Академический Документы

Профессиональный Документы

Культура Документы

Air Driven Engine Mechanical Engineering Final Year Project Report

Загружено:

Ajeet KumarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Air Driven Engine Mechanical Engineering Final Year Project Report

Загружено:

Ajeet KumarАвторское право:

Доступные форматы

www.students3k.com | www.placementbix.com | www.students3k.

com

ABSTRACT

The Air Driven Engine is an eco-friendl engine which operates with compressed air.

An Air

Driven Engine uses the expansion of compressed air to drive the pistons of an engine An Air

Driven Engine is a pneumatic actuator that creates useful work b expanding compressed

air. There is no mixing of fuel with air as there is no combustion.

An Air Driven Engine makes use of !ompressed Air Technolog for its operation The

!ompressed Air Technolog is "uite simple. #f we compress normal air into a clinder the air

would hold some energ within it. This energ can be utili$ed for useful purposes. %hen this

compressed air expands& the energ is released to do work. 'o this energ in compressed air

can also be utili$ed to displace a piston

www.students3k.com | www.placementbix.com | www.students3k.com

CHAPTER 1

INTRODUCTION

At first glance the idea of running an engine on air seems to be too good to be true. Actuall&

if we can make use of air as an aid for running an engine it is a fantastic idea. As we all

know& air is all around us& it never runs out& it is non-polluting and it is free.

An Air Driven Engine makes use of !ompressed Air Technolog for its operation.

!ompressed Air Technolog is now widel preferred for research b different industries for

developing different drives for different purposes. The !ompressed Air Technolog is "uite

simple. #f we compress normal air into a clinder the air would hold some energ within it.

This energ can be utili$ed for useful purposes. %hen this compressed air expands& the

energ is released to do work.

'o this energ in compressed air can also be utili$ed to displace a piston. This is the basic

working principle of the Air Driven Engine. #t uses the expansion of compressed air to drive

the pistons of the engine. 'o an Air Driven Engine is basicall a pneumatic actuator that

creates useful work b expanding compressed air. This work provided b the air is utili$ed to

suppl power to the crankshaft of the engine.

#n the case of an Air Driven Engine& there is no combustion taking place within the engine.

'o it is non-polluting and less dangerous. #t re"uires lighter metal onl since it does not have

to withstand elevated temperatures.

As there is no combustion taking place& there is no need for mixing fuel and air. (ere

compressed air is the fuel and it is directl fed into the piston clinder arrangement. #t simpl

expands inside the clinder and does useful work on the piston. This work done on the piston

provides sufficient power to the crankshaft.

www.students3k.com | www.placementbix.com | www.students3k.com

CHAPTER 2

LITERATURE REVIEW

2.1. COMPRESSED AIR TECHNOLOGY

Air can be compressed into small volumes and can be stored in suitable containers at high

pressures. 'uch air compressed into containers is associated with an amount of energ. %hen

the stored compressed air is released freel it expands thereb releasing the energ associated

with it. This energ released can be utili$ed to provide useful work.

The compression& storage and release of the air together are termed as the !ompressed Air

Technolog. This technolog has been utili$ed in different pneumatic sstems. This

technolog has been undergoing several ears of research to improve its applications.

!ompressed air is regarded as the fourth utilit& after electricit& natural gas& and water.

!ompressed air can be used in or for)

*neumatics& the use of pressuri$ed gases to do work.

vehicular transportation using a compressed air vehicle

scuba diving

To inflate buoanc devices.

!ooling using a vortex tube.

+as dusters for cleaning electronic components that cannot be cleaned with water.

air brake ,rail- sstems

air brake ,road vehicle- sstems

starting of diesel engines ,an alternative to electric starting-

compressed air breathers ,such as 'uisse Air-

pneumatic air guns

pneumatic screwdrivers

2.2. TWO STROKE ENGINE

www.students3k.com | www.placementbix.com | www.students3k.com

A two-stroke engine is an internal combustion engine that completes the thermodnamic in

two movements of the piston compared to twice that number for a four-stroke engine. This

increased efficienc is accomplished b using the beginning of the compression stroke and

the end of the combustion stroke to perform simultaneousl the intake and exhaust

,or scavenging- functions. #n this wa two-stroke engines often provide strikingl

high specific power. +asoline ,spark ignition- versions are particularl useful in lightweight

,portable- applications such as chainsaws and the concept is also used in diesel compression

ignition engines in large and non-weight sensitive applications such as ships and

locomotives.

All functions are controlled solel b the piston covering and uncovering the ports as it

moves up and down in the clinder. A fundamental difference from tpical four-stroke

engines is that the crankcase is sealed and forms part of the induction process in gasoline

and hot bulb engines. Diesel engines have mostl a roots blower or piston pump for

scavenging.

.ig. /.0 working of two stroke engine

www.students3k.com | www.placementbix.com | www.students3k.com

There are no traditional valves in a two-stroke engine. #n a two-stroke the engines fires once

ever revolution. This makes the engine highl efficient and lightweight compared to four-

stroke sstems. 1ather than entering through valves& the fuel2air mixture enters through an

intake port and exhaust exits out of an exhaust port. #n place of traditional valves the two-

stroke engine uses the piston3s position to force out exhaust or suck in fuel mixture.

1eeds are vital to a two-stroke sstem. The reeds are placed between the intake manifold and

the carburetor& open and close to allow the fuel 2 air mixture to enter the case of the engine

and trap it& and ensure the proper exchange of gasses in the engine. This procedure might

sound complex& but it is& in fact& extremel effective and eas to understand.

The whole ccle can be explained as follows)

0- As the piston moves from bottom dead center to top dead center it creates a vaccum to

draw the fuel 2 air mixture through the carburetor and past the reed valve assembl.

/- The piston moves down from top dead center to bottom dead center. The reed closes&

causing the pressure to build in the clinder. The movement of the piston uncovers the intake

port and pressuri$ed the fuel 2 air mixture.

3- The piston now moves up from bottom dead center to top dead center& effectivel ending a

ccle and starting another. The spark plug ignites the compressed mixture& sending piston

back down.

4- At this point the piston uncovers the exhaust port& allowing the spent gasses to escape. As

it continues to bottom dead center& it uncovers the intake port and allows the fuel 2 air

mixture through the carburetor and past the reed valve assembl.

2.3. SOLENOID VALVE

A solenoid valve is an electromechanical valve for use with li"uid or gas. The valve is

controlled b an electric current through a solenoid coil. 'olenoid valves ma have two or

more ports) in the case of a two-port valve the flow is switched on or off5 in the case of a

www.students3k.com | www.placementbix.com | www.students3k.com

three-port valve& the outflow is switched between the two outlet ports. 6ultiple solenoid

valves can be placed together on a manifold.

