Академический Документы

Профессиональный Документы

Культура Документы

2009 BBM Service Manual

Загружено:

jgokey0 оценок0% нашли этот документ полезным (0 голосов)

93 просмотров43 страницыManual

Оригинальное название

2009 Bbm Service Manual

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документManual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

93 просмотров43 страницы2009 BBM Service Manual

Загружено:

jgokeyManual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 43

SECTI ON 1: HYDROSTATI C SYSTEM

TO CHANGE HYDRO OI L ON COMMERCI AL MODELS, REMOVE OI L

RETURN LI NES FROM TOP OF HYDRO TANK AND PLACE THEM I N

A DI SPOSABLE OI L CONTAI NER. START AND RUN MOWER

UNTI L OI L LEVEL I S REDUCED DOWN TO ABOUT 2 OF OI L

REMAI NI NG I N THE TANK. DO NOT ALLOW AI R TO ENTER THE

OI L LI NES I N THE BOTTOM OF THE TANK. KEEP I N MI ND THAT

ONLY ABOUT 75% OF THE HYDRO OI L CAN BE CHANGED AT A

TI ME. USE ONLY 20W50 MOTOR OI L I N THE HYDRO SYSTEM.

CHANGE HYDRO OI L FI LTERS BY UNSCREWI NG THEM FROM THE

FI LTER HEAD. FI LL NEW FI LTERS WI TH 20W50 MOTOR OI L

BEFORE I NSTALLI NG. USE ONLY BAD BOY REPLACEMENT

FI LTERS. USI NG ANY OTHER FI LTER WI LL RESULT I N DAMAGE

TO THE HYDRO SYSTEM AND VOI D THE WARRANTY.

ONCE THE SYSTEM I S REFI LLED WI TH OI L, LI FT REAR OF

MOWER UNTI L TI RES ARE OFF THE GROUND. START ENGI NE,

RELEASE PARKI NG BRAKE, PUSH CONTROL ARMS FORWARD,

STAY CLEAR OF MOVI NG REAR TI RES, OPEN AND CLOSE THE

BYPASS VALVE ON EACH PUMP ABOUT 6-10 TI MES BY

LOOSENI NG AND TI GHTENI NG THE BOLT SHOWN I N THE ABOVE

PHOTO. THI S WI LL PURGE THE AI R FROM THE SYSTEM.

(THE BYPASS BOLT HAS A HOLE DRI LLED THROUGH THE SI DE

OF THE BOLT HEAD). THI S VALVE ALSO SERVES AS A NEUTRAL

FOR MOVI NG THE MOWER WI THOUT THE ENGI NE RUNNI NG.

WHEN SERVI CI NG A LI GHT DUTY COMMERCI AL MOWER WI TH A

SEALED TRANSAXLE UNI T, START BY REMOVI NG THE FI LTER

SKI D PLATE ON THE BOTTOM OF EACH UNI T. THE SKI D I S HELD

ON BY THREE 10MM BOLTS. NEXT, REMOVE THE FI LTER. THE

FI LTER ALSO SERVES AS THE OI L DRAI N. EACH TRANSAXLE

HOLDS ABOUT 2 QUARTS OF HYDRO OI L. REI NSTALL NEW

FI LTERS AND SKI D PLATES. USE ONLY HYDRO-GEAR OR BAD

BOY HYDRO FI LTERS. USE OF ANY OTHER TYPE OF FI LTER

WI LL RESULT I N DAMAGE TO THE HYDRO SYSTEM AND VOI D

THE WARRANTY.

THE FI LL PLUG I S LOCATED AT THE TOP CENTER OF THE

I NSI DE CASE OF EACH TRANSAXLE. USE ONLY 20W50 MOTOR

OI L I N THE HYDRO SYSTEM.

