Академический Документы

Профессиональный Документы

Культура Документы

Chapter - 10 Recommended Practice For ESP Failure Analysis

Загружено:

dewidar1234Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter - 10 Recommended Practice For ESP Failure Analysis

Загружено:

dewidar1234Авторское право:

Доступные форматы

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

1

Recommended Practice for ESP

Dismantle, Inspection & Failure

Analysis (DIFA)

Table of Content

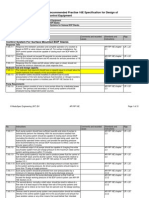

Section Content Page

1.0 Purpose 2

2.0 Post Failure 3

3.0 Pre-Pulled Requirements 3

4.0 Pulling the ESP 4

4.1 Critical Pull Observation 4

4.2 Disassembly of the ESP at well site 5

5.0 Dismantle, Inspection, & Failure

Analysis (Difa) 10

5.1 Preparation 10

5.2 Cable 11

5.3 Pumps 11

5.4 BOI/GS 16

5.5 Protector(s) 17

5.6 Motor(s) 21

5.7 Downhole Monitoring Device (Sensor) 26

6.0 Root Cause Analysis (RCA) 26

7.0 Difa Report Format 28

7.1 Cover 28

7.2 Table of Contents 29

7.3 Distribution 29

7.4 Well Information 29

7.5 Trend Analysis 29

7.6 ESP Identification information 30

7.7 Dismantle Inspection Findings 30

7.8 Summary of Results 30

7.9 Recommendations 30

7.10 Photograph Gallery 30

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

2

Recommended Practice for ESP

Dismantle, Inspection & Failure

Analysis (DIFA)

Introduction

This document outlines the standard for

dismantle inspection and failure analysis (DIFA) of electric

submersible pumps (ESPs). The local engineering manager shall

authorize a DIFA for any pulled ESP equipment. The electric

submersible pump vendor is responsible for conducting and

producing the DIFA and DIFA report, respectively. However,

significant portions of the required data must be provided by

customer. Customer, and its affiliates, shall be a partner in

reviewing and approving the DIFA and DIFA report.

11.1. Purpose

The purpose of this standard is to determine the root cause

of an ESP failure. Identification of this root cause should

lead to operational and/or equipment modifications which

ultimately result in improved runlife performance. It is

imperative that the analysis commence prior to the pulling of

the failed equipment. It is equally important that the DIFA

recommended changes be implemented by customer, its affiliates

and the vendor. All too often, maximizing run life is not

accomplished because ESP failures are not properly identified.

Many factors must be investigated and documented to determine

the ultimate cause of failure. The first flaw discovered in

the failure of an ESP system is often times given full

responsibility for the failure. This identified method of

analysis can result in a much shorter average run life in a

given well and/or field. Maximizing run life of ESP's can be

accomplished through proper analysis of failure modes and

investigating all aspects of the ESP system. This process can

take many hours and/or weeks, particularly if the field is

being analyzed for the first time. It is important to note

that when investigating a single failure, one must also take

into account the entire field operation and procedures along

with the complete history of ESP performance in that field.

Customer personnel shall be responsible for the administration

of this standard in the respective business units. Each

manufacturer shall have a specific DIFA Procedure that

meets, or exceeds, the requirements as outlined in this

standard. Any variation from this standard must be approved by

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

3

a customer representative prior to commencing a failure

analysis program.

11.2. Post Failure

When the ESP equipment has failed, it is important that all

relative information be captured. The following items, if

available, shall be captured and quarantined for inclusion

into the DIFA.

All motor controller/VSD operational data.

Amp charts, or amperage data.

Downhole monitoring data.

SCADA or life of well system, data (e.g. LOWIS, ESP Watcher,

Wellview, Xspoc, etc.). This data shall include any surface

processing equipment data that may be relevant.

Histories of choke settings inclusive of choke setting at

time of failure.

Production data (oil, gas & water).

History of actions taken prior and after the shutdown (e.g.

number of restart attempts, etc.)

Well ESP failure history (if available), inclusive of

previous DIFA reports from the same well.

Chemical treatment history.

Initial sizing and design reports

Installation reports

Any daily field reports that may detail sequence of events

or equivalent

11.3. Pre-Pull Requirements

Prior to pulling the equipment, all parties should be advised

that the pulling of the failed equipment is an integral part

of determining the cause of failure. Any unusual events, or

items, should be captured as part of the pull report. All key

electrical readings should be checked and recorded prior to

commencing pulling operations. In addition to the standard

items supplied by the service company for pulling ESP

equipment, the following items are required to be available

during pulling operations:

12 each, 1 pint, wide mouth, plastic sample bottles.

24 each, 1 quart, plastic bags (zip-lock type).

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

4

36 each 2 x 6 cards to be used as identification markers

in photographs.

Permanent markers.

Grease sticks (yellow or white) to circle/identify critical

items.

Digital camera to take pictures of any/all unique items.

Pressure monitoring equipment (5-25 psi capability) to

check protector/seal shaft seals and ascertain if any

pressure is between motor and lower protector/seal chamber

while pulling. Fittings to be specified by vendor.

New shipping caps and shipping caps gaskets (plastic and

steel). Used shipping caps may be used if in a like-new

condition.

The most recent downhole schematic (including the completion

profile); wellbore profile to include pump setting depths

(MD & TVD), etc.

The most recent ESP run report

Any/all well intervention history (inclusive of critical

well file information, installation report, etc.)

Approved pull procedure detailing responsibilities

throughout the ESP retrieval process

Note:

Prior to commencing the pull, the company representative shall

review how the protector/seal will be pressure checked in the

field. This item cannot be captured after the protector/seal

has been disconnected from the motor interface.

11.4. Pulling the ESP

4.1. Critical Pull Observations

The following items should be monitored throughout the

pulling of the equipment.

Wellhead feed through mandrel (mechanical and electrical

condition)

Monitor cable for mechanical damage

Monitor cable for any electrical blowouts

Monitor cable for out-gassing. If this is considered a

possibility, the maximum pulling speed should not exceed 6-10

stands per hour.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

5

Confirm number of retrieved cable bands are the same as

during the installation

Condition of any/all splices in the cable, inclusive of the

motor lead extension (MLE) to cable splice.

If any splice is suspected of being a problem, the point of

the splice should be noted on the pull of the report.

If the MLE to cable splice is noted as problematic, the cable

shall be cut approximately 2-4 (~ 1 meter) above, and

below, the splice and retrieved for further evaluation.

Condition of Pothead Entry Point. NOTE: The pothead should

NEVER be disconnected in the field. The MLE should be cut 1-3

feet (~ 0.5-1 meter) above the pothead connection.

Discoloration of any pump or motor housing which would

evidence extreme temperature. Items noteworthy include:

o Blue/black coloring

o Paint blistering

o Melted lead from the MLE

Plugged intake with debris or collapsed intake screen. (Take

samples if debris is found)

Corrosion of cable and/or equipment

Obvious signs of impact to housings or cable

Obvious signs that the housings are bent

Note and/all electrical arcing damage and exact location.

Signs of MLE cutting into housings due to vibration.

Condition of cable and protectorlizers (or cable clamps).

Any obvious signs of tubing damage (corrosion, holes, collar

splits, etc.).

4.2. Disassembly of the ESP at the Well site

It is critical that valuable data be captured during the

disassembly of the ESP. Customer shall have the right to

approve/disapprove the evaluation process of any samples taken

during pulling the ESP, inclusive of the evaluation company

(laboratory, etc.).

4.2.1 Cable/Feedthroughs/Pigtails

Examine the well file prior to pulling the ESP and

determine the number of splices (if any) in the ESP cable and

the number of bands/cable clamps installed during the

installation of the ESP.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

6

Conduct a megger test through the feedthrough prior to

disconnecting from the lower pigtail. Note the readings on

the pull report.

Record the serial number of all penetrators and penetrator

connectors. Quarantine the penetrators and penetrator

connectors for possible further examination.

