Академический Документы

Профессиональный Документы

Культура Документы

Porozni Materijali

Загружено:

Ana RisticОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Porozni Materijali

Загружено:

Ana RisticАвторское право:

Доступные форматы

POROZNI MATERIJALI

Teksturalne osobine

Silica Carbon Zeolite

V. Dondur 2011.

Important properties are:

Surface area - determined by BET

Pore structure

Chemical composition of the surface.

Techniques for studying composition of surface include

IR and Raman

X-ray fluorescence (XRF)

Low energy electron diffraction (LEED)

X-ray photoelectron spectroscopy (ESCA)

Auger-electron spectroscopy (AES)

Porosity is usually defined as the ratio of the

volume of pores and voids to the volume occupied

by the solid.

In many cases the internal surface area is

much larger than the external surface area and

the agglomerate then possesses a well-defined

pore structure.

Texture and morphology of porous

systems

pore size

pore shape

pore-size distribution (same size or

various sizes?)

pore volume

specific surface area of adsrbent

0.5nm

Pore diameters

micropores (< 2 nm)

mesopores (2 - 50 nm)

macropores (> 50 nm)

Pore Size and Shape

0.5nm

Table 1. Definitions: porous solids

Term Definition

Porous solid Solid with cavities or channels which are deeper than they are wide

open pore Cavity or channel with access to the surface

Interconnected pore Pore which communicates with other pores

Blind pore' Pore with a single connection to the surface (Deadend pore)

Closed pore Cavity not connected to the surface

Void Space between particles

Miclopore Pore of internal width less than 2 nm

Mesopore Pore of internal width between 2 and 50 nm

Macropore Pore of internal width greater than 50 nm

Pore size Pore width (diameter of cylindrical porc or distance between opposite walls of slit)

Pore volume Volume of pores determined by stated method

Porosity Ratio of total pore volume to apparent volume of particle or powder

Total porosity Ratio of volume of voids and pores (open and closed) to volume occupied by solid

Open porosity Ratio of volume of voids and open pores to volume occupied by solid

Surface area Extent of total surface area as determined by given method under stated

conditions

External surface area Area of surface outside pores

Intemal surface area Area of pore walls

Density Density of solid, excluding pores and voids

Apparent density Density of material including closed and inaccessible pores, as determined by

stated method

ACTIVATED Carbon pores consist of:

1. Micro pores with a radius of less than 1 nm (small pores)

2. Meso pores with a radius of 1-25 nm (medium pores)

3. Macro pores with a radius larger than 25 nm (large

pores)

Large pores are used for the transport of liquid through

the carbon, and absorption occurs in the medium and

small pores. Pores are formed during the

manufacturing process, when the carbon is activated.

The activation basically means that pores are created in

a non-porous material by means of chemical reactions.

AFM image of a typical nanoporous

alumina template (dark areas are

pores and the surrounding light

areas are aluminum oxide around

the pores (pore diameter is ~50nm)

SEM image of a typical nanoporous

alumina (dark areas are pores and

the surrounding light areas are

aluminum oxide around the pores

(pore diameter is ~25nm)

SILICATE / ALUMINOSILICATE POROUS MATERIALS

Macroporous

(>500)

Mesoporous

(20-500)

Microporous

(<20)

Crystalline

Amorphous

Crystalline

Crystalline

Amorphous

Amorphous

ZEOLITES

ZEOTYPES

POROSILS

CLINOPTILOLITE

SILICALITE

MCM-41

ETS-10

Silica Gel

SiO2

?

?

SiO2

SiO2

SiO2

Figure 1 Microporous polymer.

These polymers are formed by

cross-linking linear chains of

monomer. Cross-links (shown as

heavy lines above) create very

small pores within the three

dimensional

matrix.

Figure 2. Macroporous

polymer.

These materials have a high

degree of cross-linking,

preventing

them from swelling in solvents.

Pores are larger than gels,

but are irregular and terminate

inside the matrix. Total pore

volumes are typically 50%.

Figure 3. High internal phase

emulsion. HIPE polymers,

illustrated

above, contain extremely

large cavities that are

interconnected.

Cavities are of micrometer

dimensions, rather than angstrom

dimensions of conventional

polymers. Total pore volume

can exceed 90%.

polymers

Broken sphere of Cavilink polymer.

This is interior

of polymer type shown in Fig. 9

and shows cavities and pores

fully communicating with sphere

surface.

Cavilink polymer with fully open surface.

This SEM

photo shows distinctive regularity

of cavities in Cavilink polymers.

Cavities have diameters greater

than 10,000 . Higher magnifications

reveal characteristic interconnected

structure, (see Fig. 7).

Cavilink polymer with fully open

surface.

Higher magnifications

reveal characteristic interconnected

Structure.

Pore Shapes

Slit

Ink-bottle

Cylindrical

Wedge

a b

d c

Pore Diameters and Measurement

Techniques

Experimental techniques

capillary condensation

Hg intrusion

microscopy

Pore Shape Selectivity

Reactant selectivity

+

Product selectivity

CH

3

OH +

Restricted transition-state selectivity

Why is it important? It dictates the diffusion process through the

material.

