Академический Документы

Профессиональный Документы

Культура Документы

Reduce Static Charge Buildup with Antistatic Additives

Загружено:

Phi Hai Tinh0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров2 страницыANTISTATIC P042 / L STATIC CHARGE IS OF SIGNIFICANT PROBLEM WHEN PROCESSING OR HANDLING PLASTIC MATERIALS. COMMON PROBLEMS MAY BE SPARK FORMATION, DUST PICK UP, STATIC CLING IN A FILM, RISK OF ELECTRICAL SHOCKS TO EMPLOESS. TO DISSIPATE CHARGE THE SURFACE RESIS

Исходное описание:

Оригинальное название

Antistatics p042 l

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документANTISTATIC P042 / L STATIC CHARGE IS OF SIGNIFICANT PROBLEM WHEN PROCESSING OR HANDLING PLASTIC MATERIALS. COMMON PROBLEMS MAY BE SPARK FORMATION, DUST PICK UP, STATIC CLING IN A FILM, RISK OF ELECTRICAL SHOCKS TO EMPLOESS. TO DISSIPATE CHARGE THE SURFACE RESIS

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров2 страницыReduce Static Charge Buildup with Antistatic Additives

Загружено:

Phi Hai TinhANTISTATIC P042 / L STATIC CHARGE IS OF SIGNIFICANT PROBLEM WHEN PROCESSING OR HANDLING PLASTIC MATERIALS. COMMON PROBLEMS MAY BE SPARK FORMATION, DUST PICK UP, STATIC CLING IN A FILM, RISK OF ELECTRICAL SHOCKS TO EMPLOESS. TO DISSIPATE CHARGE THE SURFACE RESIS

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

ANTISTATIC P042/L

STATIC CHARGE IS OF SIGNIFICANT PROBLEM WHEN PROCESSING OR HANDLING PLASTIC MATERIALS

DUE TO THE REASON THAT THE PLASTICS DOES NOT DISSIPATE OR EARTH THE CHARGE THEY GAIN

DURING PROCESSING OR HANDLING. THIS LEADS TO STATIC CHARGE BUILD UP. THE COMMON PROBLEMS

MAY BE SPARK FORMATION, DUST PICK UP, STATIC CLING IN A FILM, RISK OF ELECTRICAL SHOCKS TO

EMPLOESS WORKING ON MACHINES, RISK OF SUDDEN FIRE. THE REASON OF PLASTIC FOR NOT

DISSIPATIING CHARGE IS THE LOW DIELECTRIC CONSTANT AND THE HIGHER SURFACE RESISTIVITY. THE

MAGNITUDE OF CHARGE DEPENDS ON THE DEGREE OF CONTACT, FRICTIONAL PROPERTIES, RELATIVE

HUMIDITY IN THE AIR .PLASTICS IS AT 10 TO POWER OF 15 OHMS AT 20C AND 50% RELATIVE HUMIDITY . TO

DISSIPATE CHARGE THE SURFACE RESISITIVITY SHOULD BE AT 10TO POWER OF OHMS.

TO AVOID THESE THINGS, ANTISTATIC ADDITIVES ARE DEVELOPED.

THESE ANTISTATIC ADDITIVES WHICH ATTRACKS MOISTURE FROM THE ATMOSPHERE FORMS A

MICROSCOPIC CONDUCTIVE LAYERS ON THE PLASTIC PRODUCT WHICH ALLOWS CHARGE TO DISSIPATE.

THESE ADDITIVES ARE MIGRATING TYPE AND THERMALLY STABLE. THIS RESULTS IN THE REDUCTION OF

SURFACE RESISTIVITY IN THE PLASTICS TO AS LOW AS 10 TO POWER OHMS !CONSIDEREDAS E"CELLENT

SURFACE RESISITIVITY# FROM LEVEL OF 10 TO POWER 1$ WHICH IS CON SIDERED AS POOR SURFACE

RESISTIVITY

FOR ACCURATE ADDITION LEVELS IT IS RECOMMENDED TO BE USED IN MASTERBATCH FORM.

PERFORMANCE OF THE MASTERBATCH WILL IMPROVE WITH THE INCREASING RELATIVE HUMIDITY.

WHEN MASTERBATCH IS ADDED TO THE POLYMER, THE POLYMER ACTS AS A RESERVOIR OF THIS

ADDITIVE AND THEN IT MIGRATES TO SURFACE.

THERE ARE 2 TYPES OF ANTISTATIC ADDITIVES:

1. %UICK BUILD OF ANTISTATIC EFFECT DURINGTHE PROCESSING. FACILITATES DISCHARGE IMMEDIATELY

OF THE CHARGES. THE ADDITIVE USE DIN THIS IS MONOESTER BASED. THIS IS NOT A LONG TERM EFFECT.