Examine the feedthrough on the lower side of the tubing

hanger. Inspect for any signs of possible mechanical damage.

Examine the lower pigtail to feedthrough connection. Insure

the feedthrough and pigtail were properly connected (it will

be necessary to refer the appropriate feedthrough

manufacturer for the proper make up procedure).

Disconnect the feedthrough from the lower pigtail and conduct

a megger test. Note the readings on the pull report. Make

note if any fluid is found in the connector when

disconnected.

Give particular attention to any unusual signs of tension on

the feedthrough and pigtail. Confirm there was some amount of

slack left for thermal expansion; note in the pull report.

Closely inspect the splice from the lower pigtail to ESP

cable. Examine the splice for signs of excessive heat,

mechanical damage, etc.

Inspect the ESP cable for mechanical damage while pulling the

ESP.

If the location of the splices are known, or become visible

(typically, splice locations are easily identifiable),

closely inspect the splice for any signs of damage or

potential failure.

Items to note as the ESP is pulled:

o Is the cable out-gassing?

o Loss of bands or cable clamps.

o Excessive swelling of the cable.

o The condition of the cable armor

Heavily corroded?

Is the armor broken?

Is the armor parted from longitude type stress?

When the cable has been disconnected from the motor, complete

a megger test and note results on the pull report.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

7

4.2.2 Check-Valve & Tubing Drain Valve

If a check-valve and tubing drain valve were installed;

note the distance from the pump to the valves on the pull

report. Indicate the type of check & drain valves that were

installed. Take digital photographs of the valves, if

warranted.

Items to evaluate.

Did the tubing pull wet?

Was the check valve plugged or fully operational?

Retrieve any debris samples from the top of the check valve

and/or drain valve, if present.

Quarantine the valves for future examination.

4.2.3 Pump(s)/Discharge Head

Key items to observe during the disassembly of the

pump(s) (take photographs of any unusual items):

Debris in the head/intake of the pump? If debris is present

collect samples, place in a plastic bag and label.

Debris between pump sections (if more than one pump section

was installed).

Discoloration of the pump housing(s)?

Shaft(s) rotation observations

o Check shaft rotation from top end of the top pump before

disassembling.

o Check shaft rotation of each pump section from the bottom

end as each pump section is removed (with pump in a

horizontal position).

o Check shaft side play (radial stability) at each end of

each pump section.

o Does the shaft rotate freely?

Does the pump or pump trim show demonstrate evidence of

corrosion? (Trim is defined as the nuts, bolts washers,

etc.).

If the equipment was flame spray coated for corrosion

protection, is the coating showing signs of degradation or

damage from installation/pulling?

If the pump(s) were shimmed with loose shims in the

couplings (some compression type pumps), place the shims in

a plastic bag and label appropriately. DO NOT tamper with

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

8

shaft extension screws or captive shims. Note on pull

report.

Was the oring heat set? Insure that the oring remains with

the discharge head for future examination.

Place new or cleaned shipping caps on the pump(s). Use new

orings or gaskets as needed.

4.2.4 Intake/Gas Separator

Key items to observe during the disassembly of the intake

or gas separator:

Check for excessive side play at both ends of the shaft.

Is the shaft setting height correct?

Did the shaft fall out of the intake?

Were the intake ports plugged? If so, take a sample of the

debris.

Did the intake have a screen? If so, observe the condition

of the screen. Was it collapsed? Was debris plugged into the

screen? If so, take a sample and place in a plastic bag,

identifying appropriately.

Was the oring heat set? Insure that the oring remains with

the intake/gas separator for future examination.

4.2.5 Protector(s)/Seal(s)

It is critical that the shaft seals be checked prior to

disassembly of the protector/seal to motor interface.

Using the pressure checking equipment as required for the

type of equipment being utilized check to confirm if any

pressure is contained between the protector (seal)/motor

interface point. Pressure checking equipment consists of the

proper tool to connect to a drain/fill location at or near

the head of the motor/seal interface. The check shall be

read on a pressure gauge (0-50 psi).

If a seal is found to be leaking, capture the leak with a

photograph.

Capture fluid samples while disassembling the protector/seal

from the motor. Observe for well fluid contamination and

note on the pull report.

Captured well fluid samples shall be returned to the

vendors service center for further examination during the

equipment teardown.

When disconnected from the intake, observe if there is any

material in the head of the protector/seal.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

9

Check the shaft for radial stability.

Note:

Drain all labyrinth chambers prior to laying down the

seal/protector. Consult with the manufacturers field service

technician.

Place new or cleaned steel shipping caps on the protector/seal

and place in a shipping box or on a proper supporting surface

on a trailer.

4.2.6 Motor(s)

Key items to observe during the disassembly of the

motor(s) (take photographs of any unusual items):

NOTE: Do NOT disconnect the pothead from the motor. If at all

possible, cut the MLE at least 3 feet (~1 meter) above the

pothead or above the upper most thrust bearing in the

protector/seal. This will allow examination of the cable

condition where it passes by the thrust bearing in the

protector/seal.

Discoloration of the motor housing(s)?

Electrical readings of the motor.

Attempt to smell the motor oil and note if the oil has a

burnt smell.

Capture fluid samples from the motor head & base as well as

any connection points (if tandem motors). Observe for well

fluid contamination and note on the pull report.

Captured well fluid samples shall be returned to the

vendors service center for further examination during the

equipment teardown.

If tandem motors; observe the connection point between the

motors. Make note of any unusual events such as bent

connection points, cracked insulators, etc.

If a sensor/gauge was installed, give particular attention

to the connection and observe for any signs of leaks or

mechanical damage. DO NOT disconnect the gauge from the base

of the motor. The motor should be returned with the gauge

still connected.

Observe rotation of the shafts and make note on the pull

report how the shaft turns.

Place new, or cleaned, shipping caps on the motor(s) (only

steel shipping-caps to be used on motors; plastic shipping-

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

10

caps are not acceptable). Place the motor in a shipping box or

on a proper supporting surface on a trailer.

4.2.7. Downhole Monitoring Devices (Sensors)

DO NOT disconnect the gauge from the motor if at all

possible. If the gauge must be disconnected at the well site,

proceed with the following steps. Key items to observe during

the disassembly of the gauge from the motor (take photographs

of any unusual items):

Note any impact loading on the bottom of the gauge.

Observe the connection point when disassembled from the

motor.

Observe for well fluid contamination.

Place new or cleaned shipping caps on the device. Use new

gaskets or orings as needed.

5.0 Dismantle, Inspection & Failure Analysis (DIFA)

5.1. Preparation

The dismantling of the ESP shall be conducted in a

controlled environment where extensive observations can be

completed. It may not be necessary to dismantle all pieces of

the ESP. Each component shall be evaluated for bench testing

prior to commencing the dismantling of the respective

component. Customer shall determine if a component shall, or

shall not, be dismantled based upon test data and data

supplied by the manufacturer. Customer shall have the right to

approve/disapprove the evaluation process of any samples,

inclusive of the evaluation company (laboratory, etc.). Prior

to commencing dismantle operations, identification cards shall

be prepared. These cards shall contain the following

information for each component and should be visible in any

photographs taken of the component:

Well Identification

Component Identification

Serial Number

Date of dismantle

In addition to the standard tooling to disassemble the ESP,

the following tools/items shall be available:

Original sizing data (hard copy to be present at dismantle

if available)

Pull & Run Report.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

11

Field service reports (if any) during the period of

operation.

Operational data captured immediately upon failure of the

ESP (inclusive of all relevant well file information)

Any/all samples taken during the pull of the ESP

Magnifying glass with high intensity lamp.

Calipers to measure bearings/bushings/pump stages, etc.

Long jaw calipers

Shore A hardness tester

Drop gauge

Hole Mics

Metal ruler and tape measure

Magnet

Multiple flashlights with high intensity beams

12 each, 1 pint, plastic sample bottles.