Pore Size and Diffusion Regimes

Configurational

diffusion

Surface

migration

1000 100 10 1 0.1

10

-4

10

-8

10

-12

10

-16

1000 100 10 1 0.1

100

50

0

E

a

(kJ/mol)

D (m

2

/s)

Pore diameter (nm)

Pore diameter (nm)

Molecular

diffusion

Knudsen

diffusion

Surface

migration

Knudsen number: K

n

= /d

= molecular free path length

d= characteristic pore diameter

K

n

<< 1 bulk diffusion

K

n

>> 1 Knudsen diffusion

Types of diffusion

Molecular

Knudsen

Surface

Cylindrical pore

d

p

d

m

Volumetric Adsorption Measurement

N

2

(77.3 K) or

Ar, He, CH

4

, CO

2

, Kr

adsorbate

adsorbent

pressure

gauge

P

V

1

V

2

high vacuum

PV=nRT

Adsorption Isotherms

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

Adsorption

Desorption

p is gas pressure

po is vapour pressure

Adsorption Isotherms

III

n

a

d

p / p

0

VI

n

a

d

p / p

0

V

n

a

d

p / p

0

I

n

a

d

p / p

0

p / p

II

n

a

d

0

B

IV

n

a

d

p / p

0

B

Langmuir Adsorption

Isotherm (Type I)

Assumptions:

homogeneous surface

(all adsorption sites energetically identical)

monolayer adsorption (so no multilayer adsorption)

no interaction between adsorbed molecules

p K

p K

n n n

m m ad

+

= u =

1

I

n

a

d

p / p

0

LANGMUIR ISOTHERM

Assumptions

all adsorption sites equivalent

ability of adsorbate to bind is independent of

whether the adjacent sites are occupied or not.

adsorbate behaves as an ideal gas in gas phase

only monomolecular adsorption takes place

adsorbed molecules occupy fixed sites

heat of adsorption is independent of surface

coverage.

Type II and IV Isotherms

Multilayer adsorption (starting at B)

Common for pore-free materials

Similar to II at low p

Pore condensation at high p

p / p

II

n

a

d

0

B

IV

n

a

d

p / p

0

B

Type III and V Isotherms

III

n

a

d

p / p

0

V

n

a

d

p / p

0

Strong cohesion force between

adsorbed molecules, e.g. when

water adsorbs on hydrophobic

activated carbon

Similar to III at low p

Pore condensation at high p

Surface Area & Monolayer Capacity

S = n

m

A

m

N

monolayer

capacity (mol/g)

specific surface

area (m

2

/g)

area occupied by one

molecule (m

2

/molecule)

Avogadros number

(molecules/mol)

BET model: S

BET

t model: S

t

Properties of Adsorbates for Physisorption

Measurements

Adsorbate Boiling Point (K) A

m

(nm

2

/molecule)

N

2

77.3 0.162

Ar 87.4 0.142

CO

2

194.5 0.17

Kr 120.8 0.152

N

2

Adsorption Isotherm in ZSM-5

0

1

2

3

4

5

6

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

Langmuir Adsorption?

strong adsorption at low p due to condensation in

micropores

at higher p saturation due to finite (micro)pore volume

Adsorption and Desorption Isotherms

BET (Brunauer, Emmett, Teller) Method

Modification of Langmuir isotherm

Both monolayer and multilayer adsorption

Layers of adsorbed molecules divided in:

First layer with heat of adsorption AH

ad,1

Second and subsequent layers with H

ad,2

= AH

cond

BET isotherm:

BET equation does not fit entire adsorption isotherm

different mechanisms play a role at low and at high

p

( )

0

m m

0

ad

1 1

p

p

C n

C

C n p p n

p

+ =

|

.

|

\

|

A A

=

RT

H H

C

cond ad

exp

BET ADSORPTION ISOTHERMS

Assumptions:

Multiple layers form and langmuir model applies to

each layer.

Heat of adsorption, AHads for first layer has a value

determined by properties of surface and adsorbate,

but for second and all subsequent layers, it is equal

to heat of vapourization AH vap.

Evaporation (or desorption) only occurs from

exposed surfaces.

