbon steel, painted and shall be to the pressure vessel code

9.1.2

9.1.3 9.1.4

9.1.5 9.1.6 9.1.7

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 15 of 31

applicable to the project. 9.1.8 All tubing shall be 316 Stainless Steel and in imperial sizes. Permissible OD/ wall thickness shall be as follows: 9.1.9 9.1.10 "ODx0.049"wallthickness

Actuator colors shall be: RAL3001 Signal Red for Fail Close ROSOVs. These ROSOVs will be used as tank body ( inlet/outlet) isolation with shutdown application for tank overfills protection. Bidder shall have the ROSOVs with actuator installed in 90Deg. angle with nozzle/ pipeline axis. Accessories Accessories such as solenoid valves, AFRs etc., shall be procured and mounted by Bidders Local Station in a field mounted cabinet. External tubing connection shall be either "O.D. Instruments shall be tropicalized for humidity and fungus and shall be termite resistant, IP65 classification. Bidder shall be completely responsible for the Functioning of the control scheme as per data sheet requirements. Solenoid valves shall be certified EExd (except when data sheet calls for EExi) coil rating 230V AC. Integral terminals shall be provided for the termination of cabling. Flying leads from the coil enclosure shall not be used. Pneumatic solenoid valves shall be constructed of stainless steel body, stainless steel trim and SS enclosure. Zero copper aluminium enclosures with two pack epoxy finish are acceptable. The pneumatic actuator shall be fitted with micro switches as limit switches, one at the open and one at the closed position. The switches shall operate at less than 5% of the valve travel from their respective limits. Limit Switches should be EExd. Bidder shall supply full technical specification of the switches in his offer. Switches shall be pre-cabled to a junction box mounted on the actuator using NPT metallic glands. Junction boxes shall be made from stainless steel, environmentally rated IP65 and certified EExd for use in Zone1 hazardous areas as standard. Cables shall be clearly identified at both ends using securely fitted PVC cable markers. All cable cores and wiring shall be fitted with core identification ferrules at each end. All cores shall be terminated in terminals. All tube bending shall be carried out cold by gradually applied pressure using an approved type bending machine. Bending shall not include hammering or the application of any force which may damage the tube. Tube cutting shall be executed using an approved type tube cutter, saw cuts are not to be made. After cutting the ends shall be dressed with the appropriate belling tool to ensure that a restriction has not been introduced. Prior to installation ,the tubing shall be internally cleaned ,degreased with a suitable solvent and then dried.

9.2 9.2.1

9.2.2.

9.2.3.

9.2.4.

9.2.5.

9.2.6.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 16 of 31

9.2.7.

All actuators/ valves shall be fitted with a permanently attached stainless steel labels (not wired-on) showing as a minimum the following information: Bidders name & OEM name Model & serial numbers Instrument tag number Manufacturers standard data Position on actuation medium failure Materials of construction of valve body Pressure and temperature ratings(valve only)

9.2.8. 9.2.9.

Fireproofing of actuator is not envisaged. All accessories mounted on valve assemblies shall be capable of withstanding line vibrations & surge. ROSOV Operation ROSOVs are part of SIS which consists of SIL3 ESD Safety PLC, SIL2 capable High Level Switch/ any other input element & ROSOVs as final control element. Each ROSOV shall be with Emergency Close (Shut-off) Local Station which shall be located outside the dyke which is 20mtrs minimum from the ROSOVs.

9.3 9.3.1. 9.3.2.

9.3.3. Emergency Shut-off Local Station shall be made from LM-6 & having valid CCOE approval. Controls shall be mounted on front & shall be protected against inadvertent operation. 9.3.4. ROSOV Operation will be as follows:a. The valve can be closed from the Local Station for Close Control. No mechanical manual overrides , lock out devices or by-passes are permitted. b. In addition to SIS functionality, the ROSOV can be closed from the control room either from ESD push button or through all operator interface stations for Operators interaction with ESD safety PLC system(SIS) via the Graphical User Interface(GUI) facilities of the Terminal Automation System, wherever provided, with access control & security levels defined. c. A dedicated ESD graphics screens showing the status of each SIS connected equipment shall be developed by Terminal Automation System (TAS) vendor. 9.3.5. To reset , the system must be reset from the Emergency Reset station in control room or through TAS Operator Interface.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 17 of 31

10.0 10.1 10.1.1

Inspection and Tests

General The Manufacturer shall perform all inspection and tests as per the requirements of this specification and the relevant codes, prior to shipment, at his works. Such inspection and tests shall be, but not limited to the following: All valves shall be visually inspected. Dimensional check on all valves shall be carried out as per the Owner approved drawings. Owner shall have the right to inspect/witness the tests. An indicative QAP has been furnished in the tender document. The bidder shall develop further this QAP based upon the specifications in the tender & submit the same for approval. Acceptance of the materials shall be subject to inspection, approval and release by the inspection agency designated by Owner. Inspection will be carried out as per the scope of inspection detailed in this specification and as per the relevant standard, for which all arrangements/ facilities shall be made by successful bidder. Painting shall be in line with Painting specifications. Test certificates should make specific mention that the valves conform to its relevant Standard. It should also include the date of manufacture and surface preparation/ painting. Chemical composition and mechanical properties shall be checked as per relevant material standards and this specification, for each heat of steel used. a) Non-destructive examination of individual valve material and components consisting of ,but not limited to castings, forgings, plate and assembly welds shall be carried out by the Manufacturer. b)Body castings of all valves shall be radio-graphically examined on 100% of the surface of critical areas as per ASME B16.34. Procedure and acceptance criteria shall be as per ASME B16.34.

