Академический Документы

Профессиональный Документы

Культура Документы

API Tube Thickness Calculation1

Загружено:

pandiangv0 оценок0% нашли этот документ полезным (0 голосов)

191 просмотров5 страницCAL

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документCAL

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

191 просмотров5 страницAPI Tube Thickness Calculation1

Загружено:

pandiangvCAL

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

STRENGTH CALCULATION

EQUIPMENT : BLOW DOWN PIPING

CLIENT : NASH ENGINEERING FZCO

ENGINEERING : SUPER ENGINEERING SERVICES

DESIGN & CONSTRUCTION CODE : ASME B31.1, 2012 EDITION

MANUFACTURER : SUPER ENGINEERING SERVICES

DUBAI

AKS PANDIAN UDK

SES-CAL-168-001 14.05.14

DATE PREPARED CHECKED APPROVED DOCUMENT NO.

APPROVED CHECKED

01 Sheet

Rev. 00

SES\001\14

STRENGTH CALCULATION

DESCRIPTION PREPARED

Equip.

MFR'S

SERIAL No.

BLOW DOWN PIPING

SUPER ENGINEERING

SERVICES

REV.NO.

Index

Cover Sheet

Index

Revision Status - Drawing

Revision Status - STRENGTH CALCULATION sheet

List of Standards/Codes

Design Data

Hydrostatic Test Pressure

Material Constructions

Allowable Stress

Radiographic Examinations

Heat Treatment

Pipe thickness calculation

AKS PANDIAN UDK

PREPARED

REV.NO.

CHECKED APPROVED DOCUMENT NO.

DESCRIPTION PREPARED

SES-CAL-168-001

APPROVED CHECKED

14.05.14

DATE

02

12

09

10

11

Sheet

05

06

07

08

SES\001\14

S.No.

04

Sheet No.

01

PIPING CALCULATIONS

03

01

02

03

STRENGTH CALCULATION

Equip.

MFR'S

SERIAL No.

BLOW DOWN PIPING

02

07

Rev. 00

08

09

10

05

06

11

Description

SUPER ENGINEERING

SERVICES

12 to 14

04

STATUS OF CALCULATION DUE TO REVISION IN DRAWING

S.

No

Rev.

SUPER ENGINEERING

SERVICES

Approved Checked Prepared Reason For Revision

Pages

Affected

Drawing No.

Page Of

Calculation

DOCUMENT NO. DATE

PREPARED CHECKED APPROVED

SES-CAL-168-001 14.05.14

REV.NO. DESCRIPTION

00

SES\001\14

STRENGTH CALCULATION

03 Sheet

Rev.

Equip. BLOW DOWN PIPING

MFR'S SERIAL

No.

REVISION STATUS FOR STRENGTH CALCULATIONS

0 1 2 3 4 0 1 2 3 4 0 1 2 3 4

P

P

P

P

P

P

P

P

P

P

P

P

P

P

DATE

14.05.14

DOCUMENT NO.

SES-CAL-168-001

APPOVED CHECKED PREPARED Description Rev. No.

12

13

14

8

9

10

11

4

5

6

7

SES\001\14

2

3

Sheet REV. No.

No.

STRENGTH CALCULATION

MFR'S SERIAL

No.

Equip. BLOW DOWN PIPING

04 Sheet

Rev. 00

REV. No. Sheet

No.

1

Sheet REV. No.

No.

SUPER

ENGINEERING

SERVICES

1

00

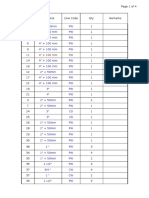

Pipe thickness calculation - As per API 12K - 5.1.1

S.No. Units

01

02

03

04

05 bar(g)

06 C

07 mm

08 mm

09 mm

10 bar(g)

11 mm

12

Minimum required thickness

14 mm

15

Maximum Internal working pressure

bar(g)

17 C

C

Nominal thickness

D = Outside diameter of pipe

Item No.

