Академический Документы

Профессиональный Документы

Культура Документы

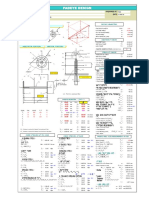

Design Calculation 4-Padeyes

Загружено:

Muhammad YahdimanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design Calculation 4-Padeyes

Загружено:

Muhammad YahdimanАвторское право:

Доступные форматы

ProjectTitle: Customer : Chevron

PreparedBy : TF

CheckedBy : RS

ApprovedBy : AS

1.DATA

1.Load

TareWeight DL = 1.500 Ton

LiveLoad LL = 3.000 Ton

SafetyFactor SF = 2.5

TotalLoadStructure = 9.750 Ton

PadeyesQuantity n = 4 EA

LoadPerPadeye P = 4.5 Ton BSEN120791:2006Section5.2.2.2:(3xR.g)/(n1)

SideLoad(10%) Ph = 0.450 Ton

2.Shackle

UseShackle= 4 3/4 Ton OK

PinShackle= 22.40 mm 2.24 cm

GapShackle= 31.80 mm 3.18 cm

3.MaterialofPadeyes

ASTMA36(Fy) 2531 Kg/cm

4.PinHoleGap

SWL>200Ton Max 5 mm

SWL<200Ton Max 3 mm

2.PADEYESDIMENSIONS

1.PinHole

MaximumRadius(ro)

PinHole = 24 mm = 2.40 cm

ro = 12 mm = 1.20 cm

2.MainPlate

MinThickness = 9 mm

UseThickness(T) = 25 mm = 2.50 cm

Radius(R) = 45 mm = 4.50 cm

3.CheekPlate

MinThickness = 5 mm

Thickness(t) = 0 mm = 0.00 cm

ConnectionBetweenShackleandPadeyes Radius(r) = 28 mm = 2.80 cm

Hole OK Lag 1.60 mm

Thickness OK Lag 6.80 mm High(I) = 68 mm = 6.80 cm

Radius OK Lag 38.5 mm Length(L) = 112 mm = 11.2 cm

31.8 71.5 4.BaseConnection

25 33.0 Thickness(ts) = 10 mm = 1.00 cm

Length Ls = 55 mm = 5.50 cm

Lt = 156 mm = 15.60 cm

DesignCalculationPadeyesforToolContainer

Rev:0

PT.BUKAKATEKNIKUTAMA

ENGINEERINGDEPARTMENT

t t

T

L

l

CL

R

r

0

r

DrawingNo.: ContractNo.: Page1of4

ProjectTitle: Customer : Chevron

PreparedBy : TF

CheckedBy : RS

ApprovedBy : AS

DesignCalculationPadeyesforToolContainer

Rev:0

PT.BUKAKATEKNIKUTAMA

ENGINEERINGDEPARTMENT

3.CHECKINGONSTRESSES

1.CheckBearingStress

A

BR

= *(T+2t) = 560 mm

= 5.60 cm

P

A

BR

FBR = 0.9Fy = 2277.9 Kg/cm

fBR < FBR OK

2.ShearStress

As = 2*(T(Rro)+2t(rro)) DoubleShearArea

= 1650 mm = 16.5 cm

P

AS

FS = 0.4Fy = 1012.4 Kg/cm

fS < FS OK

3.AxialStress

A

T

= (l+R2ro)*T+2*(2r2ro)*t

= 3325 mm = 33.25 cm

P

A

T

FT = 0.6Fy = 1518.6 Kg/cm

fT < FS OK

4.BendingStress

OutofPlane

M = Ph*I

= 3060 Kgcm

Inertia = (2*ts*Ls3+L*ts)/12

= 399381.6 mm

= 39.94 cm

Y = Ls/2

= 27.50 mm

= 2.75 cm

S = Inertia/Y

= 14.52 cm

M

S

= 210.70 Kg/cm

FB = 0.66Fy

= 1670.46 Kg/cm OK

135.3 Kg/cm

fS = = 272.7 Kg/cm

= f

T

=

= f

BR

= 803.6 Kg/cm

fB =

DrawingNo.: ContractNo.: Page2of4

ProjectTitle: Customer : Chevron

PreparedBy : TF

CheckedBy : RS

ApprovedBy : AS

DesignCalculationPadeyesforToolContainer

Rev:0

PT.BUKAKATEKNIKUTAMA

ENGINEERINGDEPARTMENT

InPlane

Inertia = ((Ls*Lt

3

)L

3

*(LsT))/12

= 790.92 cm

Y = 2.75 cm

S = Inertia/Y

= 287.61 cm

M

S

= 10.64 Kg/cm

FB = 0.66Fy

= 1670.46 Kg/cm OK

5.HertzPressure

f

HRZ

= 0.591*(PE/K

D

)

