Академический Документы

Профессиональный Документы

Культура Документы

Bag Filter Calculations, Mr. Bokaian's

Загружено:

Mohsen Ardestani100%(4)100% нашли этот документ полезным (4 голоса)

2K просмотров24 страницыCalculation of bag filters

Оригинальное название

Bag Filter Calculations, Mr. Bokaian's Copy

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документCalculation of bag filters

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

100%(4)100% нашли этот документ полезным (4 голоса)

2K просмотров24 страницыBag Filter Calculations, Mr. Bokaian's

Загружено:

Mohsen ArdestaniCalculation of bag filters

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 24

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 1 OF 24

A Dedusting points

1 Troughed belt conveyor

2 Steel apron feeder

3 Steel apron feeder, bulk material standing

4 Deep bucket conveyor

5 Box feeder

6 Weigh belt

7 Bucket elevator, chain - type

8 Bucket elevator, belt - type, single casing

9 Bucket elevator, belt - type, double casing

10 Vibrating trough without flex seal, bulk material falling

11 Vibrating trough without flex seal, bulk material standing

12 Vibrating trough with flex seal, bulk material falling

13 Vibrating trough with flex seal, bulk material standing

14 Vibrating screen without flex seal

15 Vibrating screen with flex seal

16 Aeropol

17 Poldos pressure vessel conveyor

18 Fluidor

19 Clinker silo feed, silo penthouse closed, 1 feed opening

20 Clinker silo feed, silo penthouse closed, 2 feed opening

21 Clinker silo feed, silo penthouse closed, 3 feed opening

22 Clinker silo feed, silo penthouse open, 1 feed opening

23 Clinker silo feed, silo penthouse open, 2 feed opening

24 Clinker silo feed, silo penthouse open, 3 feed opening

25 Clinker silo feed, cover trapezoidal plate, 1 feed opening

26 Clinker silo feed, cover trapezoidal plate, 2 feed opening

27 Clinker silo feed, cover trapezoidal plate, 3 feed opening

28 Bin on top, 1 feed opening

29 Bin on top, 2 feed opening

30 Bin on top, pneumatic feed

31 Polycom

32 Feed hopper

33 Crusher, moisture level < 6%

34 Hammer crusher

35 Vaccume relief

36 Bulk loading, open

37 Cement cooler

38 Other machines / aggregates

DEDUSTING

surt:\techdata\dedusting\procedure.xls

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 2 OF 24

B Types of dust

a) Non - Wearing / Abrasive dust

1 Dust from lime stone

2 Dust from clay

3 Dust from marl

4 Raw mix dust

5 Coal dust

6 Exit dust from raw material dryers

7 Raw gypsum dust

b) Wearing / Abrasive dust

1 Dust from iron ore

2 Dust from slag

3 Exit dust from kiln

4 Cement kiln dust

5 Clinker dust

6 Cement dust

C Recommended air velocities in dedusting pipes

a) Non - Abrasive dust

vmax. = max. air velocity = 19 m/s

vmin = min. air velocity = 13 m/s

b) Abrasive dust

vmax. = max. air velocity = 16 m/s

vmin. = min. air velocity = 10 m/s

D Recommended standard pipe (OD) sizes

139.7 1118

219.1 1219.0

273.0 1422

323.9 1626

355.6 1700

406.4 1800

457.2 1900

558.8 2000

609.6 2100

711.2 2200

813 2300

914 2400

1016 2500

1067

DEDUSTING

surt:\techdata\dedusting\procedure.xls

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 3 OF 24

E Calculation for Pipe size and air velocity

V = Volume i.e. volume of to be dedusted in m3/h

V = (pi/4) * (Di/1000)

2

* vmax * 3600 where

vmax = max velocity in m/s

Di = pipe I D in mm.

Di = 1000 * [(4 * V) / (3600 * pi * vmax)]

0.5

in mm

Select standard pipe size D from given table corresponding to Di

D D

Selected Selected

pipe O D pipe O D

> 0.0 < 131.7 139.7 >= 1059 < 1110 1118

>= 160.3 < 211.1 219.1 >= 1110 < 1211 1219.0

>= 211.1 < 265.0 273.0 >= 1211 < 1414 1422

>= 265.0 < 315.9 323.9 >= 1414 < 1618 1626

>= 315.9 < 347.6 355.6 >= 1618 < 1692 1700

>= 347.6 < 398.4 406.4 >= 1692 < 1792 1800

>= 398.4 < 449.2 457.2 >= 1792 < 1892 1900

>= 449.2 < 500 558.8 >= 1892 < 1992 2000

>= 500 < 602 609.6 >= 1992 < 2092 2100

>= 602 < 703 711.2 >= 2092 < 2192 2200

>= 703 < 805 813 >= 2192 < 2292 2300

>= 805 < 906 914 >= 2292 < 2392 2400

>= 906 < 1007 1016 >= 2392 < 2492 2500

>= 1007 < 1059 1067

Calculate air velocity v considering selected pipe dia. D

v = 1000 * ((4 * V) / (3.6* pi * (D - 8)

2

) in m/s

Calculated velocity should be >= vmin <= vmax

Example : Volume calculated V is 7561.51 m

3

/h

Di = 1000 * [(4 * V) / (3600 * pi * vmax)]

0.5

in mm

= 375.173

D = 406.4 selected from the table

v = 1000 * (4 * V / (3.6 * pi * (D - 8)

2

) in m/s

= 16.8491

DEDUSTING

pipe I D pipe I D

Di Di

Calculated Calculated

surt:\techdata\dedusting\procedure.xls

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 4 OF 24

E Calculation for air volume

1 Troughed belt conveyor

Discharge point

Air volume Vd in m

3

/h

Vd = kt * kh * ( Belt width in mm) * ( (belt speed in m/s) / 1.7)

0.5

* 3.6 in m

3

/h

Where

kt = 1 if temperature <= 40

0

C

= 1.1 if temperature > 40

0

C

kh = 0.65 if height of slope <= 3 m

= 1 if height of slope > 3 m

Feed front point

Air volume Vff in m

3

/h

Vff = ( Belt width in mm) *( (belt speed in m/s) / 1.7)

0.5

* 3.6 in m

3

/h

Feed back point

Air volume Vfb in m

3

/h

Vfb = kb * 60 in m

3

/h

kb = 12.2 if belt width is > 1000 mm

= 8.5 if belt width is <= 1000 mm

Example Belt width 2500 mm

Height of slope 4 m

Belt speed 1.2 m/s

Temperature 20

0

C

Vd =1*1 *( 2500) *( (1.2) / 1.7)

0.5

* 3.6 in m

3

/h

= 7561.51 m

3

/h

Vff = ( 2500) * ( (1.2) / 1.7)

