Академический Документы

Профессиональный Документы

Культура Документы

Bearing 1 PDF

Загружено:

Ankit SuriАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bearing 1 PDF

Загружено:

Ankit SuriАвторское право:

Доступные форматы

75

15

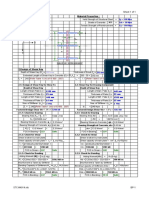

POT BASE THK.

28

PAD 26THK.

SPIG. PROJ . 36

160

DOWEL

(FOR SUBSTRUCTURE

ONLY)

DRILL AND TAP

M 20x40mmDEEP

6

POT BASE THK.

28

360LENGTH OF

PISTON FLAT

540 + 1 PCD

530

430

520LENGTH

OF SSPLATE

D

I

R

E

C

T

I

O

N

O

F

M

O

V

E

M

E

N

T

EQ

14. HEIGHT OF PEDESTALS SHALL BE ADJ USTED AS PER THE VERTICAL

8500

8500

R.C.C DETAILS OF PEDESTAL

PLAN

1LAYERSTO BE PLACED

20mmBELOW TOP SURFACE

AND 2ndLAYER TO BE PLACED

100mmBELOW TOP SURFACE.

5 NOS. 12O STIRRUPS

16 O VERTICAL BARS

2 LAYERS 8 mmO M.S. 75 C/C(MESH)

430WIDTH OF SSPLATE

Y

PLAN

340 POT BASE

O 480

PISTON O 420

EQ

EQ

850

340

850

850

5 NOS. 12 O STIRRUPS

24NOS.

16 O BARS

POT BASE O 480

POT/PISTON DETAILS

POT WALL O.D. 460

380 POT INTERNAL O

CLEARANCE AVAILABLE BETWEEN ABUTMENTS CAP TOP AND BOTTOM

OF BEARING BEAM.

a) PLAN DIMENSIONS :-0 TO +5 mm

c) HEIGHT OF ELASTOMER :-0/+5%

2) UNMACHINED :CLASS 2 OF IS:4897

1) MACHINED :-0 TO +I mm

b) OVERALL HEIGHT :-0 TO +3 mm

d) HEIGHT OF ANY STEEL COMPONENT

CASTINGS SHALL BE ULTRASONICALLY TESTED & CERTIFICATES SUBMITTED,

b) TEST ON WELDING:SOUNDNESS OF WELDING SHALL BE CERTIFIED BY

13. TOLERANCES

THE MANUFACTURER.

QUALITY LEVEL 3 AS PER IS:9565

EQ

X

EQ

X

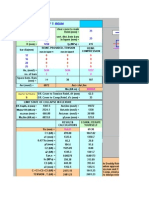

490

550

Y

LUG DETAIL

DRILL HOLES OF 20O

FOR M20Gr. 8.8BOLTS.

TOP PLATE

25THK.

ABOVE SPIG. 15THK.

VERTICAL FACE OF PISTON 10

47

POT DEPTH

SPIG. PROJ . 36

PAD 26THK.

13 DISTRIBUTION PLATE SSPLATE 3mmTHK.

12

3mmTHK S.SSTRIP WELDED/SCREWED

DIMENSION-PISTON 360x20mm

DIMENSION-GUIDE BAR 520X20mm

POT BASE O 480

POT WALL O.D. 460

540 + 1 PCD

2d

5d

540 + 1 PCD

POT BASE O 480

POT WALL O.D. 460

SECTION AT X - X

d=Dia. of

Bolt

+ 1 PCD 540

POT BASE

O 480

PAD 380 O x 26 THK.

FLANGE

16THK.

1 2

195

SECTION AT Y - Y

DOWEL

WELD 12x12x50mm

ANTI ROTATI0N LUG

10

9. WELDING

a) TESTS ON CASTING: TESTS SPECIFIED IN IS: 1030 WILL BE PERFORMED

a) SILICON GREASE WILL BE APPLIED AT PTFE STAINLESS STEEL INTER FACE.

b) ANCHORE SLEEVES WILL BE CEMENT COATED AT SITE.