ONCE THE SYSTEM I S FI LLED WI TH OI L, LI FT REAR OF MOWER

UNTI L REAR TI RES ARE OFF THE GROUND. START ENGI NE,

RELEASE PARKI NG BRAKE, PUSH DRI VE HANDLES FORWARD,

STAY CLEAR OF MOVI NG REAR TI RES. NEXT, PULL THE

NEUTRAL BYPASS LEVERS (LOCATED AT THE REAR OF THE

FRAME, ON EI THER SI DE OF THE MUFFLER) I N AND OUT 6-10

TI MES TO PURGE THE SYSTEM OF ANY AI R. I T MAY BE

NECESSARY TO ADD MORE OI L TO THE OVERFLOW TANK AFTER

10-15 MI NUTES OF RUNNI NG. THESE BYPASS LEVERS ALSO

SERVE AS A NEUTRAL FOR MOVI NG THE MOWER WI THOUT THE

ENGI NE RUNNI NG.

THE HYDRO OVERFLOW TANK ON A ZT MODEL I S LOCATED

BEHI ND THE SEAT. NOTI CE THE FULL COLD LI NE AT THE

BOTTOM OF THE TANK. USE ONLY 20W50 MOTOR OI L I N THI S

TANK.

SECTI ON 2: DRI VE BELT

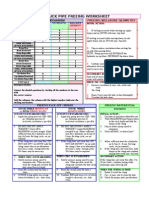

SHOWN ABOVE I S THE AOS/DI ESEL PUMP BELT TENSI ONER.

TI GHTENI NG THE TWO J AM NUTS ON THE LEFT SI DE WI LL

I NCREASE THE BELT TENSI ON ON ALL MODELS. FACTORY

SETTI NG I S ABOUT .030 (ABOUT THE THI CKNESS OF A CREDI T

CARD) BETWEEN COI LS AS SHOWN BELOW.

SHOWN ABOVE I S A TYPI CAL PUMP BELT TESI ONER FOR PUP

AND LI GHTENI NG MODELS.

SHOWN ABOVE I S A TYPI CAL PUMP BELT LAYOUT FOR MOST

COMMERCI AL MODELS.

SECTI ON 3: ENGI NE

SHOWN ABOVE I S A KAWASAKI ENGI NE WI TH THE QUI CK

DRAI N OI L DRAI N LOCATED ON THE LEFT SI DE OF THE ENGI NE.

USE A FLAT SCREW DRI VER AS SHOWN TO LOOSEN THE DRAI N.

MOST MODELS HAVE A DRAI N HOSE I NSTALLED ON THE ENGI NE

FOR EASI ER OI L CHANGES. ALL GAS ENGI NES USED BY BAD

BOY HAVE AN OI L CAPACI TY OF 2 QUARTS. BAD BOY

RECOMMENDS THAT THE OI L AND FI LTER BE CHANGED EVERY

50-60 HOURS OF USAGE.

THE FUEL FI LTER I S LOCATED I N THE FUEL LI NE ABOUT 12

FROM THE CARBURATOR ON THE SI DE OF THE ENGI NE. NOTE

THE DI RECTI ON OF FLOW ON THE SI DE OF THE FI LTER.

REPLACE ONCE A YEAR.

MOST ALL MODELS HAVE A VACUUM OPERATED FUEL PUMP

BOLTED TO THE SI DE OR TOP OF THE ENGI NE. THE PUMP HAS

A FUEL I N , A FUEL OUT , AND A VACUUM LI NE COMI NG FROM

THE ENGI NE BLOCK. FUEL FLOW CAN BE CHECKED HERE I F

THE PUMP I S SUSPECTED TO BE DEFECTI VE.

WHEN SERVI CI NG THE FUEL SYSTEM ON THE CAT DI ESEL, I T I S

NECESSARY TO PURGE THE AI R FROM THE SYSTEM BY

LOOSENI NG THE 9/16 BOLT ON TOP OF THE FUEL FI LTER AND

PUMPI NG THE FUEL BULB UNTI L AI R BUBBLES ARE NO LONGER

VI SI BLE.

REMOVE AND I NSPECT AI R CLEANER WEEKLY. (MORE OFTEN I N

DUSTY CONDI TI ONS). DO NOT BLOW FI LTER OUT WI TH AI R

PRESSURE, THI S WI LL CAUSE THE FI LTER TO BE FI LLED WI TH

TI NY HOLES THAT WI LL ALLOW DI RT TO ENTER. I NSTEAD, TAP

FI LTER ON SI DE TO REMOVE ANY DEBRI S. REPLACE AT LEAST

ONCE A YEAR, MORE OFTEN I N DUSTY CONDI TI ONS.