0.5

* 3.6 in m

3

/h

= 7561.51 m

3

/h

Vfb = 12.2* 60 in m

3

/h

= 732.00 m

3

/h

2 Steel apron feeder

Discharge point

Air volume Vd in m

3

/h

Vd = 1.15 * kt * kh * ( width in mm) * 3.6 in m

3

/h

Where

kt = 1 if temperature <= 40

0

C

= 1.16 if temperature > 40

0

C

kh = 1 if height of slope <= 3 m

= 1.1 if height of slope > 3 m

DEDUSTING

surt:\techdata\dedusting\procedure.xls

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 5 OF 24

Feed point

Air volume Vf in m

3

/h

Vf = kt * kh * ( width in mm) * 3.6 in m

3

/h

Example Width 2500 mm

Height of slope 6 mm

Temperature 30

0

C

Vd =1.15 * 1 * 1.1 * ( 2500) *3.6 in m

3

/h

= 11385 m

3

/h

Vf =1*1.1 *( 2500) *3.6 in m

3

/h

= 9900 m

3

/h

3 Steel apron feeder, bulk material standing

Feed point

Air volume Vf in m

3

/h

Vd = 1.25 * kt * ( width in mm) in m

3

/h

Where

kt = 1 if temperature <= 40

0

C

= 1.1 if temperature > 40

0

C

Example Width 2500 mm

Temperature 30

0

C

Vf =1.25 * 1 * ( 2500) in m

3

/h

= 3125 m

3

/h

4 Deep bucket conveyor

Discharge point

Air volume Vd in m

3

/h

Vd = 1.15 * kt * kh * ( width in mm) * 3.6 in m

3

/h

kt = 1 if temperature <= 40

0

C

= 1.16 if temperature > 40

0

C

kh = 1 if height of slope <= 3 m

= 1.1 if height of slope > 3 m

Feed point

Air volume Vf in m

3

/h

Vf = kt * kh * ( width in mm) * 3.6 in m

3

/h

Example Width 1400 mm

Height of slope 4 m

Temperature 30

0

C

KRUPP INDUSTRIES INDIA LTD

DEDUSTING

surt:\techdata\dedusting\procedure.xls

DESIGN Calculation Procedure

MANUAL SHEET 6 OF 24

Vd =1.15 * 1 * 1.1 * ( 1400) *3.6 in m

3

/h

= 638 m

3

/h

Vf =1*1.1 *( 630) *3.6 in m

3

/h

= 5544 m

3

/h

5 Box feeder

Discharge point

Air volume Vd in m

3

/h

Vd = km * ( width in mm) * 3.6 in m

3

/h

Where

km = 0.6 if moisture level < 6 %

= 0.4 if moisture level > 6 %

Feed point

Air volume Vf in m

3

/h

Vf = 0.27 * ( width in mm) * 3.6 in m

3

/h

Example Width 2500

Moisture level % 4

Vd =0.4 * ( 2500) *3.6 in m

3

/h

= 3600 m

3

/h

Vf =0.27*( 2500) *3.6 in m

3

/h

= 2430 m

3

/h

6 Weigh belt

Discharge point

Air volume Vd in m

3

/h

Vd = 0.525 * kt * ( width in mm) * 3.6 in m

3

/h

Where

kt = 1 if temperature <= 40

0

C

= 1.15 if temperature > 40

0

C

Feed point

Air volume Vf in m

3

/h

Vf = 480 in m

3

/h when (tph * 1.4) < 480

Vf =1.4 * ( tph ) in m

3

/h when (tph * 1.4) > 480

Example Width = 2500 mm

tph = 600 tph

Temp. 30

0

C

KRUPP INDUSTRIES INDIA LTD

DEDUSTING

surt:\techdata\dedusting\procedure.xls

DESIGN Calculation Procedure

MANUAL SHEET 7 OF 24

Vd =0.525 * 1 * ( 2500 ) *3.6 in m

3

/h

= 11385 m

3

/h

Vf =1.4 * 600 in m

3

/h

= 840 m

3

/h

7 Bucket elevator, chain - type

Bottom boot

Air volume Vb in m

3

/h

Vb = 0 when height < 12 m

Vb = 14.61 * ( width in mm)0.67815 in m3/h If temperature <= 40

0

C

Vb = 13.28 * ( width in mm)0.6777 in m3/h If temperature > 40

0

C

Top hood

Air volume Vt in m

3

/h

Vt = 19.33 * ( width in mm)

0.67836

in m

3

/h If temperature <= 40

0

C

Vt = 26.56 * ( width in mm)

0.6777

in m

3

/h If temperature > 40

0

C

Example Width 1000 mm

Height 30 m

Temp. 30

0

C

Vb = 14.61 * ( 1000)

0.67815

in m

3

/h

= 1582 m

3

/h

Vt = 19.33 * ( 1000)

0.67836

in m

3

/h

= 2096 m

3

/h

8 Bucket elevator, belt type, single casing

Top hood

Air volume Vt in m

3

/h

Vt = 27.41 * ( width in mm)

0.741

in m

3

/h If temperature <= 40

0

C

Vt = 46.1 * ( width in mm)

0.6877

in m

3

/h If temperature > 40

0

C

Example Width 1000 mm

Height 30 m

Temp. 30

0

C

Vb = 27.41 * ( 1000)

0.741

in m

3

/h

= 4580.46 m

3

/h

KRUPP INDUSTRIES INDIA LTD

DEDUSTING

surt:\techdata\dedusting\procedure.xls

DESIGN Calculation Procedure

MANUAL SHEET 8 OF 24

9 Bucket elevator, belt type, double casing

Bottom hood

Air volume Vb in m

3

/h

Vb = 0 in m

3

/h If height < 12 m

Vb = 11.8 * ( width in mm)

0.741

in m

3

/h If temperature <= 40

0

C

Vb = 40.92 * ( width in mm)

0.52

in m

3

/h If temperature > 40

0

C

Top hood

Air volume Vt in m

3

/h

Vt = 15.62 * ( width in mm)

0.741

in m

3

/h If temperature <= 40

0

C

Vt = 21.5 * ( width in mm)

0.752

in m

3

/h If temperature > 40

0

C

Example Width 1000 mm

Height 30 m

Temp. 30

0

C

Vb = 11.8 * ( 1000)

0.741

= 1972 m

3

/h

Vt = 15.62 * ( width in mm)

0.741

= 2610 m

3

/h

10 Vibrating trough without flex seal, bulk material falling

Feed point

Air volume Vf in m

3

/h

Vf = 0.16 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature <= 40

0

C

Vf = 0.2 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature > 40

0

C

Discharge point

Air volume Vd in m

3

/h

Vd = 0.6 * ( width in mm) * 3.6 If temperature <= 40

0

C

Vd = ( width in mm) * 3.6 If temperature > 40

0

C

Example Width 1500 mm

Length 8 m

Temp. 100

0

C

Vf = 0.2 * ( 1500) * 3.6 * (1 + 2 * 8 )

