Академический Документы

Профессиональный Документы

Культура Документы

Flooded Systems: Cornell Pump Company 16261 SE 130 Avenue Clackamas, OR 97015 Tel: (503) 653-0330 Fax (503-) 653-0338

Загружено:

Alejandra Vega AvilezИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Flooded Systems: Cornell Pump Company 16261 SE 130 Avenue Clackamas, OR 97015 Tel: (503) 653-0330 Fax (503-) 653-0338

Загружено:

Alejandra Vega AvilezАвторское право:

Доступные форматы

Cornell Pump Company

16261 SE 130

th

Avenue

Clackamas, OR 97015

Tel: (503) 653-0330

Fax (503-) 653-0338

www.cornellpump.com

info@cornellpump.com

Flooded Systems

This system attempts to realize some of the energy efficiency of the liquid overfeed

system, but like the DX system, still relies on the high side pressure to move refrigerant

through the system. The fundamental difference between a flooded system and a DX

system is the evaporator coils are fully wetted (in fact flooded, hence the name). Instead

of using a thermal expansion valve, each evaporator has its own small receiver attached.

The bottom of the receiver is more or less at the same level as the bottom of the coil, and

the liquid level is about equal with the outlet of the coil. Liquid enters the coil by gravity,

and as it boils off, the liquid vapor mixture, being less dense, rises to the coil outlet. The

vapor is drawn off the top of the mini receiver or surge drum by the compressor and the

liquid continues to recirculate via thermosyphon. As the liquid level in the surge drum

drops because of evaporation a float controlled expansion valve opens up, and high

temperature, high pressure liquid flashes into low temperature, low pressure liquid in the

surge drum.

This type of system does, indeed, operate much more energy efficiently than the DX

system because the entire coil surface is wetted, and none of it is wasted to perform

superheating for compressor protection. Nevertheless, the liquid is still moved through

the system by high side pressure, so the head pressure cannot be allowed to float down

with the ambient to take advantage of cooler weather.

Вам также может понравиться

- Refrigeration Liquid Recirculation SystemsДокумент7 страницRefrigeration Liquid Recirculation Systemsgoodspeed_phОценок пока нет

- Expansion Vessel in A Solar Installation: White PaperДокумент9 страницExpansion Vessel in A Solar Installation: White PaperKhizerОценок пока нет

- Solar Automobile FridgeДокумент4 страницыSolar Automobile FridgeRahul SinghОценок пока нет

- Group 2 Basic Refrigerationsystem and ComponentsДокумент25 страницGroup 2 Basic Refrigerationsystem and ComponentsVipin VetriОценок пока нет

- Reasons Why TXVs Underfeed RefrigerantДокумент5 страницReasons Why TXVs Underfeed RefrigerantD HarОценок пока нет

- Metering DevicesДокумент8 страницMetering DevicesKudzai ManyanyeОценок пока нет

- 588-Water Cooler Cum HeaterДокумент6 страниц588-Water Cooler Cum Heatersanu222100% (3)

- Rac, Module 3-NoteДокумент81 страницаRac, Module 3-NoteShan Mathews VettikuzhiyilОценок пока нет

- Hot and Cold Water DespensorДокумент6 страницHot and Cold Water DespensorMohamedFasilОценок пока нет

- Air Conditioning System TroubleshootingДокумент4 страницыAir Conditioning System TroubleshootingGary KenmoreОценок пока нет

- The Refrigerant CircuitДокумент1 страницаThe Refrigerant CircuitRefrigerantОценок пока нет

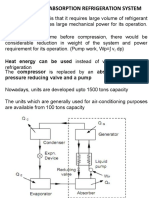

- Vapour Absorption Refrigeration SystemДокумент12 страницVapour Absorption Refrigeration SystemHarshОценок пока нет

- CEP AnsДокумент1 страницаCEP Ansarid-dexterОценок пока нет

- BUILDING UTILITIES 2 Building HVAC SystemsДокумент142 страницыBUILDING UTILITIES 2 Building HVAC Systemsjona serranoОценок пока нет

- Fresh Water Generator On Ships 2Документ16 страницFresh Water Generator On Ships 2Hamilton RamaОценок пока нет

- Ac Compressor OperationДокумент3 страницыAc Compressor OperationshalabyahmedОценок пока нет

- Automotive HVAC # Pressure ZonesДокумент3 страницыAutomotive HVAC # Pressure ZonesVishal SaxenaОценок пока нет

- Submitted By: Hans Wilson C Mechanical Dept ME03913Документ12 страницSubmitted By: Hans Wilson C Mechanical Dept ME03913Hans wilsonОценок пока нет

- What Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?Документ3 страницыWhat Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?a4104165Оценок пока нет

- Gas Pressure Recirculation Systems An American PhenomenaДокумент16 страницGas Pressure Recirculation Systems An American PhenomenaChristina ArgesanuОценок пока нет

- Gas Pressure Recirculation Systems - An American PhenomenaДокумент16 страницGas Pressure Recirculation Systems - An American PhenomenaJim Wright, P.E.Оценок пока нет

- Vapor Compression Refrigeration SystemДокумент11 страницVapor Compression Refrigeration Systemm_alodat6144Оценок пока нет

- Ac How It WorksДокумент4 страницыAc How It Workshassanain_100Оценок пока нет

- VarsДокумент16 страницVarsNikhil SinghОценок пока нет

- RefrigerationДокумент65 страницRefrigerationyassinОценок пока нет

- What Is Air Conditionig?Документ19 страницWhat Is Air Conditionig?Vishakha PatelОценок пока нет