'olenoid valves are the most fre"uentl used control elements in fluidics. Their tasks are to

shut off& release& dose& distribute or mix fluids. The are found in man application areas.

'olenoids offer fast and safe switching& high reliabilit& long service life& good medium

compatibilit of the materials used& low control power and compact design.

A solenoid valve has two main parts) the solenoid and the valve. The solenoid converts

electrical energ into mechanical energ which& in turn& opens or closes the valve

mechanicall. A direct acting valve has onl a small flow circuit& shown within section E of

this diagram. This diaphragm piloted valve multiplies this small flow b using it to control

the flow through a much larger orifice.

'olenoid valves ma use metal seals or rubber seals& and ma also have electrical interfaces

to allow for eas control. A spring ma be used to hold the valve opened or closed while the

valve is not activated.

fig. /./ working of solenoid valve

www.students3k.com | www.placementbix.com | www.students3k.com

A- Input side

B- Diaphragm

C- Pressure chamber

D- Pressure relief conduit

E- Solenoid

F- Output side

The diagram above shows the design of a basic valve. At the top figure is the valve in its

closed state. The water under pressure enters at A. B is an elastic diaphragm and above it is a

weak spring pushing it down. The function of this spring is irrelevant for now as the valve

would sta closed even without it. The diaphragm has a pinhole through its center which

allows a ver small amount of water to flow through it. This water fills the cavit Con the

other side of the diaphragm so that pressure is e"ual on both sides of the diaphragm. %hile

the pressure is the same on both sides of the diaphragm& the force is greater on the upper side

which forces the valve shut against the incoming pressure. #n the figure& the surface being

acted upon is greater on the upper side which results in greater force. 7n the upper side the

pressure is acting on the entire surface of the diaphragm while on the lower side it is onl

acting on the incoming pipe. This result in the valve being securel shut to an flow and& the

greater the input pressure& the greater the shutting force will be.

#n the previous configuration the small conduit D was blocked b a pin which is the armature

of the solenoid E and which is pushed down b a spring. #f the solenoid is activated b

drawing the pin upwards via magnetic force from the solenoid current& the water in

chamber C will flow through this conduit D to the output side of the valve. The pressure in

chamber C will drop and the incoming pressure will lift the diaphragm thus opening the main

valve. %ater now flows directl from A to F.

%hen the solenoid is again deactivated and the conduit D is closed again& the spring needs

ver little force to push the diaphragm down again and the main valve closes. #n practice

there is often no separate spring& the elastomer diaphragm is moulded so that it functions as

its own spring& preferring to be in the closed shape.

.rom this explanation it can be seen that this tpe of valve relies on a differential of pressure

between input and output as the pressure at the input must alwas be greater than the pressure

www.students3k.com | www.placementbix.com | www.students3k.com

at the output for it to work. #f the pressure at the output& for an reason& rise above that of the

input then the valve would open regardless of the state of the solenoid and pilot valve.

#n some solenoid valves the solenoid acts directl on the main valve. 7thers use a small&

complete solenoid valve& known as a pilot& to actuate a larger valve. %hile the second tpe is

actuall a solenoid valve combined with a pneumaticall actuated valve& the are sold and

packaged as a single unit referred to as a solenoid valve. *iloted valves re"uire much less

power to control& but the are noticeabl slower. *iloted solenoids usuall need full power at

all times to open and sta open& where a direct acting solenoid ma onl need full power for

a short period of time to open it& and onl low power to hold it.

'olenoid valves are used in fluid power pneumatic and hdraulic sstems& to control

clinders& fluid power motors or larger industrial valves. Automatic irrigation

sprinkler sstems also use solenoid valves with an automatic controller. Domestic washing

machines and dishwashers use solenoid valves to control water entr to the machine. #n the

paintball industr& solenoid valves are usuall referred to simpl as 8solenoids.8 The are

commonl used to control a larger valve used to control the propellant ,usuall compressed

air or !7/-. #n the industr& 8solenoid8 ma also refer to an

electromechanical solenoid commonl used to actuate a sear.

9esides controlling the flow of air and fluids solenoids are used in pharmacolog

experiments& especiall for patch-clamp& which can control the application of agonist or

antagonist.

2.4. AIR COMPRESSOR

An air compressor is a device that converts electrical power or gas into kinetic energ b

pressuri$ing and compressing air& which is then released in "uick bursts. There are numerous

methods of air compression& divided into either positive-displacement or non-positive

displacement tpes.

*ositive-displacement air compressors work b forcing air into a chamber whose volume is

reduced to effect the compression. *iston-tpe air compressors use this principle b pumping

air into an air chamber through the use of the constant motion of pistons. The use

unidirectional valves to guide air into a chamber& where the air is compressed. 1otar screw

www.students3k.com | www.placementbix.com | www.students3k.com

compressors also use positive-displacement compression b matching two helical screws

that& when turned& guide air into a chamber& the volume of which is reduced as the screws

turn. :ane compressors use a slotted rotor with varied blade placement to guide air into a

chamber and compress the volume.

;on-positive-displacement air compressors include centrifugal compressors. These devices

use centrifugal force generated b a spinning impeller to accelerate and then decelerate

captured air& which pressuri$es it.

The air compressors seen b the public are used in < main applications)

To suppl a high-pressure clean air to fill gas clinders

To suppl a moderate-pressure clean air to suppl air to a submerged surface supplied

diver

To suppl a large amount of moderate-pressure air to power pneumatic tools

.or filling tires

To produce large volumes of moderate-pressure air for macroscopic industrial

processes ,such as oxidation for petroleum coking or cement plant bag house purge

sstems-.

6ost air compressors are either reciprocating piston tpe or rotar vane or rotar screw.

!entrifugal compressors are common in ver large applications. There are two main tpes of

air compressor=s pumps) 7il lubed and oiless. The oiless sstem has more technical

development& but the are more expensive& louder and last less than the oiled lube pumps.

9ut the air delivered has better "ualit. The best choice depends of the application that the

user needs.

2.5. INFRARED PAIR

The infrared pair mainl consists of an infrared emitter and an infrared sensor. The infrared

emitter emits the infrared ras to the infrared sensor. The sensor senses the infrared ras

which are emitted b the emitter. 9oth the emitter and the sensor are >EDs of same rating.

The are placed in correct position face to face and are aligned in a straight line. The are

www.students3k.com | www.placementbix.com | www.students3k.com

also placed close together and are enclosed b a covering with an opening for the ras to

pass. This helps to increase the accurac of the sensing of the sensor to its maximum.