= 18360 m

3

/h

Vd = (1500) * 3.6

= 5400 m

3

/h

KRUPP INDUSTRIES INDIA LTD

DEDUSTING

surt:\techdata\dedusting\procedure.xls

DESIGN Calculation Procedure

MANUAL SHEET 9 OF 24

11 Vibrating trough without flex seal, bulk material standing

Feed point

Air volume Vf in m

3

/h

Vf = 0.08 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature <= 40

0

C

Vf = 0.12 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature > 40

0

C

Discharge point

Air volume Vd in m

3

/h

Vd = 0.4 * ( width in mm) * 3.6 If temperature <= 40

0

C

Vd = 0.8 * ( width in mm) * 3.6 If temperature > 40

0

C

Example Width 1500 mm

Length 8 m

Temp. 100

0

C

Vf = 0.12 * ( 1500) * 3.6 * (1 + 2 * 8 )

= 11016 m

3

/h

Vd = 08 * (1500) * 3.6

= 4320 m

3

/h

12 Vibrating trough with flex seal, bulk material falling

Feed point

Air volume Vf in m

3

/h

Vf = 0.08 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature <= 40

0

C

Vf = 0.12 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature > 40

0

C

Discharge point

Air volume Vd in m

3

/h

Vd = 0.4 * ( width in mm) * 3.6 If temperature <= 40

0

C

Vd = 0.7 * ( width in mm) * 3.6 If temperature > 40

0

C

Example Width 1500 mm

Length 8 m

Temp. 100

0

C

Vf = 0.12 * ( 1500) * 3.6 * (1 + 2 * 8 )

= 11016 m

3

/h

Vd = 0.7 * (1500) * 3.6

= 3780

KRUPP INDUSTRIES INDIA LTD

DEDUSTING

surt:\techdata\dedusting\procedure.xls

DESIGN Calculation Procedure

MANUAL SHEET 10 OF 24

13 Vibrating trough with flex seal, bulk material standing

Feed point

Air volume Vf in m

3

/h

Vf = 0.05 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature <= 40

0

C

Vf = 0.075 * ( width in mm) * 3.6 * (1 + 2 * Length in m ) If temperature > 40

0

C

Discharge point

Air volume Vd in m3/h

Vd = 0.35 * ( width in mm) * 3.6 If temperature <= 40

0

C

Vd = 0.55 * ( width in mm) * 3.6 If temperature > 40

0

C

Example Width 1500 mm

Length 8 m

Temp. 100

0

C

Vf = 0.075 * ( 1500) * 3.6 * (1 + 2 * 8 )

= 6885 m

3

/h

Vd = 0.55 * (1500) * 3.6

= 2970

14 Vibrating screen without flex seal

Feed point

Air volume Vf in m

3

/h

Vf_spec = 0 If length / width < 2.5

Vf_spec = kt * 0.6 * ( width in mm ) * 3.6 If length / width > 2.5

kt = 1 If temperature <= 40 0C

kt = 1.1 If temperature > 40 0C

Vf = Vf_spec

Screen track

Air volume Vst in m3/h

Vst_spec = 0.3 * ( width in mm ) * 3.6 If temperature <= 40

0

C

Vst_spec = 1.1 * 0.3 * ( width in mm ) * 3.6 If temperature > 40

0

C

Vst = 0 If length / width < 2.5

Vst = Vst_spec If length / width > 2.5

Discharge point

Air volume Vd in m

3

/h

Vd_spec = 0.75 * ( width in mm ) * 3.6 If temperature <= 40

0

C

Vd_spec = 1.3 * ( width in mm ) * 3.6 If temperature > 40

0

C

KRUPP INDUSTRIES INDIA LTD

DEDUSTING

surt:\techdata\dedusting\procedure.xls

DESIGN Calculation Procedure

MANUAL SHEET 11 OF 24

Vd = Vf_spec + Vst_spec + Vd_spec If length / width < 2.5

Vd = Vd_spec If length / width > 2.5

Example Width 1500 mm

Length 8000 mm

Temp. 100 0C

Vf_spec = 1.1 * 0.6 * (1500 ) * 3.6

= 3564

Vf = Vf_spec

= 3564 m

3

/h

Vst_spec = 1.1*0.3 * ( 1500 ) * 3.6

= 1782

Vst = Vst_spec

= 1782 m

3

/h

Vd_spec = 1.3 * ( 1500 ) * 3.6

= 7020

Vd = Vd_spec

= 7020 m

3

/h

15 Vibrating screen with flex seal

Feed point

Air volume Vf in m

3

/h

Vf_spec = 0 If length / width < 2.5

Vf_spec = 0.2 * ( width in mm ) * 3.6 If length / width > 2.5

Vf = Vf_spec If temperature <= 40

0

C

Vf = 1.1 * Vf_spec If temperature > 40

0

C

Screen track

Air volume Vst in m

3

/h

Vst_spec = 0.3 * ( width in mm ) * 3.6 If temperature <= 40

0

C

Vst_spec = 0.55 * ( width in mm ) * 3.6 If temperature > 40

0

C

Vst = Vf_spec +Vst_spec If length / width < 2.5

Vst = Vst_spec If length / width > 2.5

Example Width 1500 mm

Length 8000 mm

Temp. 100

0

C

Vf_spec = 0.2 * (1500 ) * 3.6

= 1080

Vf = 1.1 * Vf_spec

= 1188 m

3

/h

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

DEDUSTING

DEDUSTING

surt:\techdata\dedusting\procedure.xls

MANUAL SHEET 12 OF 24

Vst_spec = 0.55 * ( 1500 ) * 3.6

= 2970

Vst = Vst_spec

= 2970 m

3

/h

16 Aeropol

Pressure vessel

Air volume Vpa in m

3

/h

Vpa = 0.00000000002 * (Aeropol dia.)

4

+ 0.00000024 * (Aeropol dia.)

3

- 0.001 * (Aeropol dia.)

2

+ 1.353 * ( Aeropol dia.) - 221.1 vessel dia. In mm

800 1000 1250 1600 2000 2500

352 392 425 498 725 1443

6 7 7 8 12 24

Conveying pipe

Air volume Vcp in m

3

/h

Vcp = tph * ((273 + temp) / 273) * 1.1

Example Aeropol dia. 1000 mm

tph 65

Temperature 80

0

C

Vpa = 391.90 m3/h

Vcp = 92.45 m3/h

17 Poldos pressure vessel conveyor

Fluidisation air

Air volume Vfl in m

3

/h

Vfl = 2 * (spec air volume) * ((273 + Temperature) / 293)

Where

spec air volume = air volume for aeration in m

3

/h

Temperature = aeration air temperature in

0

C

Compressor

Air volume Vc in m

3

/h

Vfl = (spec air volume) * ((273 + Temperature) / 293) * 1.1

Where

spec air volume = air volume of compressor in m

3

/h

Temperature = compressor air temperature in

0

C

Example Volume for aeration air in m

3

/h 150

Temperature of aeration air in

0

C 30

Volume for compressor air in m

3

/h 8000

Temperature of compressor air in

0

C 30

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure DEDUSTING

Aeropol dia

m3/h

m3/min

surt:\techdata\dedusting\procedure.xls

MANUAL SHEET 13 OF 24

Vfl = 2 * (150) * ((273 + 30) / 293)