10.1.2

10.1.3

10.1.4

10.1.5 10.1.6

10.1.7

10.1.8

All valves shall be tested in compliance with the requirements of API598/ API609. During pressure testing, valves shall not have sealant lines and other cavities filled with sealant , grease or other foreign material. The drain ,vent and sealant lines shall be either included in the hydrostatic shell test or tested independently. No leakage is permissible during hydrostatic testing. The body cavity selfrelieving feature meeting the requirements of this specification shall also be checked. A supplementary air seat test as per API609 shall be carried out for all valves. a. A bubble tight seal is required without the use of any sealant. No leakage is allowed. Test pressure shall be held for at least15minutes.

10.1.9

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 18 of 31

b. Valves shall be subjected to Operational Torque Test as per supplementary test Requirement of API609 under hydraulic pressure equal to maximum differential pressure corresponding to the valve rating. c. Valves shall be subjected to anti-static testing as per supplementary test requirement of API609. 10.1.10 10% of valves for each size shall be tested after assembly of the valve and actuator at the valve Manufacturers works. At least five open-close- open cycles without internal pressure and five open-close-open cycles with maximum differential pressure shall be performed on the valve actuator assembly. The time for full open to full close shall be recorded during testing. If required, the actuator shall be adjusted to ensure that the opening and closing times are within the limits stated in Actuator Data Sheet issued for the purpose. In case the tests do not meet the requirements, retesting/rejection of the lot shall be decided by Owners Inspector. Owner reserves the right to perform stage-wise inspection and witness tests as indicated above at Manufacturers works prior to shipment. Manufacturer shall give reasonable access and facilities required for inspection to the Owners Inspector. Owner reserves the right to require additional testing at any time to confirm or further investigates a suspected fault. The cost incurred shall be to Manufacturers account. In no case shall any action of Owner or his Inspector relieve the Manufacturer of his responsibility for material, design, quality or operation of valves.

10.1.11 10.1.12

10.1.13

10.1.14 Inspection and tests performed/ witnessed by the Owners Inspector shall in no way relieve the Manufacturers obligation to perform the required inspection and tests. 10.2 Actuator For ROSOVs the following tests shall be provided prior to shipping: Actuator operation, Cycle (open-close) each valve with its actuator at least five times, for proper actuator operation. Verify that valve position coincides with position indicators. Opening-closing position Actuator output speed & Open-Close time Actuator travel setting Operational torque test as per API609.

10.3 10.3.1

Test Certificates Manufacturer shall submit the following certificates:

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 19 of 31

a)Mill test certificates relevant to the chemical analysis and mechanical properties of the materials used for valve construction as per the relevant standards. b)Test certificates on hydrostatic and pneumatic tests complete with records of timing and pressure of each test. c)All other test reports and certificates as required by API598/ API609 and this specification. The certificates shall be valid only when signed by TPI. Only those valves which have been certified by Owners Inspector shall be dispatched from Manufacturers works. 11.0 11.1 11.2 Spares & Accessories Manufacturer shall furnish list of recommended spares and accessories for valves required during start-up and commissioning. Manufacturer shall furnish list with price of recommended spares and accessories required for two years of normal operation and maintenance of valves. Documentation All documents language. 12.1 shall be in English

12

Documentation with offer: Bidder shall submit the following documents along with offer:

12.1.1

General arrangement/ assembly drawings showing all features and relative positions and sizes of vents, drains, actuator, painting, coating and other external parts together with over all dimensions along with weight, air consumption, minimum air pressure requirement &opening-closing time. Sectional drawing showing major parts with reference numbers and material specification. In particular, a blow-up drawing of disc seat assembly shall be furnished complying the requirement of this specification. Sizing calculations for selected actuator. Torque curves for the actuators along with the break torque and maximum allowable stem torque. In addition, sizing criteria and torque calculations shall also be submitted for actuated valves. As a mandatory requirement, Bidder shall firm up the Make &Model of actuator, other accessories like limit switches, SOV, AFR, etc.at the time of submission of bids & same shall not be changed after PO placement. Bidder shall submit decodification sheet for each type and size for valve and actuator along with torque value . Descriptive technical catalogues of the Manufacturer. Details of support foot, including dimensions and distance from valve centerline to bottom of support foot Manufacturer who intends bidding, must submit at bid stage, certificate and

12.1.2

12.1.3

12.1.5

12.1.6 12.1.7 12.1.8

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 20 of 31

report for successful fire type-tests for valves in accordance withAPI-607/ BS EN 12266(Part 2)/ API6FA, as applicable in Valve Data Sheet along with copy of valid API-609 Certificate. Failure to comply with this requirement shall be a cause of rejection of the offer. 12.1.9 Details for calculating overall Safety Instrumented Systems SIL assessment which requires inputs from each SIS device manufactures who contributes in SIF like Initiators, Logic Solver & Final Control element, hence it is implied on actuated valve OEM to provide all necessary information viz SIL Certification, Functional Safety Manual, PFDAVG, SFF, TProof,, NE, S, D for individual devices of actuated valve & then complete package i.e. full actuated valve.