FINISH PAINT.TOTAL DRY FILM THICKNESS >160 MICRONS.

11. GREASING:

12. TESTS:

a) ALL NON WORKING SURFACES WILL BE COATED WITH 2 COATS OF EPOXY

PRIMER & ONE OR MORE COATS EACH OF EPOXY INTERMEDIATE AND

a) ALL WELDING WILL BE MANUAL METAL ARC PROCESS CONFORMING TO

IS:814, PRE HEATING & POST WELD STRESS RELIEVING TO BE DONE

10. FINISHING

IF REQUIRED.

6. ACESSORIES TO IS 226/2062.

8. THE STAINLESS STEEL PLATE SHALL BE STICH WELDED SCREWED ON THE

PROPERTIES REGARDING TENSILE STRENGTH ETC. AS PER BS:5400 SEC 9.2,

7. CONFINED PTFE WILL BE OF UNFILLED QUALITY AND WILL HAVE REQUIRED

BS 3784 & BS 6564.THE THICKNESS SHALL BE >OR =45 MM.

BACKING PLATE.

5. ANCHORES: HSS BOLTS OF Gr. 8.8 & SLEEVE MATERIAL AS PER IS 2062.

AGEING WILL BE AS PAR TABLE-I-PROPERTIES OF ELASTOMER IN

c) MIN ELONGATION AT BREAK , MAX COMPRESSION SET & ACCELERATED

b) MIN. TENSILE STRENGTH MPaIS:3400 (PART I) 15.5

a) HARDNESS IRHD IS:3400 (PART II) 50+5

IRC:83 (PART II).

530

490

630

DISTRIBUTION PLATE OF SIZE 530x630x25THK.

WELDED WITH SUPERSTRUCTURE BY

CONTINOUSFILLET WELDING

27.5

7 8 4 5

FLANGE 16THK.

27.5

TOP PLATE

25THK.

3

12

ABOVE SPIG. 15THK.

15

13

11

16

GUIDE BAR

HEIGHT 20

14

50

M 20x45mmLONG for POT

M 20x45mmLONG for TOP PLATE

Gr. 8.8HSSBOLT

C/W FLAT WASHER

9

SIDE TO RECEIVE BOLTS OF M20 DIA. AND SHALL BE FIXED TO THE

STEEL SUPERSTRUCTURES CONTINOUS FILLET WELDING ALL ALONG THE

CONFINED ELASTOMER INSIDE POT WILL HAVE FOLLOWING PROPERTIES:

2. ALL DIMENSIONS ARE IN mmUNLESS OTHERWISE MENTIONED.

4. MATERIALS

3. PCD =PITCH CIRCLE DIAMETER.

EDGES FOR THE OTHER SIDE.

1. ANCHORING ARRANGEMENT WITH SUPERSTRUCTURE SHALL BE THROUGH

DISTRIBUTION PLATE HAVING DRILL AND TAPE OF SUITABLE SIZE ON ONE

NOTES :-

40

2

2

Вам также может понравиться

- Combined Footing Design: ASDIP Foundation 3.2.2Документ4 страницыCombined Footing Design: ASDIP Foundation 3.2.2Rodain NajjarОценок пока нет

- Two Way Slabs PDFДокумент5 страницTwo Way Slabs PDFmathuОценок пока нет

- Type FRB1. 333 Ton Free Sliding Bearing DesignДокумент8 страницType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaОценок пока нет

- A Bridge RuleДокумент120 страницA Bridge RulemanishОценок пока нет

- Summary Safe of Structural Design of Box and WallДокумент7 страницSummary Safe of Structural Design of Box and WallRatul PalodhiОценок пока нет

- Truss Bridge Steel Members Design As Per IRS CodeДокумент96 страницTruss Bridge Steel Members Design As Per IRS CodeStructural SpreadsheetsОценок пока нет

- Bow String Girder Steel Members Design As Per IRC CodeДокумент967 страницBow String Girder Steel Members Design As Per IRC CodeStructural SpreadsheetsОценок пока нет

- Jim CK Load - Calc 052611Документ19 страницJim CK Load - Calc 052611GSVОценок пока нет