= 310 m

3

/h

Vfl = (spec air volume) * ((273 + Temperature) / 293) * 1.1

= 9100

18 Fluidor

Aeration air

Air volume Va in m

3

/h

Va = ka * ((width in mm)/1000) * (length in m) * 60 * (273 + temp)/293 * 1.1

ka = 2 in m3/min/m

2

for raw meal, cement

= 5 in m3/min/m

2

for circulating material

= 6.7 in m3/min/m

2

for grits

Example width 300 mm

length 25 m

temperature 30

0

C

Va = 2 * (300/1000) * 25 * 60 * (273 + 30)/293 * 1.1 for raw meal / cement

1024 m

3

/h

Va = 5 * (300/1000) * 25 * 60 * (273 + 30)/293 * 1.1 for circulating material

2559 m

3

/h

Va = 6.7 * (300/1000) * 25 * 60 * (273 + 30)/293 * 1.1for grits

3430 m

3

/h

19 Clinker silo feed silo penthouse closed, 1 feed opening

Silo

Air volume Vs in m

3

/h

Vs = (Dia of silo/1000)

2

* pi()/4 * (Dia of silo/2000) * 0.5773503/3 * 3

Feed opening

Air volume Vf in m

3

/h

Vf = width of opening in mm * height of opening in mm /1000 * 1.5 * 3.6

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 10000 mm

width 2000 mm

height 2500 mm

Vs = (10000/1000)

2

* pi()/4 * (10000/2000) * 0.5773503/3 * 3

227 m

3

/h

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure DEDUSTING

surt:\techdata\dedusting\procedure.xls

MANUAL SHEET 14 OF 24

Vf = 2000 * 2500 /1000 * 1.5 * 3.6

27000 m

3

/h

Vr = Vf = 27000 m

3

/h as Vs < Vf

20 Clinker silo feed silo penthouse closed, 2 feed opening

Silo

Air volume Vs in m

3

/h

Vs = (Dia of silo/1000)

2

* pi()/4 * (Dia of silo/2000) * 0.5773503/3 * 3

Feed opening 1

Air volume Vf1 in m

3

/h

Vf1 = width of opening1 in mm * height of opening1 in mm /1000 * 1.5 * 3.6

Feed opening 2

Air volume Vf2 in m

3

/h

Vf2 = width of opening2 in mm * height of opening2 in mm /1000 * 1.5 * 3.6

Vf = Vf1 + Vf2

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 12000 mm

width1 1000 mm width1 900 mm

height1 1250 mm height2 1300 mm

Vs = (12000/1000)

2

* pi()/4 * (12000/2000) * 0.5773503/3 * 3

392 m

3

/h

Vf1 = 1000 * 1250 /1000 * 1.5 * 3.6

6750 m

3

/h

Vf2 = 900 * 1300 /1000 * 1.5 * 3.6

6318 m

3

/h

Vf = Vf1+Vf2 = 13068 m

3

/h

Vr = Vf = 13068 m

3

/h as Vs < Vf

21 Clinker silo feed silo penthouse closed, 3 feed opening

Silo

Air volume Vs in m

3

/h

Vs = (Dia of silo/1000)

2

* pi()/4 * (Dia of silo/2000) * 0.5773503/3 * 3

Feed opening 1

Air volume Vf1 in m

3

/h

Vf1 = width of opening1 in mm * height of opening1 in mm /1000 * 1.5 * 3.6

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure DEDUSTING

surt:\techdata\dedusting\procedure.xls

MANUAL SHEET 15 OF 24

Feed opening 2

Air volume Vf2 in m

3

/h

Vf2 = width of opening2 in mm * height of opening2 in mm /1000 * 1.5 * 3.6

Feed opening 3

Air volume Vf3 in m

3

/h

Vf3 = width of opening3 in mm * height of opening3 in mm /1000 * 1.5 * 3.6

Vf = Vf1 + Vf2 +Vf3

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 15000

width1 1000 width1 900 width3 900

height1 1250 height2 1300 height3 1300

Vs = (15000/1000)

2

* pi()/4 * (15000/2000) * 0.5773503/3 * 3

765 m

3

/h

Vf1 = 1000 * 1250 /1000 * 1.5 * 3.6

6750 m

3

/h

Vf2 = 900 * 1300 /1000 * 1.5 * 3.6

6318 m

3

/h

Vf3 = 900 * 1300 /1000 * 1.5 * 3.6

6318

Vf = Vf1 + Vf2 + Vf3

19386 m

3

/h

Vr = Vf = 19386 m

3

/h as Vs < Vf

22 Clinker silo feed silo penthouse open, 1 feed opening

Silo

Air volume Vs in m

3

/h

Vs = (Dia of silo/1000)

2

* pi()/4 * (Dia of silo/2000) * 0.5773503/3 * 3

Feed opening

Air volume Vf in m

3

/h

Vf = width of opening in mm * height of opening in mm /1000 * 2 * 3.6

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 10000

width 2000

height 2500

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure DEDUSTING

surt:\techdata\dedusting\procedure.xls

MANUAL SHEET 16 OF 24

Vs = (10000/1000)

2

* pi()/4 * (10000/2000) * 0.5773503/3 * 3

227 m

3

/h

Vf = 2000 * 2500 /1000 * 2 * 3.6

36000 m

3

/h

Vr = Vf = 36000 m

3

/h as Vs < Vf

23 Clinker silo feed silo penthouse open, 2 feed opening

Silo

Air volume Vs in m

3

/h

Vs = (Dia of silo/1000)

2

* pi()/4 * (Dia of silo/2000) * 0.5773503/3 * 3

Feed opening 1

Air volume Vf1 in m

3

/h

Vf1 = width of opening1 in mm * height of opening1 in mm /1000 * 2 * 3.6

Feed opening 2

Air volume Vf2 in m

3

/h

Vf2 = width of opening2 in mm * height of opening2 in mm /1000 * 2 * 3.6

Vf = Vf1 + Vf2

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 12000

width1 1000 width2 900

height1 1250 height2 1300

Vs = (12000/1000)

2

* pi()/4 * (12000/2000) * 0.5773503/3 * 3

392 m

3

/h

Vf1 = 1000 * 1250 /1000 * 2 * 3.6

9000 m

3

/h

Vf2 = 900 * 1300 /1000 * 2 * 3.6

8424 m

3

/h

Vf = 17424 m

3

/h

Vr = Vf = 17424 m

3

/h as Vs < Vf

24 Clinker silo feed silo penthouse open, 3 feed opening

Silo

Air volume Vs in m

3

/h

Vs = (Dia of silo/1000)