C = Additional thickness (For corrosion,

thread depth)

t

m

= Minimum thickness available

S = Max. allowable stress as per 5.3

y = coefficient when T is less than D/6

Minimum available is grater than minimum

required

13

t

m

= Minimum thickness available

DOCUMENT NO. DATE

As per table-2 - Max. Working Pressure 146.169 2120

CPSF-21-V-102 E Drg. No.

Design temperature

P = Internal design pressure

Material specification

Vessel

HEATER TREATER

PREPARED CHECKED APPROVED

GV PANDIAN

psig

10.06.14

Maximum allowable design temperature as per

5.1.2

F

Hence Satisfactory

API-12K-0003 UDK

2

SA 106 GR.B

mm

20000

F

Hence Satisfactory

psig 6.200 89.924

1378.9

1.500 0.059 in

Item Return Pipe

STRENGTH CALCULATION

Sheet

Rev.

MFR'S

SERIAL NO.

DESCRIPTION

N-484

DATA

11.113 0.438 in

219.100 8.626 in

12.700 0.500 in

11.113

2.483 0.098 in

85 185 F

0.438 in

psig

0.4

16 bar(g) 125.4 1818.7

Vessel operating temperature is less than the

max. allowable design temperature

Operating Temperature 85

121 250

185

psig

Вам также может понравиться

- Pressure Vessel - Asme - Strength - Calculation - ManualДокумент38 страницPressure Vessel - Asme - Strength - Calculation - ManualEsapermana Riyan100% (3)

- MD He Tema Asme v0.1Документ31 страницаMD He Tema Asme v0.1Sharon Lambert100% (1)

- Rectangular Vessel Stress CalculationДокумент2 страницыRectangular Vessel Stress Calculationpastyl100% (1)

- Heat Exchanger DesignДокумент7 страницHeat Exchanger Designsiva sankarОценок пока нет

- ASME VIII CalculationДокумент14 страницASME VIII CalculationWan Wei100% (1)

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselДокумент36 страницBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungОценок пока нет

- Skirt Support TrialДокумент11 страницSkirt Support TrialAbhishek Nag0% (1)

- Shell and Tube Heat Exchanger SpreadsheetДокумент2 страницыShell and Tube Heat Exchanger SpreadsheetHernan Cardenas Franco100% (1)

- Pressure VesselДокумент507 страницPressure Vesselpradip11100% (1)

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Документ35 страницDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainОценок пока нет

- Gasket Dimension (ASME B16.5 & B16.47)Документ4 страницыGasket Dimension (ASME B16.5 & B16.47)amaОценок пока нет

- Horizontal Cylindrical Tank Volume and Level CalculatorДокумент5 страницHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraОценок пока нет

- Calculation of Lifting ForcesДокумент9 страницCalculation of Lifting ForcesprantikduarahОценок пока нет

- 350 V Pressure Vessel Strength CalculationДокумент3 страницы350 V Pressure Vessel Strength CalculationTanCM100% (1)

- If Any Data - Please Entry This Data: Equipment: Pressure VesselДокумент19 страницIf Any Data - Please Entry This Data: Equipment: Pressure VesselES RouzaОценок пока нет

- 17 Asmeviii A-2 Reverse Integral FlangeДокумент1 страница17 Asmeviii A-2 Reverse Integral FlangepastylОценок пока нет

- Design Calculations For Pressure ShellДокумент33 страницыDesign Calculations For Pressure ShellGeorge GeorgianОценок пока нет

- Hinge Calculation FormulasДокумент2 страницыHinge Calculation FormulasamaОценок пока нет

- PIPE Sizes and Sch. TABLEДокумент1 страницаPIPE Sizes and Sch. TABLEs.vijayaraghavanОценок пока нет

- External Pressure CalculationsДокумент40 страницExternal Pressure Calculationsmisterdavi50% (2)

- WRC Check List CriteriaДокумент1 страницаWRC Check List CriteriaAlvin Smith100% (1)