2. LONG LASTING ANTISTATIC PROPERTIES AFTER THE PROCESSING IS DONE. FACILITATES DISCHARGE

DURING THE PACKING AND THE TRANSPORTATION OF THE PACKED PRODUCTS. IN THIS THERE ARE

NORMAL HEAT STABLE PRODUCTS FOR POLYOLEFINS WHICH ARE ETHO"YLATED AMINES AND ALSO HIGH

HEAT STABLE PRODUCTS LIKE ALKYL SULPHONATES FOR ENGINEERING PLASTICS.

EVEN THE SYNERGISTIC BLENDS ARE GIVING THE BEST OF %UICK AND LONG LASTING RESULTS.

POLYTECH

AN ISO &001'2000 COMPANY

PRODUCT SPECIFICATION SHEET

Distributed by M()C*+,

-

H.C*(M(/* .00(1+' N.. 223132H, T45./6 C./6 D(/* S74++7, T8/ B(/* D(974(17, H. C*( M(/* C(7:, V(+7/8,

T+)' ;<<$50&05 F8=' ;<<$;&;>>1 E,8()'(/0.?,()1*+,@)897(1.1., *77@'33 AAA.,()1*+,@)897(1.1.,

Prayag

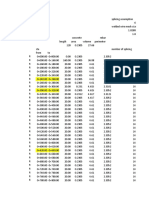

DESCRIPTION OF GRADES OF PRAYAG

(A) P041 (GMS, RAPID ACTION, PE CARRIER RESIN)- 15% ACTIVE CONTENT.

DOSAGE:

FOR LDPELLDPE --1-2 %FOR FILM, 2-4% IN IN!ECTION, 2-10% IN EPE SHEETS AND

SHEET E"TR#SION.

FOR HDPE : 1-2% FOR FILM, 1-4%IN IN!ECTION

($) P042L (ETA, LONG TERM ANTISTATIC, PE CARRIER RESIN) : 10 % ACTIVE

DOSAGE:

FOR LDPELLDPE -- 1% IN FILMS, 1-5% IN IN!ECTION AND SHEET E"TR#SION

FOR HDPE: 1%-2%IN FILMS, 1-5% IN IN!ECTION AND SHEET E"TR#SION

NOTE: PLEASE DISC#SS %ITH #S FOR SPECIFIC APPLICATIONS AND PROD#CT

SELECTION .

APPEARANCE ' T48/9)51+/7 A*(7+ 648/5)+9

CARRIERRESIN : STANDARD GRADES HAVE SPECIFIED CARRIER RESIN . %E CAN OFFER

SPECIFIC CARRIER RESIN ANTISTATIC MASTER$ATCHES LI&E PS $ASED AND SAN $ASED

. .

ADVANTAGES '

R'()*+,-. ,. /+0+,* *1023' +- 405,4)4 -6 10+- 7-8'2 -6 9 0/

7'2 +1' (-/03'/ 0.( 320('/.

G,:'/ ;)<2,*0+,.3 '66'*+ +- +1' 72-*'//

C-.+2,<)+'/ +- /4--+1, /1,.= /)260*'

N- Y';;-8,.3 D,/*-;-20+,-.

E./)2'/ 60/+ 4-);( 6,;;,.3

E0/= 2';'0/'

PAC&ING ' HDPE W..B+/ C869 .0 25 K69 N+7.

POLYTECH

AN ISO &001'2000 COMPANY

Distributed by M()C*+,

-

H.C*(M(/* .00(1+' N.. 223132H, T45./6 C./6 D(/* S74++7, T8/ B(/* D(974(17, H. C*( M(/* C(7:, V(+7/8,

T+)' ;<<$50&05 F8=' ;<<$;&;>>1 E,8()'(/0.?,()1*+,@)897(1.1., *77@'33 AAA.,()1*+,@)897(1.1.,

Prayag

Вам также может понравиться

- 02UP Product Record (En)Документ8 страниц02UP Product Record (En)Mohamed NabilОценок пока нет

- Review of The Robustness of Epoxy Passive Fire Protection Tech PaperДокумент19 страницReview of The Robustness of Epoxy Passive Fire Protection Tech Paperuserscribd2011100% (1)

- Delamination in Wood Wood Products and Wood-Based CompositesДокумент416 страницDelamination in Wood Wood Products and Wood-Based CompositesSabrina PhilippeОценок пока нет

- Pub - Modern-Plastics-Handbook-240-311 ES PDFДокумент116 страницPub - Modern-Plastics-Handbook-240-311 ES PDFLaura CervantesОценок пока нет