2

* pi()/4 * (Dia of silo/2000) * 0.5773503/3 * 3

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 17 OF 24

DEDUSTING

surt:\techdata\dedusting\procedure.xls

Feed opening 1

Air volume Vf1 in m

3

/h

Vf1 = width of opening1 in mm * height of opening1 in mm /1000 * 2 * 3.6

Feed opening 2

Air volume Vf2 in m

3

/h

Vf2 = width of opening2 in mm * height of opening2 in mm /1000 * 2 * 3.6

Feed opening 3

Air volume Vf3 in m

3

/h

Vf3 = width of opening3 in mm * height of opening3 in mm /1000 * 2 * 3.6

Vf = Vf1 + Vf2 +Vf3

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 15000

width1 1000 width1 900 width3 900

height1 1250 height2 1300 height3 1300

Vs = (15000/1000)

2

* pi()/4 * (15000/2000) * 0.5773503/3 * 3

765 m

3

/h

Vf1 = 1000 * 1250 /1000 * 2 * 3.6

6750 m

3

/h

Vf2 = 900 * 1300 /1000 * 2 * 3.6

6318 m

3

/h

Vf3 = 900 * 1300 /1000 * 2 * 3.6

6318

Vf = Vf1 + Vf2 + Vf3

19386 m

3

/h

Vr = Vf = 19386 m

3

/h as Vs < Vf

25 Clinker silo feed cover trapezoidal plate, 1 feed opening

Silo

Air volume Vs in m

3

/h

Vs1 = Dia of silo / 2000 * pi() / 180 * 35

Vs2 = 1.2 * 293 / (273 + temp)

Vs3 = Vs1 * (1.2 - Vs2) * 10

Vs4 = (2 * Vs3 / (3 * Vs2))

0.5

if

(Dia of silo /1000)

2

* pi()/4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

< Dia of silo / 1000 * pi() * width annular gap * Vs4 * 3.6

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 18 OF 24

DEDUSTING

surt:\techdata\dedusting\procedure.xls

then

Vs = (Dia of silo /1000)

* pi() * width annular gap * Vs4 * 3.6

otherwise

Vs = (Dia of silo /1000)

2

* pi() / 4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

Feed opening

Air volume Vf in m

3

/h

Vf = width of opening in mm * height of opening in mm /1000 * 2 * 3.6

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 10000 annular gap 50 temp 40

width 2000

height 2500

Vs1 = 10000 / 2000 * pi() / 180 * 35

3.05433

Vs2 = 1.2 * 293 / (273 + temp)

1.12332

Vs3 = Vs1 * (1.2 - Vs2) * 10

2.34198

Vs4 = (2 * Vs3 / (3 * Vs2))

0.5

1.17894

(Dia of silo /1000)

2

* pi()/4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

= 453

Dia of silo / 1000 * pi() * width annular gap * Vs4 * 3.6

= 6667

Vs = (10000/1000) * pi() * width annular gap * Vs4 * 3.6

6667 m

3

/h

Vf = 2000 * 2500 / 1000 * 2 * 3.6

36000 m

3

/h

Vr = Vf = 36000 m

3

/h as Vs < Vf

26 Clinker silo feed cover trapezoidal plate, 2 feed opening

Silo

Air volume Vs in m

3

/h

Vs1 = Dia of silo / 2000 * pi() / 180 * 35

Vs2 = 1.2 * 293 / (273 + temp)

Vs3 = Vs1 * (1.2 - Vs2) * 10

Vs4 = (2 * Vs3 / (3 * Vs2))

0.5

if

(Dia of silo /1000)

2

* pi()/4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

< Dia of silo / 1000 * pi() * width annular gap * Vs4 * 3.6

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 19 OF 24

DEDUSTING

surt:\techdata\dedusting\procedure.xls

then

Vs = (Dia of silo /1000)

* pi() * width annular gap * Vs4 * 3.6

otherwise

Vs = (Dia of silo /1000)

2

* pi() / 4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

Feed opening

Air volume Vf in m

3

/h

Vf1 = width of opening1 in mm * height of opening1 in mm /1000 * 2 * 3.6

Vf2 = width of opening2 in mm * height of opening2 in mm /1000 * 2 * 3.6

Vf = Vf1 + Vf2

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 12000 annular gap 50 temp 40

width1 1000 width2 900

height1 1250 height2 1300

Vs1 = 12000 / 2000 * pi() / 180 * 35

3.05433

Vs2 = 1.2 * 293 / (273 + temp)

1.12332

Vs3 = Vs1 * (1.2 - Vs2) * 10

2.34198

Vs4 = (2 * Vs3 / (3 * Vs2))

0.5

1.17894

(Dia of silo /1000)

2

* pi()/4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

= 784

Dia of silo / 1000 * pi() * width annular gap * Vs4 * 3.6

= 8000

Vs = (12000/1000) * pi() * width annular gap * Vs4 * 3.6

8000 m

3

/h

Vf1 = 1000 * 1250 / 1000 * 2 * 3.6

9000 m

3

/h

Vf2 = 900 * 1300 / 1000 * 2 * 3.6

8424 m

3

/h

Vf = Vf1 + Vf2

17424

Vr = Vf = 17424 m

3

/h as Vs < Vf

27 Clinker silo feed cover trapezoidal plate, 3 feed opening

Silo

Air volume Vs in m

3

/h

Vs1 = Dia of silo / 2000 * pi() / 180 * 35

Vs2 = 1.2 * 293 / (273 + temp)

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 20 OF 24

DEDUSTING

surt:\techdata\dedusting\procedure.xls

Vs3 = Vs1 * (1.2 - Vs2) * 10

Vs4 = (2 * Vs3 / (3 * Vs2))

0.5

if

(Dia of silo /1000)

2

* pi()/4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

< Dia of silo / 1000 * pi() * width annular gap * Vs4 * 3.6

then

Vs = (Dia of silo /1000)

* pi() * width annular gap * Vs4 * 3.6

otherwise

Vs = (Dia of silo /1000)

2

* pi() / 4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

Feed opening

Air volume Vf in m

3

/h

Vf1 = width of opening1 in mm * height of opening1 in mm /1000 * 2 * 3.6

Vf2 = width of opening2 in mm * height of opening2 in mm /1000 * 2 * 3.6

Vf3 = width of opening3 in mm * height of opening3 in mm /1000 * 2 * 3.6

Vf = Vf1 + Vf2 + Vf3

Required air volume Vr in m

3

/h

Vr = Vs If Vs > Vf

Vr = Vf If Vs < Vf

Example Silo dia 15000 annular gap 50 temp 40

width1 1000 width2 900 width3 900

height1 1250 height2 1300 height3 1300

Vs1 = 15000 / 2000 * pi() / 180 * 35

3.05433

Vs2 = 1.2 * 293 / (273 + temp)

1.12332

Vs3 = Vs1 * (1.2 - Vs2) * 10

2.34198

Vs4 = (2 * Vs3 / (3 * Vs2))

0.5

1.17894

(Dia of silo /1000)