TORQUE THE CLUTCH BOLT TO 50 FT. LBS. ON ALL MODELS.

RETORQUE AT EVERY OI L CHANGE.

KEEP RADI ATOR SCREEN CLEAN AND FREE OF DEBRI S ON

LI QUI D COOLED MODELS. CHECK SCREEN HOURLY DURI NG

DRY CONDI TI ONS. SLI DE RADI ATOR SCREEN UP TO REMOVE.

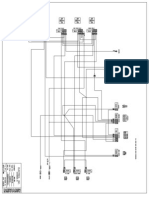

SECTI ON 4: ELECTRI CAL SYSTEM

ON MOST LARGER COMMERCI AL ENGI NES (27 HP AND UP). THE

25 AMP MAI N FUSE I S LOCATED ABOUT 3 FROM THE STARTER

ON THE ENGI NE.

ON SMALLER COMMERCI AL AND LI GHT DUTY COMMERCI AL

MOWERS, THE 25 AMP MAI N FUSE I S LOCATED J UST BEHI ND

THE BATTERY CONNECTED TO THE STARTER SOLI NOI D.

ALWAYS CHECK THE CONDI TI ON OF THE WI RI NG HARNESS

GROUND CABLE. THE GROUND I S LOCATED J UST I NSI DE OF

THE RI GHT SI DE FUEL TANK ON MOST MODELS. ENSURE THAT

THE GROUND I S CONNECTED, CLEAN, AND TI GHT. ON SOME

MODELS, THI S WI RE MAY BE CONNECTED TO THE NEGATI VE

SI DE OF THE BATTERY.

CHECK THE CONDI TI ON AND CONNECTI ON OF THE RELAYS

LOCATED UNDER THE SEAT. ENSURE THAT THEY ARE CLEAN

AND CONNECTED. MAKE SURE THAT WI RE TERMI NAL ENDS

HAVE NOT BEEN PUSHED OUT OF THE RELAY BLOCK.

ON MOST MODELS, THE RED WI RE COMI NG OUT OF THE ENGI NE

I S THE CHARGI NG WI RE FROM THE ALTERNATOR. CHECK FOR

13.6 - 14.2 VOLTS DC AT THI S WI RE WI TH ENGI NE AT FULL

THROTTLE.

SECTI ON 5: FRAME

TORQUE FRONT FORK CASTLE NUT TO 40 FT.LBS. BE SURE TO

SPI N THE FORK WHI LE TORQUI NG THE NUT TO ENSURE THAT

NO BEARI NG DAMAGE I S DONE.

BE SURE TO REI NSTALL THE COTTER PI N I NTO THE CASTLE

NUT. ALWAYS TRY TO GO TI GHTER ON THE NUT TO FI ND A

CASTLATI ON FOR THE PI N TO FI T I N. NEVER BACK THE

BEARI NG TENSI ON OFF AFTER TORQUI NG THE NUT, THI S WI LL

SPRI NG THE BEARI NG CAGE.

TORQUE REAR WHEEL LUGS TO 65-75 FT.LBS. RETORQUE AT

EVERY OI L CHANGE.

THERE I S ONE GREASE FI TTI NG I N EACH FRONT WHEEL AND

ONE I N EACH FRONT CASTER BEARI NG HOUSI NG. GREASE AT

EVERY ENGI NE OI L CHANGE.

THERE I S ONE GREASE FI TTI NG ON EACH OF THE ACTUATOR

BAR PI LLOW BLOCKS LOCATED UNDER THE FUEL TANKS.

GREASE TWI CE A SEASON.

THE PUMP BELT TENSI ONER I S LOCATED UNDER THE ENGI NE

AND HAS A GREASE FI TTI NG AT I TS PI VOT POI NT. GREASE AT

EVERY ENGI NE OI L CHANGE.

THE DECK BELT TENSI ONER I S LOCATED AT THE REAR OF THE

DECK AND HAS A GREASE FI TTI NG ON I TS PI VOT POI NT.