- HDPE Geomembrane - AlvatechДокумент10 страницHDPE Geomembrane - AlvatechshgsuhermanОценок пока нет

- Explosion ProtectionДокумент20 страницExplosion Protectionzirimia100% (1)

- CEMFLEX ULTRA - TDS Cementitious WaterproofingДокумент2 страницыCEMFLEX ULTRA - TDS Cementitious WaterproofingAnoop ShankarОценок пока нет

- NEMA Comparison Insulating Gasket - G7 - G9 - G10 - G11Документ3 страницыNEMA Comparison Insulating Gasket - G7 - G9 - G10 - G11asoka.pw0% (1)

- Aircraft Selection GuideДокумент6 страницAircraft Selection GuideRohit MunaОценок пока нет

- Adhesive Engineering Selection GuideДокумент10 страницAdhesive Engineering Selection GuideAnonymous PWzkeB100% (1)

- Chapter 2 SM Done!Документ25 страницChapter 2 SM Done!Aq AidilОценок пока нет

- Effect of Antistatic Additives on Properties of Polyethylene FoamsДокумент6 страницEffect of Antistatic Additives on Properties of Polyethylene FoamsEliton S. MedeirosОценок пока нет

- 4.elastoseal P100Документ2 страницы4.elastoseal P100adchem123Оценок пока нет

- Chem Bond Tech For PV Modules 1979 - 5101-132Документ37 страницChem Bond Tech For PV Modules 1979 - 5101-132KOUROSH PARDISОценок пока нет

- Paints Coatings Novel Teta Free Polyamides 2k Epoxy SystemsДокумент10 страницPaints Coatings Novel Teta Free Polyamides 2k Epoxy SystemsHugo WizenbergОценок пока нет

- Additive MasterbatchesДокумент4 страницыAdditive MasterbatchesChinmoy DholeОценок пока нет

- Polyken 936 TapeДокумент2 страницыPolyken 936 TapeKyaw Kyaw AungОценок пока нет

- Elan-Tron MC4260 W4260 IngДокумент4 страницыElan-Tron MC4260 W4260 IngZdzisław LatoОценок пока нет

- Basf Processing Styrinic Polymers and CopolymersДокумент14 страницBasf Processing Styrinic Polymers and CopolymersTejender SinghОценок пока нет

- 11 Insulating Materials PDFДокумент24 страницы11 Insulating Materials PDFidlemineОценок пока нет

- TMP F222Документ7 страницTMP F222FrontiersОценок пока нет

- Ea 934naДокумент4 страницыEa 934nalacsmm982Оценок пока нет

- New Developments in Antistatic and Conductive Additives: Migrating AntistatsДокумент4 страницыNew Developments in Antistatic and Conductive Additives: Migrating AntistatsEliton Medeiros Candido de MacêdoОценок пока нет

- Clearstrength E 920: Product DescriptionДокумент8 страницClearstrength E 920: Product DescriptionHan PhamОценок пока нет

- Transparent Films On Polymers For Photovoltaic Applications: J. Herrero, C. Guill !enДокумент6 страницTransparent Films On Polymers For Photovoltaic Applications: J. Herrero, C. Guill !enAnand Sreekantan ThampyОценок пока нет

- GLK7673-20100826174134-2010 Aroflint FlyerДокумент2 страницыGLK7673-20100826174134-2010 Aroflint FlyerUsama AwadОценок пока нет

- Silica Aerogel MicrosphereДокумент9 страницSilica Aerogel MicrosphereJuan PabloОценок пока нет

- Review - RECYCLED POLYESTER AND ITS PHYSICAL PROPERTIES - Review - USAДокумент28 страницReview - RECYCLED POLYESTER AND ITS PHYSICAL PROPERTIES - Review - USAAhmedОценок пока нет

- Recycling of Condensation Plastics: GPEC 2004 Paper Abstract #52Документ8 страницRecycling of Condensation Plastics: GPEC 2004 Paper Abstract #52Anjum ParkarОценок пока нет

- Patch Panel - Envpep111246en - v0Документ4 страницыPatch Panel - Envpep111246en - v0arnabzicoОценок пока нет

- Epocoat 111 PDFДокумент3 страницыEpocoat 111 PDFjunaid112Оценок пока нет

- Baytron - Coatingguide 2014Документ12 страницBaytron - Coatingguide 2014Bala SingamОценок пока нет

- Tech - Info Electrically Conductive Plastics - EnglishДокумент16 страницTech - Info Electrically Conductive Plastics - EnglishcharlesОценок пока нет