2

* pi()/4 * Dia of silo / 2000 * 0.5773503 / 3 * 6

= 1530

Dia of silo / 1000 * pi() * width annular gap * Vs4 * 3.6

= 10000

Vs = (15000/1000) * pi() * width annular gap * Vs4 * 3.6

10000 m

3

/h

Vf1 = 1000 * 1250 / 1000 * 2 * 3.6

9000 m

3

/h

Vf2 = 900 * 1300 / 1000 * 2 * 3.6

8424 m

3

/h

Vf3 = 900 * 1300 / 1000 * 2 * 3.6

8424 m

3

/h

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 21 OF 24

DEDUSTING

surt:\techdata\dedusting\procedure.xls

Vf = Vf1 + Vf2 + Vf3

25848

Vr = Vf = 25848 m

3

/h as Vs < Vf

28 Bin on top 1 feed opening

V = 1 * width1 * height1 / 1000 *3.6 m

3

/h if temperature <= 40

0

C

= 1.15 * width1 * height1 / 1000 *3.6 m

3

/h if temperature > 40

0

C

Example width1 1000 mm

height 1200 mm

temp. 30

0

C

V = 1000 * 1200 /1000 * 3.6

= 4320

29 Bin on top 2 feed opening

V1 = 1 * width1 * height1 / 1000 *3.6 m

3

/h if temperature <= 40

0

C

= 1.15 * width1 * height1 / 1000 *3.6 m

3

/h if temperature > 40

0

C

V2 = 1 * width2 * height2 / 1000 *3.6 m

3

/h if temperature <= 40

0

C

= 1.15 * width2 * height2 / 1000 *3.6 m

3

/h if temperature > 40

0

C

V = V1 + V2 m

3

/h

Example width1 800 mm width1 500 mm

height 1000 mm height 800 mm

temp. 30

0

C temp. 30

0

C

V1 = 800 * 1000 /1000 * 3.6

= 2880

V2 = 500 * 800 /1000 * 3.6

= 1440

V = 4320 m

3

/h

30 Bin on top PNEUMATIC FEED

V = 1.4 * tph m

3

/h

31 Polycom

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 22 OF 24

DEDUSTING

surt:\techdata\dedusting\procedure.xls

32 Feed hopper

V = 0.5 * width * height / 1000 * 3.6 m

3

/h

33 Crusher moisture level < 6%

Inlet

Vi = 61 * width_inlet * height_inlet / 1000000 * 60 m

3

/h

Outlet

Vo = 76 * width_inlet * height_inlet / 1000000 * 60 m

3

/h

34 Hammer crusher

Inlet

Vi = 61 * width_inlet * height_inlet / 1000000 * 60 m

3

/h

Outlet

Vo = 107 * width_inlet * height_inlet / 1000000 * 60 m

3

/h

35 Vacuume relief

Air volume V in m

3

/h

Y1 = 1.3089969

X = Abs( Temp. * 100) / ( 8 * 7.85 * 9.81 )

If X > 1 Then

Y2 = Atn(-1 / Sqr ( -1 * 1 + 1 ) ) +2 * Atn ( 1 ) '=arccos(1)'

Else

Y2 = Atn(-X / Sqr ( -X * X + 1 ) ) +2 * Atn ( 1 ) '=arccos(X)'

Y3 = width * length * 0.000001

Y4 = Y3 * ( Cos ( Y2 ) - Cos ( Y1 )

If Y2 > Y1 Then

V = 0

Else

V = ( 2 * Y4

2

* Abs((Temp1 * 100) / (1.8 *1.2)))

0.5

* 3600 * ((273 +Temp) / 293 )

Example width 550 mm

length 550 mm

Temp1 = Temp 60

0

C

Temp2 = Temp1 5

0

C

Y1 = 1.309

X = Abs( 5 * 100) / ( 8 * 7.85 * 9.81 )

0.8116

Y2 = ACOS(X) As X < 1

0.62391

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 23 OF 24

DEDUSTING

surt:\techdata\dedusting\procedure.xls

Y3 = width * length * 0.000001

0.3025

Y4 = Y3 * ( Cos ( Y2 ) - Cos ( Y1 ))

0.16722

Y2 < Y1 Hence

V = ( 2 * Y4

2

* Abs((Temp1 * 100) / (1.8 *1.2)))

0.5

* 3600 * ((273 +Temp) / 293 )

14720.7 m

3

/h

36 Bulk loading open

Air volume in m

3

/h

If Dia of hood > 0

V = Dia. Of hood / 1000 * PI(0 * 0.1 * 2.5 * 3600 * (273 +Temp) / 293

If Dia of hood = 0

V =( width / 1000 + length / 1000) * 2 * 0.1 * 2.5 * 3600 * (273 +Temp) / 293

Example1 Dia. Of hood 500 mm

Temp 20

0

C

V = Dia. Of hood / 1000 * PI(0 * 0.1 * 2.5 * 3600 * (273 +Temp) / 293

1413.72 m

3

/h

Example2 width 800 mm

length 400 mm

Temp 20

0

C

V = (width / 1000 + length / 1000) * 2 * 0.1 * 2.5 * 3600 * (273 +Temp) / 293

2160

37 Cement cooler

Fluidor

Air volume Vf in m

3

/h

Vf = ka * ((width in mm)/1000) * (length in m) * 60 * (273 + temp)/293 * 1.1

ka = 2 in m3/min/m

2

for raw meal, cement

= 5 in m3/min/m

2

for circulating material

Example width 500 mm

length 25 m

temperature 100

0

C

Va = 2 * (500/1000) * 25 * 60 * (273 + 100)/293 * 1.1for raw meal / cement

2101 m

3

/h

Va = 5 * (500/1000) * 25 * 60 * (273 + 30)/293 * 1.1 for circulating material

4266 m

3

/h

Screw conveyor

Air volume Vsc in m

3

/h

KRUPP INDUSTRIES INDIA LTD

DESIGN Calculation Procedure

MANUAL SHEET 24 OF 24

Dsc is Dia. Of screw conveyor in mm

DEDUSTING

surt:\techdata\dedusting\procedure.xls

If

( Dsc / 1000)

2

/ 2 - 0.5 * (Dsc / 1000 )

2

* PI() / 4 *2* 3600 < 510 + 1.237 * Dsc

Then

Vsc = 510 + 1.237 *Dsc

Else

Vsc = ( Dsc / 1000)

2

/ 2 - 0.5 * (Dsc / 1000 )

2

* PI() / 4 *2* 3600

Example Dsc 500 mm

( Dsc / 1000)

2

/ 2 - 0.5 * (Dsc / 1000 )

2

* PI() / 4 *2* 3600

-706.73

510 + 1.237 * Dsc

1128.5

Vsc = 510 + 1.237 *Dsc

1128.5 m

3

/h

Cement cooler

Air volume Vcc in m

3

/h

Vcc = tph * 1.2

Example tph 100

Vcc = tph * 1.2

120 m

3

/h

38 Other machine

V = Air volume in m3/h

surt:\techdata\dedusting\procedure.xls

Вам также может понравиться

- Rotary Kilns: Transport Phenomena and Transport ProcessesОт EverandRotary Kilns: Transport Phenomena and Transport ProcessesРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Bag Filter Design CalculationsДокумент2 страницыBag Filter Design CalculationsSnehendu Biswas69% (13)