GREASE AT EVERY ENGI NE OI L CHANGE.

THE CONTROL ARM BLOCKS HAVE GREASE FI TTI NGS LOCATED

ON THE TOP AND BOTTOM OF EACH BLOCK. GREASE ONE TI ME

A YEAR.

WHEN ADJ USTI NG THE TRACKI NG ON THE MOWER, THE

LENGTH OF THE PUSHRODS CAN BE CHANGED BY SCREWI NG

THE SWI VEL J OI NT I N OR OUT ON THE ENDS OF THE RODS.

SHORTENI NG THE OVERALL LENGTH OF THE ROD SLOWS THE

PUMP DOWN. LENGTHENI NG THE ROD WI LL I NCREASE THE

SPEED OF THE PUMP.

ON COMMERCI AL MODELS, THE REACTI ON OF THE HYDRO

PUMPS AND THE RESI STANCE FELT I N THE CONTROL ARMS

CAN BE ADJ USTED BY MOVI NG THE PUSHRODS OR THE

DAMPENERS UP OR DOWN I N THE MOUNTI NG HOLES.

MOVI NG DAMPENERS UP, LESS RESI STANCE.

DAMPENERS DOWN, MORE RESI STANCE.

MOVI NG PUSHRODS UP, SLOWER REACTI ON.

PUSHRODS DOWN, FASTER REACTI ON.

TO SERVI CE THE PARKI NG BRAKE SYSTEM, THE REAR BRAKE

ASSEMBLY REQUI RES A HUB PULLER TO REMOVE THE BRAKE

DRUM AS SHOWN ABOVE. THE AXLE NUT MUST BE REPLACED

AND TORQUED TO 200 FT.LBS. BE SURE TO REI NSTALL THE

COTTER PI N.

SECTI ON 6: CUTTI NG DECK

TO REMOVE THE DECK BELT, LI FT UP ON THE BELT WHI LE

ROTATI NG THE PULLEY TO ROLL THE BELT UP AND OFF OF THE

PULLEY. (BE SURE NOT TO GET YOUR FI NGERS BETWEEN BELT

AND PULLEY).

TO CHECK THE LEVEL OF THE DECK, START ON A FLAT

SURFACE AND SET THE AI R PRESSURE I N ALL FOUR TI RES.

RAI SE THE DECK UP, AND MEASURE ALL FOUR CORNERS OF

THE DECK TO SEE I F I T I S LEVEL FROM LEFT TO RI GHT AND

FRONT TO BACK. ALL DECKS SHOULD BE LEVEL FROM LEFT TO

RI GHT AND HAVE A PI TCH DOWN I N THE FRONT.

I F DECK ADJ USTMENTS ARE NECESSARY, START WI TH THE

CHAI N LENGTH ADJ USTERS. THESE ADJ USTERS AFFECT THE

OVERALL HI EGHT OF THE DECK AND THE LEVEL FROM LEFT TO

RI GHT.

THE LARGE TURN BUCKLES ON THE FRONT OF THE DECK ONLY

AFFECT THE PI TCH OF THE DECK OR THE LEVEL FROM FRONT

TO BACK.

THE DECK SPRI NG TENSI ON I S CRI TI CAL. I F THE TENSI ON I S

TOO MUCH, I T WI LL CAUSE THE SPRI NG TO BREAK. I F TOO

LOOSE, THE BELT CAN J UMP OFF OR SLI P ON THE PULLEYS

AND CAUSE A CUT QUALI TY I SSUE. WI TH THE DECK UP, THE

SPRI NG COI L GAP SHOULD BE ABOUT .025 - .030 (ABOUT THE

THI CKNESS OF A BUSI NESS CARD). SPRI NG TENSI ON

ADJ USTMENTS CAN BE MADE BY SLI DI NG THE BOLT SHOWN

ABOVE FORWARD OR BACKWARD I N THE SLOT OF THE DECK.

ON AN AOS/DI ESEL MODEL, DECK BELT ADJ USTMENTS CAN BE

MADE BY SLI DI NG THE REAR V I DLER PULLEYS UP OR DOWN

I N THEI R SLOTS.