12.1.10 Details of manufacturing / testing facilities available with the bidder and rated production capacity. 12.1.11 Detailed bar chart showing different stages of design, manufacture, testing and dispatch schedules. 12.1.12 Deviations from specifications and attachments if any. 12.1.13 QAP formats duly filled and signed. 12.1.14 Confirmation regarding the codes & standards specified for different works. 12.1.15 List of recommended spares and accessories for valves &actuators for startup & commissioning. 12.1.16 List of recommended spares and accessories for valves & actuators for 2(two) years normal operation. 12.1.22 Guarantee for performance, workmanship & materials of construction. 12.2 12.2.1 Documentation after Purchase Order placement: Within three weeks of placement of order, the Manufacturer shall submit six copies of, but not limited to the following drawings/ documents for Owners approval: a) Sizing of actuator & selected model for approval. b) Detailed sectional arrangement drawings showing all parts with reference numbers and material specifications. c) Assembly drawings with overall dimensions and features. d) Hazardous area classification for valve accessories, electrical power consumption for each type and size of valve for approval e) Installation requirements f) QA plan for approval Manufacture of valves shall commence only after approval of the above documents. Once the approval has been given by Owner, any changes in design, material and method of Manufacture shall be notified to Owner whose approval in writing of all changes shall be obtained before the valve is manufactured.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 21 of 31

12.2.2

Manufacturer shall submit one reproducible and six copies of the following: a) Test certificates as specified in specification. Inspection certificates & test reports shall be supplied for all mandatory test as per the applicable codes. b) Manual for installation, erection, maintenance and operation instructions, including a list of recommended spares for the valves. Details of corrosion resistant paint to be applied on the valves.

c) 12.2.4

Material test and analysis certificates (physical properties, chemical composition & heat treatment report) shall be furnished for the valves supplied. Material test certificates for other parts shall also be furnished during inspection. Other relevant information/drawings/ documents as required by Owner. All the above documents shall be in addition to those mentioned in individual specifications of valves. Documentation & Drawings: Six sets of final documentation shall be submitted in hardcopy and softcopy.

12.2.6 12.2.7 12.3

12.3.1.

General arrangement/ assembly drawings showing all features and relative positions and sizes of vents, drains, actuator, painting, coating and other external parts together with over all dimensions, Sectional drawing showing major parts with reference numbers and material specification , In particular a blow-up drawing of Disc-seat assembly. Sizing of actuator & selected model with torque details for valves & actuators Overall general arrangement and dimensional cross sectional drawings of valves, showing part list, material list, weights etc. Actuator Make, Model, details of selection based on torque, air & electrical power consumption for each type and size of valve. Inspection certificates & test reports shall be supplied for all mandatory test as per the applicable codes. Operation and maintenance manual. Installation requirements. Calibration certificates, Technical catalogue for valves, actuators & all accessories mounted on valve.

12.3.2. 12.3.3. 12.3.4. 12.3.5. 12.3.6. 12.3.7. 12.3.8.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 22 of 31

13.0

COMMISSIONING ASSISTANCE & WARRANTIES AND TRAINING:

13.1 Vendor shall depute his commissioning engineer to all locations of IOCL/BPCL/HPCL as covered in Purchase order for commissioning supervision of valves and actuators & stabilization of valve & actuators operations without any extra charges. The representative shall ensure that the actuator is commissioned successfully. All expenses for site services shall be borne by manufacturer/vendor bidder 13.2 Vendor shall provide warranty for the performance of valves for 18 months from date of dispatch or 12 months from date of installation, whichever is later subject to not exceeding 24 months from date of dispatch. Manufacturer shall have / develop adequate service support in India to provide technical after sales service in India with in 48 hrs. Notice & shall guarantee supply of parts, services for at least 10 years for all valves supplied by way of an undertaking. Site training ( At Owner works) : The scope of work of vendor shall include coordination, arranging faculty, bring them to Owner's training center, arranging lodging and boarding, transportation etc. for Training of Owner's personnel. Owner's responsibility will be limited to providing Training hall with all requisite training aids and arranging food / snacks during training session. The training program will comprise of classroom training and explanation of details of valves. The group to be trained will comprise of persons from all disciplines of maintenance, operation and other associated departments. The specialist installation / commissioning engineer(s) of valves the training covering operational and maintenance aspects. will conduct

13.3

13.4

Training shall be arranged for Multidisciplinary group. Vendor shall arrange to provide one day trainings at site in all the regions to appraise Purchasers engineers / operators on operations & maintenance of valves. (One day Training at 10 locations in India for 12-15 persons each) 13.5 (Training at vendor works): The scope will include co-ordination for arranging training for officers at vendor works for 3-4 days. The group deputed for training will comprise of two multi-disciplinary groups of 15 officers each drawn from operation, maintenance departments of all the 3 purchasing companies with a group leader. All lodging and boarding and traveling expenses of IOCL/BPCL/HPCL personnel will be borne by owners. However all requisite training material like literature/documents shall be provided by the vendor. Vendor shall include cost of such training in their offer. 13.6 Manufacturer shall guarantee that the materials and machining of valves and fittings comply with the requirements in this specification and in the Purchase