- RetainingWall SBC 150Документ35 страницRetainingWall SBC 150Elvis GrayОценок пока нет

- Elastomeric Bearing Design for Solid Slab Decking SpanДокумент8 страницElastomeric Bearing Design for Solid Slab Decking SpanCivil MexОценок пока нет

- Beam Design and Vibration AnalysisДокумент9 страницBeam Design and Vibration AnalysisjatinОценок пока нет

- Plate Girder Bridge BOMДокумент8 страницPlate Girder Bridge BOMankitОценок пока нет

- Bolted ConnectionsДокумент1 страницаBolted ConnectionsManju BirjeОценок пока нет

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementДокумент9 страниц2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilОценок пока нет

- Design of Elastomeric BearingsДокумент6 страницDesign of Elastomeric BearingsHarshitha GaneshОценок пока нет

- Concrete slab strengthening designДокумент4 страницыConcrete slab strengthening designSherwin CairoОценок пока нет

- Influencelines Lineas de InfluenciaДокумент6 страницInfluencelines Lineas de InfluenciaMarlon MartinezОценок пока нет

- Free POT/PTFE BearingДокумент25 страницFree POT/PTFE BearingZakee MohamedОценок пока нет

- Elastomercic Bearing DN (14+872 MNB)Документ19 страницElastomercic Bearing DN (14+872 MNB)Ankur ChauhanОценок пока нет

- Analysis and Design of Abutment.Документ18 страницAnalysis and Design of Abutment.rakesh yadavОценок пока нет

- Base Plate BiaxilДокумент19 страницBase Plate BiaxilGunjan KolarkarОценок пока нет

- CribДокумент1 страницаCribskumarsrОценок пока нет

- Industrial ShedДокумент8 страницIndustrial ShedHiren DesaiОценок пока нет

- 36 MTR SpanДокумент13 страниц36 MTR SpanAnonymous sfkedkymОценок пока нет

- 39 M Deck Type Truss Bridge - ConnectionДокумент1 страница39 M Deck Type Truss Bridge - Connectionvibishnan100% (1)

- Calculation of loads and stresses for a 16.5m steel girder bridge spanДокумент1 страницаCalculation of loads and stresses for a 16.5m steel girder bridge spansups madiОценок пока нет

- Design of Circular Pile Cross SectionДокумент4 страницыDesign of Circular Pile Cross Sectionkarthikmr85Оценок пока нет

- I. Partial Safety Factors: II. Section PropertiesДокумент150 страницI. Partial Safety Factors: II. Section Propertiespinakin nikash100% (1)

- R4B01 Itd CV Bas 401 Des 4026 PDFДокумент16 страницR4B01 Itd CV Bas 401 Des 4026 PDFSayantan PaulОценок пока нет

- Detailed Design of Free Pot BearingДокумент7 страницDetailed Design of Free Pot BearingDevesh SinghОценок пока нет

- Design of Flexible End Plate ConnectionsДокумент35 страницDesign of Flexible End Plate ConnectionsARUNKUMAR KОценок пока нет

- Static Analysis On Tied Arch BridgeДокумент7 страницStatic Analysis On Tied Arch BridgeIJRASETPublicationsОценок пока нет

- Analysis of prestressed solid and voided slab bridgeДокумент7 страницAnalysis of prestressed solid and voided slab bridgeankitОценок пока нет

- Technical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionДокумент6 страницTechnical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionAshutosh RawatОценок пока нет

- FULL VS PARTIAL HEIGHT RE WALL COSTSДокумент2 страницыFULL VS PARTIAL HEIGHT RE WALL COSTSNaresh SharmaОценок пока нет

- Box Type Abutment DesignДокумент23 страницыBox Type Abutment Designsanjay verma100% (2)

- Pile Design SpreadsheetДокумент180 страницPile Design SpreadsheetsubamanivelОценок пока нет

- RESULT-Pile Group-276+778-AbutmentДокумент807 страницRESULT-Pile Group-276+778-AbutmentPraveen CyssanОценок пока нет