24 each, 1 quart, plastic bags (zip-lock type).

36 each 3 x 6 cards (blue or white preferred) to be used

as identification markers in photographs.

Permanent markers.

Dry air source or nitrogen (avoid using compressed air that

is not properly dried).

Round plastic containers for storing items such as shaft

seals, etc.

Digital Camera.

5.2 Cable

In many cases, the cable is examined and tested separately

from the ESP equipment dismantle. Customer shall reserve the

right to witness any testing and repair that may be done to

the cable.

5.3 Pump(s)

The following provides the minimum requirements for

dismantling the pump section(s) of an ESP. Required reference

documents, or information from vendor:

Stage compression details

All major wear surfaces dimensions and tolerances as follows:

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

12

Mixed flow impeller

Balance Ring

Ring Groove

Vane

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

13

Radial flow impeller

Skirt

Bore

Hubs

Sleeves

Bushings

Shaft settings

Pump Test Report (new)

Prior to disassembling the pump section, the shaft shall be

checked for rotation. If the shaft rotates, customer shall

determine if the pump shall be placed on a pump test bench and

tested prior to dismantle. If possible, flush the pump prior

to testing and collect any samples that may be flushed from

the pump. Also, prior to disassembly, ask that a new pump

stage be provided for comparison purposes. The new stage will

allow a visual comparison in key areas of the pump stage.

Pump Dismantle

Verify the pump serial number on the nameplate.

Inspect the condition of the pump housing

o Check for scale buildup, collect samples if present.

o Inspect the housing for corrosion and/or holes in the

housing. If holes are present, note the location relative

to the bottom end of the pump.

o Check for mechanical damage (dents, vibration from the

cable, scratching and bends).

o Visually inspect the housing for straightness (flop test).

o If the pump(s) have a flame spray corrosion coating,

visually inspect the coating and note any areas where the

coating is not intact.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

14

o Check for any signs of heat that would result from spinning

diffusers.

Shaft Settings & Inspection

o Check the shaft for ease of rotation (typical nomenclature

is: free, rough, hard or stuck).

o Confirm the shaft is rotating at the opposite end of the

pump.

o Take the appropriate head and base measurement for the

shaft settings. Compare these to the manufacturers factory

settings.

o Push the shaft to the down position and take measurements;

repeat in the up position. This will determine the shafts

axial movement. Compare to the manufacturers factory

settings.

o If applicable attach a dial indicator on the inside of the

shaft spline, or on a coupling, to measure run-out when the

shaft is rotated. Repeat this procedure on either-end of

the pump. Compare to the manufacturers factory settings.

Head & Base Inspection

o Remove the head and inspect the bushing for wear, plugging,

corrosion, erosion. Inspect the condition of the threads on

the head.

o If the pump has a threaded bearing support, measure the

distance from the end of the housing to the top of the

bearing support to determine the gap between the head and

support.

o Inspect the bearing support for wear with particular

attention to corrosion and erosion.

o If it is a compression type pump remove the compression per

the manufacturers instructions. Thereafter, remove the

base and complete a similar inspection as was conducted on

the pump head.

o Pull/push the impeller and diffuser stack from the housing.

Note: insure that the snap rings and 2-piece rings are in

place (consult with the manufacturer for each pumps

specific design).

o Note on the dismantle report if the impeller and diffuser

stack are difficult to pull from the housing.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

15

O-rings

o Check all o-rings for damage such as extrusion, feathering,

explosive decompression, compression set, etc. Observe for

any signs of leak past the o-ring.

o Give particular attention to any o-rings on the OD of the

diffuser. Observe the o-ring for swelling and hardness (due

to heat, etc).

Impeller & Diffuser, Bearing Sections Inspection

o Wipe off the OD of the diffuser stack and number the stages

from bottom (stage #1) to top (stage #X).

o Remove the stages and shaft from the housing. Slide all

stages off the shaft with sleeves and spacers.

o Note any diffusers that show signs of spinning on the

exterior.

o Inspect the o-rings that are in the pump stages (diffuser

OD).

o Inspect all impellers for any signs of thrust, abrasive

wear and/or radial wear. Give particular attention to the

pads, bores and hubs. Check for one-sided wear.

o Observe all components for discoloration that would

indicate wellbore fluid damage or possible heat damage.

o Randomly remove some of the thrust washers and check for

thickness and brittleness. Note the type of thrust washers

and compare with a new thrust washer. Confirm the same type

of thrust washers were used throughout the pump.

o If any foreign material is found in the pump, collect a

sample for further analysis and testing. Label on the

collection bag the location of the material.

o With the pump components laid out from base to head, take

key measurements in the top five stages, middle five stages

and bottom five stages. All wear surfaces should be

measured (e.g. skirts, bores, hubs, sleeves, bushings

etc.). This information will be used later to plot a trend

analysis. Note, the manufacturers dimensions and

tolerances of all components will be required. The

manufacturer should supply this information in advance or

at the time of the dismantle.

o Inspect the bushings and sleeves between the stages for

wear, cracks or abrasive indications. Note the material

type of the bushings and sleeves and the spacing of any

abrasion resistant (AR) bearings.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

16

o Note and record the spacing of any/all stage bearings.

Shaft Inspection

o Visually inspect the shaft spline on both ends. Observe the

splines for straightness and coupling engagement. If a

coupling is only partially engaged damage may be noted at

the upper end of the spline. Refer to the manufacturers

guidelines for checking shaft straightness.

o Place the shaft on a bench with the keyway facing up.

Observe the shaft for straightness or twisting.

o If the shaft utilizes shim nuts remove and measure with a

caliper.

o Inspect the shaft surface of any obvious issues such as

pitting, galling, erosion beneath the shaft sleeves, one-

sided wear, etc.

5.4 Intakes/Gas Separators

The intake/gas separator and discharge head should be

dismantled in conjunction with the pump.

Required reference documents, or information from vendor:

Head/base bushing dimensions & tolerances

Visual Inspection

o Inspect the O.D. of the housing for corrosion, pitting,

burns, mechanical damage, scale, holes, etc.

o A note should be made if the O.D. has a corrosion resistant

coating, and whether or not the gas separator has shipping

caps.

o After the respective internal parts are removed, the

condition of the I.D. as well as internal parts should be

examined noting any erosion, corrosion, or other

abnormalities.

Bearings and Bushings

o Inspect all bearings, bushings and sleeves noting wear

(one-sided or concentric), presence of foreign materials

and general condition. Collect samples of any foreign

materials.

Shaft

o Turn the shaft and note whether it turns free, hard, rough

or stuck. Note condition of shaft and splines, including

wear or twisting, corrosion or other mechanical damage.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

17

Intake Screen

o Observe condition of intake screen, noting presence of

foreign materials or screen collapse. Note if an intake

screen was not present. If the intake screen is not present

was it noted on the installation report?

5.5. Protector(s)/Seal(s)

The following provides the minimum requirements for

dismantling the protector/seal section(s) of an ESP. Required

reference documents, or information from vendor:

Manufacturers specific dismantle procedure for the

appropriate protector/seal to be dismantled.

Shaft settings & dimensions, tolerances

Head & base bushing dimensions and tolerances

Specification for bag material hardness (Shore A)

Seal Test Report (new)

Reference vendor documents for testing bag type and labyrinth

protectors/seals.

Standard for testing dielectric breakdown of insulating

liquids. (Reference ASTM D-877-Standard Test Methods for

Dielectric Breakdown Voltage for Insulation Liquids using

disk electrodes).

Protector/Seal Dismantle (while is it necessary to follow the

dismantle guidelines of the specific manufacturer, it is

imperative that the following items be inspected, at a

minimum. Compare the two documents to insure that all of the

following steps are met.)

Verify the protector/seal serial number on the nameplate.