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 23 of 31

Order. 13.7 Manufacturer is bound to replace or repair all valve parts which should result defective due to in adequate engineering or to the quality of materials and machining. If valve defect or malfunctioning cannot be eliminated, Manufacturer shall replace the valve without delay. Any defect occurring during the period of Guarantee shall be attended to by making all necessary modifications and repair of defective parts free of charge to the Owner as per the relevant clause of the bid document. All expenses shall be to Manufacturers account. Site Service/Site Visits by Experts for TAS . ROSOVs (ESDVs): Valve Vendor shall depute expert service engineer/engineers to site, for co-ordination with TAS contractor for complete integrated testing of the system & stroking of the valves

13.8 13.9

14.0 14.1

15.0 15.1

Painting, Marking and Shipment Actuated Valve assembly surface shall be thoroughly cleaned, freed from rust and grease and applied with sufficient coats of corrosion resistant paint. Surface preparation shall be carried out by shot blasting to SP-6 in accordance with Steel Structures Painting Council Visual Standard SSPC-VIS-1. Manufacturer shall indicate the type of corrosion resistant paint used in the drawings submitted for approval. All valves shall be marked as per API 609.The units of marking shall be metric except Nominal Diameter which shall be in inches. Marking shall be done by diestamping on the cover or on the housing. Valve ends shall be suitably protected to avoid any damage during transit. All threaded and machined surfaces subject to corrosion shall be well protected by a coat of grease or easily removable Rust Preventative material. All valves shall be provided with suitable protectors for flange faces, securely attached to the valves. All valve openings shall be positively sealed by suitable blanking plates or plastic plugs. Adhesive tape sealing of opening without blanking plates or plugs will not be acceptable. All sealant lines and other cavities of the valve shall be filled with sealant before shipment. Packaging and shipping instructions shall be as perAPI609 and procurement documentation. Packaging shall be in accordance with the Project packing Specification. All valves shall be transported in the fully close condition

15.2 15.3

15.4

15.5 15.6

15.7

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 24 of 31

15.8

On packages, following shall be marked legibly with suitable marking ink: a) Order Number b) Manufacturers Name c) Valve size and rating d) Tag Number at least on 3 sides of packing, legible from distance. e) Serial Number

16.0

Storage Valves and components must be stored under cover and out of contact with the ground and SHALL NEVER BE EXPOSED TO WETTING BY SALT WATER OR SALT

16.1

SPRAY.

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 25 of 31

DATA SHEET VALVE 1 2 Valve Size Valve Type As per BQO DESIGN PARTICULARS Triple Offset high performance , metal to metal seated, non-rubbing, torque seated, double flange end, quarter turn, anti-static, anti-blow out stem arrangement butterfly valve. Complete actuated valve shall be SIL3 capable certified by third party agencies like TUV/Exida API 609 As per API 609, Long Pattern API 598 API 6FA/API-607-Vth Edition, Zero leakage before, during after fire. 150# 90 Degrees Bi-directional, tight shut-off in either direction Required Required CONSTRUCTION Cast (in Single Piece) Cast Bar-forged (No casting) Double flanged as per ANSI B 16.5RF 150#, RF, 63-125 AARH, smooth finish ASTM A216 Gr. WCB ASTM A216 Gr. WCB/ASTM A105 UNS S 31801 Duplex SS+ Graphite ASTM A182F6a UNS S31600 ASTM A 516 UNS 31600+ Graphite Stellited Gr. 21 Weld Overlay SS 316 SS 316/ Hardfaced /Cobalt based alloy TESTING 1.5 times the flange rating (30 bar #150) 22 bar #150, test duration as per standard NA (6 bar # 150)

3 4 5 6 7 8 9 10 11

Mfg. Standard Face to Face Inspection and Testing Fire Safe ANSI Class Rated Travel Flow direction Fire Safe Anti Static Device

12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

Body Disc Stem End Connection Flange & finish MATERIAL Body Disc Seal Ring Stem Bushing Disc Retainer Flange Disc and Bottom Flange Seat Pin/Nut/Washers Thrust Bearing Body Hydro-test Seat Hydro-test Pneumatic Seat

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 26 of 31

30

Test Leakage Class required Safety Integrity Level SIL Certification Std. Third Party Certification Dust Excluder Quick Exhaust Valve Fire Safe Box Volume/ Buffer Tanks Port Protector Pilot Valve Make & Model Weight in kgs Design Pressure Design temperature Fail Action Valve Torque+25% safety margin

Zero Leakage/ bubble tight shutoff SPECIAL REQUIREMENTS SIL 3 capable for actuated valve when it is Type A Device IEC 61508 TUV/Exida ACCESSORIES FOR ROSOV N.A. N.A. N.A. N.A. N.A. BTS BTS BTS PROCESS DATA As per #150 -5 to +65 deg. Centigrade Fail to Close BTS