.ig. /.3 #1 pair

CHAPTER 3

THE COMPONENTS

The ma?or components of our Air Driven Engine consist of)

0. T(E E;+#;E

/. T(E '7>E;7#D :A>:E

3. T(E :A>:E A!T@AT#7; 'A'TE6

4. T(E *#*E 'A'TE6

<. T(E *1E''@1E +A@+E 'A'TE6

www.students3k.com | www.placementbix.com | www.students3k.com

CHAPTER 4

THE ENGINE

The basic engine that we have used in the pro?ect is a normal two stroke petrol engine. The

details of the engine are as follows)

6ake) 9a?a? 6BC

Displacement) DB.C4cc.

;o. of clinders) 0

www.students3k.com | www.placementbix.com | www.students3k.com

.ig. 4.0 The Engine

%e onl needed a simple piston-clinder arrangement with an outlet and an exhaust. 9ut as

we know a normal two stroke engine contained several ports and it also had the spark plug

which we didn3t re"uire. 'o& several modifications had to be done on the engine to suit our

purpose.

The modifications comprised of)

!losing the transfer port

!losing the inlet port

1emoving the spark plug from the clinder head

*roviding an inlet at the place of the spark plug

*roviding a suitable connector at the clinder head

The transfer port was to be sealed to provide maximum sealing of the piston-clinder

arrangement so that the chances of escape of air from the clinder can be avoided. %e made

use of m-seal and araldite to seal off the transfer port. .irst a fine "uantit of m-seal was

www.students3k.com | www.placementbix.com | www.students3k.com

filled in the transfer port full except for a small clearance to appl araldite. Then the m-seal

was allowed to solidif. After that araldite was applied in another laer and was allowed to

solidif. Thus the transfer port was closed with the help of the adhesives.

.ig. 4./ !linder 9lock

The inlet port also was re"uired to be closed to avoid mild chances of leakage. #t was much

easier to close the inlet port. The inlet port contains a 1eed valve at its start. This valve is

basicall a non-return valve. 'o if we screw it tightl there wouldn3t be chances of escape of

air through the inlet port. This was carried out to close the inlet port.

There is no combustion taking place in an Air Driven Engine. 'o naturall there is no need

for the spark plug. 'o the spark plug is removed from its respective position that is on the top

of clinder head. #t would be great if we provide the inlet for compressed air at the position

of the spark plug as it is better to let the air enter from the top of the piston. 'o the connector

which is used to connect the pipe from the compressed air tank has to be fixed at the position

of the spark plug. The connector contains an 102/ thread of 9'*T standard. 'o we tapped the

www.students3k.com | www.placementbix.com | www.students3k.com

same thread on the clinder head at the position of the spark plug. Then the suitable

connector was fixed on the clinder head.

.ig 4.3 !linder (ead

CHAPTER 5

THE SOLENOID VALVE

A solenoid valve is an electromechanical valve for use with li"uid or gas. The valve is

controlled b an electric current through a solenoid coil. 'olenoid valves are the most

www.students3k.com | www.placementbix.com | www.students3k.com

fre"uentl used control elements in fluidics. Their tasks are to shut off& release& dose&

distribute or mix fluids. The are found in man application areas.

.or controlling the air flow in and out of the engine we use a 32/ pilot operated normall

closed valve. The smbol of the 32/ valve is as shown)

.ig <.0 :alve 'mbol

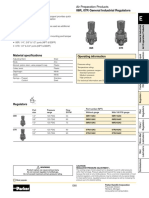

The specifications of the valve are the following)

7rifice) 0/mm.

7perating pressure range) /-0Cbar

.low rate) 3CCC>itres2minute

!oil width) 3/mm.

:oltage) /4: D!

Dut ccle) !ontinuous

The 32/ solenoid valve utili$ed in our pro?ect is shown in the following picture)

www.students3k.com | www.placementbix.com | www.students3k.com

.ig. <./ The 'olenoid :alve

The construction and the working of the 32/ solenoid valve can be explained with the help of

the following diagram)

www.students3k.com | www.placementbix.com | www.students3k.com

.ig <.3 !onstruction and %orking

The figure shows the operation of a pilot operated 32/ pneumatic valve. The solenoid

operates the small pilot valve directl. 9ecause this valve has a small area& a low operating

force is re"uires. The pilot valve applies line pressure to the top of the control valve causing

it to move down& closing the exhaust port. %hen it contacts the main valve disc there are two

forces acting on the valve stem. The pilot valve applies a downwards force of *ED& where *

is the line pressure and D is the area of the control valve. >ine pressure also applies an

upwards force *EE to the stem& where E is the area of the main valve. The area of the control

valve& D& is greater than area of the main valve E& so the downwards force is the larger and

the valve opens.

www.students3k.com | www.placementbix.com | www.students3k.com

%hen the solenoid de-energi$es& the space above the control valve is vented. >ine and spring

pressure on the main valve causes the valve stem to rise again.

www.students3k.com | www.placementbix.com | www.students3k.com

CHAPTER 6

VALVE ACTUATION SYSTEM

The valve actuation sstem is the sstem used to actuate the valve mechanism. The valve

here used is a 32/ solenoid valve. This valve we used here is an alwas closed valve. This

valve works onl when a high voltage is applied to it. ;ormall this high voltage is <v. The

suppl voltage of this valve is /4v. The high voltage for the opening of the valve is provided

b the circuit. %hen a high voltage is applied to the valve it gets open.

The main components of the valve actuation sstem are the following

0. #nfrared pair

#nfrared emitter

#nfrared sensor

/. Electronic circuit

3. 9atteries

4. %iring sstem

<. :alve Timing Disc

www.students3k.com | www.placementbix.com | www.students3k.com

6.1. INFRARED PAIR

The infrared pair mainl consists of an infrared emitter and an infrared sensor. The infrared

emitter emits the infrared ras to the infrared sensor. The sensor senses the infrared ras

which are emitted b the emitter. 9oth the emitter and the sensor are led3s of same rating.

The are placed in correct position face to face and are aligned in a straight line. The are

also placed close together and are enclosed b a covering with an opening for the ras to

pass. This helps to increase the accurac of the sensing of the sensor to its maximum.

