Академический Документы

Профессиональный Документы

Культура Документы

insulation cal (绝热厚度计算)

Загружено:

huangjlОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

insulation cal (绝热厚度计算)

Загружено:

huangjlАвторское право:

Доступные форматы

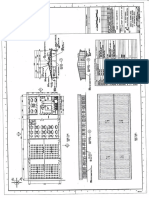

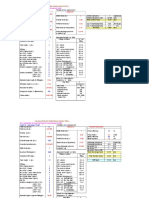

anti - condense thickness calculation (anit-sweat) as per GB/T 15586-1995 a plane sibgle layer (DN>1000mm) la = 0.

055359 conduct coefficient W/(m.K) t= ta = ts = 39 environment temperature ( summery) 35 insulation ouside surface temperature

foam galss la=0.05+0.000233tm =

o o o

7 pipe or equipment outidse surface temperature

C C C

as = 8.14 heat exchanger coefficient insulation thinckness = la(ts-t)/(as(ta-ts))= 0.04760602 m = 47.60601966 mm

W/(m2K)

0.055359

ts=td+3= wind speed v=

35 30 economy as= 17.07723

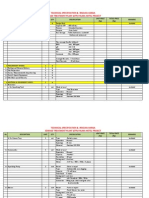

heat insulation as per SH 3010-2000 b . Circicle thickness diameter <1m la = 0.08205 conduct coefficient t= ta = ts = as = Di= Do= Do*lnDo/Di= 2(la/as*)((t-ts)/(ts-ta))= insulation thinckness =

4.3.2.2-4.3.2.3 W/(m.K)

700 pipe or equipment outidse surface temperature 10 environment temperature ( summery) 35 insulation ouside surface temperature 8.141 heat exchanger coefficient 0.82 piping or equipment diamter 1.25 piping or equipment insulation diamter 0.526993113 if the left two figue is equal then claculation is OK 0.536182287 (Do-Di)/2= 0.215 = 215

super galss fiber la= 0.043+0.00011tm =

o o o

0.08205

e temperature

C C C ts=td+3= wind speed v= 6 30 economy as= 17.07723

W/(m2K)

Do is OK

m m (by guess)

al then claculation is OK m mm

Вам также может понравиться

- Tanks Hell Min ThicknessДокумент1 страницаTanks Hell Min ThicknesshuangjlОценок пока нет

- Tempo Craft MixДокумент2 страницыTempo Craft MixkamlОценок пока нет

- Cost To Cost (Price List)Документ4 страницыCost To Cost (Price List)vikramnathawatОценок пока нет

- Smart Glass ProcedureДокумент117 страницSmart Glass ProcedureFrancis DhanarajОценок пока нет

- Furnace Area & VolumeДокумент22 страницыFurnace Area & VolumeRajnath Rajbhar PanchamОценок пока нет

- MTO For StructureДокумент2 страницыMTO For StructureRajnath Rajbhar PanchamОценок пока нет

- 2-Year 2014 BaseДокумент25 страниц2-Year 2014 BaseMohamed MolhamОценок пока нет

- C2 PN 003 Manpower Recruit - 0Документ8 страницC2 PN 003 Manpower Recruit - 0ebsmsartОценок пока нет

- BIDBOLLAND PILE Schedule Equipment Load ArhДокумент3 страницыBIDBOLLAND PILE Schedule Equipment Load Arhsivasan10006098Оценок пока нет

- AFMC (Medical) Solved Paper 2013 PDFДокумент32 страницыAFMC (Medical) Solved Paper 2013 PDFAnkur BanerjeeОценок пока нет

- Hilti Core CuttingДокумент5 страницHilti Core CuttingSarinОценок пока нет

- Request Form JaimonДокумент306 страницRequest Form JaimonjaimonjoyОценок пока нет

- Drawing Atap WP 7Документ1 страницаDrawing Atap WP 7Fresly PatriaОценок пока нет

- Man Hour EstimationДокумент2 страницыMan Hour EstimationSergio SmithОценок пока нет

- Vessel'S Midnight Ullage ReportДокумент29 страницVessel'S Midnight Ullage ReportnawhiОценок пока нет