- Water Chillers 85Документ2 страницыWater Chillers 85Rohit ShresthaОценок пока нет

- Evaporators: Waste Heat RecoveryДокумент8 страницEvaporators: Waste Heat RecoveryJitendra KumarОценок пока нет

- Power Plant Instrumentation Unit 3Документ4 страницыPower Plant Instrumentation Unit 3Mohit RanaОценок пока нет

- Refrigeration Expansion ValveДокумент15 страницRefrigeration Expansion ValvemahaОценок пока нет

- Condensers 2011Документ22 страницыCondensers 2011Chris BouchardОценок пока нет

- Air Conditioning TechnologyДокумент9 страницAir Conditioning TechnologyAhmed AzadОценок пока нет

- Solar RefrigerationДокумент31 страницаSolar RefrigerationPrabhat Sharma100% (1)

- Report On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversityДокумент14 страницReport On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversitysouravОценок пока нет

- Nes Module IIIДокумент12 страницNes Module IIIVenuОценок пока нет

- Expansion in a-WPS OfficeДокумент2 страницыExpansion in a-WPS OfficeMalecha SebastianОценок пока нет

- Refrigeration and Air-Conditioning: Unit - 3Документ30 страницRefrigeration and Air-Conditioning: Unit - 3SAATVIK JAINОценок пока нет

- PowerplantДокумент6 страницPowerplantYehosuah RanoaОценок пока нет

- Solar RefrigerationДокумент31 страницаSolar RefrigerationAMIT PRAJAPATI88% (8)

- Refrigeration and Air Conditioning Systems Onboard Ships-Vapour Compression SystemsДокумент32 страницыRefrigeration and Air Conditioning Systems Onboard Ships-Vapour Compression SystemsSatyabrat GaanОценок пока нет

- TPP - A Presentation On Thermal Power PlantsДокумент30 страницTPP - A Presentation On Thermal Power PlantsSounak SasmalОценок пока нет

- Experiment Title:: Flow Through Orifices (Exp1)Документ12 страницExperiment Title:: Flow Through Orifices (Exp1)hahahaaОценок пока нет

- Steam HammeringДокумент5 страницSteam HammeringMuhammad JunaidОценок пока нет

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFДокумент13 страницRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesОценок пока нет

- 639974b189f9f7 07444594Документ7 страниц639974b189f9f7 07444594ndoyeОценок пока нет

- What Is Cascade Refrigeration SystemДокумент5 страницWhat Is Cascade Refrigeration SystemLeo Van Ezel Arcay100% (2)

- Closed and Open Feed SystemДокумент7 страницClosed and Open Feed SystemRoneil BaculioОценок пока нет

- Refrigeration With Hot and Cooled BoxДокумент69 страницRefrigeration With Hot and Cooled Boxkris_soneОценок пока нет

- Kettle Type Reboiler WorkingДокумент7 страницKettle Type Reboiler WorkingCepi Sindang KamulanОценок пока нет

- Working Fluid Natural Convection: Solar Water HeaterДокумент8 страницWorking Fluid Natural Convection: Solar Water HeateranjanaОценок пока нет

- Expansion Valves - Working PrincipleДокумент3 страницыExpansion Valves - Working PrinciplePradeep Sukumaran100% (1)

- Refrigeration CycleДокумент5 страницRefrigeration CycleMa Zaira ObilloОценок пока нет

- A Report On Boiler Feed WaterДокумент11 страницA Report On Boiler Feed WaterAustin UdofiaОценок пока нет

- PERFORMANCE TEST ON VAPOUR COMPRESSION REFRIGERATION SYSTEM USING R290 & R134a MIXTUREДокумент7 страницPERFORMANCE TEST ON VAPOUR COMPRESSION REFRIGERATION SYSTEM USING R290 & R134a MIXTUREJASH MATHEWОценок пока нет

- Types of EvaporatorsДокумент12 страницTypes of Evaporatorsapi-377437388% (8)

- Air Conditioner Expansion ValveДокумент4 страницыAir Conditioner Expansion ValveMohammed Jahir HusainОценок пока нет

- Powerplant - Cooling Sytem Cooling Tower Feedwater Heater Condenser EvaporatorДокумент32 страницыPowerplant - Cooling Sytem Cooling Tower Feedwater Heater Condenser EvaporatorYehosuah RanoaОценок пока нет

- Basic Air Conditioning System.2022 NotesДокумент25 страницBasic Air Conditioning System.2022 NotesKITSAO SAMUELОценок пока нет

- Kanana MakathimoДокумент38 страницKanana MakathimoAlejandra Vega AvilezОценок пока нет

- Paste Thickening Iron Ore TailingsДокумент8 страницPaste Thickening Iron Ore TailingsAlejandra Vega Avilez100% (1)

- Cornell Vertical Close Coupled Solids Handling Pumps: (Choose)Документ2 страницыCornell Vertical Close Coupled Solids Handling Pumps: (Choose)Alejandra Vega AvilezОценок пока нет

- TAILIN ThickenerДокумент0 страницTAILIN ThickenerAlejandra Vega AvilezОценок пока нет

- Filtration Media Making The Right Choice: Page - 1Документ7 страницFiltration Media Making The Right Choice: Page - 1Alejandra Vega AvilezОценок пока нет