- 498 Plate Girder CombinedДокумент1 страница498 Plate Girder CombinedYash DhabaliaОценок пока нет

- Design of Pile Cap Using Strut and Tie ModelДокумент159 страницDesign of Pile Cap Using Strut and Tie ModelLavender HoneyОценок пока нет

- POT Design R0Документ9 страницPOT Design R0VB665Оценок пока нет

- Optimization PSC Bridge An ExampleДокумент13 страницOptimization PSC Bridge An Exampleani4576Оценок пока нет

- Analysis of slab culvert bridges using two methodsДокумент7 страницAnalysis of slab culvert bridges using two methodsjeeva anandОценок пока нет

- Post-Tensioning Format For Pc-Girder General InformationДокумент1 страницаPost-Tensioning Format For Pc-Girder General InformationTirthajit RoyОценок пока нет

- Column Interaction DiagramДокумент4 страницыColumn Interaction DiagramankitОценок пока нет

- Fix Base As Per Is Code - Seismic DetailingДокумент1 страницаFix Base As Per Is Code - Seismic DetailingrohitnrgОценок пока нет

- Construction of Grade Separator Pier Cap Beam DesignДокумент4 страницыConstruction of Grade Separator Pier Cap Beam Designmohana tОценок пока нет

- Rectangular Ground Supported Tank Impulsive and Convective Forces (For Reference)Документ28 страницRectangular Ground Supported Tank Impulsive and Convective Forces (For Reference)Hari prasad GaddamОценок пока нет

- Analysis of T-Beam: Nos in Layer 1 Nos in Layer2Документ46 страницAnalysis of T-Beam: Nos in Layer 1 Nos in Layer2Kanaiyalal N. ShethОценок пока нет

- IS 1343 Bursting and bearing reinforcement calculationsДокумент2 страницыIS 1343 Bursting and bearing reinforcement calculationsArun KumarОценок пока нет

- BA 001 R0A (Without Mezzanine)Документ1 страницаBA 001 R0A (Without Mezzanine)Muhammad Hassan TariqОценок пока нет

- Chapter 10 Design of Prestressed 761661594169023Документ15 страницChapter 10 Design of Prestressed 761661594169023Puzzle ArtsОценок пока нет

- Pot Bearing DrawingДокумент1 страницаPot Bearing DrawingMiguel Belda DiezОценок пока нет

- TS 60-300 Floor Deck Profile Data Sheet - 2013Документ5 страницTS 60-300 Floor Deck Profile Data Sheet - 2013maheshbandhamОценок пока нет

- Comparative Finite Element Analysis of Pikotek VCS and RTJ PDFДокумент28 страницComparative Finite Element Analysis of Pikotek VCS and RTJ PDFAbigor45Оценок пока нет

- Cost Comparison PCC Vs RCC ReturnДокумент3 страницыCost Comparison PCC Vs RCC Returndesign MridcОценок пока нет

- Load calculation and section properties for ROB designДокумент121 страницаLoad calculation and section properties for ROB designEr Navneet JassiОценок пока нет

- Br. No.-312 AДокумент99 страницBr. No.-312 AShashibhushan SinghОценок пока нет

- Revised Foundation For 315 Mva Transformer. 28-10-09 - ModelДокумент1 страницаRevised Foundation For 315 Mva Transformer. 28-10-09 - ModelIrshad KhanОценок пока нет

- Thickness Cal. Fo DM Water Storage Tank-API 650Документ15 страницThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Raft Design Sheet.Документ106 страницRaft Design Sheet.Ankit SuriОценок пока нет

- Book 1Документ1 страницаBook 1Ankit SuriОценок пока нет

- RMSA (2+2) SCHOOL ConcreteДокумент2 страницыRMSA (2+2) SCHOOL ConcreteAnkit SuriОценок пока нет

- Sikament HE200: Super Plasticiser/AcceleratorДокумент2 страницыSikament HE200: Super Plasticiser/AcceleratorAnkit SuriОценок пока нет

- Indian Concrete CodeДокумент25 страницIndian Concrete CodePiv0terОценок пока нет

