Академический Документы

Профессиональный Документы

Культура Документы

Heavy Weight Drill Pipe

Загружено:

scribd66aАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Heavy Weight Drill Pipe

Загружено:

scribd66aАвторское право:

Доступные форматы

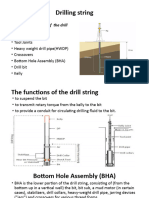

Heavy Weight Drill Pipe Mempunyai dinding yang tebal dengan berat 2 - 3 kari dari drill pipe standard.

Kegunaan penggunaan heavy weight driil pipe adarah sebagai berikut : Mengurangi kerusakkan pipa dengan adanya zona transisi. Mengurangi penggunaan drill collar Menghemat biaya directional drilling, mengurangi torque dan

kecenderungan perubahan kemiringan Drill pipe jenis ini berfungsi sebagai pemberat rangkaian pipa bor pada kondisi-kondisi khusus, misalnya pada waktu terjadi down hole problem, seperti pipa terjepit (pipe sticking), runtuhan shale (slouging shale) dan sebagainya. Heavy weight drill pipe is the most commonly used in the vertical section of the hole and provides weight on the bit for directional drilling while maintaining more flexibility than a drill collar. Heavy weight is also knows as hevi-wate or HWDP in the industry. Heavy weight drill pipe has a "center upset", also known as wear pad, that increases tube life by protecting the tube from wearing on the outer diameter by keeping the tube away from the hole wall. It also reduces hole drag and differential sticking problems. The walls of heavy weight drill pipe are thicker and have longer upsets compared to conventional drill

pipe, as well as being stronger with high tensile strength. There are a variety of specifications of heavy weight drill pipe. Heavyweight drill pipe (HWDP) may be used to make the transition between the drill collars and drill pipe. The function of the HWDP is to provide a flexible transition between the drill collars and the drill pipe. This helps to reduce the number of fatigue failures seen directly above the BHA. A Heavy Weight Drill Pipe (HWDP) looks like a normal drill pipe except for an upset centered along the tube which helps to prevent excessive buckling. HWDP is used as a transitional stiffness section, typically between the stiff and rigid drill collars and the relatively light and flexible drill pipe joints to reduce fatigue failures directly above the bottom hole assembly. Its wall thickness is up to 3 times that of a similar-sized normal drill pipe to add additional weight to the bit. HWDP is used most commonly in directional drilling because it bends more easily and helps to control torque and fatigue in high-angle operations. HWDP is manufactured in accordance with API Spec. 7/7-1 guideline

Вам также может понравиться

- Revolutionary Drill Pipe WiperДокумент2 страницыRevolutionary Drill Pipe WiperSid ShahОценок пока нет

- 05 Oil Field Tubulars and HydraulicsДокумент38 страниц05 Oil Field Tubulars and HydraulicsAly RasyidОценок пока нет

- WR Retrieving Tool Product DatasheetДокумент2 страницыWR Retrieving Tool Product DatasheetEvolution Oil ToolsОценок пока нет

- Rope SocketДокумент4 страницыRope SocketJohnОценок пока нет

- BSPT Thread Sizes and DimensionsДокумент3 страницыBSPT Thread Sizes and DimensionsOrlando Rebelo100% (1)

- Wash OverДокумент2 страницыWash OverSegundo VillenaОценок пока нет

- Ring Type Joint Gaskets Styles: R, RX, BXДокумент2 страницыRing Type Joint Gaskets Styles: R, RX, BXiswantmachooОценок пока нет

- SARA Ring GasketДокумент4 страницыSARA Ring Gasketbehnam197Оценок пока нет

- Drilling The Well: Figure 77. Variations in Hole Diameter Caused by Differences in Sedimentary Rock LayersДокумент7 страницDrilling The Well: Figure 77. Variations in Hole Diameter Caused by Differences in Sedimentary Rock LayersweldsvОценок пока нет

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringДокумент19 страницSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13Оценок пока нет

- D445 Lubricated Fishing Bumper Sub ManualДокумент22 страницыD445 Lubricated Fishing Bumper Sub Manualnjava1978Оценок пока нет

- Toro Drilling Tools CatalogДокумент36 страницToro Drilling Tools CatalogroicinoОценок пока нет

- Drillstring Hardbanding: Arcraft Plasma IndiaДокумент10 страницDrillstring Hardbanding: Arcraft Plasma Indiapavi32Оценок пока нет

- Norris: Steel Sucker Rods & Pony RodsДокумент5 страницNorris: Steel Sucker Rods & Pony RodsRicardo Pulido RamìrezОценок пока нет

- SD Slip ManualДокумент9 страницSD Slip ManualGregory StewartОценок пока нет

- BraceCatalogue 2011 NP ART 7Документ317 страницBraceCatalogue 2011 NP ART 7AlBesselОценок пока нет

- Conozca Soluciones Energéticas: Conceptos de Barreras de PozosДокумент10 страницConozca Soluciones Energéticas: Conceptos de Barreras de PozosAtreya Pacheco Acosta Miguel AngelОценок пока нет