Inspect the condition of the protector/seal housing

o Check for scale buildup, collect samples if present.

o Inspect the housing for corrosion and/or holes in the

housing.

o Check for mechanical damage (dents, vibration from the

cable, scratching and bends).

o Visually inspect the housing for straightness.

o If the protector/seal has a flame spray corrosion coating,

visually inspect the coating and note any areas where the

coating is not intact.

o Inspect the vent holes for plugging or debris.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

18

o Visually inspect the drain and fill valve locations for any

extruded lead gaskets.

Coupling(s)

o Inspect the coupling closely with a flashlight.

o Look for any stress damage in the splines.

o If debris is found, collect a sample.

Perform a housing leak test at the various vent ports (this

will be manufacturer specific; refer to the appropriate

manufacturer for the exact locations and pressure sequence).

The goal of this step is to test each housing connection

point to verify integrity. Use soapy water to inspect for

leaks. Give particular attention to lock plates and/or joint

welds (if utilized).

Cut lock plates/joint welds if required.

Disassembly of the protector/seal (Note: it is imperative to

refer to the specific manufacturer guidelines for

protector/seal disassembly. Each protector/seal type will

vary depending on the manufacturer and type of protector/seal

utilized.)

o Check the shaft for ease of rotation (typical nomenclature

is: free, rough, hard or stuck).

o Confirm the shaft is rotating at the opposite end of the

protector/seal.

o Push the shaft to the down position and take measurements;

repeat in the up position. This will determine the shafts

axial movement. Compare to the manufacturers factory

settings.

o Attach a dial indicator on the inside of the shaft spline,

or on a coupling, to measure run-out when the shaft is

rotated. Repeat this procedure on either-end of the unit.

Compare to the manufacturers factory settings.

o The protector/seal is to be positioned at a minimum 45

degree angle to insure the mechanical seal is covered with

oil.

o Starting at the head of the protector/seal, apply 5 psi of

air pressure through the appropriate vent hole and rotate

the shaft in both directions. If no bubbles are observed,

the mechanical seal is good. Air pressure is to be applied

for minimum of (2) minutes

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

19

o Before checking. If the mechanical seal leaks, replace the

shipping cap and repeat the test, soaping the joints to

observe for leaks.

o Continue disassembling the protector/seal from the head

down. Repeat the process of checking each mechanical seal

as it is reached. Each time, insure the protector/seal is

at, or near, a 45 degree angle prior to checking the

mechanical seal.

o As valves are removed from the protector/seal, inspect the

integrity of the lead gaskets. Give attention to any areas

where the lead gasket was not properly deformed

(compressed) for a possible leak path or where the lead

gasket may have been fully extruded due to being over-

tightened. Note findings on the report.

o Check all o-rings for damage such as extrusion, feathering,

explosive decompression, compression set, etc. Observe for

any signs of leak past the o-ring.

Inspection of Mechanical (Shaft) Seals

o Remove the snap ring that holds the mechanical seal and

slide the mechanical seal from the shaft.

o Remove and inspect the runner surface.

o Inspect the mechanical seal bellows, spring, runner and

seat for wear, scoring, chipping or broken face. Check the

elastomer for pliability , stiffness, hardness. Parts

should be labeled and sealed for further inspection at a

later date, if required.

Inspection of Chambers & Bags

o Inspect each chamber for corrosion, condition of threads

contamination, etc. Fluid samples shall be taken from each

chamber and identified appropriately for future examination

if appropriate.

o Inspect each bag, bag clamps and general condition. Note

the amount and type of fluid in the bag and on the outside

of the bag. Obtain samples in all sections. Insure samples

are labeled as collected from the different chambers,

inside the bags, etc.

o Inspect the external condition of any/all bags. Give

particular attention to the area of the bag clamps and

along the seam of the bag.

o Where applicable, remove the bag frame assembly (once

again, refer to the specific manufacturer guidelines and

procedures). After sealing the bag frame, inflate with air

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

20

and submerse the bag frame into water and look for air

bubbles.

o Locate the markings on the bag and identify the material

(the manufacturer may utilize a specific code). Check the

bag for splits, bubbles, evidence of decompression, etc.

o Where applicable, remove the bag from the guide/frame and

inspect for well fluid or other foreign material. If any

foreign material is found, collect a sample for further

evaluation. Once again, collect fluid samples from inside

the bag and identify appropriately. Additionally, collect a

sample of the bag material and place in a plastic bag for

possible future laboratory examination.

Thrust Bearing Inspection

o Remove the thrust bearing from the thrust chamber per the

manufacturers recommended procedure.

o Inspect the base bushing for any wear such as scoring, one-

side wear or galling.

o Inspect the thrust bearings and both sides of the runner

for any signs of operating in water, up thrust, down

thrust, uneven wear, deflected thrust runner, scoring,

excessive heat, fretting, etc.

o Fretting (or fretting corrosion) - The ASM Handbook on

Fatigue and Fracture defines fretting as: "A special wear

process that occurs at the contact area between two

materials under load and subject to minute relative motion

by vibration or some other force."

Head & Base Bushing & Shaft Inspection

o For the head and base locations, examine for bushing wear,

scoring, leak tracks, oring groove condition and

internal/external corrosion.

o Examine the shaft at the bushing and seal surfaces and note

any unusual wear (e.g. one-sided), scoring, etc.

o Visually inspect the shaft spline on both ends. Observe the

splines for straightness and coupling engagement. If a

coupling is only partially engaged damage may be noted with

damage at the upper end of the spline.

o Observe the shaft for any frosting that may occur.

Frosting is defined as the transfer of base bushing

material on to the motor shaft.

o Place the shaft on a bench and observe the shaft for

straightness or twisting.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

21

o If the shaft utilizes shim nuts remove and measure with a

caliper.

o Inspect the shaft surface of any obvious issues such as

pitting, galling, one-sided wear, etc.

5.6. Motor(s) (Includes the MLE & Pothead)

The following provides the minimum requirements for

dismantling the motor(s) section of an ESP.

Required reference documents, or information from vendor:

Shaft settings

Shaft settings & dimensions, tolerances

Head & base bushing dimensions and tolerances

Rotor, rotor bearing dimensions, tolerances

Any other relevant dimensions as required by the specific

manufacturer

Motor Test Report (new) (include the vibration data if

available)

Motor pit test (if applicable).

Motor Winding Information (to include details regarding

magnet wire splicing during original manufacture).

Standard for testing dielectric breakdown of insulating

liquids. (Reference ASTM D-877-Standard Test Methods for

Dielectric Breakdown Voltage for Insulation Liquids using

disk electrodes).

Review the electrical readings from the pull report and

reconfirm. Complete an electrical check on the motor prior to

removing the MLE connection at the pothead if possible. At a

minimum, the motor should be:

Megger test

Resistance readings taken

KV (dielectric) test on an oil sample taken from the base of

the motor

Refer the specific manufacturer for minimum acceptable

readings. Prior to removing the MLE/Pothead or removing a

gauge (if attached)

Perform a pressure test on the motor housing. Connect an air

hose (be sure to use either a dry air source or nitrogen) to

the drain/fill valve and apply 10 psi. Hold for a minimum of

1 minute, monitoring to confirm the motor holds pressure. If

the pressure drops below 10 psi, spray soapy water at the

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

22

pothead, head/base joints to ascertain the location of the

leak.

If the motor passes the initial electrical inspection, the

motor should be tested per the manufacturers recommended

guidelines. If a recommended guideline does not exist, the

motor can be raised to a vertical position and flushed with

appropriate new motor oil. Use a new piece of filter paper to

drain the oil from the motor to collect any solids that may be

present. Refill the motor with new motor oil and repeat the

process, using a second piece of filter paper. After the

second refill, place the motor on the motor test bench and

complete a full slant idle motor test. The motor vibration

should be recorded during the slant idle test. Compare the

vibration data to the original motor test data. Any solids

removed from the motor should be evaluated as to their origin

(i.e. brass shavings, sludge, etc.). If the motor passes the

slant idle motor test, prepare to hi-pot the motor. If the

motor fails the slant idle motor test, proceed to dismantle.