.ig F.0 #1 *air

www.students3k.com | www.placementbix.com | www.students3k.com

.ig. F./ #1 *air position

The figure shows the arrangements of the infrared sensors placed at face to face. The are

arranged on a flexible aluminum sheet so that the can be ad?usted as re"uired. The need to

be at sufficient distance apart to avoid collision with the disc.

www.students3k.com | www.placementbix.com | www.students3k.com

6.2. THE ELECTRONIC CIRCUIT

The electronic circuit mainl consists of the following components namel

0. *ower suppl

/. *ower suppl connector

3. :oltage regulator

4. 1esistors

<. :oltage divider

F. #nfrared emitter connector

D. #nfrared sensor connector

B. Transistor

G. :alve connector

0C. !omparator

.ig. F.3 The circuit

F./.0. *7%E1 '@**>A

The power suppl used here is a /4v suppl. This voltage is provided b two batteries each of

/4v and /.<A rating. These batteries are connected in series.

F././. *7%E1 '@**>A !7;;E!T71'

www.students3k.com | www.placementbix.com | www.students3k.com

The circuit is provided with a connector which is a two socket connector. The male connector

is placed in the electronic circuit and the female connector is provided at the other end. The

power suppl connectors are soldered to the circuit.

F./.3. :7>TA+E 1E+@>AT71

The voltage regulator used here is 1+ DBC<. This voltage regulator has three terminals

namel

1eference

#nput

7utput

The reference terminal is grounded and the input terminal is provided with the suppl. This

circuit converts the /4v dc into <v dc. All the components in this circuit onl work on <v.

Thus the /4v need to be stepped down to <v in order to avoid burning of the circuit

components. This <v is taken out through the output terminal.

.ig.F.4 :oltage 1egulator

F./.4. 1E'#'T71'

www.students3k.com | www.placementbix.com | www.students3k.com

The resistors are used to step down the current from the main suppl. The main resistors used

are the following.

0CCH

4DC

0CH

0H

0<CI/

.ig. F.< 1esistors

The figure shows the 0CCH resistor. This component is connected before the voltage

regulator to step down the high current of /4 v suppl.

F./.<. :7>TA+E D#:#DE1'

The voltage dividers are used to divide the voltage according to the purpose. An e"ual

amount of resistors can be used to divide the circuit. (ere two 0<CH resistors are used to

divide the <v to /.<v dc to be supplied to the comparator.

www.students3k.com | www.placementbix.com | www.students3k.com

.ig F.F :oltage Divider

F./.F. T1A;'#'T71'

The transistor here used is 3C3<. This component is used as a switching device to switch the

<v to the solenoid valve. #t consists of three terminals. The emitter is grounded. The base is

connected to the output terminal ,0- of the comparator and the collector terminal of the

transistor is connected to the solenoid valve.

.ig F.D Transistor

www.students3k.com | www.placementbix.com | www.students3k.com

F./.D. !76*A1AT71

The comparator here used is lm </B. #t mainl consists of B terminals out of which <

terminals are in use. The negative terminal is connected to the voltage divider and the

positive terminal is connected to the sensor. The output is taken from the output terminal to

the transistor which acts as a switching device. The fourth terminal is grounded and the

eighth terminal is given the <v suppl.

.ig F.B

The < terminals used are the following

;egative terminal,/-

*ositive terminal,3-

7utput terminal,0-

+round terminal,4-

'uppl terminal,B-

www.students3k.com | www.placementbix.com | www.students3k.com

.ig F.G !omparator

6.3. BATTERIES

The batteries used here have a rating of 0/v& /.<A. The solenoid valve works onl on /4v.

(ence the batteries need to be connected in series to obtain /4v.

.ig F.0C 9atteries

6.4. WIRING SYSTEM

www.students3k.com | www.placementbix.com | www.students3k.com

The wiring sstem mainl consists of wires that are used to connect the components in the

actuation sstem

6.5. VALVE TIMING DISC

The valve timing disc is used to represent the position of the piston inside the clinder in a

schematic manner. This helps to explain the piston position more accuratel.

.ig F.00 :alve Timing Disc

The portion bulged out is the power stroke region. This is the region corresponding to the

region between the outer dead centre and the portion ?ust before the opening of exhaust. The

disc rotates in the clockwise direction. The prescribed angle on the disc for the power stroke

is 0CB3. The disc has a radius of B.< cm.

www.students3k.com | www.placementbix.com | www.students3k.com

6.6. THE WORKING OF THE CIRCUIT

.ig F.0/ The !ircuit

The suppl voltage as shown in the figure is /4v dc. This high voltage is supplied to the

voltage regulator. A 0CCH resister is used before the voltage regulator inorder to reduce the

high current to the circuit. The voltage regulator regulates the voltage and step down it to <v

dc& since all the components in the circuit works onl on <v dc. This <v is given to all the

components in the circuit. The emitter is provided with a 4DC ohm resistor and the collector is

provided with a 0CH resistor which reduces the voltage further. A voltage divider is used in

order to divide the <v to /.<v to provide it to the comparators. The transistor works as a

switch.

www.students3k.com | www.placementbix.com | www.students3k.com

The emitter is forward biased and the collector is reversed biased. The emitter sends infrared

radiations continuousl and this is sensed b the sensor. Thus the circuit is short circuited.

(ence low voltage is given to the comparator. %hen the power stroke region is reached the

path gets cut off and as a result a high voltage is produced in the sensor circuit and this is

given to the comparator. !omparator onl provides the output when the input in the positive

terminal is above <v. Thus during the power stroke region the comparator is provided with a

high voltage and thus it provides a high voltage at its output. This output is given to the

transistor through a 0H resistor. The transistor acts as a switch. #t conducts onl when a high

voltage is applied to it& and when this high voltage reaches it conducts it to the 32/ solenoid

valve.

The solenoid valve has three terminals namel

0. 1eference terminal

/. #nput terminal

3. 7utput terminal

The input terminal is connected to the suppl and the output terminal and the reference

terminal are shorted. The high voltage ,<v- is given to the shorted circuit and thus the valve

opens and the pressuri$ed air is allowed to enter the clinder of the engine. Thus the engine

works.

www.students3k.com | www.placementbix.com | www.students3k.com

6.7. THE CIRCUIT LAYOUT

.ig. F.03 The !ircuit >aout

www.students3k.com | www.placementbix.com | www.students3k.com

This is the circuit laout used to implement our designed circuit to realit. This laout is

obtained using the *!9 laout software. This is made b drawing this schematic diagram in a

copper board and is placed in a solution of ferric chloride for 0< to /< min.

CHAPTER 7

THE PIPE SYSTEM

The pipe sstem is used to connect the components involved in the passage of the

compressed air. #t is used to connect the clinder to the solenoid valve and the solenoid valve

to the clinder head.

.ig. D.0 The *ipe 'stem

(ere polurethane pipes are used of diameter of 0/mm and length of 0m. The are made of

hard and flexible material so that the are able to pass the compressed air more efficientl

www.students3k.com | www.placementbix.com | www.students3k.com

and are highl flexible. These pipes are able to withstand high pressure and so are used to

transport compressed air. The are perfectl suited to be inserted to the one touch male

connector.