- Rmsa School SteelДокумент16 страницRmsa School SteelAnkit SuriОценок пока нет

- Jindal SHS and RHSДокумент16 страницJindal SHS and RHSSham SuriОценок пока нет

- Pubinbiss03is 875 3 1987 PDFДокумент67 страницPubinbiss03is 875 3 1987 PDFAnkit SuriОценок пока нет

- IRC 6-1966 Standard Specifications for Road Bridge Loads and StressesДокумент40 страницIRC 6-1966 Standard Specifications for Road Bridge Loads and StressesArun Ks100% (2)

- JAMMU AND KASHMIR POWER DEVELOPMENT CORPORATION BEARING CAPACITY TEST REPORTSДокумент4 страницыJAMMU AND KASHMIR POWER DEVELOPMENT CORPORATION BEARING CAPACITY TEST REPORTSAnkit SuriОценок пока нет

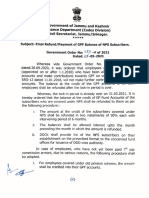

- Department (Codes Division) : Subject:-Final Refund/Payment of GPF Balance of NPS SubscribersДокумент3 страницыDepartment (Codes Division) : Subject:-Final Refund/Payment of GPF Balance of NPS SubscribersAnkit SuriОценок пока нет

- Raft Design Sheet.Документ106 страницRaft Design Sheet.Ankit SuriОценок пока нет

- An 150 9001Документ2 страницыAn 150 9001Ankit SuriОценок пока нет

- JAMMU AND KASHMIR POWER DEVELOPMENT CORPORATION BEARING CAPACITY TEST REPORTSДокумент4 страницыJAMMU AND KASHMIR POWER DEVELOPMENT CORPORATION BEARING CAPACITY TEST REPORTSAnkit SuriОценок пока нет

- JAMMU AND KASHMIR POWER DEVELOPMENT CORPORATION BEARING CAPACITY TEST REPORTSДокумент4 страницыJAMMU AND KASHMIR POWER DEVELOPMENT CORPORATION BEARING CAPACITY TEST REPORTSAnkit SuriОценок пока нет

- IS-13920 2016 AmendmentsДокумент14 страницIS-13920 2016 AmendmentsShakil Akhter100% (4)

- 10column SteelДокумент1 страница10column SteelAnkit SuriОценок пока нет

- Truss CalculationsДокумент16 страницTruss CalculationsAnkit SuriОценок пока нет

- SampleДокумент14 страницSampleAnkit SuriОценок пока нет

- Essential Roof Truss Design TermsДокумент45 страницEssential Roof Truss Design TermsAnkit SuriОценок пока нет

- Is 1893 - 1 2002Документ41 страницаIs 1893 - 1 2002kumardbgОценок пока нет

- 7 SizeДокумент1 страница7 SizeAnkit SuriОценок пока нет

- 30,000Документ3 страницы30,000Ankit SuriОценок пока нет

- Wind Speed Map IndiaДокумент12 страницWind Speed Map IndiaAn1rudh_Sharma100% (1)

- Raft Design Sheet.Документ59 страницRaft Design Sheet.Ankit SuriОценок пока нет

- Digital Sign PrintДокумент1 страницаDigital Sign PrintAnkit SuriОценок пока нет

- QhlogsДокумент1 страницаQhlogsMohit KoladiaОценок пока нет

- 3column SteelДокумент1 страница3column SteelAnkit SuriОценок пока нет

- Short Term Deflection: CK y ST SC C SДокумент6 страницShort Term Deflection: CK y ST SC C SAnkit SuriОценок пока нет

- NBFM Elevation ViewДокумент1 страницаNBFM Elevation ViewAnkit SuriОценок пока нет

- CRD - c124 CRD-C124-73 Method of Test For Specific Heat of Aggregates, Concrete, and Other Materials (Method of Mixtures)Документ3 страницыCRD - c124 CRD-C124-73 Method of Test For Specific Heat of Aggregates, Concrete, and Other Materials (Method of Mixtures)azharbОценок пока нет

- Companyprofile For Executives15pagesR1Документ15 страницCompanyprofile For Executives15pagesR1Venus AndromadagalaxyОценок пока нет