1/2

D1*D2 D1 =

D1D2 D2 = Hole

= 336.0 mm P = Pin

= 33.6 cm E = Loadperunitlength

Contactlengthbetweenpinandplate 2.1E6 kg/cm

2

= T+2t

= 25.0 mm = 2.5 cm

fHRZ = 6269 Kg/cm

FHRZ = 6328 Kg/cm

4.WELDING

1.WeldingonCheekPlatetoMainPlate

UseElectrodeE70XX(70Ksi)

Fy = 2531 kg/cm

2

(BasedonAWSD1.1)

Fv = 0.4Fy

= 1012.4 kg/cm

2

LoadperCheekPlate

P.t

T+2.t

0

25

= 0.00 Kg

KD =

fB =

OK

Pc =

=

DrawingNo.: ContractNo.: Page3of4

ProjectTitle: Customer : Chevron

PreparedBy : TF

CheckedBy : RS

ApprovedBy : AS

DesignCalculationPadeyesforToolContainer

Rev:0

PT.BUKAKATEKNIKUTAMA

ENGINEERINGDEPARTMENT

Lw = 1/2*2*3.14*r+2l

= 311.92 mm

= 31.192 cm

0.707 * Lw * Tw * Fv Pc

Tw = 0.0000 cm

TakesminimumTw = 20 mm

2.WeldingBetweenPadeyes

WeldingType:FilletWeld20mm

WeldingThickness (Tw) = 0.9 cm 5.5

WeldingLength (Lw) = 48 cm 1 (cm)

WeldingArea (Aw) = 22 cm 11

WeldingSectionModuli (Ww) = 177 cm

AllowableWeldingStress:

Mat'lGradeA36 (Fv) = 1012.4 kg/cm

2

InternalForce:

ShearForce (V) = 4500 Kg

BendingMoment (M) = Px0.5xLt

= 35100 Kg.cm

StressesonWelding:

Shearstress (fv) = V/Aw

= 202.70 kg/cm

2

Bendingstress (fb) = M/Ww

= 198.68 kg/cm

2

Resultantstress (fR) = (fv^2+fb^2)^0.5

= 283.84 kg/cm

2

Checkstress: fR<Fv OK

DrawingNo.: ContractNo.: Page4of4

Вам также может понравиться

- Design Calculation LiftingДокумент19 страницDesign Calculation LiftingAbu Al Sayyid100% (1)

- Spreader Bar CalculationДокумент2 страницыSpreader Bar Calculationmahhor82_63564383870% (10)

- Padeye Calculation For Lifting AnalysisДокумент3 страницыPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- 17 Padeye - Spreadsheet Rev AДокумент12 страниц17 Padeye - Spreadsheet Rev Aoluomo1Оценок пока нет

- Padeye Calculation Calculations To Determine The Pad Eye Thickness Is Based On DNV 2Документ1 страницаPadeye Calculation Calculations To Determine The Pad Eye Thickness Is Based On DNV 2Zulham Chandra100% (1)

- SWI PadeyeДокумент11 страницSWI PadeyeFian ArdiyanaОценок пока нет

- Davit Arm CalculationДокумент4 страницыDavit Arm Calculationjoeriji0% (1)

- 6a Padeye Aisc 360 2005Документ6 страниц6a Padeye Aisc 360 2005mjlazoОценок пока нет

- My Padeye CalcДокумент10 страницMy Padeye CalcReda Elawady100% (1)

- Spreader Beam BLOCK EДокумент23 страницыSpreader Beam BLOCK Evaminos85% (13)

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveДокумент5 страницCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaОценок пока нет

- Input Rev. NO: L + (c1 + c2) TWДокумент6 страницInput Rev. NO: L + (c1 + c2) TWMudasir MughalОценок пока нет

- Padeye PATIДокумент43 страницыPadeye PATIbayu_23RОценок пока нет

- Spreader Bar CalculationДокумент1 страницаSpreader Bar Calculationjirrsama100% (1)

- Lifting Sets Calculation - API RP 2AДокумент11 страницLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Lifting Trunnion AnalysisДокумент1 страницаLifting Trunnion Analysisprajwal86Оценок пока нет

- Pad Eye New ReleaseДокумент10 страницPad Eye New ReleaseRaza AidanОценок пока нет

- EC3 - Offshore Padeye DesignДокумент4 страницыEC3 - Offshore Padeye Designscaricatutto100% (1)

- Offshore PadeyeДокумент2 страницыOffshore PadeyeFAR_A_DAYОценок пока нет

- Calculation PadeyeДокумент6 страницCalculation PadeyeAddy Sumoharjo ST100% (1)