7.1. CONNECTORS

!onnectors are used to connect the pipes with the components used in this pro?ect. The tpe

of connector used is one touch male connector which has an internal hexagonal socket. The

specification of the thread is 9'*T 102/ ,9ritish standard piping thread-. The outer diameter

is /0.<mm and the inner diameter is 0/mm.

.ig D./ connectors

www.students3k.com | www.placementbix.com | www.students3k.com

CHAPTER

PRESSURE GAUGE SYSTEM

The pressure gauges are used to measure or displa the pressure at the position at which the

pressure gauge is installed. There are different ranges of the pressure gauges. C to 0C bar

pressure gauges are used in this pro?ect. A t shaped female connector is used to install the

pressure gauge in the sstem and it also holds the pressure gauge at position. The pressure

gauge is connected to the inlet of the solenoid valve. This helps to measure the pressure inlet

to the solenoid valve.

www.students3k.com | www.placementbix.com | www.students3k.com

.ig B.0 *ressure +auge 'stem

CHAPTER !

WORKING OF AIR DRIVEN ENGINE

7ur air engine works on the same principle of that of an internal combustion engine. The

onl difference between the two is that in an internal combustion engine5 the explosion of

fuel in the combustion chamber produces the energ to move the piston& while in an air

engine the energ for moving piston is ac"uired from the supplied compressed air.

The complete assembl of our air engine consists of slightl modified ic engine& valve timing

disc attached to the flwheel of the engine& sensor controlled valve mechanism& piping

sstem& gauge sstem& air compressor and air tank.

www.students3k.com | www.placementbix.com | www.students3k.com

.ig. G.0 %orking

.ig. G./ :alve Timing

.or the proper and continues working of the engine the timing with which the compressed air

is supplied is of great importance. 'o in order to make it precise we used sensor controlled

valve mechanism. The valve timing disc is made with utmost precision to precise operation

of valve. .or that the outer dead centre region ,7D!- of the piston is found out and is marked

on to the fixed valve timing disc. 9 the same method the point ?ust before the exhaust port

opening,E*7- is found out and marked on the disk with the help of a cross sectional change.

www.students3k.com | www.placementbix.com | www.students3k.com

.or starting5 the engine is cranked b the kicker. This will rotate the crankshaft along with the

valve timing disk in the clockwise direction. During this rotation the 7D! region of the disc

cuts the #1 beam first and followed b the E*7 region.

%hen the #1 beam is first cut b 7D! region& the circuit activates the solenoid valve b

electric signal. At the moment the valve gets opened and allows the flow of compressed air

into the clinder from the tank through the piping sstem. The whole region from the point of

7D! to E*7 on the valve timing disk is opa"ue and does not allows the #1 beam through it.

'o all the wa long the circuit maintains the solenoid valve open b suppling a continuous

suppl of electric current to the valve. At the same time the compressed air from the tank

continues to fill in the clinder there b pushing the piston further towards the bottom dead

centre,9D!-. 9ut to increase the fuel efficienc the fuel suppl should be cut-off before

reaching the E*7.

'o when the E*7 region of the valve timing disc sweeps past awa from between the #1

sensors& the #1 beam will make connection again. This will cut the suppl to the solenoid

valve there b closing the valve. This will prevent the valve from being open at the same

time of E*75 increasing efficienc.

%hen the disc rotates further& the valve remains closed throughout the area from the E*7 to

the 7D! as the #1 beam is closed. And this ccle continue.

www.students3k.com | www.placementbix.com | www.students3k.com

CHAPTER 1"

TESTING

1".1. PURPOSE OF TESTING

>oad testing is the process of loading the engine for the purpose of calculating the maximum

tor"ue and brake power b a load testing apparatus.

1".2. TESTING APPARATUS

.or load testing our air engine5 we made the testing apparatus our-self consisting of brake

drum& spring balance& rope and holding frame.

www.students3k.com | www.placementbix.com | www.students3k.com

.ig. 0C.0 brake drum

The brake drum of our testing apparatus was made b slightl modifing the clutch disc of

our engine itself and coupled it to the crankshaft. The spring balance is held in place to the

main frame through a hole drilled into it. The rope is then tied to the hook of the spring

balance. The other end of the rope is circled over the brake drum b a single loop in

clockwise direction. The weight placing base is attached to the loose end of the rope. Extra

care is taken in order to make sure that the spring balance& the rope and the weights are in

straight line.

1".3. TESTING PRINCIPLE

0C.3.0. 91AHE *7%E1

9rake horsepower is the measure of an engine=s horsepower without the loss in power caused

b the gearbox& alternator& differential& water pump& and other auxiliar components such as

power steering pump& muffled exhaust sstem& etc. 9rake refers to a device which was used

to load an engine and hold it at a desired 1*6. During testing& the output tor"ue and

rotational speed were measured to determine the brake horsepower. (orsepower was

originall measured and calculated b use of a brake drum connected to the engine=s output

shaft. 9rake power is the power produced b the engine as measured b the brake drum.

www.students3k.com | www.placementbix.com | www.students3k.com

9rake power J9*3 K

%here5

w0 K weight added in kg&

w/ K load shown in spring balance in kg&

; K speed in 1*6&

d K diameter of rope in mm&

D K diameter of brake drum in mm

g K gravitational constant.

www.students3k.com | www.placementbix.com | www.students3k.com

0C.3./. '*E!#.#!AT#7;' 7. TE'T#;+ A**A1AT@'

Diameter of brake drum D K .0/m K0/Cmm

Diameter of rope d K .C0/m K0/mm

+ravitational constant K G.B0

.ig. 0C./ brake drum of our engine

www.students3k.com | www.placementbix.com | www.students3k.com

1".4. TESTING PROCEDURE

0. 6ade sure that all the connections were made correctl.

/. 6ade sure that the valve of compression tank is in closed position.

3. Then the tank is filled up to the re"uired pressure b running the compressor.

4. The electrical circuit is turned on b closing the connection.

<. 6ade sure that the engine is in no load condition.

F. Then the valve of the compressor tank is opened graduall to the maximum.

D. .or the engine to start running it is cranked with the help of the kicker.

B. %hen the engine starts running and gained speed5 no load readings of pressure in

9A1 as indicated b the pressure gauge on the engine and the speed of the brake

drum in 1*6 as indicated b the tachometer is taken down.

G. This process is repeated for different values of pressure ranging between 0bar and

Gbar and the corresponding readings of speed of rotation are noted.

0C. The readings thus obtained are tabulated in the tabular column.