THE CONDI TI ON OF THE BLADES CAN DRASTI CLY AFFECT THE

CUT QUALI TY OF THE MOWER DECK. REPLACE AS NECESSARY.

THESE BLADES WERE USED CONSI DERABLY TOO LONG.

RESHARPENI NG I S RECOMMENDED BY PROFESSI ONALS ONLY

TO DETERMI NE WHEN THE BLADE NEEDS TO BE REPLACED AND

BECAUSE OF THE NEED FOR REBALANCI NG.

TO CHANGE BLADES, I T MAY BE EASI ER TO USE A PI ECE OF

WOOD TO KEEP THE BLADE FROM TURNI NG SO THAT THE BOLT

CAN BE LOOSENED. RETORQUE THE BLADE BOLTS TO 90 - 110

FT.LBS.

THE BLADE SPI NDLES CONTAI N A SEALED BALL BEARI NG I N

THE TOP AND BOTTOM OF THE SPI NDLE. THE BEARI NGS ARE

REPLACEABLE FOR A MORE COST EFFECTI VE REPAI R.

Вам также может понравиться

- QB78 CO2 Air Rifle TuningДокумент14 страницQB78 CO2 Air Rifle Tuningaakk75100% (7)

- Mass Effect 5e - The HomebreweryДокумент253 страницыMass Effect 5e - The HomebreweryRony Do CarmoОценок пока нет

- George Irvine III: DIR DivingДокумент41 страницаGeorge Irvine III: DIR DivingSyed Alwi Alattas100% (2)

- AR15 A2 Rifle DiagramДокумент1 страницаAR15 A2 Rifle DiagramJoel WatsonОценок пока нет

- 01-02-1 Assembly, Gears Ratio Clock WoodДокумент1 страница01-02-1 Assembly, Gears Ratio Clock Woodjgokey100% (1)

- Pipeline Arrangement in Oil TankersДокумент11 страницPipeline Arrangement in Oil TankersManpreet SinghОценок пока нет

- Hook LadderДокумент36 страницHook LadderMahalingappa RaviОценок пока нет

- Westco Hydraulic Tubing Tongs 5500 ManualДокумент37 страницWestco Hydraulic Tubing Tongs 5500 ManualLucas Lewis0% (3)

- Tru Ball Incredible ReleaseДокумент2 страницыTru Ball Incredible ReleaseJohnОценок пока нет

- Helicopter MaintenanceДокумент347 страницHelicopter MaintenanceJai Deep88% (24)

- Kelly SpinnerДокумент10 страницKelly Spinnerardser100% (1)

- Ifs Scorpio 06 2006 V0Документ49 страницIfs Scorpio 06 2006 V0JOSE FRANCISCOОценок пока нет

- Manual in Mast FurlingДокумент8 страницManual in Mast FurlingAnne Lymn100% (1)

- Rejetting The CV CarburetorДокумент28 страницRejetting The CV CarburetorЮрий100% (1)

- 9N 2N 8N New Holland Service ManualДокумент156 страниц9N 2N 8N New Holland Service Manualmardukzek100% (9)

- Pool Closing GuideДокумент4 страницыPool Closing GuideSteve CeeОценок пока нет

- Manual - AR2 Wiring HarnessДокумент77 страницManual - AR2 Wiring HarnessMickОценок пока нет

- Series 600: Globe Style Sizes 3 Through 42 InchesДокумент8 страницSeries 600: Globe Style Sizes 3 Through 42 Inchesrizviabbas2012Оценок пока нет

- Plug Setting Tool and Junk Basket: Purpose of The ServiceДокумент15 страницPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Оценок пока нет

- ATE Engine Mod 5-11-14Документ12 страницATE Engine Mod 5-11-14Drazen Dan MijacikaОценок пока нет

- BMV Elec Man GДокумент44 страницыBMV Elec Man GJavier Jara PerezОценок пока нет

- Johnson Evinrude Water Circulation RepairsДокумент14 страницJohnson Evinrude Water Circulation RepairsTonyОценок пока нет