- Repair and Reinforcing Techniques for Steel ComponentsДокумент108 страницRepair and Reinforcing Techniques for Steel ComponentsValy CoulibalyОценок пока нет

- CHEMISTRY PROFESSIONAL ACT RA 10657Документ5 страницCHEMISTRY PROFESSIONAL ACT RA 10657Shai Sta CatalinaОценок пока нет

- Geran Penyelidikan Fundamental Ipta (FRGS) Fasa 2/2007 Universiti Teknologi Mara (Uitm) Senarai Yang Berjaya BagiДокумент12 страницGeran Penyelidikan Fundamental Ipta (FRGS) Fasa 2/2007 Universiti Teknologi Mara (Uitm) Senarai Yang Berjaya BagiFadzila AzniОценок пока нет

- Transdermal Drug Delivery System ReviewДокумент8 страницTransdermal Drug Delivery System ReviewParth SahniОценок пока нет

- Welding examination and postweld heat treatment requirementsДокумент2 страницыWelding examination and postweld heat treatment requirementssanketОценок пока нет

- Food Processing and Preservation Technology (CFB 30004) Unikl Lab Manual MicetДокумент4 страницыFood Processing and Preservation Technology (CFB 30004) Unikl Lab Manual MicetNurul SyafiqahОценок пока нет

- 1967 US Army Vietnam War Explosives and Demolitions 187pДокумент186 страниц1967 US Army Vietnam War Explosives and Demolitions 187pwwwsurvivalebookscomОценок пока нет

- 05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPДокумент17 страниц05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPRahul RanjanОценок пока нет

- Catalog: PrefaceДокумент155 страницCatalog: PrefaceTalita Yasmin TalitaОценок пока нет

- A Review On Hybrid Laser Arc WeldingДокумент22 страницыA Review On Hybrid Laser Arc WeldingAkshay AcchuОценок пока нет

- Bpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Документ1 страницаBpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Amol TupeОценок пока нет

- Spirax Sarco SV74 SeriesДокумент2 страницыSpirax Sarco SV74 Series20040384iОценок пока нет

- Density Tower-Sphsummer 2Документ3 страницыDensity Tower-Sphsummer 2api-322723623Оценок пока нет

- Topic 2 SimpleDistillationДокумент52 страницыTopic 2 SimpleDistillationJA NableОценок пока нет

- Econo SprayДокумент1 страницаEcono SprayEliasОценок пока нет

- VMP Manual PDFДокумент106 страницVMP Manual PDFkikiОценок пока нет

- IR Spectroscopy Problem Set 1Документ0 страницIR Spectroscopy Problem Set 1Jules BrunoОценок пока нет

- General Chemistry II Module on Intermolecular ForcesДокумент5 страницGeneral Chemistry II Module on Intermolecular ForcesJerry De Leon TaayОценок пока нет

- Shell Corena S4 R 68 MSDSДокумент7 страницShell Corena S4 R 68 MSDSNg Thiam YongОценок пока нет

- GM 9984001Документ3 страницыGM 9984001Felipe De la cruzОценок пока нет

- Ocean Pollution ThesisДокумент7 страницOcean Pollution Thesisjenniferslatteryranchocucamonga100% (2)

- DilutionДокумент12 страницDilutioncristina tina100% (1)

- Glyconutrients and MannatechДокумент5 страницGlyconutrients and MannatechJillyStoneyОценок пока нет

- Dod Ammunition and Explosives Safety StandardsДокумент537 страницDod Ammunition and Explosives Safety StandardsMehmet Ali TahancalioОценок пока нет

- Alcor Atf Super - enДокумент2 страницыAlcor Atf Super - enronaldОценок пока нет

- IMA MCQsДокумент18 страницIMA MCQsPCOP Pharmacy100% (1)

- s15 Miller Chap 5b LectureДокумент22 страницыs15 Miller Chap 5b LecturesilviaОценок пока нет

- Pipe Hanger CatalogДокумент228 страницPipe Hanger CatalogIldefonso FloresОценок пока нет