- Bag Filter Calculation1234567 IPДокумент24 страницыBag Filter Calculation1234567 IPsujith kumarОценок пока нет

- Ball Mill DesignДокумент6 страницBall Mill DesignElwathig Bakhiet100% (2)

- Bag Filter: Technical Manual For Installation, Operation and MaintenanceДокумент14 страницBag Filter: Technical Manual For Installation, Operation and MaintenanceAnand Kesarkar100% (2)

- Bag Filter Selector: Filter Type: C (For This Type of Filter Contact Area Genovese)Документ8 страницBag Filter Selector: Filter Type: C (For This Type of Filter Contact Area Genovese)Ashish GulabaniОценок пока нет

- Bag Filter CalculationДокумент2 страницыBag Filter Calculationjenifferrayen71% (7)

- Design Recommendations For Process FiltersДокумент8 страницDesign Recommendations For Process FiltersKenny RuizОценок пока нет

- Bag Filter Flow RateДокумент1 страницаBag Filter Flow RatemorlsОценок пока нет

- Bag House Filter DesignДокумент5 страницBag House Filter DesignShermal FernandoОценок пока нет

- G/C Ratio Calculation: Assumed ValuesДокумент11 страницG/C Ratio Calculation: Assumed ValuesAntoinette ChuaОценок пока нет

- Bucket Elevator Design StudyДокумент24 страницыBucket Elevator Design StudyIrfan AhmedОценок пока нет

- Conveyor Design Summary ReportДокумент1 страницаConveyor Design Summary ReportAlejandro Castro0% (1)

- Basic Criteria For Selection of Bag FilterДокумент33 страницыBasic Criteria For Selection of Bag FilterMuhammadShoaib100% (3)

- Pneumatic Conveying System Design Calculation: Input Parameters Unit ValueДокумент6 страницPneumatic Conveying System Design Calculation: Input Parameters Unit ValueTECHCONS Consulting and Engineering Pvt Ltd0% (1)

- Design of Rotary DryerДокумент2 страницыDesign of Rotary Dryernizar ahmad57% (7)

- Calculation of Air-Slide Conveyor: January 2017Документ7 страницCalculation of Air-Slide Conveyor: January 2017Hannan yusuf KhanОценок пока нет

- Fabric Filter DesignДокумент16 страницFabric Filter DesignDragan GasicОценок пока нет

- Overall Heat Balance - 11.08.2008Документ8 страницOverall Heat Balance - 11.08.2008Tamer FathyОценок пока нет

- Vent CalcДокумент5 страницVent CalcMichael LagundinoОценок пока нет

- 6 Bag House BasicsДокумент27 страниц6 Bag House BasicsPANKAJ AGRAHARI100% (1)

- Nitincalculation Spray Dryer & HagДокумент5 страницNitincalculation Spray Dryer & HagNITIN P SHAH100% (2)

- Bag Filter CalculationДокумент3 страницыBag Filter CalculationNITIN P SHAHОценок пока нет

- Screw Conveyor DesignДокумент8 страницScrew Conveyor DesignPavan Kumar100% (1)

- Spider Air Slide Design For Line-1Документ8 страницSpider Air Slide Design For Line-1Irfan AhmedОценок пока нет

- Airslide CalculationДокумент1 страницаAirslide Calculationsunil_supeda33% (3)

- Data and Result Calculation Bag FilterДокумент2 страницыData and Result Calculation Bag FilterUmmiey SyahirahОценок пока нет

- Air Slide Data SheetДокумент2 страницыAir Slide Data SheetTECHCONS Consulting and Engineering Pvt LtdОценок пока нет

- Airslide Calculation Form Project: Department: Equipment NoДокумент3 страницыAirslide Calculation Form Project: Department: Equipment NoManoj Thakur0% (1)

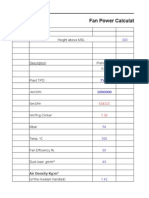

- Kiln Pre Heater Fan Power CalculationДокумент4 страницыKiln Pre Heater Fan Power CalculationVijay Bhan67% (3)

- Belt Selection CalculationДокумент29 страницBelt Selection CalculationElwathig BakhietОценок пока нет

- Hopper Volume Calculation PDFДокумент1 страницаHopper Volume Calculation PDFAnonymous 5XvUbWynn50% (2)

- ATEC Preheater Data Sheet - Old EnglДокумент2 страницыATEC Preheater Data Sheet - Old Englayaskant751001100% (1)

- Mechanical Conveyors: 29 Materials HandlingДокумент2 страницыMechanical Conveyors: 29 Materials HandlingSMNCI Cadet EngineersОценок пока нет

- HRC CalculationДокумент15 страницHRC CalculationTIRIANTOОценок пока нет

- Dry Process KilnДокумент20 страницDry Process KilnISLAM I. Fekry100% (8)

- Material Transfer in Rotary KilnsДокумент3 страницыMaterial Transfer in Rotary KilnsMehrdad AminkazemiОценок пока нет

- Screw Conveyor ManualДокумент14 страницScrew Conveyor ManualDavid100% (1)

- Bucket Elevator Design StudyДокумент24 страницыBucket Elevator Design StudyVeena100% (1)

- Fan Flow CalculationДокумент1 страницаFan Flow CalculationvvijaybhanОценок пока нет

- Lifter DesignДокумент6 страницLifter DesignMarcelo GuarachiОценок пока нет

- Data Sheet Jet Pulse Bag FilterДокумент1 страницаData Sheet Jet Pulse Bag FilterHassan SleemОценок пока нет

- How To Check Variability of Mass Flow in A Pneumatic Conveying System PDFДокумент4 страницыHow To Check Variability of Mass Flow in A Pneumatic Conveying System PDFnazmul hasanОценок пока нет

- Rotary Airlock Valve PDFДокумент15 страницRotary Airlock Valve PDFPIY777Оценок пока нет

- Fabric Filter Design VariablesДокумент14 страницFabric Filter Design VariablesElumalai Srinivasan100% (1)

- Screw Flight Development CalculationДокумент15 страницScrew Flight Development CalculationEmperor8983% (6)

- Dust Collection System: Raw Material Handling PlantДокумент83 страницыDust Collection System: Raw Material Handling PlantVishal HiremathОценок пока нет

- Dedusting System PDF FreeДокумент54 страницыDedusting System PDF FreeghassanОценок пока нет

- Dedusting SystemДокумент54 страницыDedusting SystemIrfan Ahmed100% (1)

- Perhitungan ConveyorДокумент88 страницPerhitungan ConveyorLukmanulHakimОценок пока нет

- Trash Rack CalculationДокумент8 страницTrash Rack Calculationsumit67% (3)