- Technical Specification & Rincian Harga Sewage Treatment Plant (STP) Palma Hotel ProjectДокумент6 страницTechnical Specification & Rincian Harga Sewage Treatment Plant (STP) Palma Hotel ProjectrudiawanОценок пока нет

- S-000-1654-0990V - 0 - 0010 Human Resource Management Plan NSRP Nghi SonДокумент7 страницS-000-1654-0990V - 0 - 0010 Human Resource Management Plan NSRP Nghi SonjenniferОценок пока нет

- Pipe CalculationДокумент10 страницPipe CalculationTrishul Nath PallayОценок пока нет

- DATASHEETДокумент3 страницыDATASHEETJiJO J JOSEОценок пока нет

- Foundation Excavation Cost Estimate Excel SheetДокумент2 страницыFoundation Excavation Cost Estimate Excel Sheethakim imtiyazОценок пока нет

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CДокумент8 страницSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CAgus MarpaungОценок пока нет

- G LST 001 Ab Tank Farm in ProgressДокумент270 страницG LST 001 Ab Tank Farm in ProgressPhilippe AlexandreОценок пока нет

- Ventilation CalculationДокумент6 страницVentilation CalculationJaks JaksОценок пока нет

- Calculation Relief LoadДокумент4 страницыCalculation Relief LoadElias EliasОценок пока нет

- Copy of Work Pack SampleДокумент9 страницCopy of Work Pack Samplesreedar20052185Оценок пока нет

- Esp Calculation Exhaust Air-TaДокумент4 страницыEsp Calculation Exhaust Air-TaAshiq NishmaОценок пока нет

- 2SBR REACTOR - 1MLD - BOD Only PDFДокумент7 страниц2SBR REACTOR - 1MLD - BOD Only PDFHRK65Оценок пока нет

- Load ScheduleДокумент16 страницLoad ScheduleXander Delinya100% (1)

- LC1 - C2001-33BQ-0000 - Pump Room - Rev01Документ111 страницLC1 - C2001-33BQ-0000 - Pump Room - Rev01suheil samaraОценок пока нет

- 1.0 Pipe LoadingsДокумент103 страницы1.0 Pipe LoadingsMoses LugtuОценок пока нет

- TBA SCRUBBER SYSTEM GFL B-15-KGДокумент23 страницыTBA SCRUBBER SYSTEM GFL B-15-KGsachin.patelОценок пока нет

- TDS Futura AS Euk GB PDFДокумент4 страницыTDS Futura AS Euk GB PDFFu AdОценок пока нет

- CBD Apartments Boq EstimateДокумент271 страницаCBD Apartments Boq EstimateRiddell P JereОценок пока нет

- Master Deliverable Register: C Electrical C1Документ2 страницыMaster Deliverable Register: C Electrical C1LaelaeОценок пока нет

- Comments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplyДокумент2 страницыComments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplybecpavanОценок пока нет

- Pipe Eng Codes PDFДокумент1 страницаPipe Eng Codes PDFkamlОценок пока нет

- Price List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevДокумент67 страницPrice List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevRenny DevassyОценок пока нет

- BFV Nom... H... en - Mot Valve v9 Nom - (Actuator Nom) - NewДокумент6 страницBFV Nom... H... en - Mot Valve v9 Nom - (Actuator Nom) - NewHans MuntheОценок пока нет

- Pressure RegulatorДокумент2 страницыPressure RegulatorSemangraya76Оценок пока нет

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksДокумент2 страницы7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPОценок пока нет

- Boq D2 - CTДокумент2 страницыBoq D2 - CTNirman EngineeringОценок пока нет

- BunkerHose DatasheetДокумент2 страницыBunkerHose Datasheetmohit_mg100% (1)

- Waste Management in Silcotub (Cathodic Blocks & High Alumina Waste Recovery 18-19)Документ4 страницыWaste Management in Silcotub (Cathodic Blocks & High Alumina Waste Recovery 18-19)Anca ElenaОценок пока нет

- Design For EO & PO Scrubbing System (Rev.02) - Case2Документ70 страницDesign For EO & PO Scrubbing System (Rev.02) - Case2Ashish PawarОценок пока нет

- Lvgo Water Cooler Data Sheet E-0107Документ6 страницLvgo Water Cooler Data Sheet E-0107mohsen ranjbarОценок пока нет