- Design Pressure and Temperature for Flanges and GasketsДокумент4 страницыDesign Pressure and Temperature for Flanges and GasketsSergio SmithОценок пока нет

- LPG Transport Tank Inspection ReportДокумент18 страницLPG Transport Tank Inspection ReportES RouzaОценок пока нет

- Calculator - U Tubes - HSA & QtyДокумент4 страницыCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Final Weld Strength CalnsДокумент5 страницFinal Weld Strength CalnsamachmouchiОценок пока нет

- Manhole DavitДокумент2 страницыManhole DavitgaratetaОценок пока нет

- Design Calculation Sheet: H2So4 Neutralization TankДокумент43 страницыDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunОценок пока нет

- UHX CalcsДокумент5 страницUHX CalcsRajesh Panchal100% (1)

- Saddle Calc PD5500Документ6 страницSaddle Calc PD5500Vamsi SОценок пока нет

- Titanium Bellows Design CalculationsДокумент8 страницTitanium Bellows Design CalculationsNamıkОценок пока нет

- Auto PipeДокумент18 страницAuto PipeAdi SutardiОценок пока нет

- Master CalculationsДокумент37 страницMaster Calculationsb89502164Оценок пока нет

- Cylindrical pressure vessel design manualДокумент32 страницыCylindrical pressure vessel design manualAris Purniawan100% (1)

- Bio Gas Excel Calculation SheetДокумент5 страницBio Gas Excel Calculation SheetsrivarmaОценок пока нет

- Sample4 PVEliteДокумент66 страницSample4 PVEliteSourav Hait100% (1)

- Pressure Vessel CalculationsДокумент1 страницаPressure Vessel Calculationsmoonstar_dme100% (3)

- Saddle CalcДокумент26 страницSaddle CalcVamsi S100% (2)

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFДокумент4 страницыBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiОценок пока нет

- Nozzle FEA CalculationДокумент64 страницыNozzle FEA CalculationberylqzОценок пока нет

- Nozzle Reinf Calc (Rough)Документ12 страницNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Section VIII CalДокумент19 страницSection VIII CalPradeep Kothapalli100% (1)

- 0.0mechanical Design Calculation For Chlorine Recuperator PDFДокумент156 страниц0.0mechanical Design Calculation For Chlorine Recuperator PDFDarshan PanchalОценок пока нет

- Air SeparatorsДокумент2 страницыAir SeparatorsНемања КараклајићОценок пока нет

- Pressure Vessel Asme Strength Calculation ManualДокумент38 страницPressure Vessel Asme Strength Calculation ManualEsapermana Riyan80% (5)

- Elliptical Head Design ToolДокумент1 страницаElliptical Head Design ToolSudjono BroОценок пока нет

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantДокумент49 страницDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Оценок пока нет

- Secondary superheater stress calculation documentДокумент45 страницSecondary superheater stress calculation documentbrintopvОценок пока нет

- 9952T 1311 F0001 PD2 A CДокумент169 страниц9952T 1311 F0001 PD2 A CBarbara HowellОценок пока нет

- Stress Calculation for Steam Outlet PipingДокумент11 страницStress Calculation for Steam Outlet PipingAvinash Vivek100% (1)

- Ibr CalculationsДокумент9 страницIbr Calculationsaroonchelikani67% (3)

- Mechanical Calculations for Air Receiver Pressure VesselДокумент32 страницыMechanical Calculations for Air Receiver Pressure VesselAndiWSutomoОценок пока нет

- Sizing Calculation PDFДокумент52 страницыSizing Calculation PDFDwi Cahyono SembadaОценок пока нет

- Above Ground Piping Wall Thickness CalculationsДокумент7 страницAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Pressure relief valve specification sheetДокумент2 страницыPressure relief valve specification sheetYücel KaosjunkieОценок пока нет

- Sample Calculation ReportДокумент9 страницSample Calculation ReportmikimecОценок пока нет