- Transcriptor Skeleton Turntable Owners ManualДокумент20 страницTranscriptor Skeleton Turntable Owners ManualMatt RichmondОценок пока нет

- Kenmore 385.15218400 Sewing Machine Service ManualДокумент32 страницыKenmore 385.15218400 Sewing Machine Service ManualdrhajiОценок пока нет

- Bha HandlingДокумент7 страницBha HandlingAbdul Hameed OmarОценок пока нет

- Hooligun 450 Owner's Manual PDFДокумент29 страницHooligun 450 Owner's Manual PDFKacper ŁukomskiОценок пока нет

- Stuck Pipe ChartДокумент3 страницыStuck Pipe ChartJorge Luis Ortiz100% (2)

- RB26 Head PortingДокумент24 страницыRB26 Head PortingJam Bab0% (1)

- U.S Spars Routine Maintenance For In-Mast Furling SystemДокумент2 страницыU.S Spars Routine Maintenance For In-Mast Furling SystemMike SosinkoОценок пока нет

- Running CasingДокумент6 страницRunning CasingAbdul Hameed OmarОценок пока нет

- HHOДокумент33 страницыHHOSimona IordacheОценок пока нет

- Valve Adjustment For 16 Valve Suzuki GS MotorsДокумент9 страницValve Adjustment For 16 Valve Suzuki GS Motorsmiki-likiОценок пока нет

- Volvo 740 SolutionДокумент26 страницVolvo 740 SolutionPaulo MandingaОценок пока нет

- TF 727 RebuildДокумент10 страницTF 727 Rebuild4porte3Оценок пока нет

- Service Manual 150cc EngineДокумент78 страницService Manual 150cc EngineManuel Mendez laresОценок пока нет

- Mini Downpipe InstallationДокумент9 страницMini Downpipe InstallationKosamaОценок пока нет

- Daewoo DW-172C DWM161C011Документ26 страницDaewoo DW-172C DWM161C011GIOVANNI VIDAL MORALESОценок пока нет

- Repairing A Dripping TapДокумент6 страницRepairing A Dripping TapApollyonОценок пока нет

- GeneratorДокумент24 страницыGeneratorAlvin A. Santiago100% (1)

- Water Pump Remove and Replace: 2002 VTX 1800CДокумент10 страницWater Pump Remove and Replace: 2002 VTX 1800CGheorghe DanielОценок пока нет

- Water Pump Removal For A 1997 Chevrolet BlazerДокумент7 страницWater Pump Removal For A 1997 Chevrolet Blazerpirana316Оценок пока нет

- WFT 000483Документ4 страницыWFT 000483Abboud KingОценок пока нет

- K63& 65 REBUILDДокумент5 страницK63& 65 REBUILDpepin1971Оценок пока нет

- CV Carb TuningДокумент7 страницCV Carb Tuningmark_dayОценок пока нет

- Ex Up System MaintenanceДокумент12 страницEx Up System MaintenanceDerek CaseyОценок пока нет

- Siphon Sucker System10Документ3 страницыSiphon Sucker System10mylovelyhorseОценок пока нет

- How To Build A Generator Using An Electric MotorДокумент6 страницHow To Build A Generator Using An Electric MotorKHOI TIMОценок пока нет

- AC Compressor & Other Related AC ProblemsДокумент14 страницAC Compressor & Other Related AC ProblemsJohanna Christine CaballesОценок пока нет

- WWW 018999Документ39 страницWWW 018999Andhie OsloОценок пока нет

- SU Idiot GuideДокумент7 страницSU Idiot GuideHimanshu SinghОценок пока нет

- Peco Filter CaseДокумент11 страницPeco Filter CaseLuis MaureraОценок пока нет

- Control Valve Interview QuestionsДокумент4 страницыControl Valve Interview Questionsarunrajmech09Оценок пока нет

- QB-78 Quik-Tune Removing The StockДокумент4 страницыQB-78 Quik-Tune Removing The StockLaszlo Csok100% (1)

- Scooter Troubleshooting &tuning GuideДокумент7 страницScooter Troubleshooting &tuning GuidestuhougОценок пока нет