Rate of evaporation is equal to rate of condensation

on preceding layer.

reality model

u

5

u

4

u

3

u

2

u

1

u

0

( ) ... 3 2 1

2 1 0 m ad

+ u + u + u = = u

n n

i

1 - n n 1 - n

1

0

n n 1 - n

1

0 1 0

1

0

1 1

1

0

0

u = u = u u = u

u = u = u u = u

p K p

k

k

k p k

p K p

k

k

k p k

d

a

n

d

n

a

d

a

d a

1

st

layer

n

th

layer

For every layer

Langmuir model

Assume

RT

H

RT

H

RT

H

K K K

K K

cond n

ads

e e

e

0 , n 0 , n n

0 , 1 1

A

~ =

=

( )

|

|

.

|

\

|

+

|

|

.

|

\

|

=

0

0

0

m

ad

1 1 1

p

p

C

p

p

p

p

C

n

n

RT

H H

C

cond ads

e

A A

=

BET Model

( ) ( ) | | x 1 c 1 x 1

cx

V

v

m

+

=

BET Equation

p is gas pressure

po is vapour pressure

Vm is monolayer

volume

V is volume measured

of gas adsorbed

Step 1: Plot x / [V(1-x)] vs x

Step 2: Determine from the plot

Intercept 1 / (cV

m

)

Slope (c-1) / (cV

m

)

Step 3: Calculate c, V

m

V

m

= 1/ (slope + intercept)

( )

( )

o

m m

p p x where

cV

x c

cV x V

x

/

,

1 1

1

=

+ =

V

m

can be used to

calculate Specific Surface

Area,

S

BET

= V

m

A

m

where

A

m

is area per adsorption site

number of gas molecules /

cm3

p/p

0

n

a

d

/

n

m

(B) (A)

Low p/p

0

:

filling of micropores

favoured adsorption at

most reactive sites

(heterogeneity)

High p/p

0

:

capillary condensation

Range 0.05 < p/p

0

< 0.3 is used to determine S

BET

BET equation

Porous Silica and Alumina

Adsorption at Pore Wall

Cylindrical pore

Ink-bottle pore

Pore with shape of interstice

between close-packed particles

Adsorbed layer

t

d

p

d

m

t-method

BET

only valid in small pressure interval

interpretation not very easy

thickness (t) of adsorbed layer can be calculated

plot of t versus p for non-porous materials is the

same (has been checked experimentally)

t-plot helps in interpretation

0.354

nm

t-method

nm 354 . 0

m

ad

=

n

n

t

t

n

S

N A

t

n

S

N A n S

ad

6

t

m

9

ad

t

m m t

10 73 . 5

10 354 . 0

=

=

=

n

ad

t

Proportional to S

t

Shape of t-plots

nm 354 . 0

m

ad

=

n

n

t

t

n

ad

t

n

ad

t

n

ad

Non-porous Microporous

Micro- and

mesoporous

S

t

S

mesopores

p

n

ad

Adsorption isotherm

t = f(p)

Kelvin Equation for Nitrogen

m

0

1 2

ln

r RT

V

p

p

L

=

micro meso macro

V

L

= 34.6810

-6

m

3

/mol molar volume

= 8.88 mN/m surface tension

r is surface radius

d

m

(nm)

R

e

l

a

t

i

v

e

p

r

e

s

s

u

r

e

p

/

p

0

0

0.2

0.4

0.6

0.8

1

0.1 1 10 100 1000 10000

Pore filling Model

Cylindrical Pore Channel

Pore Size Distribution

Charge in vapor pressure for a curved surface

Hysteresis Loops

HI

n

a

d

p/p

0

H2

n

a

d

p/p

0

H3

n

a

d

p/p

0

Information on pore shape

t-curves

p/p

0

A

d

s

o

r

b

e

d

-

l

a

y

e

r

t

h

i

c

k

n

e

s

s

t

(

n

m

)

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

0 0.2 0.4 0.6 0.8 1

a

b

Halsey

Harkins-Jura-de Boer

( )

333 . 0

0

/ ln

00 . 5

354 . 0

(

=

p p

t

( )

5 . 0

0

/ log 034 . 0

99 . 13

1 . 0

(

=

p p

t

t-plot of -alumina

0

2

4

6

8

10

0.0 0.2 0.4 0.6 0.8 1.0 1.2

t ( nm)

n

a

d

(

m

m

o

l

/

g

)

S

t,micro

= 0 m

2

/g

V

t,micro

= 0 ml/g

mesopores

macropores

S

t,micro

= 0 m

2

/g

V

t,micro

= 0 ml/g

S

t

= 200 m

2

/g

Interpretation of t-Plot

nm 354 . 0

m

ad

=

n

n

t

Dubinin-Radushkevich equation

Where c

x

represents the work done by the adsorption

forces when adsorbate is brought up to a distance l

from surface

p

p

RT

o

x

ln = c

For porous solids Vo is taken to be the pore volume,

and V, the volume adsorbed at given po/p value.

|

|

.

|

\

|

|

.

|

\

|

=

p

p

E

RT

V V

o

o

ln ln ln

2

Volume of micropores

) exp(

2

c b V V

o

=

Pore Size Distribution

alumina

0.0

0.1

0.2

0.3

0.4

0.5

1 10 100 1000

d

p

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

+ =t r

o

o

p

p

RT

V

t r

ln

2

+ =

nm 354 . 0

m

ad

=

n

n

t

|

|

.

|

\

|

|

.

|

\

|

=

p

p

E

RT

V V

o

o

ln ln ln

2

t-plot of N

2

Physisorption on

ZSM-5

t (nm)

0 0.5 1

n

2

n

1

n

1

= liquid N

2

n

2

= solid N

2

n

a

d

(

m

m

o

l

/

g

)