31 32 33

34 35 36 37 38 39 40 41 42 43 44 45

General Notes: 1. 2. 3. 4. 5. BTS: Bidder to Specify Approved makes for Air Filter: Norgren, Festo, SMC, Legris Approved makes for Proximity limit switches: Honeywell, Topworks Approved makes for Pneumtic fittings & tubes: Swagelok, Sandvik, Parker Approved makes for Exhaust Valve: Scradder, SMC, Festo, Legris

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 27 of 31

DATA SHEET ACTUATOR 1 Sizing basis 1.25 times the valve torque for shut-off pressure and less than valve stem shear torque DESIGN PARTICULARS Pneumatic , spring return, air fail to close, quarter turn, self-lubricating type, suitable for TOBV on-off control, complete actuated valve shall be SIL3 capable when classified as Type A device, certified by third party agencies like TUV/Exida Scotch & Yoke design for valves of all sizes 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 SIL3 capable when classified as Type A device Spring action Close (Air Fail to close) SCOTCH & YOKE (CONSTRUCTION/ MATERIAL) Housing Carbon steel Yoke Carbon Steel Yoke Bearing Bronze Guide Block Alloy Steel Guide Bar Alloy Steel Guide Block Steel+ Bronze +PTFE Bearing Travel Stop Carbon Steel Screw Piston Carbon Steel Piston Rod Alloy Steel Piston Rod Seal NBR Rubber Piston Rod Steel + Bronze +PTFE Bearing Piston Seal O NBR Rubber Ring Cylinder Carbon Steel Cylinder Seal O NBR Rubber Ring Tie Rod Alloy Steel Spring Carbon Steel Spring Container Carbon Steel Guide Rod Alloy Steel Container Rod Alloy Steel Rod Bearing Steel + Bronze+ PTFE AIR SUPPLY Max Allowable 10 kgs/ sq cms (g) Min. Pressure 4.0 Pressure kgs/sqcms (g)

Actuator Type

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 28 of 31

25 26

Available Air Supply Pneumatic Tubing Orientation Stroke Time Hazardous Area Protection Ingress Protection Air Filter Regulator Solenoid Valves Valve monitor Air Relief Valve Local Field Panel Limit Switches

4.5 to 6.5 kg/sqcms (g) size SS 316, 0.049 thickness OTHER 90 deg. To pipeline axis Open: 1 inch per Sec Close: greater than 1 inch per Sec but less than 2 inch per sec. Zone 1, Gr. IIA/IIB, T3 IP 65 as per IEC 529 ANCILLARIES Metal body, 5 micron gauge, SS tubing and auto drain As per SV Data Sheet Required Not required Required Micro switches -SPDT, 2 nos for each ROSOV, Contact rating: 230 V AC/ 24 V DC Operation. IP 65, Die Cast Aluminium, 2 cable entries with certified plugs BTS BTS BTS in Ltrs (for one cycle Open-Close-Open) Rotork, Biffi, Neles, Adams,Emerson

27 28 29 30

31 32 33 36 37 38

39 40 41 42 Notes:

Make & Model Weight in kgs Air Consumption Approved makes

1. Field Push button outside the dyke required for closing of the valve 2. Based on closing time requirement, bidder shall provide flow control valve in actuator vent and with suitable locking arrangement applied after proper setting. 3. These ROSOVs are part of SIS and used as Emergency Shut Down Valves for tank overfill protection. Complete actuated valve assembly shall be SIL3 capable as per IEC 61508, certified by third party agencies like Exida/TUV. To calculate PFD (AVG) , the ESDV PFD and SFF is required. Bidder shall submit the same with the technical offer along with third party certifications and Functional Safety Manual. 4. All accessories like SOV shall also be SIL3 capable. Individual SIL certification shall be submitted. 5. The actuator shall incorporate a safety feature such as a spring cartridge to prevent the accidental release of spring tension during servicing. The actuator spring shall be fully enclosed in a metal housing and permanently treated to resist atmospheric corrosion. The type of

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 29 of 31

treatment shall be manufacturers standard unless otherwise stated. Cadmium or zinc plating (galvanizing) of actuator spring is not permitted. 6. Instrument Air filter with pressure gauge shall have built-in relief suitable for 10 kgs/sqcms to prevent over-pressurization. 7. At no time shall a pressure regulator or any other means be used to limit/reduce actuator torque. The actuator shall withstand the maximum allowable air supply pressure. 8. Actuator design shall be self-lubricating type

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 30 of 31

DATA SHEET SOLENOID VALVE 1 2 Quantity Valve Type One for each ROSOV GENERAL 3/2 Direct acting universal type, suitable for fail safe operation (de-energised to trip), SIL2 Certified having capability for use in SIL 3 application. Instrument Air 4.0/7.5 kgs/sq.cms. 10 kgs/sq.cms BTS 65 Deg. Centigrade 95% Relative Humidity Zone 1, Gr. IIA/B, T3 SOLENOID VALVE DATA 3 way Universal Direct BTS BTS NPTF SS316 SS316 PTFE IP 65, Flameproof-Zone 1, IIA/B, T3 Certified Continuous