- Architect Supervising Notes.Документ9 страницArchitect Supervising Notes.vishalbhardwa12Оценок пока нет

- CB IGH 5 SachsДокумент6 страницCB IGH 5 SachsBoka LeventeОценок пока нет

- CHEETAH E-SHIFT Pro Series Valve BodyДокумент8 страницCHEETAH E-SHIFT Pro Series Valve BodyhidraulicОценок пока нет

- SWECO CutsheetДокумент2 страницыSWECO Cutsheetachan010100% (1)

- L Series 1770Документ76 страницL Series 1770JuprayОценок пока нет

- Crap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletОт EverandCrap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- 434 G 2 D 3 HCSNZDZДокумент104 страницы434 G 2 D 3 HCSNZDZjgokeyОценок пока нет

- Accelerator Driven Subcritical ReactorsДокумент3 страницыAccelerator Driven Subcritical ReactorsjgokeyОценок пока нет

- GitHub - Luksm - PHP-Signature-Generator - Simple Script To Generate An HTML File With A SignatureДокумент1 страницаGitHub - Luksm - PHP-Signature-Generator - Simple Script To Generate An HTML File With A SignaturejgokeyОценок пока нет

- Thermoelectric GeneratorДокумент13 страницThermoelectric GeneratorbacitusОценок пока нет

- ControlsДокумент22 страницыControlsjgokeyОценок пока нет

- Solar Box CookersДокумент23 страницыSolar Box CookersYoudont CareatallОценок пока нет

- How Will India Build Thorium Based Reactors For Electricity - QuoraДокумент4 страницыHow Will India Build Thorium Based Reactors For Electricity - QuorajgokeyОценок пока нет

- Manual Fresadora JetДокумент30 страницManual Fresadora JetDavid Fernan NuñezОценок пока нет

- 1954 M Singles Instruction ManualДокумент94 страницы1954 M Singles Instruction ManualjgokeyОценок пока нет

- Date With Danger No06Документ37 страницDate With Danger No06jgokeyОценок пока нет

- 21 26 Briggs MZДокумент1 страница21 26 Briggs MZjgokeyОценок пока нет

- US 1847 WoodДокумент2 страницыUS 1847 WoodjgokeyОценок пока нет

- Experimental Evidence For Scalar Fields Impulse EngineДокумент8 страницExperimental Evidence For Scalar Fields Impulse EnginejgokeyОценок пока нет

- My Homemade Dinner Rolls Y: Dry IngredientsДокумент1 страницаMy Homemade Dinner Rolls Y: Dry IngredientsjgokeyОценок пока нет

- Sniper Manual 550Документ41 страницаSniper Manual 550jgokeyОценок пока нет

- Charter Undercover 38Документ2 страницыCharter Undercover 38jgokeyОценок пока нет

- Charter Bulldog44Документ2 страницыCharter Bulldog44JustinОценок пока нет

- The AK 47Документ1 страницаThe AK 47jgokeyОценок пока нет

- Clock AssemblyДокумент1 страницаClock AssemblyjgokeyОценок пока нет

- A1272 Deck Gun ModelДокумент4 страницыA1272 Deck Gun ModeljgokeyОценок пока нет

- Short Form 2006 RelaysДокумент12 страницShort Form 2006 RelaysjgokeyОценок пока нет

- Fuel Cell Green Power Los Alamos ReviewДокумент36 страницFuel Cell Green Power Los Alamos Reviewale_xxx123Оценок пока нет

- Unimill ManualДокумент5 страницUnimill Manualjgokey100% (1)

- 86 OWNERS MANUA WR65 Minibike PDFДокумент27 страниц86 OWNERS MANUA WR65 Minibike PDFjgokeyОценок пока нет

- 1928 AJS Instruction Manual K7 K10 OHC Models PDFДокумент7 страниц1928 AJS Instruction Manual K7 K10 OHC Models PDFjgokeyОценок пока нет

- A Codes and Ciphers PrimerДокумент17 страницA Codes and Ciphers Primer156roОценок пока нет

- Scope and Sequence Plan Stage4 Year7 Visual ArtsДокумент5 страницScope and Sequence Plan Stage4 Year7 Visual Artsapi-254422131Оценок пока нет