- PV Elite Heat Exchanger CalculationsДокумент99 страницPV Elite Heat Exchanger CalculationscbousmuОценок пока нет

- Storage Tank Design Calculations for Hydrogen PeroxideДокумент12 страницStorage Tank Design Calculations for Hydrogen Peroxidechompink6900Оценок пока нет

- PZ D CS Pi SP 015 02Документ60 страницPZ D CS Pi SP 015 02epbamdadОценок пока нет

- Bang Head Here PDFДокумент12 страницBang Head Here PDFhalackОценок пока нет

- Gland steam condenser specification sheetДокумент2 страницыGland steam condenser specification sheetRais RijalОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Wind Load Calculation ReportДокумент2 страницыWind Load Calculation ReportpandiangvОценок пока нет

- As Me Certificate Holder ReportДокумент5 страницAs Me Certificate Holder ReportpandiangvОценок пока нет

- Crosby Eye Bolt G 291Документ1 страницаCrosby Eye Bolt G 291pandiangvОценок пока нет

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffДокумент4 страницыUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvОценок пока нет

- CharttorqueswgДокумент2 страницыCharttorqueswgYutana RuxnakОценок пока нет

- Washer ThicknessДокумент2 страницыWasher ThicknesspandiangvОценок пока нет

- 06 Eurocodes Steel Workshop WALDДокумент6 страниц06 Eurocodes Steel Workshop WALDpandiangvОценок пока нет

- Force and Moment Sketches ModelДокумент1 страницаForce and Moment Sketches ModelpandiangvОценок пока нет

- Studding Outlets Dimensions & SpecificationsДокумент2 страницыStudding Outlets Dimensions & SpecificationspandiangvОценок пока нет

- 999 Industrial Guide 2010Документ42 страницы999 Industrial Guide 2010kasosei100% (1)

- Design Base Plate ThicknessДокумент6 страницDesign Base Plate ThicknesspandiangvОценок пока нет

- Xylan Offshore FlierДокумент2 страницыXylan Offshore FlierpandiangvОценок пока нет

- Ship Motion LoadДокумент4 страницыShip Motion LoadpandiangvОценок пока нет

- Peppers Catalogue Approved AccessoriesДокумент16 страницPeppers Catalogue Approved AccessoriespandiangvОценок пока нет

- Peppers Catalogue Approved AccessoriesДокумент16 страницPeppers Catalogue Approved AccessoriespandiangvОценок пока нет

- F1554 Grade 105 - F1554 Anchor BoltsДокумент2 страницыF1554 Grade 105 - F1554 Anchor BoltspandiangvОценок пока нет

- Nut DetailsДокумент1 страницаNut DetailspandiangvОценок пока нет

- Guidance Notes RevisionДокумент8 страницGuidance Notes RevisionpandiangvОценок пока нет

- Design and Development PlanningДокумент6 страницDesign and Development PlanningpandiangvОценок пока нет

- Buoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9Документ5 страницBuoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9RonoОценок пока нет

- A Lok Tube FittingsДокумент88 страницA Lok Tube FittingsCesarОценок пока нет

- S2 - Jaw and Jaw-136Документ1 страницаS2 - Jaw and Jaw-136pandiangvОценок пока нет

- Pub57 - CDS - Guide (2006 W-2010 Update)Документ78 страницPub57 - CDS - Guide (2006 W-2010 Update)Russ FordОценок пока нет

- TMCP Steels For Offshore StructuresДокумент3 страницыTMCP Steels For Offshore StructurespandiangvОценок пока нет

- Load-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigДокумент12 страницLoad-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigpandiangvОценок пока нет

- Project Execution PlanДокумент1 страницаProject Execution PlanpandiangvОценок пока нет

- WRC Input InstructionДокумент2 страницыWRC Input InstructionpandiangvОценок пока нет

- FAC1 Z 833001 - Rev 5Документ1 страницаFAC1 Z 833001 - Rev 5pandiangv100% (1)