- Data Sheet ExxonMobil HDPE HD 9856BДокумент2 страницыData Sheet ExxonMobil HDPE HD 9856BMayrarelCadpeОценок пока нет

- Splash Pro System: "ISO 9001 Certified"Документ4 страницыSplash Pro System: "ISO 9001 Certified"SOFYAN ALAMONAОценок пока нет

- Taisox 8001Документ2 страницыTaisox 8001Le Minh TuanОценок пока нет

- DownloadДокумент20 страницDownloadkeyur1109Оценок пока нет

- The Polyurea Revolution: Protective Coatings For The 21st CenturyДокумент4 страницыThe Polyurea Revolution: Protective Coatings For The 21st CenturyMihaela LetОценок пока нет

- Product Technical InformationДокумент3 страницыProduct Technical Informationtedak2Оценок пока нет

- Preparation of Fluorine-Doped Tin Oxide by A Spray Pyrolysis Deposition and Its Application To The Fabrication of Dye-Sensitized Solar Cell ModuleДокумент1 страницаPreparation of Fluorine-Doped Tin Oxide by A Spray Pyrolysis Deposition and Its Application To The Fabrication of Dye-Sensitized Solar Cell ModuleFahad ArefeenОценок пока нет

- Coaltar EpoxyДокумент2 страницыCoaltar EpoxyAnonymous YN4aNlОценок пока нет

- Erapol EHP70DДокумент2 страницыErapol EHP70DqwepoolОценок пока нет

- Dr. Fixit Heat Insulating Exterior CoatingДокумент3 страницыDr. Fixit Heat Insulating Exterior CoatingVivek SharmaОценок пока нет

- Sun 2020Документ11 страницSun 2020mepcОценок пока нет

- Ens TecДокумент28 страницEns TecBorja CanalsОценок пока нет

- Mapefix EP 385/585 Epoxy Resin AnchorДокумент9 страницMapefix EP 385/585 Epoxy Resin Anchordiv_bamaniaОценок пока нет

- RETRO REFLECTIVE SHEETING MATERIALS PROPOSALДокумент25 страницRETRO REFLECTIVE SHEETING MATERIALS PROPOSALHannaОценок пока нет

- Applications of Functionalized Polyethylene Terephthalate Aerogels From Plastic Bottle Waste 2019Документ10 страницApplications of Functionalized Polyethylene Terephthalate Aerogels From Plastic Bottle Waste 2019Atam ZakoyanОценок пока нет

- Design and Fabrication of Bottle Crushing Machine Using PLC ScadДокумент6 страницDesign and Fabrication of Bottle Crushing Machine Using PLC ScadBehayle TerayeОценок пока нет

- Emaco S88C TDSДокумент2 страницыEmaco S88C TDSMerdan JumagylyjovОценок пока нет

- The Importance of Ethylene-Tetrafluoroethylene For Building DaylightingДокумент20 страницThe Importance of Ethylene-Tetrafluoroethylene For Building DaylightingAjay KushwahaОценок пока нет

- HYSOL® FP4323 (ES4323) : Technical Data SheetДокумент2 страницыHYSOL® FP4323 (ES4323) : Technical Data SheetAsad NaeemОценок пока нет

- Advanced Recycled Polyethylene Terephthalate Aerogels From Plastic Waste For Acoustic and Thermal Insulation ApplicationsДокумент13 страницAdvanced Recycled Polyethylene Terephthalate Aerogels From Plastic Waste For Acoustic and Thermal Insulation ApplicationsKhoa Học- Khám Phá-Nghệ ThuậtОценок пока нет

- Tecnical R 802Документ16 страницTecnical R 802Dyah Ayu100% (1)

- Retrowrap HD Specifications (2014)Документ15 страницRetrowrap HD Specifications (2014)Alfredo Solorzano MaloОценок пока нет

- Use of Nanoparticles For Enhancing The Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints-A ReviewДокумент29 страницUse of Nanoparticles For Enhancing The Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints-A Reviewmkumar_234155Оценок пока нет

- Ea 9396Документ4 страницыEa 9396lacsmm982Оценок пока нет

- CP 300 (A) - QCP-050 Cosmetic Repair of Ramp Retaning WallsДокумент5 страницCP 300 (A) - QCP-050 Cosmetic Repair of Ramp Retaning WallstarekОценок пока нет

- Crystallinity and Dimensional Stability of Biaxial Oriented Poly (Lactic Acid) FilmsДокумент7 страницCrystallinity and Dimensional Stability of Biaxial Oriented Poly (Lactic Acid) FilmsLong LeОценок пока нет