6

3

0

Mercury Intrusion Curve of -

Alumina

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.1 1 10 100 1000

p (MPa)

V

(

m

l

/

g

)

Texture Data of Commercial Catalysts

Material Mean d

p

(nm) S

BET

(m

2

/g)

Catalyst supports

Silica gel 10 200

6 400

4 800

-Al

2

O

3

10 150

5 500

Zeolite 0.6-2 400-800

Activated carbon 2 700-1200

TiO

2

400-800 2-50

Aerosil SiO

2

- 50-200

Catalysts

MeOH synthesis (Cu/ZnO/Al

2

O

3

) 20 80

NH

3

synthesis (Fe/Al

2

O

3

/K

2

O) 100 10

Reforming (Pt/Re/Al

2

O

3

) 5 250

Epoxidation (Ag/o-Al

2

O

3

)

200 0.5

Mercury Intrusion Porosimetry

p

d

14860

p

=

Hg does not wet surfaces; pressure is needed to

force intrusion

From a force balance:

(d in nm, p in bar)

Convenient method for determining pore volume

versus pore size

Discrepancy S

Hg

and S

BET

for Microporous Materials

Hg cannot penetrate small (micro)pores,

N

2

can

Uncertainty of contact angle and

surface tension values

Cracking or deforming of samples

Surface Areas - S

Hg

and S

BET

Adsorbent S

Hg

S

BET

u

m

2

/g m

2

/g deg

Iron Oxide 14.3 13.3 130

Tungsten Oxide 0.11 0.10 130

Anatase 15.1 10.3 130

Hydroxy Apatite 55.2 55.0 130

Carbon Black (Spheron-6) 107.8 110.0 130

0.5 % Ru/-Al

2

O

3

237.0 229.0 140

0.5 % Pd/-Al

2

O

3

115.0 112.0 140

TiO

2

Powder 31.0 25.0 140

Sintered Silica Pellets 20.5 5.0 140

Zeolite H-ZSM-5 39.0 375.0 140

Norit Active Carbon R1 Extra 112.0 915.0 140

Texture Properties

N

2

-physisorption Hg-porosimetry

S

BET

S

t

V

p

d

p

S

Hg

V

p

d

p

m

2

/g m

2

/g ml/g nm m

2

/g ml/g nm

Wide Pore Silica 78 52 0.91 47 80 0.92 54

-Alumina

196 202 0.49 10 163 0.49 10

o-Alumina

9 8 0.12 112 12 0.48 150

Active Carbon 1057

a

28 0.51 2 0.6 0.46 106

Raney Ni 76 - 0.14 5.80 - - -

ZSM-5 345 344 0.19 0.58 11 1.1 820

b

a

p/p

0

range of 0.01-0.1 was used in the calculation.

b

intraparticle voids.

N

2

Adsorption Isotherms & Pore Volume

Distributions

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

wide-pore silica -alumina

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

0.00

0.02

0.04

0.06

0.08

0.10

1 10 100 1000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

0.0

0.1

0.2

0.3

0.4

0.5

1 10 100 1000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

N

2

Adsorption Isotherms & Pore Volume

Distributions

o-alumina activated carbon

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

0.000

0.002

0.004

0.006

0.008

0.010

1 10 100 1000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

0.0

0.1

0.2

0.3

0.4

0.5

1 10 100 1000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

}

Tensile strength effect

N

2

Adsorption Isotherms & Pore Volume

Distributions

Raney Ni ZSM-5

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

p/p

0

n

a

d

(

m

m

o

l

/

g

)

1

0.00

0.02

0.04

0.06

0.08

0.10

1 10 100 1000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

0

2

4

6

8

10

0.0 0.5 1.0 1.5 2.0

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

Hg Intrusion Curves & Pore Volume

Distributions

wide-pore silica -alumina

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.1 1 10 100 1000

p (MPa)

V

(

m

l

/

g

)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.1 1 10 100 1000

p (MPa)

V

(

m

l

/

g

)

0

0.02

0.04

0.06

0.08

1 10 100 1000 10000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

0.0

0.1

0.2

0.3

0.4

0.5

1 10 100 1000 10000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

Hg Intrusion Curves & Pore Volume

Distributions

o-alumina activated carbon

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.1 1 10 100 1000

p (MPa)

V

(

m

l

/

g

)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.1 1 10 100 1000

p (MPa)

V

(

m

l

/

g

)

0.000

0.001

0.002

0.003

0.004

0.005

1 10 100 1000 10000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

0.000

0.002

0.004

0.006

0.008

0.010

1 10 100 1000 10000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

Hg Intrusion Curves & Pore Volume

Distributions

Raney Ni ZSM-5

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.1 1 10 100 1000

p (MPa)

V

(

m

l

/

g

)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.1 1 10 100 1000

p (MPa)

V

(

m

l

/

g

)

0.00

0.02

0.04

0.06

0.08

0.10

1 10 100 1000 10000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

0

0.001

0.002

0.003

0.004

0.005

1 10 100 1000 10000 100000

d

pore

(nm)

d

V

/

d

d

(

m

l

/

g

/

n

m

)