3 4

Fluid Fluid Data a. Inlet Pressure Min./Max. b. Design Pressure (Shutoff diff.) c. Flow d. Temperature Humidity Area Classification

5 6

7 8 9 10 11 12 13 14 15 17 18

Type- Operation Action Body Size Port End Connection Body Material Trim Material Packing-soft seals Enclosure Protection Type of Energisation Power Supply a. Operating VoltageEnergisation b. Drop Out Voltage c. Power Consumption Coil a. Type of Coil b. Style of coil

230 V AC / 50 Hz BTS BTS Single-Suitable for specified Haz. Area Class

19

JOINT WORKING GROUP (IOCL/BPCL/HPCL)

DocNo: ROSOV/ INDU S TR Y SPECS/001 Rev: 2 Page 31 of 31

c. Insulation class d. Cable Entry e. Cable Gland f. Terminals g. Other wetted parts h. Leakage

Standard Class F or better as per IEC60085/IS1271 NPT(F)+Plug SS 304, double compression Internal for 2.5sqmm conductors Vendors design Zero Leakage SPEC. ACC. Solenoid valves with mounting brackets SS 304 Installation/ Operation instructions to be supplied CCOE/CMRI type approvals to be submitted As required Shall be supplied suitable for haz. area classification ASCO/ Herion (Norgren)

20 21 22 23 24 26 27

Mounting Name Plate DocumentsCatalogue/Manual Certification SS tubing Cable glands/Reducers/Plug s/Shrouds Approved makes for SOV

Notes: 9. Suitable anti-vibration terminal blocks shall be provided for cable terminations. Terminals shall be clip-on type (screw less), Phoenix/ Wago make 10. Flameproof Nickel plated brass, double compression cable glands shall be provided. Cable glands shall be covered with shroud. Extra cable entry shall be plugged with suitable E Exd Plug.

Вам также может понравиться

- Company Profile - PetrominДокумент26 страницCompany Profile - Petrominapi-306897329100% (2)

- Enterprise Data Management PDFДокумент18 страницEnterprise Data Management PDFRajesh MurugesanОценок пока нет

- How Cathay Pacific Leveraged IT to Support Business GrowthДокумент2 страницыHow Cathay Pacific Leveraged IT to Support Business Growthranjeeeth8569100% (1)

- PMS PDFДокумент215 страницPMS PDFAlvin Smith100% (4)

- CODES AND STANDARDS TITLESДокумент2 страницыCODES AND STANDARDS TITLESKamal SkОценок пока нет

- Coriolis Mass Flow MeterДокумент2 страницыCoriolis Mass Flow MeterSreejesh SundaresanОценок пока нет

- PIP PCECV002-2018 Pressure Regulators Selection GuidelinesДокумент5 страницPIP PCECV002-2018 Pressure Regulators Selection Guidelines刘旭Оценок пока нет

- Stockdale Method Roundabout PDFДокумент50 страницStockdale Method Roundabout PDFAnonymous O7BzqVvmIОценок пока нет

- MSG3Документ14 страницMSG3carrot123456Оценок пока нет

- Honda Sales ProjectДокумент72 страницыHonda Sales Projectsurendar100% (2)

- Export PDS To Smart 3D User's GuideДокумент6 страницExport PDS To Smart 3D User's Guidedaisyduck2013Оценок пока нет

- 50B10 Standard Assembly LibraryДокумент78 страниц50B10 Standard Assembly Libraryishu vohraОценок пока нет

- PZ D CS Pi SP 015 02Документ60 страницPZ D CS Pi SP 015 02epbamdadОценок пока нет

- Vibration Analysis 2Документ6 страницVibration Analysis 2Loxman ZahariОценок пока нет

- PVRVДокумент4 страницыPVRVbkkbrazil100% (1)

- Flow Measurement StandardДокумент26 страницFlow Measurement StandardDeborah MalanumОценок пока нет

- RotameterДокумент9 страницRotameterSimbu Arasan100% (1)

- 123939-60A3 R1 Instrumentation Symbols and IdentificationДокумент31 страница123939-60A3 R1 Instrumentation Symbols and IdentificationSaid SalemОценок пока нет

- API 2000 5th Vs 6th FinalДокумент21 страницаAPI 2000 5th Vs 6th FinalCepopaky CangkrukanОценок пока нет

- SEM-9487E Breather ValveДокумент8 страницSEM-9487E Breather ValveRexx Mexx100% (1)

- Technical Notes and Specifications Part CДокумент29 страницTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- Datasheet of Butterfly ValveДокумент2 страницыDatasheet of Butterfly Valvedhaval3gОценок пока нет

- V Cone Flowmeter PDFДокумент16 страницV Cone Flowmeter PDFRajesh KrishnamoorthyОценок пока нет

- Control Valve MR Tender Specifications 79649aДокумент20 страницControl Valve MR Tender Specifications 79649asyamsulОценок пока нет

- Hook Ups PDFДокумент8 страницHook Ups PDFAnonymous d7Jde8Оценок пока нет

- Datahseet For Strainer With Air EliminatorДокумент4 страницыDatahseet For Strainer With Air Eliminatorvinoj chandranОценок пока нет