- 1a. Create Your Yosemite Zone USB DriveДокумент9 страниц1a. Create Your Yosemite Zone USB DriveSimon MeierОценок пока нет

- 7 Hive NotesДокумент36 страниц7 Hive NotesSandeep BoyinaОценок пока нет

- Crisostomo Vs Courts of Appeal G.R. No. 138334 August 25, 2003Документ5 страницCrisostomo Vs Courts of Appeal G.R. No. 138334 August 25, 2003RGIQОценок пока нет

- Sinteza Engleza TradusaДокумент6 страницSinteza Engleza TradusaRobert TintaОценок пока нет

- Silverio Nuanez Verified ComplaintДокумент10 страницSilverio Nuanez Verified ComplaintMichael_Lee_RobertsОценок пока нет

- EE/CS-320 - Computer Organization & Assembly Language (Fall Semester 2013-14) Assignment 2Документ11 страницEE/CS-320 - Computer Organization & Assembly Language (Fall Semester 2013-14) Assignment 2Haris AliОценок пока нет

- Improving The Passenger Experience: Monitoring Airport Quality of ServiceДокумент6 страницImproving The Passenger Experience: Monitoring Airport Quality of ServiceParisa HadidianОценок пока нет

- Sciencedirect Sciencedirect SciencedirectДокумент7 страницSciencedirect Sciencedirect SciencedirectMiguel AngelОценок пока нет

- JDCF-66 220 VTДокумент13 страницJDCF-66 220 VTHusein OkhonovОценок пока нет

- Arts Q1W3Документ44 страницыArts Q1W3LEILANI PELISIGASОценок пока нет

- Writing NuocRut Ver02Документ118 страницWriting NuocRut Ver02thuy linhОценок пока нет

- Efqm Success-Story-Book LRДокумент34 страницыEfqm Success-Story-Book LRabdelmutalabОценок пока нет

- Roque v. IACДокумент3 страницыRoque v. IACBryce KingОценок пока нет

- 27 HestiaДокумент24 страницы27 HestiaAlberto AdameОценок пока нет

- FDI and FIIДокумент17 страницFDI and FIIsharathОценок пока нет

- SAM3-P256 Development Board Users Manual: This Datasheet Has Been Downloaded From at ThisДокумент21 страницаSAM3-P256 Development Board Users Manual: This Datasheet Has Been Downloaded From at ThissunnguyenОценок пока нет

- Group 5 Transforming Banana Stem Waste To Eco Tote Bag.Документ4 страницыGroup 5 Transforming Banana Stem Waste To Eco Tote Bag.Gabriel Abram JopiaОценок пока нет

- ESAT FormulaДокумент11 страницESAT FormulaSKYE LightsОценок пока нет

- Profitability Analysis (Sapphire Fibres Limited)Документ5 страницProfitability Analysis (Sapphire Fibres Limited)Aqsa MoizОценок пока нет

- Polymer AbbreviationsДокумент9 страницPolymer AbbreviationsFernando GuerreroОценок пока нет

- Google Cloud PlatformДокумент17 страницGoogle Cloud PlatformAathithya MahendranathОценок пока нет

- Linux Memory ExplainedДокумент60 страницLinux Memory ExplainedRaphael AraujoОценок пока нет

- Psar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0Документ183 страницыPsar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0PhatОценок пока нет

- RICS APC Candidate Guide-Aug 2015-WEB PDFДокумент24 страницыRICS APC Candidate Guide-Aug 2015-WEB PDFLahiru WijethungaОценок пока нет

- Đo Nhiệt Độ LI-24ALW-SelectДокумент4 страницыĐo Nhiệt Độ LI-24ALW-SelectThang NguyenОценок пока нет

- Ch03 Kinetics of Particles - Energy&Momentum Methods - Part 1Документ48 страницCh03 Kinetics of Particles - Energy&Momentum Methods - Part 1Mehmet Fatih SunçaОценок пока нет

- Reversible Motors: Additional InformationДокумент36 страницReversible Motors: Additional InformationAung Naing OoОценок пока нет