BET- & t-plots

wide-pore silica -alumina

0.0

0.1

0.2

0.3

0.4

0.5

0.00 0.05 0.10 0.15 0.20 0.25 0.30

p/p

0

p

/

[

n

a

d

(

p

0

-

p

)

]

(

g

/

m

m

o

l

)

S

BET

= 78 m

2

/g

C = 146

0.0

0.1

0.2

0.3

0.4

0.5

0.00 0.05 0.10 0.15 0.20 0.25 0.30

p/p

0

p

/

[

n

a

d

(

p

0

-

p

)

]

(

g

/

m

m

o

l

)

S

BET

= 196 m

2

/g

C = 97

0.0

0.5

1.0

1.5

2.0

2.5

0.0 0.2 0.4 0.6 0.8 1.0 1.2

t ( nm)

n

a

d

(

m

m

o

l

/

g

)

S

t,micro

=28 m

2

/g

V

t,micro

= 0.013 ml/g

0

2

4

6

8

10

0.0 0.2 0.4 0.6 0.8 1.0 1.2

t ( nm)

n

a

d

(

m

m

o

l

/

g

)

S

t,micro

= 0 m

2

/g

V

t,micro

= 0 ml/g

o-alumina activated carbon

0.0

0.1

0.2

0.3

0.4

0.5

0.00 0.05 0.10 0.15 0.20 0.25 0.30

p/p

0

p

/

[

n

a

d

(

p

0

-

p

)

]

(

g

/

m

m

o

l

)

S

BET

= 9.3 m

2

/g

C = 142

0.0

0.1

0.2

0.3

0.4

0.5

0.00 0.05 0.10 0.15 0.20 0.25 0.30

p/p

0

p

/

[

n

a

d

(

p

0

-

p

)

]

(

g

/

m

m

o

l

)

S

BET

= 1057 m

2

/g

C = 1057

p/p

0

= 0.01 - 0.1

0.00

0.05

0.10

0.15

0.20

0.25

0.0 0.2 0.4 0.6 0.8 1.0 1.2

t ( nm)

n

a

d

(

m

m

o

l

/

g

)

S

t, micro

= 1.4 m

2

/g

V

t,mcro

= 0.001 ml/g

0

5

10

15

0.0 0.2 0.4 0.6 0.8 1.0 1.2

t ( nm)

n

a

d

(

m

m

o

l

/

g

)

S

t,micro

= 856 m

2

/g

V

t,micro

= 0.42 ml/g

BET- & t-plots

Raney Ni ZSM-5

0.0

0.1

0.2

0.3

0.4

0.5

0.00 0.05 0.10 0.15 0.20 0.25 0.30

p/p

0

p

/

[

n

a

d

(

p

0

-

p

)

]

(

g

/

m

m

o

l

)

S

BET

= 76 m

2

/g

C = 46

0.0

0.1

0.2

0.3

0.4

0.5

0.00 0.05 0.10 0.15 0.20 0.25 0.30

p/p

0

p

/

[

n

a

d

(

p

0

-

p

)

]

(

g

/

m

m

o

l

)

S

BET

= 345 m

2

/g

C = -245

p/p

0

: 0.01 -0.1

0

1

2

3

4

5

0.0 0.2 0.4 0.6 0.8 1.0 1.2

t ( nm)

n

a

d

(

m

m

o

l

/

g

)

S

t,micro

= 0 m

2

/g

V

t,micro

= 0 ml/g

0

2

4

6

0.0 0.2 0.4 0.6 0.8 1.0 1.2

t ( nm)

n

a

d

(

m

m

o

l

/

g

)

S

t ,micro

= 344 m

2

/g

V

t ,micro

= 0.18 ml/g

BET- & t-plots

Sintering of Alumina upon

Heating

T

calc

(K)

S

B

E

T

(

m

2

/

g

)

Sintering

Reduction of surface area

COMMERCIAL SORBENTS AND APPLICATIONS

Only four types of generic sorbents have

dominated the commercial use of adsorption:

activated carbon, zeolites, silica gel, and activated

alumina. Estimates of

worldwide sales of these sorbents are (Humphrey

and Keller, 1997)

Activated carbon $1 billion

Zeolites $100 million

Silica gel $27 million

Activated alumina $26 million

Table 2. Examples of commercial adsorption processes and sorbents

used

Separation Adsorbent

Gas Bulk Separations

Normal paraffins/isoparaffins, aromatics Zeolite

N2/O2 Zeolite

O2/N2 Carbon molecular sieve

CO, CH4, CO2, N2, Ar, NH3/H2 Activated carbon

followed by zeolite (in

layered beds)

Hydrocarbons/vent streams Activated carbon

H2O/ethanol Zeolite (3A)

Chromatographic analytical separations Wide range of inorganic

and polymer resin agents

Gas Purification

H2O/olefin-containing cracked gas,

natural gas, air, synthesis gas, etc. Silica, alumina, zeolite (3A)