.ig 0C.3 Testing

1".5. OBSERVATIONS AFTER TESTING

www.students3k.com | www.placementbix.com | www.students3k.com

Table. 0C.0

1".6. SAMPLE CALCULATIONS

#$%&&'$% () ! *($ (+, 3 -. /0(,

Tor"ue K ,w0-w/-IL,DMd-2/NIg

K ,3-C.0- IL,C.0/MC.C0/-2/NIG.B0

9rake power J9*3 K

9* K ,/IOI43B2FC- IL,C.0/MC.C0/-2/NI,3-C.0-IG.B0 %

K4<.BF I C.03/ I /.G IG.B0 watts

K 0D/.// watts

1".7. PERFORMANCE CHARACTERISTICS

WEIGH

T

PRESSURE

1 2 3 4 5 6 7 !

NO

LOAD

344 413 456 44 513 533 545 563 5

.5 314 34 43" 45" 476 5" 516 526 556

1 3"" 363 412 44" 465 4" 45 4!" 53"

1.5 21" 26 31 4"" 441 45! 46! 474 5"6

2 2"2 21" 374 35 425 45" 46" 465 475

2.5 1 1 312 332 375 42" 436 452 46"

3 1 1 3"" 326 354 363 31 421 43

www.students3k.com | www.placementbix.com | www.students3k.com

.ig 0C.4 speed versus pressure

.ig 0C.< speed versus tor"ue

www.students3k.com | www.placementbix.com | www.students3k.com

.ig. 0C.F brake power versus pressure

#n Air Driven Engine& the speed is bound to increase with increase in the inlet pressure. The

speed versus tor"ue characteristics shows a negative linear variation. The brake power is

observed to increase with increase in the inlet pressure.

CHAPTER 12

ADVANTAGES OF AIR DRIVEN ENGINE

less costl and more effective

The air engine is an %23&&30+14$%% piston engine that uses compressed air as a source

of energ.

www.students3k.com | www.placementbix.com | www.students3k.com

S32#/% 3+ 50+&)$'5)30+. The engine can be massivel reduced in si$e

E(&6 )0 2(3+)(3+ (+, $%#(3$.

N0 43$% 7(8($, problem due to over loading. Air& on its own& is non-flammable.

L09 2(+'4(5)'$% (+, 2(3+)%+(+5% 50&)&

!omparativel the 0#%$()30+ 50&) 3& /%&&.

L3.7) 3+ 9%3.7) (+, %(&6 )0 7(+,/%. The engine runs on cold or warm air& so can be

made of lower strength light weight material such as aluminium& plastic& low

friction teflon or a combination

!ompressed-air tanks can be disposed of or $%565/%, 93)7 /%&& #0//')30+ than

batteries.

!ompressed-air engines are '+50+&)$(3+%, *6 )7% ,%.$(,()30+ #$0*/%2& associated

with current batter sstems.

The (3$ )(+- 2(6 *% $%43//%, more often and in less time than batteries can be

recharged& with re-filling rates comparable to li"uid fuels.

L3.7)%$ :%735/%& cause less damage to roads

The price of filling air tanks is significantl 57%(#%$ than petrol& diesel or biofuel. #f

electricit is cheap& then compressing air will also be relativel cheap

;'35- $%�+&% 3& (573%:%,.

CHAPTER 13

APPLICATIONS

13.1. DRIVE FOR CONVEYORS

www.students3k.com | www.placementbix.com | www.students3k.com

Air driven engines can be used as drives for different tpes of conveors such as 9elt

conveors& !hain conveors& 'crew conveors& etc&. it is normall used for slow speed

conveors. 6edium load can onl be used.

.ig 03.0 belt conveor

13.2. <OB CLAMPING

#n operations like carpentr ?ob clamping generall re"uires low loading. Air Driven Engine

can provide this low load clamping.

13.3. FLUID PUMPS

Air Driven Engine can also be utili$ed for small displacement pumps of low pressure

capacities.

www.students3k.com | www.placementbix.com | www.students3k.com

13.4. AUTOMOBILES

The usage of the Air Driven Engine is possible for automobiles as two wheelers and light

motor vehicles.

.ig. 03./ air car

CHAPTER 14

CONCLUSION

www.students3k.com | www.placementbix.com | www.students3k.com

%e were able to successfull complete the design and fabrication of the Air Driven Engine.

9 doing this pro?ect we gained the knowledge about pneumatic sstem and how automation

can be effectivel done with the help of pneumatic sstem. %e were also able to gain

practical knowledge about the basics of the normal #! engine and solenoid valves.

The Air Driven Engine provides an effective method for power production and transmission.

Even though its applications are limited currentl& further research could provide wider

applications.

CHAPTER 15

FUTURE SCOPE

www.students3k.com | www.placementbix.com | www.students3k.com

P Design and fabrication of a new engine made of light metal will give better results.

P @sage of compressed air tanks for storage and suppl will give it more scope in

automobiles.

P 6uch like electrical vehicles& air powered vehicles would ultimatel be powered through

the electrical grid. This makes it easier to focus on reducing pollution from one source& as

opposed to the millions of vehicles on the road. Transportation of the fuel would not be

re"uired due to drawing power off the electrical grid. This presents significant cost

benefits. *ollution created during fuel transportation would be eliminated.

P !ompressed-air vehicles operate to a thermodnamic process as air cools down when

expanding and heats up when being compressed. As it is not possible in practice to use a

theoreticall ideal process& losses occur and improvements ma involve reducing these&

e.g.& b using large heat exchangers in order to use heat from the ambient air and at the

same time provide air cooling in the passenger compartment. At the other end& the heat

produced during compression can be stored in water sstems& phsical or chemical

sstems and reused later.

P ;ew engine designs5 as shown in fig 04.0 shows the improved variants of the air engine.

%ith these tpe of engines5 which is more efficient5 air powered automobiles could gain a

bright scope in future.