- 052KP 01 New 24" Gas Transmission Pipeline To Alkhalij Power Generation Station Control /ESD and Operating Philosophy 052KP 01 PHL IN 001, Rev.01Документ26 страниц052KP 01 New 24" Gas Transmission Pipeline To Alkhalij Power Generation Station Control /ESD and Operating Philosophy 052KP 01 PHL IN 001, Rev.01Jabel Oil Services Technical DPTОценок пока нет

- Data Sheet Daniel Model 788 Digital Control Valve en 43714Документ16 страницData Sheet Daniel Model 788 Digital Control Valve en 43714dreyko77Оценок пока нет

- N2 Regulator and Gauges DatasheetДокумент4 страницыN2 Regulator and Gauges DatasheetpavanОценок пока нет

- B.3.7 - Control Valves, Shut Down, Self Acting Regulators SpecДокумент11 страницB.3.7 - Control Valves, Shut Down, Self Acting Regulators SpecThuc TruongОценок пока нет

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFДокумент612 страницGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahОценок пока нет

- Ongc 2004a Rev 7Документ78 страницOngc 2004a Rev 7dzardoniОценок пока нет

- Nit 1 1Документ102 страницыNit 1 1Gaurav TripathiОценок пока нет

- DWS 2510 Valve SpecificationДокумент7 страницDWS 2510 Valve SpecificationsudjonoОценок пока нет

- Instrumentation Design BasisДокумент176 страницInstrumentation Design BasisHarshkumar Patel100% (1)

- Jockey PumpДокумент5 страницJockey PumpRobson Custódio de SouzaОценок пока нет

- PIP PCDPS001-2018 Packaged Equipment Instrumentation Documentation Requirements Sheet and InstructionsДокумент10 страницPIP PCDPS001-2018 Packaged Equipment Instrumentation Documentation Requirements Sheet and Instructions刘旭Оценок пока нет

- Line Sizing Factors and Criteria for Liquids and GasesДокумент3 страницыLine Sizing Factors and Criteria for Liquids and GasesWade ColemanОценок пока нет

- PH Analyser Manual PH-13-SДокумент22 страницыPH Analyser Manual PH-13-SSunil Chouhan100% (1)

- Analyser Sample SystemsДокумент19 страницAnalyser Sample Systemsaslam.amb100% (1)

- 107 01r0Документ23 страницы107 01r0losmoscasbr-1Оценок пока нет

- 015-FH-1002 (Rev.1) PDFДокумент8 страниц015-FH-1002 (Rev.1) PDFarjun PV RaoОценок пока нет

- Flowmeter Selection Guide OverviewДокумент2 страницыFlowmeter Selection Guide OverviewtusharmhaОценок пока нет

- Induced Vibration HXДокумент7 страницInduced Vibration HXPatricia.PОценок пока нет

- Design Basis - Package - B224-999-80-43 EDB-1002Документ12 страницDesign Basis - Package - B224-999-80-43 EDB-1002Esakki muthu100% (1)

- Kpo 00 Elt SPC 00029Документ29 страницKpo 00 Elt SPC 00029rameshqc100% (1)

- Fdocuments - in - Hook Up Flow Aramco PDFДокумент14 страницFdocuments - in - Hook Up Flow Aramco PDFjosejohn1Оценок пока нет

- Solenoid Valve - Which Insulation ClassДокумент2 страницыSolenoid Valve - Which Insulation ClassMohd Firdaus100% (2)

- FN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeДокумент1 страницаFN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeAjay ChodankarОценок пока нет

- SamplingДокумент20 страницSamplingShesharam ChouhanОценок пока нет

- 12 MGDP I 1150 0 (Instr Utility Air Calculation)Документ2 страницы12 MGDP I 1150 0 (Instr Utility Air Calculation)cytech6619Оценок пока нет

- J3 Emergency Shutdown System SpecificationДокумент53 страницыJ3 Emergency Shutdown System SpecificationDinesh BoopalanОценок пока нет

- QR 1008 Fire Pump JockeyДокумент1 страницаQR 1008 Fire Pump JockeyLéandre Ettekri NdriОценок пока нет

- Specification For LP Gas Reciprocating Compressor PackageДокумент25 страницSpecification For LP Gas Reciprocating Compressor Packageashok100% (1)

- 3082-ET-A-005 - Diverter Damper System ManufacturingДокумент137 страниц3082-ET-A-005 - Diverter Damper System Manufacturingmanh hung leОценок пока нет

- 6 44 0006 Rev6Документ415 страниц6 44 0006 Rev6karunaОценок пока нет

- EGP3-03.20 Technical Requirements For Piping ComponentsДокумент31 страницаEGP3-03.20 Technical Requirements For Piping ComponentsMathias OnosemuodeОценок пока нет

- DS For Chlorine Analyzer-Rev-0Документ26 страницDS For Chlorine Analyzer-Rev-0anbesivam87_49857255Оценок пока нет

- Steam-Injected GT ExerciseДокумент9 страницSteam-Injected GT ExerciseYinka AkinkunmiОценок пока нет