CO2/C2H4, natural gas, etc. Zeolite, carbon molecular

sieve

Hydrocarbons, halogenated organics,

solvents/vent streams Activated carbon, silicalite,

others

Sulfur compounds/natural gas, hydrogen,

liquefied petroleum gas (LPG), etc. Zeolite, activated alumina

SO2/vent streams Zeolite, activated carbon

Odors/air Silicalite, others

Indoor air pollutantsVOCs Activated carbon, silicalite,

resins

Tank-vent emissions/air or nitrogen Activated carbon, silicalite

Hg/chlor-alkali cell gas effluent Zeolite

Liquid Purifications

H2/organics, oxygenated organics,

halogenated organics, etc., dehydration Silica, alumina, zeolite, corn grits

Organics, halogenated organics,

oxygenated organics,etc./H2Owater purification Activated carbon, silicalite, resins

Inorganics (As, Cd, Cr, Cu,

Se, Pb, F,Cl, radionuclides, etc.)/H2Owaterpurification Activated carbon

Odor and taste bodies/H2O Activated carbon

Sulfur compounds/organics Zeolite, alumina, others

Decolorizing petroleum fractions, syrups,vegetable oils, etc. Activated carbon

Various fermentation products/fermentor effluent Activated carbon, affinity agents

Drug detoxification in the body Activated carbon

Liquid Bulk Separations

Normal paraffins/isoparaffins, aromatics Zeolite

p-xylene/o-xylene, m-xylene Zeolite

Detergent-range olefins/paraffins Zeolite

p-Diethyl benzene/isomer mixture Zeolite

Fructose/glucose Zeolite

Chromatographic analytical separations Wide range of

inorganic, polymer,

and

affinity agents

Pore Structures of Zeolites

a b

ZSM-5 Mordenite

Figure 3: Nano-porous materials are generated after etching mesomorphic block

copolymers selectively.

Вам также может понравиться

- Fundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringОт EverandFundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringОценок пока нет

- L12 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiДокумент25 страницL12 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyОценок пока нет

- Handouts PDFДокумент53 страницыHandouts PDFSandeep ChallaОценок пока нет

- L14 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiДокумент50 страницL14 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyОценок пока нет

- Catalyst Characterization - W6Документ33 страницыCatalyst Characterization - W6Safitri WulansariОценок пока нет

- Adsorption ReviewДокумент29 страницAdsorption ReviewJason PacilОценок пока нет

- Surface Area and Porosity-1Документ37 страницSurface Area and Porosity-1Ghana Cintai DiaОценок пока нет

- Heterogeneous Catalysis: Most Heterogeneous Catalysts Are Supported CatalystsДокумент30 страницHeterogeneous Catalysis: Most Heterogeneous Catalysts Are Supported CatalystsAhom CKОценок пока нет

- Syahrul SSKM 3-Surface CharacterizationДокумент41 страницаSyahrul SSKM 3-Surface CharacterizationHusna KamiliaОценок пока нет

- ERT 313 Bioseparation Engineering Adsorption: Prepared By: Miss Hairul Nazirah Abdul HalimДокумент25 страницERT 313 Bioseparation Engineering Adsorption: Prepared By: Miss Hairul Nazirah Abdul HalimlsueyinОценок пока нет

- Particale Properties NotesДокумент65 страницParticale Properties Notesdaoud saleemОценок пока нет

- L16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiДокумент25 страницL16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyОценок пока нет

- Membrane Lecture 1Документ16 страницMembrane Lecture 1writtingtuОценок пока нет

- Nanochemistry PDFДокумент60 страницNanochemistry PDFRahool Doshi100% (2)

- Task IIIДокумент17 страницTask IIIpeg2010Оценок пока нет

- Surface Area and Pore Size DistributionДокумент36 страницSurface Area and Pore Size DistributionWanderson MoraesОценок пока нет

- --Документ70 страниц--The TinyStrikerОценок пока нет

- Ceramic Membranes in Energy andДокумент19 страницCeramic Membranes in Energy andXiaoqin ZouОценок пока нет

- 03 Catalyst CharacterizationДокумент39 страниц03 Catalyst CharacterizationMegan TorresОценок пока нет

- Katkat07 PDFДокумент45 страницKatkat07 PDFHarold Fernando Guavita ReyesОценок пока нет

- File 1 - Reactor Analysis Unit 5 FullДокумент73 страницыFile 1 - Reactor Analysis Unit 5 FullGaming is in my DNAОценок пока нет

- Bet-Analysis: by Brunauer-Emmett-Teller 1938Документ13 страницBet-Analysis: by Brunauer-Emmett-Teller 1938harshit tiwariОценок пока нет

- 5B FiltrationДокумент58 страниц5B FiltrationWazif ZakwanОценок пока нет

- Mercury Porosimetry UpdatedДокумент35 страницMercury Porosimetry Updatedvishwanathansk100% (1)