.ig. 04.0 air engine variant

Вам также может понравиться

- Project Report On Analysis of Propeller ShaftДокумент24 страницыProject Report On Analysis of Propeller ShaftGurpreet Singh50% (8)

- Fabrication of Pneumatic Punching and Riveting MachineДокумент45 страницFabrication of Pneumatic Punching and Riveting MachineElakkiya Karthic100% (7)

- Compressed Air Vehicle PPT 2018Документ22 страницыCompressed Air Vehicle PPT 2018Anand Kumar100% (3)

- Final ReportДокумент18 страницFinal ReportYusha Patel100% (1)

- Box Shifting MechanismДокумент21 страницаBox Shifting MechanismNishant Chauhan67% (9)

- Seminar ReportДокумент15 страницSeminar ReportSachin Igoor100% (1)

- Hydraulic Power Pack and Pneumatic Service Unit ReportДокумент38 страницHydraulic Power Pack and Pneumatic Service Unit ReportVishal SahaneОценок пока нет

- Fabrication of Pneumatic Paper Cup MakinДокумент28 страницFabrication of Pneumatic Paper Cup MakinPatel NikhilОценок пока нет

- UNIT-I Impact of Jet On VanesДокумент8 страницUNIT-I Impact of Jet On VanesAjeet Kumar75% (4)

- Pedal Operated Water Pumping SystemДокумент33 страницыPedal Operated Water Pumping Systemchristin9193% (15)

- Seminar Report On Fuel From Plastic WasteДокумент32 страницыSeminar Report On Fuel From Plastic WasteAnonymous kTmfG2Ax0% (1)

- Aamer Report SeminarДокумент27 страницAamer Report SeminarRohith NarayanОценок пока нет

- Seminar ReportДокумент45 страницSeminar Reportmanaskollam0% (1)

- Gas Turbine - Seminar ReportДокумент16 страницGas Turbine - Seminar ReportVHD DevolopersОценок пока нет

- HYDRAULIC Bush Bearing Puller 2011 Ac FinalДокумент47 страницHYDRAULIC Bush Bearing Puller 2011 Ac FinalSelva Ganapathy50% (2)

- Build Vertical Axis Wind TurbineДокумент45 страницBuild Vertical Axis Wind TurbineThaha Refaye0% (2)

- Intelligent Braking System - SynopsisДокумент6 страницIntelligent Braking System - SynopsisTanviОценок пока нет

- Button Operated Electromagnetic Gear ChangerДокумент64 страницыButton Operated Electromagnetic Gear ChangermkkfakesОценок пока нет

- Sensotronic Brake ControlДокумент23 страницыSensotronic Brake Controlsai ramanaОценок пока нет

- Quick lifting jack guideДокумент36 страницQuick lifting jack guideRoyalAryans76% (17)

- Turbofan Engine Seminar ReportДокумент22 страницыTurbofan Engine Seminar ReportAbhilash Simha0% (1)

- Pneumatic HacksawДокумент6 страницPneumatic HacksawAvinash Lad100% (1)

- Fabrication Pneumatic JackДокумент43 страницыFabrication Pneumatic JackElakkiya Karthic50% (2)

- Shaper Machine SeminrДокумент20 страницShaper Machine SeminrSoumya Banerjee80% (5)

- Fuel Cell Seminar ReportДокумент67 страницFuel Cell Seminar ReportFaiz Naeem Sait100% (1)

- Project ReportДокумент37 страницProject ReportHari100% (1)

- Power Generation From Speed BreakerДокумент40 страницPower Generation From Speed BreakerSuraj Nm73% (11)

- Report-Multi Point Fuel Injection-MpfiДокумент19 страницReport-Multi Point Fuel Injection-MpfiHemant PatraОценок пока нет

- Emission Control TechniquesДокумент15 страницEmission Control Techniquesslv_prasaad100% (1)

- Heat Transfer Enhancement in Solar Water Heaters by NanofluidsДокумент63 страницыHeat Transfer Enhancement in Solar Water Heaters by NanofluidsSagar MehtaОценок пока нет

- 1000W Room Heater Mini-Project ReportДокумент18 страниц1000W Room Heater Mini-Project ReportSaket TirpudeОценок пока нет

- CNG-SEQ-KITДокумент5 страницCNG-SEQ-KITAnisha VyasОценок пока нет

- Seminar ReportДокумент7 страницSeminar ReportJithin JoseОценок пока нет

- Internal Combustion Engine Cooling MethodsДокумент52 страницыInternal Combustion Engine Cooling MethodsShiva KumarОценок пока нет

- MULTISTAGE Dumping Trolley ReportДокумент40 страницMULTISTAGE Dumping Trolley ReportAniket Sankpal50% (2)

- Scramjet ReportДокумент25 страницScramjet ReportKRITHIKA T 2228617100% (1)

- Report Car Cooling SystemДокумент31 страницаReport Car Cooling SystemOdie Sani Muharman100% (1)

- Automatic Braking System Project ReportДокумент58 страницAutomatic Braking System Project Reportshivam sharma100% (1)

- Road Marking Materials and Application TechniquesДокумент9 страницRoad Marking Materials and Application TechniquesMalith De SilvaОценок пока нет

- Repoart On Automatic Braking Sysytem 1Документ29 страницRepoart On Automatic Braking Sysytem 1VISHAL SEHRAОценок пока нет

- Three Axis Hydraulic Modern TrailerДокумент124 страницыThree Axis Hydraulic Modern Trailerganesh83% (6)

- Final Project Report Foot Step (With Out Footer)Документ47 страницFinal Project Report Foot Step (With Out Footer)Deepak Raj R100% (3)

- Seminar Topics Department of Mechanical EngineeringДокумент4 страницыSeminar Topics Department of Mechanical EngineeringMallik KglОценок пока нет

- Automatic Pneumatic Punching and Riveting MachineДокумент4 страницыAutomatic Pneumatic Punching and Riveting MachineElakkiya Karthic100% (1)

- Project Report of Diffuser AnalysisДокумент37 страницProject Report of Diffuser AnalysissuryaОценок пока нет

- What Are Different Types of Brakes?Документ9 страницWhat Are Different Types of Brakes?Japhet Charles Japhet Munnah100% (1)

- Automatic Braking System for VehiclesДокумент82 страницыAutomatic Braking System for Vehiclesbalabooks100% (1)

- Fabrication of Dual Brake in Single Liver SystemДокумент7 страницFabrication of Dual Brake in Single Liver SystemMalarОценок пока нет

- A Technical Seminar Report On Recent Development in The Field of AerodynamicsДокумент38 страницA Technical Seminar Report On Recent Development in The Field of AerodynamicsRoney Mathew0% (1)

- Electric Power Generation Using Foot Step MethodДокумент5 страницElectric Power Generation Using Foot Step MethodMailvelan BalasubramaniamОценок пока нет

- Presentation On AIR POWERED VEHICLEДокумент26 страницPresentation On AIR POWERED VEHICLEVishal SrivastavaОценок пока нет

- Automobile Air Conditioning Using Exhaust GasesДокумент18 страницAutomobile Air Conditioning Using Exhaust GasesniketanrОценок пока нет

- Electro Megnetic Brake SystemДокумент46 страницElectro Megnetic Brake SystemBalvinder PrajapatiОценок пока нет