Complete a final KV (dielectric) test on an oil sample taken

from the base of the motor.

Motor Dismantle

Verify the motor(s) serial number on the nameplate.

Inspect the condition of the motor(s) housing o Check for

scale buildup, collect samples if present.

o Inspect the housing for corrosion and/or holes in the

housing.

o Check for mechanical and electrical damage.

o Visually inspect the housing for straightness.

o If the motor has a flame spray corrosion coating, visually

inspect the coating and note any areas where the coating is

not intact.

Remove Shipping Caps

o Inspect the shipping caps for any signs of debris, solids

or water since being pulled from the well.

Remove the remaining MLE & Pothead

o Inspect and test the pothead for any signs of possible

damage such as:

Look for signs of heat

Confirm the age of the MLE/Pothead was it reused?

Oring damage

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

23

Surface damage to the sealing areas

Elastomer integrity

Check the pothole for evidence of fluid tracking.

o If a sample was collected and tested during the slant idle

test, the following 3 steps are not required.

Drain the motor oil from the motor; collect a sample for

dielectric testing. This sample should be compared to the

sample collected when pulling the equipment from the well.

Check the condition of the motor oil and note on the

report (standard nomenclature is: clear, dark, emulsified,

metal/brass shavings).

After completing the dielectric test on the motor oil,

observe the motor oil for well fluid by letting it set for

a period of time to ascertain if anything settles out on

bottom, or top, of the motor oil.

o Complete an electrical check of the motor without the

pothead connected.

o If tandem motors, complete individual electrical tests of

each motor.

Shaft Settings & Inspection o Check the shaft for ease of

rotation (typical nomenclature is: free, rough, hard or

stuck). Rotate the shaft by using a motor coupling and an

insert tool to turn the shaft.

o Confirm the shaft is rotating at the opposite end of the

motor.

o Measure the shaft axial/lateral movement. Compare to the

manufacturers factory settings.

o Use a dial indicator to check run-out at the head and base

of the shaft. Compare to the manufacturers factory

settings.

Thrust Bearing & Runner

o Remove the thrust bearing and runner, inspect same.

o Check the condition of the runner face and surface.

o Check the thrust bearing for scoring, smearing,

galling.

Remove the Motor Head & Rotor String

o After removing the motor head, inspect the head bushing for

any abnormal wear. Check the oring sealing area for any

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

24

signs of damage and a resulting leak path. Typically, leak

paths will have be manifested in a discolored area.

o Check the threads on the motor head for any signs of

galling.

o Check the lead cables for physical or electrical damage.

o Check the condition of the end coils for obvious and

visible signs of a burn.

o If the stator is grounded, look for carbon trails, copper

balls to lead to the location of a burn.

o If necessary, insert a scope into the stator and inspect.

o Check all orings for damage such as extrusion, feathering,

explosive decompression, compression set, etc. Observe for

any signs of leaks past the o-ring.

o If the rotor string was difficult to remove, check for any

areas where heat may have affected the string resulting in

warping. Check for straightness.

o Inspect each rotor for discoloration and rotor strike.

Typically, the rotors will be gray in color with copper

colored end rings.

o Note any discoloration of the copper. Give particular

attention if the copper appears black as this is an

indication of H2S.

o Inspect the rotor bearings for spinning (if non-locking

type rotor bearings). If the manufacturer used a locking

rotor bearing inspect/confirm the rotor bearing locked

correctly. This may vary from manufacturer to manufacturer.

o After removal of the rotor string, inspect the slot liner

to determine if it is in its proper position. Determine if

it has shrunk into the slots.

Perform Electrical Check on the Stator

o Check the stator for phase to phase balance. If the motor

section is an upper tandem or center tandem motor, it will

be necessary to connect the phases together at the base of

the motor. The sequence for checking the stator should be:

A-B; B-C, C-A. Under normal conditions, the stator should

be balanced phase to phase within 5%. Refer to the

appropriate manufacturers guidelines. Compare the readings

to the original readings taken at time of manufacture or

the most recent available readings (e.g. readings taken

prior to installation).

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

25

o After checking the stator phase to phase, remove the jumper

at the base of the motor and check for resistance to

ground. Use a minimum of a 1000 VDC megger (a 5000 VDC

megger is preferred if available). Typically, the reading

on each phase should read 2000+ meg ohms. Be sure to

discharge the phase after testing to ground.

o Note: if the stator tests grounded and the burn is not

easily visible, destructive testing may be required.

Destructive testing requires the stator to be cut in

sections to expose suspected areas of a possible failure.

Rotor, Thrust Washer, Rotor Bearing & Sleeve Removal

o Check the condition of the thrust washers. If the thrust

washers have been exposed to excessive heat they will be

brittle. Also inspect the thrust washers for abnormal wear.

o Inspect the rotors for wear, any signs of possible rotor

strike against the stator and any residue buildup on the

OD/ID of the surfaces.

o Dimensionally check the rotors and rotor bearings.

o Inspect the rotor bearings for any signs of spinning

(assumes a non-locking rotor bearing).

o Inspect locking rotor bearings for engagement.

o Inspect all components for discoloration due to heat or

exposure to well fluid.

Base Inspection

o Check all o-rings for damage such as extrusion, feathering,

explosive decompression, compression set, etc. Observe for

any signs of leaks past the o-ring.

o Check the base bushing for abnormal wear, grooving or one

sided wear.

o Check all connection points for arcing or burns.

o Check the end coils for burns.

Final Shaft Inspection (after removal of rotors)

o Inspect the shaft for signs of heat or any abnormal wear.

o Check the head and base bushing areas for polishing,

scoring or excessive wear.

o Check the sleeve surfaces for discoloration, wear and

scoring.

o Inspect the oil holes for plugging.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

26

5.7 Downhole Monitoring Devices (Sensors)

If a downhole monitoring (i.e. sensor, gauge, etc.) is

installed conduct an evaluation of the component.

o Complete an inspection of the housing for corrosion,

erosion and mechanical damage.

o Follow the manufacturers guidelines and complete an

electrical/electronic integrity test.

o Inspect the connection point between the motor and the

monitoring device. Note any unusual damage.

o For a motor oil sensor, document the length of the lead to

the thermocouple.

6.0 Root Cause Analysis (RCA) & The Why Analysis

The purpose of Root Cause Analysis (RCA) is to enable an

investigation (in this case failure analysis) to produce

sufficient learning to prevent recurrence, or to have an

excellent chance of preventing recurrence, of whatever

undesired event or issue is being investigated. In order to

have sufficient learning, a Root Cause Analysis shall identify

the physical, human and latent cause(s), of the undesired

event or issue. If we do not identify and correct the

physical, human and latent cause(s), the undesired event or

issue may repeat if the same cause triggers similar undesired

events or issues in the same or other equipment, systems,

processes, etc.

There are generally two types of application of root cause

analysis: a) significant sporadic events, or b) significant

chronic issues.

Sporadic: Significant sporadic events are low-frequency,

high impact events that are typically very visible and

severe.

Chronic: Chronic issues are typically high-frequency, low

impact (per occurrence) issues that may not be very visible,

but over time, usually exceed the cost of sporadic events

when the multiple impacts are accumulated. A focus on chronic

issues will typically have the most impact.

o What is deemed to be chronic can be relative. For

example, suppose an offshore platform shuts in twice within

a six-month period of time for the same reason, resulting

each time in a significant loss of production. That could

be considered chronic even though it is neither high

frequency nor low impact per occurrence.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

27

Evidence Gathering

o While this recommended practice is concerned primarily with

analysis of evidence, it should be understood that evidence

gathering itself, is an essential part of a quality

investigation. The people who gather evidence must

understand what evidence should be gathered and how to

gather that evidence. They must be able to interpret the

information, and they must have the ability to accurately

convey that information. Anyone designated to gather

evidence should have received proper training or be under

the direct supervision of someone who has been so trained.