- Blowout Preventer - Wikipedia PDFДокумент70 страницBlowout Preventer - Wikipedia PDFEndhy Wisnu Novindra100% (1)

- SFT-709 Fishing Kit ChecklistДокумент1 страницаSFT-709 Fishing Kit ChecklistJose Antonio Acosta100% (1)

- Norris Polished Rods (P004-V02-072208) - 1Документ5 страницNorris Polished Rods (P004-V02-072208) - 1Rodrigo RuizОценок пока нет

- Centralizers & StopCollarsДокумент19 страницCentralizers & StopCollarsSaurabh Parihar100% (1)

- Tenaris Running Manual 01Документ20 страницTenaris Running Manual 01advantage025Оценок пока нет

- EP046 - Jar Operational Manual - 6Документ8 страницEP046 - Jar Operational Manual - 6bigpimpinmo80100% (1)

- Casing Friendly Hardbanding Facts and MythsДокумент3 страницыCasing Friendly Hardbanding Facts and Mythssdb158Оценок пока нет

- Optimal Spacing For Casing Centralizer PDFДокумент10 страницOptimal Spacing For Casing Centralizer PDFimampranadipaОценок пока нет

- Understanding IU, EU and IEU Drill Pipe UpsetsДокумент2 страницыUnderstanding IU, EU and IEU Drill Pipe Upsetsmadonnite3781Оценок пока нет

- Basic of Drillpipe Tensile Capacity and Its Calculation PDFДокумент5 страницBasic of Drillpipe Tensile Capacity and Its Calculation PDFMokr AchourОценок пока нет

- Gagemaker ProductsДокумент50 страницGagemaker ProductsMelquiades Hernández GonzálezОценок пока нет

- VFP - Vam Eis - en PDFДокумент30 страницVFP - Vam Eis - en PDFZed ZedОценок пока нет

- NV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 ManualДокумент22 страницыNV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 ManualDiana Carolina Rojas TorresОценок пока нет

- "Ticfwg" By-Pass Blanking Plug: (Top No Go)Документ1 страница"Ticfwg" By-Pass Blanking Plug: (Top No Go)Edwin AbelloОценок пока нет

- Chapter 5 - Drill BitДокумент18 страницChapter 5 - Drill BitAbhinav Goyal100% (1)

- 02IDPT Drill Bits #2Документ48 страниц02IDPT Drill Bits #2AboZaidОценок пока нет

- 101937-Technical Unit WR Retrieving Tool 4 1-2Документ4 страницы101937-Technical Unit WR Retrieving Tool 4 1-2Evolution Oil ToolsОценок пока нет

- Drill Pipe MakingДокумент2 страницыDrill Pipe MakingamithakimОценок пока нет

- Tubulars and Tubular Services Catalog: DrilcoДокумент29 страницTubulars and Tubular Services Catalog: DrilcoDoni KurniawanОценок пока нет

- Drill Collar LoresДокумент4 страницыDrill Collar LoresAnsar AkhtarОценок пока нет

- 24 Pilot Mill 2Документ2 страницы24 Pilot Mill 2jorge vargas zapataОценок пока нет

- Iv-0017-21 Overshot Standard X42093Документ1 страницаIv-0017-21 Overshot Standard X42093ivan dario benavides bonillaОценок пока нет

- Drill Pipe ManДокумент46 страницDrill Pipe ManMohamed SaeedОценок пока нет

- DST Slip Joint PDFДокумент8 страницDST Slip Joint PDFcrni rokoОценок пока нет

- HALLIBURTON Mismatched IronДокумент20 страницHALLIBURTON Mismatched Ironjonobel567Оценок пока нет

- Intermediate Inspection CriteriaДокумент2 страницыIntermediate Inspection CriteriaKaleem UllahОценок пока нет

- Tubing ManДокумент30 страницTubing ManГалинаОценок пока нет

- IV-0794-20 CROSS OVER Pin-Box 05807HДокумент1 страницаIV-0794-20 CROSS OVER Pin-Box 05807Hivan dario benavides bonillaОценок пока нет

- IADC Well Control Worksheet Surface Stack Wait and WeightДокумент3 страницыIADC Well Control Worksheet Surface Stack Wait and WeightJorge Toala100% (1)

- AADE 05 NTCE 52 - PatilДокумент8 страницAADE 05 NTCE 52 - PatilAhmad Reza FarokhiОценок пока нет

- VAM FJL Torque TableДокумент17 страницVAM FJL Torque TableKhaledFekairОценок пока нет

- Drilltech Services (USA) Inc: Spiro-TorqДокумент10 страницDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanОценок пока нет

- Choke ManifoldДокумент2 страницыChoke Manifoldpractimac123Оценок пока нет

- Overshot overview guide for fishing toolsДокумент1 страницаOvershot overview guide for fishing toolsShazly Sayed AhmedОценок пока нет

- Tubulars Tubular Services Catalog PDFДокумент29 страницTubulars Tubular Services Catalog PDFHERNANDO CASTILLO100% (1)