- Project ReportДокумент7 страницProject ReportAnkit SinghalОценок пока нет

- "Engine Cooling System": Seminar Presentation OnДокумент15 страниц"Engine Cooling System": Seminar Presentation OnMastering Solidworks0% (1)

- Air Driven Engine Mechanical Engineering Final Year Project Report 140317065312 Phpapp01 PDFДокумент52 страницыAir Driven Engine Mechanical Engineering Final Year Project Report 140317065312 Phpapp01 PDFpandu100% (2)

- Air Driven Engine Mechanical Engineering Final Year Project ReportДокумент50 страницAir Driven Engine Mechanical Engineering Final Year Project ReportHamza ShahidОценок пока нет

- Air Driven Engine VehicleДокумент7 страницAir Driven Engine VehicleBharanidharan RajmohanОценок пока нет

- Pneumatic Key Way Cutter (Slotting Machine)Документ7 страницPneumatic Key Way Cutter (Slotting Machine)balabooksОценок пока нет

- .Fabrication of Air Hybrid TricycleДокумент4 страницы.Fabrication of Air Hybrid TricycleRishikesh GunjalОценок пока нет

- Master Air Starting Valve ExploredДокумент13 страницMaster Air Starting Valve Exploredavm4343100% (1)

- Analysis of Refrigerant Flow Distribution in EvaporatorsДокумент9 страницAnalysis of Refrigerant Flow Distribution in EvaporatorsAjeet KumarОценок пока нет

- Alcup-Akkenergy Conservation in DieselДокумент12 страницAlcup-Akkenergy Conservation in DieselAshishKumarОценок пока нет

- Fuel InjectionДокумент11 страницFuel InjectionAjeet KumarОценок пока нет

- Turbocharger and SuperchargerДокумент37 страницTurbocharger and SuperchargerEng Osama HusamОценок пока нет

- 5 C AluminiumДокумент8 страниц5 C AluminiumAnnelle PalafoxОценок пока нет

- DocumentДокумент64 страницыDocumentSmail HedibelОценок пока нет

- Plane Stress LoadingДокумент19 страницPlane Stress LoadingAjeet Kumar100% (1)

- LS 25S 250L Datasheet Sullair Corporation LS Series GlobalSpec PDFДокумент2 страницыLS 25S 250L Datasheet Sullair Corporation LS Series GlobalSpec PDFOscar BarronОценок пока нет

- 3 - Simple Pneumatic Circuits Using Trainer KitДокумент14 страниц3 - Simple Pneumatic Circuits Using Trainer KitAbhay SinghОценок пока нет

- HG Metaris MHPVB & MPVH Cut-Sheet WebДокумент4 страницыHG Metaris MHPVB & MPVH Cut-Sheet Webpiyush sharmaОценок пока нет

- Technical Offer: Pump Description Pump ModelДокумент4 страницыTechnical Offer: Pump Description Pump ModelPraveen PrajapatiОценок пока нет

- Centrifugal Pump Specific Speed Primer: Fluid FT H Usgpm Q RPM N NДокумент8 страницCentrifugal Pump Specific Speed Primer: Fluid FT H Usgpm Q RPM N Nshafeeqm3086Оценок пока нет

- Beldos Belpump-Lift 1050 Transfer Pump - Spec SheetДокумент2 страницыBeldos Belpump-Lift 1050 Transfer Pump - Spec SheetJonathan FajardoОценок пока нет

- Riko DN10003 PN10 SZ40 22mayДокумент5 страницRiko DN10003 PN10 SZ40 22maystiven villanuevaОценок пока нет

- 07r313ac - ParkerДокумент1 страница07r313ac - ParkerPercy Quispe - IVAFIОценок пока нет

- VV Important 4 Krofta ADTДокумент2 страницыVV Important 4 Krofta ADTBhaskar BethiОценок пока нет

- DR412i Maintenance Kit PlannerДокумент2 страницыDR412i Maintenance Kit PlannerEmanuel Nicolas VillarruelОценок пока нет

- Hydraulic Machines Lab Report Characteristic CurvesДокумент11 страницHydraulic Machines Lab Report Characteristic CurvesBaran ShafqatОценок пока нет

- RAB Pekerjaan Cover ManholeДокумент2 страницыRAB Pekerjaan Cover ManholeAdhe Ahmad YazidОценок пока нет

- Expansion valve malfunction diagnosisДокумент1 страницаExpansion valve malfunction diagnosisJulietina PerezОценок пока нет

- Equipment Audit Sheet 23jan2015Документ36 страницEquipment Audit Sheet 23jan2015michaelnoiОценок пока нет

- Pump Piping ManualДокумент16 страницPump Piping ManualJOBIN YOHANNAN100% (1)

- Effect of Coanda Nozzle Clearance On The Flow Characteristics of Air Amplifier IДокумент6 страницEffect of Coanda Nozzle Clearance On The Flow Characteristics of Air Amplifier IFlorea Ana GabrielaОценок пока нет

- TS 4001: Lecture Summary 8: Marine Gas TurbinesДокумент27 страницTS 4001: Lecture Summary 8: Marine Gas TurbinesVenkateswarlu KolluruОценок пока нет

- Ep 11415Документ9 страницEp 11415adewunmi olufemiОценок пока нет

- Ec460b 09Документ6 страницEc460b 09Khinmg Aye 554Оценок пока нет

- Hysys Liquid PumpingДокумент8 страницHysys Liquid PumpingEkundayo JohnОценок пока нет

- Turbomachinery AnalysisДокумент18 страницTurbomachinery AnalysiskamalОценок пока нет

- CI Kinabalu Wash Water SkidДокумент13 страницCI Kinabalu Wash Water SkidadrianioantomaОценок пока нет

- Inferential MeterДокумент1 страницаInferential MeterShilpa RamadasОценок пока нет

- PSV Sizing For VAPOUR OR GAS RELIEFДокумент4 страницыPSV Sizing For VAPOUR OR GAS RELIEFD K SОценок пока нет

- PP Aaa PP1 101Документ20 страницPP Aaa PP1 101Rabah AmidiОценок пока нет

- Turbo Machine: Ioe, T CДокумент35 страницTurbo Machine: Ioe, T CCalcgen EngineeringОценок пока нет

- SWAN Backpressure Regulator & DistributorДокумент4 страницыSWAN Backpressure Regulator & Distributor_Greg_Оценок пока нет

- Water Pumps and Pumping SystemsДокумент46 страницWater Pumps and Pumping SystemsMohamed100% (1)

- Quetions Turbo.................Документ4 страницыQuetions Turbo.................DICKSON SIMUTAMIОценок пока нет

- Fan EquipmentДокумент16 страницFan Equipmentpenglei jiОценок пока нет