- Pad Eye Design CalculationДокумент7 страницPad Eye Design CalculationLưu Xuân0% (1)

- Pad Eye Calculation DNV 2-7.3.Документ9 страницPad Eye Calculation DNV 2-7.3.Jacek75% (4)

- Lifting Lug AnalysisДокумент3 страницыLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Padeye CalculationДокумент6 страницPadeye CalculationKarun DasОценок пока нет

- Lifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamДокумент20 страницLifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamJurie_sk360888% (8)

- Lift Beam AnalysisДокумент2 страницыLift Beam Analysishuangjl100% (2)

- Padeye CheckДокумент12 страницPadeye CheckBen100% (1)

- Lifting Lug CalculationsДокумент6 страницLifting Lug CalculationsYash RamiОценок пока нет

- Spreader Beam CalculationДокумент2 страницыSpreader Beam Calculationhombre.muerto595977% (13)

- Mathcad - Spreader Bar FinalДокумент4 страницыMathcad - Spreader Bar FinalOkondu Chiedu100% (3)

- Report of Lifting Beam DesignДокумент5 страницReport of Lifting Beam Designnarutothunderjet216100% (1)

- Seafastening Calculations Transit ModifiedДокумент380 страницSeafastening Calculations Transit ModifiedUtkarsh RamayanОценок пока нет

- Lifting LugsДокумент2 страницыLifting LugsAdi Cahyoko82% (11)

- Padeye8t (Without Cheek Plate)Документ2 страницыPadeye8t (Without Cheek Plate)Mohd Khir Johari100% (1)

- Spreader Beam CalcДокумент2 страницыSpreader Beam CalcBen100% (3)

- Spreader Beam BLOCK EДокумент26 страницSpreader Beam BLOCK ESteve MoonОценок пока нет

- Calculation Lifting LugДокумент4 страницыCalculation Lifting Lugelang purbayaОценок пока нет

- Lifting PadeyeДокумент16 страницLifting PadeyeLưu XuânОценок пока нет

- Lifting Lug SampleДокумент1 страницаLifting Lug Sampleabdul marpaung0% (1)

- Lifting LugДокумент24 страницыLifting LugMas Arman Tewo100% (6)

- LiftingLug TrunnionДокумент22 страницыLiftingLug Trunnionrichardchiam100% (2)

- Lifting Lug CalculationДокумент2 страницыLifting Lug Calculationrustamriyadi100% (2)

- Spreader Bar Calculation PDFДокумент2 страницыSpreader Bar Calculation PDFFernando Humberto100% (2)

- PadEye Design CalculationДокумент7 страницPadEye Design Calculationhyoung65Оценок пока нет

- Spreader Beam CalculationДокумент4 страницыSpreader Beam CalculationMateen KhanОценок пока нет

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionДокумент11 страницRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalОценок пока нет

- Corbel DesignДокумент3 страницыCorbel DesignManoj JaiswalОценок пока нет

- Pipe Support CalculationДокумент2 страницыPipe Support Calculationjsmnjasmines86% (7)

- Design Calculation Sheet: H2So4 Neutralization TankДокумент43 страницыDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunОценок пока нет

- RectangularДокумент15 страницRectangularaku9450% (2)

- Scantling Calculation PDFДокумент6 страницScantling Calculation PDFShyamshesha GiriОценок пока нет

- Corbel BS8110Документ3 страницыCorbel BS8110Nugraha BintangОценок пока нет

- Moment Connection - Flush End Plate-19.01.06Документ48 страницMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- 26 Pressure Vessel.Документ21 страница26 Pressure Vessel.mishtinil93% (14)

- Calculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessДокумент6 страницCalculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessErin JohnsonОценок пока нет

- Base Plate Design Is 800-2007Документ6 страницBase Plate Design Is 800-2007Suneesh P91% (11)

- Section Size: W200X36: Refer Appendix D For Support ReactionsДокумент10 страницSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04Оценок пока нет

- 26 Pressure VesselДокумент21 страница26 Pressure VesseljnmanivannanmechОценок пока нет

- Shutter DesignДокумент28 страницShutter Designsubhananya50% (4)

- ITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFДокумент3 страницыITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFMuhammad YahdimanОценок пока нет

- InvoiceДокумент1 страницаInvoiceMuhammad YahdimanОценок пока нет

- Ges en SPC CC 0005 8Документ24 страницыGes en SPC CC 0005 8Muhammad YahdimanОценок пока нет

- Lampiran 1. Bagan Struktur PT. BUMA Site LATIДокумент6 страницLampiran 1. Bagan Struktur PT. BUMA Site LATIMuhammad YahdimanОценок пока нет