- Adsorption January 2023Документ49 страницAdsorption January 2023Saria ChowdhuryОценок пока нет

- Adsorption Vivek NeeriДокумент37 страницAdsorption Vivek NeeriVivek KumarОценок пока нет

- 1998 (Leofanti) Surface Area and Pore Texture of CatalystsДокумент13 страниц1998 (Leofanti) Surface Area and Pore Texture of CatalystsYahsé Rojas ChallaОценок пока нет

- EXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryДокумент9 страницEXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryavniОценок пока нет

- Air Pollution Control Technology - FinalДокумент28 страницAir Pollution Control Technology - FinalBobОценок пока нет

- BJT Ic FabricationДокумент20 страницBJT Ic Fabricationestifvnjjsnvk100% (2)

- Vinodhini B. - Mercury PorosimetryДокумент35 страницVinodhini B. - Mercury PorosimetryHarry JakeОценок пока нет

- Lecture2 MicroFabTechniques PDFДокумент10 страницLecture2 MicroFabTechniques PDFdiОценок пока нет

- Adsorption &ion Exchange11jan PDFДокумент45 страницAdsorption &ion Exchange11jan PDFMaharghya Biswas100% (1)

- Adsorption Equil Principles - 483Документ28 страницAdsorption Equil Principles - 483Raildo FiuzaОценок пока нет

- ECH3118 (Adsorption)Документ68 страницECH3118 (Adsorption)Wen Feng YeowОценок пока нет

- CHE572 Chapter 2 Particle Size Characterization PDFДокумент18 страницCHE572 Chapter 2 Particle Size Characterization PDFMuhd FahmiОценок пока нет

- Numericalsmassignments SolvedДокумент5 страницNumericalsmassignments SolvedghasОценок пока нет

- Adsorption Isotherm HLДокумент26 страницAdsorption Isotherm HLDhea RahmayantiОценок пока нет

- Porosity Determination From LogsДокумент35 страницPorosity Determination From LogsTarek Ali100% (2)

- Well Logging: by Engr. Habib U Zaman MemonДокумент103 страницыWell Logging: by Engr. Habib U Zaman MemonHoorzadi Bakhtawar OadОценок пока нет

- 3 - Gas Adsorption - PhysisorpДокумент62 страницы3 - Gas Adsorption - PhysisorpMohammad Naufal AliefОценок пока нет

- EnE 250 Air Quality Management and Pollution Control Lecture 02 - 2 APC Stationary Sources Aug 13 2015Документ152 страницыEnE 250 Air Quality Management and Pollution Control Lecture 02 - 2 APC Stationary Sources Aug 13 2015Alexis Bryan RiveraОценок пока нет

- 421 Lab ManualДокумент17 страниц421 Lab ManualAiman LatifОценок пока нет

- R20 Applied Chemistry - UNIT-3Документ28 страницR20 Applied Chemistry - UNIT-3maheshbabugandupalli7Оценок пока нет

- Lecture 03. Adsorption of Gases and Liquids On SolidsДокумент39 страницLecture 03. Adsorption of Gases and Liquids On Solidsimran24Оценок пока нет

- Models - Molec.water Adsorption DesorptionДокумент14 страницModels - Molec.water Adsorption DesorptionmanigandanОценок пока нет

- Chapter-I Introduction To Nanomaterials: Sathyabama UniversityДокумент31 страницаChapter-I Introduction To Nanomaterials: Sathyabama UniversitygollakotiОценок пока нет

- Well Logging 2015Документ84 страницыWell Logging 2015rizkylambas100% (1)

- Unit 6 NanomaterialsДокумент12 страницUnit 6 Nanomaterialssushank yadavОценок пока нет

- 1 AdsorptionДокумент68 страниц1 AdsorptionUsman KhanОценок пока нет

- Seminar JSD - IIДокумент102 страницыSeminar JSD - IIleizar_death64Оценок пока нет

- CH-440 NanotechnologyДокумент22 страницыCH-440 NanotechnologyAndrew SionОценок пока нет

- Fabrication of Nanoscale Structures: 1 Microfabrication - PhotolithographyДокумент12 страницFabrication of Nanoscale Structures: 1 Microfabrication - PhotolithographyMoataz Al-chalabiОценок пока нет

- 4.0 AdsorptionДокумент68 страниц4.0 AdsorptionWazif ZakwanОценок пока нет

- III. Vacuum Fundamentals & Technology: Why We Need Vacuum?Документ15 страницIII. Vacuum Fundamentals & Technology: Why We Need Vacuum?solanki8950Оценок пока нет

- Chapter 7 AdsorptionДокумент29 страницChapter 7 AdsorptionaliesyaОценок пока нет

- Laboratory Report 3Документ3 страницыLaboratory Report 3api-3864822Оценок пока нет

- Preparation and Characterization Techniques For The NanomaterialДокумент27 страницPreparation and Characterization Techniques For The NanomaterialSMIT CHRISTIANОценок пока нет

- Bgas PaintingДокумент85 страницBgas PaintingDandaman92% (12)