- Anullar BOPДокумент5 страницAnullar BOP0926828260sОценок пока нет

- Advanced Drilling Engineering Buckling and BendingДокумент8 страницAdvanced Drilling Engineering Buckling and BendingIdi Saley Maman100% (1)

- Drill String DesignДокумент30 страницDrill String DesignVictor ReyesОценок пока нет

- Drill String Design Group 3Документ15 страницDrill String Design Group 3Anusha AnuОценок пока нет

- Heavy Weight Drill PipeДокумент1 страницаHeavy Weight Drill PipeDhani RamaОценок пока нет

- University of ZakhoДокумент4 страницыUniversity of ZakhoNasih AhmadОценок пока нет

- Heavy Weight Drill Pipe (HWDP)Документ8 страницHeavy Weight Drill Pipe (HWDP)amol modakОценок пока нет

- 6 - Drill StringДокумент11 страниц6 - Drill Stringlovely petsОценок пока нет

- Drill Collar BehnamДокумент2 страницыDrill Collar BehnamBehnamОценок пока нет

- Calificacion de TrepanosДокумент1 страницаCalificacion de TrepanosFelix Julio Céspedes SotoОценок пока нет

- 3.1 Iron RoughneckДокумент99 страниц3.1 Iron Roughneckdanielra8567% (3)

- PDC Bits: All Comes From The Cutter Rock Interaction: Laurent Gerbaud, Stephane Menand, Hedi SellamiДокумент10 страницPDC Bits: All Comes From The Cutter Rock Interaction: Laurent Gerbaud, Stephane Menand, Hedi SellamiAhmed GharbiОценок пока нет

- Offshore EngineerДокумент68 страницOffshore Engineerfle92Оценок пока нет

- Fishing JarsДокумент29 страницFishing JarsAlexander Bohórquez MartínezОценок пока нет

- Cormorant Alpha Drilling Operations Guide Making ConnectionsДокумент10 страницCormorant Alpha Drilling Operations Guide Making ConnectionsaliОценок пока нет

- Whip StockДокумент4 страницыWhip StockSasan AbbasiОценок пока нет

- AnderGauge SpecsДокумент2 страницыAnderGauge SpecsloipvОценок пока нет

- Fundamentals of Onshore DrillingДокумент23 страницыFundamentals of Onshore Drillingعبد العزيز مروىОценок пока нет

- SGS-IND-Drilling Equipment Inspection-EN-11Документ2 страницыSGS-IND-Drilling Equipment Inspection-EN-11John DolanОценок пока нет

- Directional Drilling PDFДокумент129 страницDirectional Drilling PDFwajidkhattakОценок пока нет

- Analysis, Comparison and Application of CWD Against Conventional Drilling OperationsДокумент104 страницыAnalysis, Comparison and Application of CWD Against Conventional Drilling Operationsprakharmathur14100% (1)

- Oil Rig Components ExplainedДокумент7 страницOil Rig Components ExplainedJennifer Màrtin100% (5)

- 7.1 Inspection TeamДокумент70 страниц7.1 Inspection TeamWalid BdeirОценок пока нет

- E BookДокумент256 страницE BookShehrox Khan RindОценок пока нет

- Direction Well Trajectory DesignДокумент10 страницDirection Well Trajectory Designlaxmikant1983Оценок пока нет

- Tese Luia - Ferreira - Final PDFДокумент86 страницTese Luia - Ferreira - Final PDFadityamduttaОценок пока нет

- Appendix B - Equipment BrochureДокумент24 страницыAppendix B - Equipment BrochureAllissa SuwondoОценок пока нет

- SPE 89598 Modeling Coiled Tubing Drag Forces - Small Factors Have A Big ImpactДокумент6 страницSPE 89598 Modeling Coiled Tubing Drag Forces - Small Factors Have A Big ImpactabodolkuhaaОценок пока нет

- Stuck Pipe/Tight Pipe Incident Reporting Form: Page 1 of 2Документ2 страницыStuck Pipe/Tight Pipe Incident Reporting Form: Page 1 of 2David OrtegaОценок пока нет

- Jar Pro Drillstring Jarring Analysis SoftwareДокумент5 страницJar Pro Drillstring Jarring Analysis SoftwareHany AhmedОценок пока нет

- 02 Drill String DesignДокумент99 страниц02 Drill String DesignArkhatTompakovОценок пока нет

- River CrossingДокумент119 страницRiver CrossingMohammad Shafaet JamilОценок пока нет

- Manual de ServicioДокумент102 страницыManual de ServiciowiloОценок пока нет

- Core Barrel Running ProcedureДокумент4 страницыCore Barrel Running Proceduremahesh_mzp1954Оценок пока нет

- Horizontal Drilling Techniques & ApplicationsДокумент36 страницHorizontal Drilling Techniques & Applicationsayan100% (1)

- 6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualДокумент19 страниц6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualAnonymous F2tu2TrzVtОценок пока нет

- Griffith JarДокумент21 страницаGriffith Jarsaeed65Оценок пока нет

- Directional DrillingДокумент26 страницDirectional Drillingroaa ahmed100% (1)