- Ductulator May 2010Документ10 страницDuctulator May 2010Arshavin Watashi WaОценок пока нет

- Principle of Working of Grit ChamberДокумент11 страницPrinciple of Working of Grit ChamberAhmed Amedi100% (3)

- HVAC SystemДокумент4 страницыHVAC SystemHiba KasmiОценок пока нет

- PPE AssignmentДокумент16 страницPPE AssignmentlibbissujessyОценок пока нет

- Calculation and Design of Packed Column For AcidДокумент14 страницCalculation and Design of Packed Column For AcidDavid LambertОценок пока нет

- Ball Mill DesignДокумент6 страницBall Mill DesignBùi Hắc HảiОценок пока нет

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetДокумент4 страницы1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- Compressed Air PlantДокумент88 страницCompressed Air PlantJerico LlovidoОценок пока нет

- Surge AnlysisДокумент5 страницSurge AnlysisnaveenaeeОценок пока нет

- The Development of New Iron Making ProcessesДокумент6 страницThe Development of New Iron Making ProcessesMohsen ArdestaniОценок пока нет

- Benefication of Iron OreДокумент4 страницыBenefication of Iron OreMohsen ArdestaniОценок пока нет

- MXCOLДокумент8 страницMXCOLMohsen ArdestaniОценок пока нет

- Midrex NGДокумент8 страницMidrex NGMohsen ArdestaniОценок пока нет

- DRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEOДокумент7 страницDRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEOMohsen ArdestaniОценок пока нет

- Midrex ProcessesДокумент8 страницMidrex ProcessesMohsen ArdestaniОценок пока нет

- Fuller Chemistry Handbook, Mr. Bokaian'sДокумент58 страницFuller Chemistry Handbook, Mr. Bokaian'sMohsen ArdestaniОценок пока нет

- Stepfl TL16US24Документ2 страницыStepfl TL16US24Mohsen ArdestaniОценок пока нет

- OTE Outotec Filter Product Training Eng WebДокумент2 страницыOTE Outotec Filter Product Training Eng WebMohsen ArdestaniОценок пока нет

- Piping Material Specification-Rev0Документ25 страницPiping Material Specification-Rev0Mohsen Ardestani100% (4)

- Cementglossaryv 2 P 5Документ22 страницыCementglossaryv 2 P 5DM AfteniОценок пока нет

- Martin Screw Conveyor and ElevatorДокумент157 страницMartin Screw Conveyor and ElevatorMohsen Ardestani100% (1)

- Calcul Conveioare SurubДокумент2 страницыCalcul Conveioare SurubgvisanОценок пока нет

- Ems em FW Paneel Firetec enДокумент2 страницыEms em FW Paneel Firetec enzlatkokrsicОценок пока нет

- C50SCR PLC Complete ManualДокумент286 страницC50SCR PLC Complete ManualthuanОценок пока нет

- UntitledДокумент18 страницUntitledSpace HRОценок пока нет

- App Guide EntelliGuard - G 09 - 2020 AplicacionДокумент100 страницApp Guide EntelliGuard - G 09 - 2020 AplicacionjeorginagОценок пока нет

- PC110R 1 S N 2265000001 Up PDFДокумент330 страницPC110R 1 S N 2265000001 Up PDFLuis Gustavo Escobar MachadoОценок пока нет

- Microporous WikiДокумент2 страницыMicroporous WikiIris BalcarceОценок пока нет

- Gambaran Professional Quality of Life Proqol GuruДокумент7 страницGambaran Professional Quality of Life Proqol Gurufebrian rahmatОценок пока нет

- Circulatory SystemДокумент51 страницаCirculatory SystemTina TalmadgeОценок пока нет

- Fora Active Plus P 30 ManualДокумент32 страницыFora Active Plus P 30 ManualBvcОценок пока нет

- HOME TECH - HOME TEXTILE REVIEW. Ayman SatopayДокумент12 страницHOME TECH - HOME TEXTILE REVIEW. Ayman SatopayAyman SatopayОценок пока нет

- Crude TBP Country United Arab Emirates Distillation: MurbanДокумент2 страницыCrude TBP Country United Arab Emirates Distillation: MurbanHaris ShahidОценок пока нет

- Information HumaLyzer Primus Setting Update and Extension enДокумент3 страницыInformation HumaLyzer Primus Setting Update and Extension enluisoft88Оценок пока нет

- "Hiv and Aids Awareness of Junior and Senior High School Students" Part I: Profile of RespondentsДокумент1 страница"Hiv and Aids Awareness of Junior and Senior High School Students" Part I: Profile of RespondentsDahl xxОценок пока нет

- Optimization Process of Biodiesel Production With Ultrasound Assisted by Using Central Composite Design MethodsДокумент47 страницOptimization Process of Biodiesel Production With Ultrasound Assisted by Using Central Composite Design MethodsMiftahFakhriansyahОценок пока нет

- Rifle Threat Performance Matrix: SeriesДокумент1 страницаRifle Threat Performance Matrix: SeriesKuhnОценок пока нет

- Pentacon Six-02Документ28 страницPentacon Six-02Melissa Moreira TYОценок пока нет

- 2013 Casel GuideДокумент80 страниц2013 Casel GuideBobe MarinelaОценок пока нет

- Sand Casting OverviewДокумент166 страницSand Casting Overviewsamurai7_77Оценок пока нет

- Anatomy and Physiology Chapter 2Документ28 страницAnatomy and Physiology Chapter 2Marshalee FrancisОценок пока нет

- Executive SummaryДокумент2 страницыExecutive Summarykulsoomalam100% (1)

- NIST Standard Reference Materials® 2023 CatalogДокумент128 страницNIST Standard Reference Materials® 2023 CatalogAbdul HaseebОценок пока нет

- Windows Perfectpath: Promise Multipath DriverДокумент3 страницыWindows Perfectpath: Promise Multipath Driverpd904526Оценок пока нет

- Supply ForecastingДокумент17 страницSupply ForecastingBhavesh RahamatkarОценок пока нет

- Electrolux EKF7700 Coffee MachineДокумент76 страницElectrolux EKF7700 Coffee MachineTudor Sergiu AndreiОценок пока нет

- Biography of Murray (1893-1988) : PersonologyДокумент6 страницBiography of Murray (1893-1988) : PersonologyMing100% (1)

- Air Compressors: Instruction, Use and Maintenance ManualДокумент66 страницAir Compressors: Instruction, Use and Maintenance ManualYebrail Mojica RuizОценок пока нет

- Invertec 200 260 400tДокумент16 страницInvertec 200 260 400tJxyz QwОценок пока нет

- தமிழ் உணவு வகைகள் (Tamil Cuisine) (Archive) - SkyscraperCityДокумент37 страницதமிழ் உணவு வகைகள் (Tamil Cuisine) (Archive) - SkyscraperCityAsantony Raj0% (1)

- Case Study of Flixborough UK DisasterДокумент52 страницыCase Study of Flixborough UK Disasteraman shaikhОценок пока нет