- Cation Tests Form 4 KSSM Chemistry Chapter 7 Acid, Base and SaltДокумент24 страницыCation Tests Form 4 KSSM Chemistry Chapter 7 Acid, Base and SaltEsther Randy100% (2)

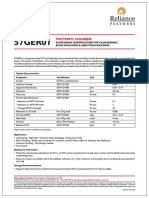

- PVC 57ger01Документ1 страницаPVC 57ger01rajesh patelОценок пока нет

- Katalog LincolnaДокумент612 страницKatalog LincolnaHaris TrešnjoОценок пока нет

- Citrus Oil Cleaner Formulations - 083Документ1 страницаCitrus Oil Cleaner Formulations - 083mndmattОценок пока нет

- 2-Lubricants CharacteristcsДокумент30 страниц2-Lubricants CharacteristcsHariajahОценок пока нет

- PulverizationДокумент26 страницPulverizationVasantha SudasinghaОценок пока нет

- Organic Chemistry Chap 11 Study GuideДокумент49 страницOrganic Chemistry Chap 11 Study GuideYarys YauОценок пока нет

- Cold Process Soap Swirling Tips: Temperatures WaterДокумент8 страницCold Process Soap Swirling Tips: Temperatures WaterGua DaОценок пока нет

- Dry Granulation by Slugging Method For Sustained Release of Model DrugДокумент50 страницDry Granulation by Slugging Method For Sustained Release of Model DrugBagus SetiawanОценок пока нет

- AISI 430 Ferritic Stainless Steel MicrostuctureДокумент7 страницAISI 430 Ferritic Stainless Steel MicrostuctureAid Farhan MaarofОценок пока нет

- 1 s2.0 S1674987123000919 MainДокумент21 страница1 s2.0 S1674987123000919 MainMatteo MainoОценок пока нет

- Class 10 Chemistry PartДокумент2 страницыClass 10 Chemistry PartVicky Singh100% (3)

- SoxhletExtraction PDFДокумент7 страницSoxhletExtraction PDFJim VelОценок пока нет

- Electrochemical Properties of The Platinum Metals: by M. Muylder N. deДокумент7 страницElectrochemical Properties of The Platinum Metals: by M. Muylder N. deLeopoldo CZОценок пока нет

- Adobe Scan Mar 06, 2023Документ12 страницAdobe Scan Mar 06, 2023niladriputatunda1Оценок пока нет

- Msds GPTMSДокумент6 страницMsds GPTMSElisabeth Kurnia BloomОценок пока нет

- The Synthesis and Structural Properties of (M (Dippe) (G - C H S) ) Complexes of PD and PT and Comparison With Their Ni AnalogДокумент8 страницThe Synthesis and Structural Properties of (M (Dippe) (G - C H S) ) Complexes of PD and PT and Comparison With Their Ni AnalogHưng LucaОценок пока нет

- Chemrite Tile Grout YC 802Документ3 страницыChemrite Tile Grout YC 802ICPL-RWPОценок пока нет

- Overview of Engg Chemistry: Assistant Professor, Dept of Applied Chemistry, Aias, Amity University, NoidaДокумент14 страницOverview of Engg Chemistry: Assistant Professor, Dept of Applied Chemistry, Aias, Amity University, Noidagaurav toppoОценок пока нет

- (PDF) Biological Iron Removal From Groundwater - A ReviewДокумент30 страниц(PDF) Biological Iron Removal From Groundwater - A ReviewRishya Prava ChatterjeeОценок пока нет

- Jurnal NanoemulsiДокумент12 страницJurnal NanoemulsiulfiОценок пока нет

- Sist en Iso 472 2014Документ15 страницSist en Iso 472 2014امین ادیب نیاОценок пока нет

- J.vibspec.2013.02.001 Ftir Batio3Документ6 страницJ.vibspec.2013.02.001 Ftir Batio3Seni Ramadhanti SОценок пока нет

- Chemistry Practical Written Work For Grade 9thДокумент12 страницChemistry Practical Written Work For Grade 9thriddhiОценок пока нет

- Chemical Equilibrium: X X X XДокумент8 страницChemical Equilibrium: X X X XAnanya AgrawalОценок пока нет

- CBSE Class 9 Science Revision Notes Chapter - 3 Atoms and MoleculesДокумент7 страницCBSE Class 9 Science Revision Notes Chapter - 3 Atoms and Moleculespavan kasaОценок пока нет

- Bahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGДокумент33 страницыBahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGMahanani SubagioОценок пока нет

- Hempel NORSOK Coating Systems: NORSOK M-501 Edition 5/6 System GuideДокумент4 страницыHempel NORSOK Coating Systems: NORSOK M-501 Edition 5/6 System GuideAlex KuvoricОценок пока нет

- M.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Документ4 страницыM.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Ƞƛǝǝm KĦáńОценок пока нет

- The Mechanism of Penetration Increase in a-TIG WeldingДокумент10 страницThe Mechanism of Penetration Increase in a-TIG WeldingA K SinghОценок пока нет