- Industrial Crops & ProductsДокумент14 страницIndustrial Crops & ProductsterОценок пока нет

- Plastics Material Selection Criteria: BY N.Mohan Kumar Cipet ChennaiДокумент16 страницPlastics Material Selection Criteria: BY N.Mohan Kumar Cipet ChennaisouravОценок пока нет

- PLASTERINGДокумент11 страницPLASTERINGAnushka KhatriОценок пока нет

- Bohler R100 enДокумент2 страницыBohler R100 enIltefatОценок пока нет

- United States Patent (10) Patent No.: US 8,372,899 B2Документ12 страницUnited States Patent (10) Patent No.: US 8,372,899 B2Alexander Franco CastrillonОценок пока нет

- RETRACTED ARTICLE Tribological Characteristics of Mongongo-Oil Based Biodiesel Blended LubricantДокумент8 страницRETRACTED ARTICLE Tribological Characteristics of Mongongo-Oil Based Biodiesel Blended LubricantAnirudh PooniaОценок пока нет

- Materials Selection For Hot Section Aircraft Engine ComponentДокумент7 страницMaterials Selection For Hot Section Aircraft Engine ComponentCaio Fazzioli TavaresОценок пока нет

- 707RC3-equations-final قوانين خرسانة 3 للدكتور ابراهيم عرمانДокумент5 страниц707RC3-equations-final قوانين خرسانة 3 للدكتور ابراهيم عرمانNirmeem NatourОценок пока нет

- Frieght List 1Документ4 страницыFrieght List 1Narendra PatilОценок пока нет

- Ottoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsДокумент3 страницыOttoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation Systemssamira bashirvandОценок пока нет

- KSA SASO QualityMarkRequirementsForSpecificProducts enДокумент1 страницаKSA SASO QualityMarkRequirementsForSpecificProducts ennavas1972Оценок пока нет

- Tyre Puncture SolutionДокумент3 страницыTyre Puncture SolutionShreyansh ShahОценок пока нет

- CV Short (Rgpillai) Jan 26 2021Документ19 страницCV Short (Rgpillai) Jan 26 2021vishwanathanskОценок пока нет

- CE 4219 Design of Steel Structure: Introductory LectureДокумент21 страницаCE 4219 Design of Steel Structure: Introductory LectureMARUFОценок пока нет

- Concrete Lined DitchДокумент18 страницConcrete Lined DitchJan Felix DonsalОценок пока нет

- Material Data Sheet: Sanicro 28Документ3 страницыMaterial Data Sheet: Sanicro 28fendixОценок пока нет

- ASTER 12G2F Data Sheet Conveyor BeltДокумент1 страницаASTER 12G2F Data Sheet Conveyor BeltKoen BidlotОценок пока нет

- How To Check Coaxial CableДокумент3 страницыHow To Check Coaxial CableAggelos KarantonisОценок пока нет

- Data Sheet: Flashbreaker® 1RДокумент1 страницаData Sheet: Flashbreaker® 1Rquyet ngoОценок пока нет

- Choose WPSДокумент175 страницChoose WPSmohamedОценок пока нет

- Superpave Mix DesignДокумент21 страницаSuperpave Mix DesignRenaldy AzharОценок пока нет

- AWG Vs Metric Ampacity - ChartДокумент1 страницаAWG Vs Metric Ampacity - Chartstor138Оценок пока нет

- Preliminary Design of Tubular Composite Structures Using Netting Theory and Composite Degradation FactorsДокумент5 страницPreliminary Design of Tubular Composite Structures Using Netting Theory and Composite Degradation FactorsDILEEP AJAYAGHOSHОценок пока нет

- Fasteners - How To Identify Stainless SteelДокумент3 страницыFasteners - How To Identify Stainless SteelMichael Lanfield Raw VeganОценок пока нет

- Lecture 5a Insulators-Introduction PDFДокумент19 страницLecture 5a Insulators-Introduction PDFwakolesha TadeoОценок пока нет

- Buildings - Sor: 2011-2012: Government of Andhra PradeshДокумент389 страницBuildings - Sor: 2011-2012: Government of Andhra PradeshsibenduОценок пока нет

- Worksheet 1 - MenesesДокумент2 страницыWorksheet 1 - MenesesDarwin MenesesОценок пока нет

- 4294-Article Text-11969-1-10-20150330Документ6 страниц4294-Article Text-11969-1-10-20150330Anthony LoñezОценок пока нет

- BILL OF MATERIALS & COST ESTIMATES FOR PROPOSED LAUNDRYДокумент5 страницBILL OF MATERIALS & COST ESTIMATES FOR PROPOSED LAUNDRYLlarch ConstructionОценок пока нет