- Soil and Rock InvestigationДокумент3 страницыSoil and Rock InvestigationMuhammad YahdimanОценок пока нет

- DNVДокумент34 страницыDNVMuhammad YahdimanОценок пока нет

- The Strategic Highway Research ProgramДокумент4 страницыThe Strategic Highway Research ProgramMuhammad YahdimanОценок пока нет

- Database Alumni Sipil FT-UHДокумент115 страницDatabase Alumni Sipil FT-UHMuhammad Yahdiman100% (1)

- JCIPДокумент5 страницJCIPdinesh.nayak.bbsrОценок пока нет

- New Microsoft Office Word DocumentДокумент5 страницNew Microsoft Office Word DocumentSukanya SinghОценок пока нет

- IbmautomtiveДокумент38 страницIbmautomtiveMeltz NjorogeОценок пока нет

- National Employment Policy, 2008Документ58 страницNational Employment Policy, 2008Jeremia Mtobesya0% (1)

- Datos Adjuntos Sin Título 00013Документ3 страницыDatos Adjuntos Sin Título 00013coyana9652Оценок пока нет

- Digestive System Worksheet 2013 2Документ3 страницыDigestive System Worksheet 2013 2contessa padonОценок пока нет

- Learning TheoryДокумент7 страницLearning Theoryapi-568999633Оценок пока нет

- Case No. Class Action Complaint Jury Trial DemandedДокумент43 страницыCase No. Class Action Complaint Jury Trial DemandedPolygondotcom50% (2)

- Introduction To FluidizationДокумент9 страницIntroduction To FluidizationEriCisacОценок пока нет

- Friday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBДокумент3 страницыFriday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDONI ARTAОценок пока нет

- Assignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFДокумент18 страницAssignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFRAKIB HOWLADERОценок пока нет

- Malling DemallingДокумент25 страницMalling DemallingVijay KumarОценок пока нет

- Inspection Report For Apartment Building at 1080 93rd St. in Bay Harbor IslandsДокумент13 страницInspection Report For Apartment Building at 1080 93rd St. in Bay Harbor IslandsAmanda RojasОценок пока нет

- Design Practical Eden Swithenbank Graded PeДокумент7 страницDesign Practical Eden Swithenbank Graded Peapi-429329398Оценок пока нет

- CH 15Документ58 страницCH 15Chala1989Оценок пока нет

- ASHRAE Elearning Course List - Order FormДокумент4 страницыASHRAE Elearning Course List - Order Formsaquib715Оценок пока нет

- The History of Music in Portugal - Owen ReesДокумент4 страницыThe History of Music in Portugal - Owen ReeseugenioamorimОценок пока нет

- Research Methods in Developmental PsychologyДокумент9 страницResearch Methods in Developmental PsychologyHugoОценок пока нет

- P66 M10 CAT B Forms and Docs 04 10Документ68 страницP66 M10 CAT B Forms and Docs 04 10VinayОценок пока нет

- MN Rules Chapter 5208 DLIДокумент24 страницыMN Rules Chapter 5208 DLIMichael DoyleОценок пока нет

- MSC ACFN2 RD4 ClassДокумент25 страницMSC ACFN2 RD4 Classmengistu jiloОценок пока нет

- Auto Turn-Off For Water Pump With Four Different Time SlotsДокумент3 страницыAuto Turn-Off For Water Pump With Four Different Time SlotsKethavath Sakrunaik K100% (1)

- Watch One Piece English SubDub Online Free On Zoro - ToДокумент1 страницаWatch One Piece English SubDub Online Free On Zoro - ToSadeusuОценок пока нет

- 7 ElevenДокумент80 страниц7 ElevenakashОценок пока нет

- Smart Plug Installation GuideДокумент9 страницSmart Plug Installation GuideFrancisco GuerreroОценок пока нет

- Contigency Plan On Class SuspensionДокумент4 страницыContigency Plan On Class SuspensionAnjaneth Balingit-PerezОценок пока нет

- Aspek Perpajakan Dalam Transfer Pricing: Related PapersДокумент15 страницAspek Perpajakan Dalam Transfer Pricing: Related PapersHasrawati AzisОценок пока нет

- C++ Program To Create A Student Database - My Computer ScienceДокумент10 страницC++ Program To Create A Student Database - My Computer ScienceSareeya ShreОценок пока нет

- AMO Exercise 1Документ2 страницыAMO Exercise 1Jonell Chan Xin RuОценок пока нет

- University Fees Structure (Himalayan Garhwal University) - UttarakhandДокумент1 страницаUniversity Fees Structure (Himalayan Garhwal University) - UttarakhandabhaybaranwalОценок пока нет