- UG&AG Tanks Cost BreakdownДокумент11 страницUG&AG Tanks Cost Breakdownkoraina2015Оценок пока нет

- Project Details Stage 2Документ61 страницаProject Details Stage 2Sagar WayakoleОценок пока нет

- Walls ConstructionДокумент2 страницыWalls Constructioncomekib310Оценок пока нет

- Standard Data Book (Road & Bridge)Документ10 страницStandard Data Book (Road & Bridge)Anonymous aNyCxZWОценок пока нет

- Index of Study MaterialsДокумент27 страницIndex of Study Materialsdebu1985Оценок пока нет

- Progress Piping GCC CaCo3Документ66 страницProgress Piping GCC CaCo3Alif Rahmat FebriantoОценок пока нет

- Bill of Entry / Export A Office of Destination: ProducedДокумент6 страницBill of Entry / Export A Office of Destination: ProducedMd. Jonirul Islam100% (1)

- Prepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaДокумент2 страницыPrepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaJojolasОценок пока нет

- Pre-Qualification Document: E-Mail: - WebsiteДокумент29 страницPre-Qualification Document: E-Mail: - WebsiteRomi MailandiОценок пока нет

- Heat Load Calculation For Pumping Station - 13Документ6 страницHeat Load Calculation For Pumping Station - 13Deepak JoyОценок пока нет

- Bio Gas B1Документ122 страницыBio Gas B1lataОценок пока нет

- BORL Feedback: Workshop On Project Execution StrategiesДокумент24 страницыBORL Feedback: Workshop On Project Execution StrategiesVinothrajaОценок пока нет

- 132kv Cables For Transformer Feeder, Cables in Duct at 9029Документ4 страницы132kv Cables For Transformer Feeder, Cables in Duct at 9029Muhammad MahmudОценок пока нет

- Design Calc Sheet - Septic Tank Rev1 15-03-09 - 200Документ12 страницDesign Calc Sheet - Septic Tank Rev1 15-03-09 - 200Bok MortegaОценок пока нет

- Bolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21Документ30 страницBolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21huangjlОценок пока нет

- Bolt Tension & Torque CalculationДокумент1 страницаBolt Tension & Torque CalculationhuangjlОценок пока нет

- Vibration Analysis PDFДокумент6 страницVibration Analysis PDFBipin RohitОценок пока нет

- Estimating TemplateДокумент16 страницEstimating TemplatehuangjlОценок пока нет

- Fuel Pump HP CalculationsДокумент8 страницFuel Pump HP CalculationshuangjlОценок пока нет

- Heat TransferДокумент1 страницаHeat TransferhuangjlОценок пока нет

- GB5782 外形尺寸及重量表 六角头 -C级 GB5780Документ2 страницыGB5782 外形尺寸及重量表 六角头 -C级 GB5780huangjlОценок пока нет

- Ydraulic Alculations: B W B HДокумент1 страницаYdraulic Alculations: B W B HhuangjlОценок пока нет

- NPSH CalculationДокумент1 страницаNPSH CalculationhuangjlОценок пока нет

- Surge Tank Size and CostДокумент1 страницаSurge Tank Size and CosthuangjlОценок пока нет

- Tank 2bДокумент1 страницаTank 2bMukeshSharmaОценок пока нет

- Pump CalculationДокумент4 страницыPump CalculationhuangjlОценок пока нет

- Air Cooled Data SheetДокумент1 страницаAir Cooled Data SheethuangjlОценок пока нет

- 吊耳计算Документ4 страницы吊耳计算huangjlОценок пока нет

- Fuel Pump HP CalculationsДокумент8 страницFuel Pump HP CalculationshuangjlОценок пока нет

- Spreadsheet For Cooling Tower PM Emissions Calculations (2012!03!09 Version)Документ1 страницаSpreadsheet For Cooling Tower PM Emissions Calculations (2012!03!09 Version)huangjlОценок пока нет

- Padeye CalДокумент6 страницPadeye Calhuangjl100% (1)

- 吊耳计算Документ4 страницы吊耳计算huangjlОценок пока нет

- External Pressure DesignДокумент395 страницExternal Pressure DesignrsubramaniОценок пока нет

- Shell and Tube Heat ExchangerДокумент19 страницShell and Tube Heat Exchangerhuangjl33% (3)