Root Cause Analysis Determination

o As stated earlier in this section, a Root Cause Analysis

shall identify the physical, human and latent cause(s), of

the undesired event or issue. If the physical, human and

latent cause(s) are not identified and corrected, then the

undesired event or issue may repeat if the same cause

triggers similar undesired events or issues in the same or

other equipment, systems, processes, etc.

o Undesired events begin with a physical cause. For example,

the shaft broke (undesired event) because it failed in

fatigue as a result of rotating bending stresses (physical

cause). This is where many investigations stop. The root

cause analysis shall not stop at this point. Identification

of the true physical cause is not a mere formality - it is

critical that the physical cause is accurately determined.

Going further to identify human and latent causes for an

incorrectly identified physical cause will not necessarily

prevent recurrence.

o People do things, or dont do things, that enable or

trigger physical causes, and these are the human causes;

for example, the mechanic misaligned the motor and the

pump. In the case of human error, there are only two

categories: 1) knew, but didnt do, or 2) didnt know, and

therefore couldnt do.

The Why Analysis

o The Why Analysis is conducted by repeatedly asking the

question "Why". Using this technique you can peel away the

layers of symptoms which can lead to the root cause of a

problem. Very often the apparent reason for a problem will

lead you to another question. To complete the why analysis

ask Why? the immediate cause occurred and write that

answer down. If the answer doesn't identify the root cause

of the problem, ask Why? again and write that answer

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

28

down. Continue this process until a root cause is

identified. Writing the answers to the why question allows

you to start documenting the sequence of events that lead

up to the incident. Use the criteria below to identify when

a root cause is found.

Benefits of using the Why Analysis

o A very simple tool to use

o Helps to identify the real root cause(s) of the incident

o Determines the relationship between different root causes

of a problem by establishing the sequence of events

o Allows creation of solutions that remove the underlying

root causes

o Not only identifies causes and solutions to eliminate the

reoccurrence of the immediate event, but eliminates the

occurrence of similar events that could occur if the root

cause(s) are not removed.

7.0 DIFA Report Format

The format shall be consistent for all reports. The

reports shall have a designated numbering format, preferably

sequentially numbered. The report shall contain a header and

footer that contain consistent information throughout the

report. The header shall contain:

o Company Name

o Title

o Reference Report number

o Well Name

The footer shall contain:

o Issue/revision number

o Page x of y numbering format.

The completed DIFA Report shall be submitted to the local

customer Engineering Manager/Supervisor/Engineer, as

designated by the local business unit. The local business unit

shall submit a report to the Artificial Lift team leader.

Electronic copies are acceptable.

7.1 Cover

The cover shall reference a specific DIFA report number;

identify the appropriate business unit and well name/number.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

29

7.2 Table of Contents

The table of contents shall detail each major area in the

report and an associated page number.

7.3 Distribution List

The distribution list page shall identify all parties that

the report is distributed to (inclusive of Customer personnel

as well vendor personnel). This page shall also identify the

person that conducted the dismantle inspection as well as the

person(s) which wrote the report.

7.4 Well Information

This page shall be considered the executive summary. This

section shall contain the following information:

o Business Unit Identification

o Well Identification

o Run Date

o Failure Date

o Pull Date

o Run Life (in days)

o Reason for Pull

o Dismantle Date

o Report Date

The written portion of this page shall state the following,

under individual headings:

o Objective a short description of the objective of the

DIFA.

o Well History a brief overview of major incidents in the

life of the well from the run date to pull date. All

unusual events should be highlighted in this paragraph.

o Pull Report a brief description of observations during

the pulling of the unit.

o Summary a short paragraph detailing the failure and

evaluated cause of failure.

7.5 Trend Analysis

This section should contain graphs/charts from available

well monitoring packages such as LOWIS, SCADA or Well view.

Customer shall make this information available to the vendors

application engineer.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

30

7.6 Electric Submersible Pump Identification Information

This section shall give complete descriptions of the

failed ESP in a table format. The table shall consist of

Equipment Description, Serial Number and Part Number.

7.7 Dismantle Inspection Findings

This section consists of multiple pages. The order of this

section shall be from top to bottom on the ESP (i.e. pump,

intake, seal/equalizer/protector, and motor). Each component

section shall contain the following:

o Header section identifying the component and its proper

description; serial number; part number

o Exterior Inspection

o Head/Base Condition

o Shaft Condition

o Component(s) Condition with extensive descriptions

o Summary of finding for the specific component

7.8 Summary of Results & Statement of Root Cause

This section shall contain 3-6 paragraphs summarizing the

findings of the DIFA. The statement of the root cause of

failure shall be made in this section.

7.9 Recommendations

This section shall contain 1-4 paragraphs recommending

future changes or highlighting key areas to monitor.

7.10 Photograph Gallery

This section shall consist of multiple pages of important

photographs that contribute to the issues discovered in the

DIFA. The page shall have 2 photographs per page, maximum. The

photographs shall be of consistent size and shall have

sufficient quality to identify the item being described. A

detailed description of the photograph shall be at the bottom

of each photograph or at the bottom of the page if a single

description is sufficient for both photographs. Where

applicable, the photograph shall utilize embedded arrows and

descriptions. Finally, as appropriate, a rectangular

description card should be included in the photograph that

identifies the well, item and serial number

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

31

Pump Photographs

Pump Housing Coating Flake (flame spray type coating)

Drag Marks on Pump Housing

Coating flaking

Drag Marks

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

32

Cut Oring on Pump Head (Note: the oring appears to be

brittle as well)

Scored Bushing in Pump Base

Cut oring & brittle

Scoring

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

33

Severe Bushing Wear

Pump Head likely deposits from tubing trash

Tubing fallback deposits

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

34

Spinning Diffuses

Typical One-Sided Pump Shaft Wear

Spinning Diffusers; note

marks on diffuser OD

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

35

Twisted Pump Shaft at Spline

Twisted Shaft Along Keyway

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

36

Scale in Pump Stage

Cracked Impeller Hub Crack Along Keyway

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

37

Eccentric destroy Impeller hub

Impeller hub completely destroyed

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

38

Severe Downthrust Wear versus New Impeller

Destroy in diffuser hub

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

39

Impeller with Whipping

Light Upthrust Wear on Impeller

Upthrust on Impeller

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

40

Heavy Upthrust Wear on Impeller

Heavy Upthrust Wear with Broken Hub

Broken Hub

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

41

Diffuser Bore with Medium Wear

One Sided Radial Wear

Medium Wear Area

Medium Wear Area

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

42

Severe downthrust

Severe upthrust

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

43

Plugging with scale

BOI & GS Photographs

Collapsed Intake Screen

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

44

Severe Intake Erosion

Plugged Gas Separator from Asphaltines

Severe Erosion

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

45

Damaged Gas Separator Inducer

Erosion in BOI exit ports

Broken Inducer

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

46

Erosion in GS against axial impeller

Severe erosion in GS against axial impeller

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

47

Erosion in BOI inlet ports

Hole in GS (Corrosion)

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

48

Scoring in zirconium bearing

Protector/Seal Photographs

Corrosion in the Lockplate Area

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

49

MLE vibration marks on the seal/protector housing

Water in the Chamber of a Seal/Protector

Water in a Seal/Protector

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

50

Scale Deposits on Mechanical Seal

Damage to Seal Bellows Due to Heat

Damage to elastomer of seal

due to heat

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

51

Severe Corrosion on the Seal/Protector Tube

Severe Deposits on the Exterior of the Seal/Protector Bag (All

Deposits Should be Collected and Examined by a Laboratory)

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

52

Bubbles in the Seal/Protector Bag

Damage to a Seal/Protector Bag

Bubbles in the bag can be

caused be defects, chemicals,

heat, etc.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

53

Damage to a Seal/Protector Bag at the Clamp Area

New thrust bearing (Solid shoe)

Damage to a bag from the

application of a clamp

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

54

New Thrust runner

New thrust bearing (high load 9 pads)

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

55

New Thrust runner (High Load)

Sever thrust load

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

56

Heavy Smearing of Standard Thrust Bearing

Severe Damage to Thrust Bearing due to Down Thrust

Heavy down thrust damage

note the pad stuck to the

runner

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

57

Damage to Seal/Protector Shaft at the Bushing Surface

Broken Seal/Protector Shaft (Note: never try to put the ends

of the shaft back together. The ends should be examined under

a microscope.)