- N1192-ST - Colour CoadingДокумент4 страницыN1192-ST - Colour CoadingpandiangvОценок пока нет

- Food Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoДокумент7 страницFood Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoSОценок пока нет

- Properties of WaterДокумент3 страницыProperties of WaterLupis HernándezОценок пока нет

- BenchTop Orbital Shakers GuideДокумент8 страницBenchTop Orbital Shakers Guidedéborah_rosales100% (1)

- E Booklet Feeding The ChakrasДокумент20 страницE Booklet Feeding The ChakrasVibrating PickleОценок пока нет

- List I (16 5 2011)Документ585 страницList I (16 5 2011)Ayaz Mani50% (2)

- Binary and TernaryДокумент13 страницBinary and TernaryRosemarie Degala LateОценок пока нет

- Class 10 science lab exam MCQ questionsДокумент4 страницыClass 10 science lab exam MCQ questionsDonkeyОценок пока нет

- Conocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: ReferencesДокумент3 страницыConocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: Referencesaneshse100% (9)

- U15 S1-2 HW KeysДокумент6 страницU15 S1-2 HW KeysRohith GudatiОценок пока нет

- 2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Документ15 страниц2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Lương Hữu Bắc100% (1)

- ME6008 WELDING TECHNOLOGY Part B IQДокумент1 страницаME6008 WELDING TECHNOLOGY Part B IQVikram mОценок пока нет

- Determination of % Available Chlorine in Bleaching PowderДокумент10 страницDetermination of % Available Chlorine in Bleaching PowderABHILASHA MISHRA0% (1)

- VOMGE Press Tool Design Course OverviewДокумент11 страницVOMGE Press Tool Design Course OverviewjanakОценок пока нет

- Johnson Industrial Screens PDFДокумент20 страницJohnson Industrial Screens PDFjaime palenzuela rodriguezОценок пока нет

- Big Batch Soap MakingДокумент24 страницыBig Batch Soap MakingAnonymous Vu1R35s4WZ100% (2)

- Solution Manual Chemical Reaction Engineering, 3rd EditionДокумент137 страницSolution Manual Chemical Reaction Engineering, 3rd Editionboni_briantoni75% (8)

- SIP MeenakshДокумент17 страницSIP MeenakshRati GuptaОценок пока нет

- BioreactorsДокумент32 страницыBioreactorskhadeeja vjfndnОценок пока нет

- AL REScheck CertificateДокумент6 страницAL REScheck Certificatebcap-oceanОценок пока нет

- Expwb3ans eДокумент67 страницExpwb3ans eOlivia LinОценок пока нет

- Urea MsdsДокумент5 страницUrea MsdsVinnyVidichiОценок пока нет

- S1XBIG58 M500 4 Tech InfoДокумент15 страницS1XBIG58 M500 4 Tech InfoFredy DanielОценок пока нет

- Cniai 34686 0003Документ45 страницCniai 34686 0003Nirosha Dilrangi PereraОценок пока нет

- Rigaku Nex QCДокумент12 страницRigaku Nex QCLuis ReyesОценок пока нет

- Presentation1. AEC GeoTech LANDFILLДокумент22 страницыPresentation1. AEC GeoTech LANDFILLAyan BorgohainОценок пока нет

- Application of Industrial and Agricultural Waste For Sustainable Construction PDFДокумент9 страницApplication of Industrial and Agricultural Waste For Sustainable Construction PDFJayesh MagarОценок пока нет

- Vestamid L Polyamide 12 - EvonikДокумент12 страницVestamid L Polyamide 12 - EvonikHaryo Armono100% (1)

- Alkaline Earth MetalДокумент33 страницыAlkaline Earth MetalSup FansОценок пока нет

- Hydrogen BondsДокумент2 страницыHydrogen BondsJohnОценок пока нет

- Gas LasersДокумент53 страницыGas LasersDheeraj100% (1)