- MR ValvesДокумент56 страницMR ValvesIdris SiddiquiОценок пока нет

- NL-WI-236-04 Nozzle Loads EquipmentДокумент3 страницыNL-WI-236-04 Nozzle Loads EquipmentChirag ShahОценок пока нет

- Unit 330Документ22 страницыUnit 330mohamed ghorabОценок пока нет

- Itp: Acidification Vessel: Tag: A-325-02-01-C3Документ8 страницItp: Acidification Vessel: Tag: A-325-02-01-C3Jeroan AyamОценок пока нет

- A 02Документ30 страницA 02senioor2004Оценок пока нет

- Piping and Instrumentation Diagram PID Designer ChecklistДокумент4 страницыPiping and Instrumentation Diagram PID Designer ChecklistHelena MartinsОценок пока нет

- Functional Specification For Deck CraneДокумент31 страницаFunctional Specification For Deck Craneaiyubi20% (1)

- Specification For Lube Oil and Dry Gas Seal SystemДокумент17 страницSpecification For Lube Oil and Dry Gas Seal Systemjahosolaris5512Оценок пока нет

- Associated Sites Quick Bill Payment Bulk Bill Payment Payment History View Bill Lodge A ComplaintДокумент1 страницаAssociated Sites Quick Bill Payment Bulk Bill Payment Payment History View Bill Lodge A ComplaintSharath KrishnanОценок пока нет

- Tender Specs - ROSOV (CH 7 (B) )Документ17 страницTender Specs - ROSOV (CH 7 (B) )Sharath KrishnanОценок пока нет

- Pressure Cycling 2010051Документ6 страницPressure Cycling 2010051Sharath KrishnanОценок пока нет

- 425-3-Cooling Load-2007Документ15 страниц425-3-Cooling Load-2007zulkifroОценок пока нет

- Up 11-22Документ91 страницаUp 11-22Tamjid Kabir100% (2)

- R/C Soaring Digest - Apr 2012Документ68 страницR/C Soaring Digest - Apr 2012Aviation/Space History LibraryОценок пока нет

- Wilson Sporting Goods V Rawlings Sporting GoodsДокумент38 страницWilson Sporting Goods V Rawlings Sporting GoodsDarren Adam HeitnerОценок пока нет

- Mechanical Engineer Resume For FresherДокумент5 страницMechanical Engineer Resume For FresherIrfan Sayeem SultanОценок пока нет

- Tecnotion Torque Motor Brochure Ver 10120150120Документ16 страницTecnotion Torque Motor Brochure Ver 10120150120ElectromateОценок пока нет

- Catalog E EslonValve ManualOperationДокумент72 страницыCatalog E EslonValve ManualOperationAnonymous ItzBhUGoiОценок пока нет

- WPD Wpbwall Fans Catalog 4820Документ24 страницыWPD Wpbwall Fans Catalog 4820beemer03Оценок пока нет

- Add-On Scenery For MS FS2004, FSX & Prepar3D: InstallationДокумент10 страницAdd-On Scenery For MS FS2004, FSX & Prepar3D: Installationrondon9897Оценок пока нет

- Specialty Lubricants: MolykoteДокумент2 страницыSpecialty Lubricants: MolykoteRildo CarvalhoОценок пока нет

- Sharing The SkiesДокумент357 страницSharing The SkiesLava R5s2019Оценок пока нет

- Module 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFДокумент42 страницыModule 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFshareyhou100% (1)

- Nota - 2245047 - Pre Manual Implementation StepsДокумент13 страницNota - 2245047 - Pre Manual Implementation StepsCarlos Manoel SouzaОценок пока нет

- Assam & Nagaland 1Документ218 страницAssam & Nagaland 1Ahmer KhanОценок пока нет

- Using Fare Quote Super Best Buyonthe Galileo CRSДокумент16 страницUsing Fare Quote Super Best Buyonthe Galileo CRSyurka06Оценок пока нет

- 51 105 PVC Dual Pipe - 20 50Документ9 страниц51 105 PVC Dual Pipe - 20 50Ankit PrajapatiОценок пока нет

- Building EstimateДокумент16 страницBuilding EstimateMrinal TalukdarОценок пока нет

- RMA Process Complete Flow SampleДокумент2 страницыRMA Process Complete Flow SampleBharathОценок пока нет

- Cookbook Measuring StrategiesДокумент27 страницCookbook Measuring StrategiesArzillo Salvatore50% (2)

- Actual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsДокумент4 страницыActual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsLovis NKОценок пока нет

- SKF SM 20 - CSTR SpecificationДокумент3 страницыSKF SM 20 - CSTR SpecificationPaweł HejmowskiОценок пока нет

- Rajasthan Power Sector Reforms Act 1999Документ41 страницаRajasthan Power Sector Reforms Act 1999Latest Laws TeamОценок пока нет

- Hoists and Winches: The Hoist & Winch Business Unit ProfileДокумент2 страницыHoists and Winches: The Hoist & Winch Business Unit ProfileMuhammad Rifqi AninditoОценок пока нет

- SOA Suite 10g Developer GuideДокумент47 страницSOA Suite 10g Developer GuideTusharОценок пока нет