Note the damage on the

shaft where the bushing is

located

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

58

Frontal View of Broken Shaft

Shaft Break often a shaft break will occur at, or near, the

spline area of the shaft as this is the weakest area.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

59

Motor Photographs

Motor Pothead Hole

Motor Head Burn (Flat Cable Area)

Inspect oring area for

damage

Burn on motor head

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

60

Failed Pothead at MLE/Pothead Interface

Massive Pothead Burn

Blowout of Pothead

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

61

Rotor subjected to light heating effect

Rotor subjected to medium to high heating effect

Rotor subjected to high heating effect

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

62

Failure in protector(s)/seal(s)

Rotor Strike

Dielectric oil contaminated

with well fluid

Rotor Strike

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

63

Rotor Strike on Motor Laminations

Burn on Lead from End-Turn

Lead burn (from end-

turn on motor)

Rotor Strike Area of

Sectioned Motor

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 10

64

Coil to Coil Burn

Burn between end-

coils classified as a

coil-to-coil burn

Вам также может понравиться

- SPE-68789-MS One PetroДокумент5 страницSPE-68789-MS One PetroAlex ZamanОценок пока нет

- ESP SystemДокумент27 страницESP SystemDario PederivaОценок пока нет

- Automotive Actuators and EVAP System TestingОт EverandAutomotive Actuators and EVAP System TestingРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Chapter 01 IntroductionДокумент12 страницChapter 01 Introductiondewidar1234100% (1)

- Artificial Lift Methods Guide for Oil WellsДокумент57 страницArtificial Lift Methods Guide for Oil WellsHaseen KaurОценок пока нет

- Artificial Lift: Abdullah Bin ZiadДокумент39 страницArtificial Lift: Abdullah Bin ZiadGilbertОценок пока нет

- Selecting An Artificial Lift MethodДокумент62 страницыSelecting An Artificial Lift MethodSiddiq MahyildinОценок пока нет

- API Recommended Practice For ESPДокумент104 страницыAPI Recommended Practice For ESPMaghfiraRamadhaniОценок пока нет

- PEG 4102 - Sucker Rod Pump Project PresentationДокумент22 страницыPEG 4102 - Sucker Rod Pump Project PresentationAlex StollОценок пока нет

- ESP: Electrical Submersible Pump OverviewДокумент17 страницESP: Electrical Submersible Pump OverviewMurad AliyevОценок пока нет

- Art Lift Slide ShowДокумент110 страницArt Lift Slide ShowAamir ShahzadОценок пока нет

- 2004 Gas Lift SeminarДокумент317 страниц2004 Gas Lift SeminarNgọc Hiệp LêОценок пока нет

- Iraq ESP1Документ6 страницIraq ESP1juliocanel2009Оценок пока нет

- Schlumberger ESP Catalog PDFДокумент189 страницSchlumberger ESP Catalog PDFAbe Rm95% (20)

- AICV InflowControlДокумент8 страницAICV InflowControlsouthliОценок пока нет

- Gas-Liquid Flow Through Electric Submersible PumpsДокумент8 страницGas-Liquid Flow Through Electric Submersible PumpspicapicОценок пока нет

- Artificial Lift Training - CopieДокумент141 страницаArtificial Lift Training - CopiesereptОценок пока нет

- Dual EspДокумент8 страницDual EspdoubleulandОценок пока нет

- ESP OptimizationДокумент17 страницESP OptimizationVictor Hugo100% (1)

- Application Engineering: Reda Esp System ComponentsДокумент4 страницыApplication Engineering: Reda Esp System Componentselsayed amerОценок пока нет

- Design of PCP WellsДокумент28 страницDesign of PCP Wellsdubang6975% (4)

- Electric Submersible PumpДокумент14 страницElectric Submersible PumpIzzah Ishak100% (1)

- ESP Failure Analysis of Forties Experience ApacheДокумент14 страницESP Failure Analysis of Forties Experience ApacheMohamed AshrafОценок пока нет

- Practical Aspects of Unloading and OperationДокумент2 страницыPractical Aspects of Unloading and OperationDeny Fatryanto EkoОценок пока нет

- ESP - Artificial LiftДокумент46 страницESP - Artificial LiftAYUОценок пока нет

- 3 ArtificialliftsystemsДокумент29 страниц3 Artificialliftsystemsstephaniebritosuare2Оценок пока нет

- ESP Pumps in Viscous LiquidsДокумент68 страницESP Pumps in Viscous Liquidsalexis_viteriОценок пока нет

- ESP Pump Selection, Evaluation Improve Well Inflow, Volumes - Oil & Gas JournalДокумент7 страницESP Pump Selection, Evaluation Improve Well Inflow, Volumes - Oil & Gas JournaljoreliОценок пока нет

- Optimising ESP Runlife - A Practical Checklist - 7th European ESP Round Table, Aberdeen 2002 PDFДокумент8 страницOptimising ESP Runlife - A Practical Checklist - 7th European ESP Round Table, Aberdeen 2002 PDFazareiforoushОценок пока нет

- The Rod Pumping - System DesignДокумент37 страницThe Rod Pumping - System Designdoubleuland100% (2)

- How To Use Vogel's ChartДокумент9 страницHow To Use Vogel's Charthawar abdul-khaliq100% (3)

- Centrifugal Pumps - How They Work & Key Design FeaturesДокумент42 страницыCentrifugal Pumps - How They Work & Key Design Featuresmostafa_ibrahim007Оценок пока нет

- 02 Forms of Artificial LiftДокумент135 страниц02 Forms of Artificial Liftام فاطمة البطاطОценок пока нет

- Echometer Well AnalysisДокумент1 страницаEchometer Well AnalysisefrasozaОценок пока нет

- Electric Submersible Pump BasicsДокумент146 страницElectric Submersible Pump BasicsAbhoe Stank100% (6)

- GAS LIFT TROUBLESHOOTING GUIDE Oilproduction PDFДокумент20 страницGAS LIFT TROUBLESHOOTING GUIDE Oilproduction PDFSteve MarfissiОценок пока нет

- A Review of Downhole Separation TechnologyДокумент8 страницA Review of Downhole Separation TechnologyIbrahim NugrahaОценок пока нет

- Overview of Beam Pump OperationsДокумент16 страницOverview of Beam Pump OperationsLEONARDO ARZUZA100% (1)

- 7 European Electric Submersible Pump Round Table Aberdeen, ScotlandДокумент8 страниц7 European Electric Submersible Pump Round Table Aberdeen, Scotlandshy_boyОценок пока нет

- 2 - Forms of Lift - ESP MethodologyДокумент78 страниц2 - Forms of Lift - ESP MethodologyMartin UdanОценок пока нет

- ESP SystemsДокумент22 страницыESP SystemsNabila GhaisaniОценок пока нет

- Dumpflood ESP Application Design: ADMA Sarb IslandДокумент16 страницDumpflood ESP Application Design: ADMA Sarb IslandMaRodОценок пока нет

- ESP Surface Component EnglishДокумент33 страницыESP Surface Component EnglishJoab BrazОценок пока нет

- Schlumberger Jet PumpДокумент2 страницыSchlumberger Jet PumpTaufiq ByomantoroОценок пока нет

- API RP 16E Control SysДокумент31 страницаAPI RP 16E Control SysAaron Higgins100% (1)

- Wellhead and Christmas TreeДокумент4 страницыWellhead and Christmas Treedinesh_hsenidОценок пока нет

- 2011 ESP WorkshopДокумент41 страница2011 ESP Workshopuekiiiiii23Оценок пока нет

- Surface EquipmentДокумент42 страницыSurface Equipmentixotee100% (1)

- Design Overview: Basic Design and Maintenance InstructionsДокумент8 страницDesign Overview: Basic Design and Maintenance InstructionsOctopusОценок пока нет

- Comparative Study Between Gas Lift and Electric Submersible Pump SystemsДокумент26 страницComparative Study Between Gas Lift and Electric Submersible Pump Systemsalejandroarturo0412100% (1)

- Sucker Rod Pump BasicsДокумент76 страницSucker Rod Pump BasicsDumitrescu GabrielОценок пока нет

- 4 Run Life OpsДокумент29 страниц4 Run Life Opshatem_eldawyОценок пока нет

- Electrical Submersible Pump (ESP) : Components (Equipment Description) PTP-6.1Документ19 страницElectrical Submersible Pump (ESP) : Components (Equipment Description) PTP-6.1nawarsОценок пока нет

- Chapter 10 Recommended Practice For ESP Failure Analysis PDFДокумент64 страницыChapter 10 Recommended Practice For ESP Failure Analysis PDFedwinОценок пока нет

- Manual Bomba KSB RPK 41 1118Документ20 страницManual Bomba KSB RPK 41 1118elegel1982100% (2)

- Norsok U-Cr-005 Subsea Production Control SystemsДокумент25 страницNorsok U-Cr-005 Subsea Production Control SystemscristianoclemОценок пока нет

- ECP 11 0507 - Compact & Micro SS Comm ProcedureДокумент6 страницECP 11 0507 - Compact & Micro SS Comm ProcedureRahul Singania100% (1)

- Procedure Field Inspection & Testing Electrical EquipmentДокумент21 страницаProcedure Field Inspection & Testing Electrical Equipmentarifadha446100% (5)

- JP - Chapter 03Документ14 страницJP - Chapter 03dewidar1234100% (1)

- Chapter - 08 Switchboard and VSDДокумент44 страницыChapter - 08 Switchboard and VSDdewidar1234100% (2)

- JP - Chapter 04Документ3 страницыJP - Chapter 04dewidar1234100% (4)

- JP - Chapter 02Документ11 страницJP - Chapter 02dewidar1234Оценок пока нет

- Chapter - 06 Power CableДокумент50 страницChapter - 06 Power Cabledewidar1234100% (5)

- Chapter 11 EconomisДокумент9 страницChapter 11 Economisdewidar1234100% (2)

- Jet PumpДокумент21 страницаJet Pumpdewidar1234100% (2)

- JP - Chapter 01Документ9 страницJP - Chapter 01dewidar1234100% (1)

- Chapter - 09 ESP Design ExamplesДокумент16 страницChapter - 09 ESP Design Examplesdewidar1234100% (11)

- Chapter 05 GSДокумент10 страницChapter 05 GSdewidar1234Оценок пока нет

- Chapter 07 TransformerДокумент48 страницChapter 07 Transformerdewidar1234100% (3)

- Chapter 04 SealДокумент25 страницChapter 04 Sealdewidar1234100% (1)

- Chapter - 03 ESP MotorДокумент80 страницChapter - 03 ESP Motordewidar1234100% (2)

- Chapter - 02 Centrifugal PumpДокумент83 страницыChapter - 02 Centrifugal Pumpdewidar1234100% (4)

- Intelligent Electromagnetic Braking for 4-Wheel VehiclesДокумент4 страницыIntelligent Electromagnetic Braking for 4-Wheel VehiclesSkive FabsysОценок пока нет

- KTR - 02 Tooth Gear CouplingsДокумент34 страницыKTR - 02 Tooth Gear CouplingsMišo SavčićОценок пока нет

- Truck Tire Data BookДокумент130 страницTruck Tire Data Bookrashom0099088Оценок пока нет

- Helioscope Simulation 13233814 SummaryДокумент3 страницыHelioscope Simulation 13233814 SummaryandisaputrawuОценок пока нет

- DSE335 Operators ManualДокумент2 страницыDSE335 Operators ManualArc HieОценок пока нет

- Dodge Avenger IAT Sensor DTC P0112 P0113 FixДокумент7 страницDodge Avenger IAT Sensor DTC P0112 P0113 Fixflash_24014910Оценок пока нет

- VR341 ManualДокумент8 страницVR341 Manualfahad pirzadaОценок пока нет

- Watt N Volt TENDER BOQДокумент24 страницыWatt N Volt TENDER BOQMohammad AliОценок пока нет

- Wabco Automated Manual Transmission (AMT) : Aftermarket Solutions For Gearbox Control Units For Volvo ApplicationsДокумент9 страницWabco Automated Manual Transmission (AMT) : Aftermarket Solutions For Gearbox Control Units For Volvo ApplicationsDieselk0% (1)

- Twice A Year Cleanig ChecklistДокумент1 страницаTwice A Year Cleanig Checklistxcxx xxxОценок пока нет

- PTCL Vendor Registration FormДокумент30 страницPTCL Vendor Registration FormHarisAslam100% (1)

- 12 Volt Bar-Mount Chain Saw Sharpener Owner'S Manual: Item # 141259Документ8 страниц12 Volt Bar-Mount Chain Saw Sharpener Owner'S Manual: Item # 141259Relyax ColiliОценок пока нет

- Electric Motors, USAДокумент15 страницElectric Motors, USAVanessa MendozaОценок пока нет

- Schneider Short Circuit CalculationДокумент36 страницSchneider Short Circuit Calculationincobar100% (2)

- Brother P-Touch PT-2420PC Parts List PDFДокумент16 страницBrother P-Touch PT-2420PC Parts List PDFMaxim100Оценок пока нет

- FS700 9b2007e PDFДокумент36 страницFS700 9b2007e PDFBd MahabubОценок пока нет

- Garment Overview PBS SystemДокумент9 страницGarment Overview PBS SystemMuskan AgarwalОценок пока нет

- Catalogo Trane LwhaДокумент26 страницCatalogo Trane LwhaAlejandro MoralesОценок пока нет

- Piston Engine FundamentalДокумент62 страницыPiston Engine Fundamentalkp subedi100% (1)

- Electrical WorkshopДокумент16 страницElectrical WorkshopSpaceCookies1868100% (1)

- Firewall III Single Shielded PairДокумент2 страницыFirewall III Single Shielded PairRenato BarbarićОценок пока нет

- Eliiot STC-Avionics-Installation-Part-2 PDFДокумент19 страницEliiot STC-Avionics-Installation-Part-2 PDFslam1212533% (3)

- HYW-20 T5: Generating RatesДокумент12 страницHYW-20 T5: Generating RatesRagowo Tri WicaksonoОценок пока нет

- Citizen A16VI Machine SpecificationsДокумент2 страницыCitizen A16VI Machine SpecificationscmganklОценок пока нет

- 02 Diagrams 5258 1Документ6 страниц02 Diagrams 5258 1Regis Consultec100% (1)

- Coa Unit-3,4 NotesДокумент17 страницCoa Unit-3,4 NotesDeepanshu krОценок пока нет

- IEC Standards for Power CablesДокумент1 страницаIEC Standards for Power CablesLucian2001Оценок пока нет

- 2,7,8, DP Aoh Condiciones TecnicasДокумент3 страницы2,7,8, DP Aoh Condiciones TecnicasFernando EncisoОценок пока нет

- Logan Lathe Model 922 ManualДокумент16 страницLogan Lathe Model 922 Manualnjsmith5Оценок пока нет

- JOINT BOX FOR OPGW CABLE 2 WayДокумент1 страницаJOINT BOX FOR OPGW CABLE 2 WayJayantОценок пока нет

- The Grid: The Fraying Wires Between Americans and Our Energy FutureОт EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureРейтинг: 3.5 из 5 звезд3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)