Академический Документы

Профессиональный Документы

Культура Документы

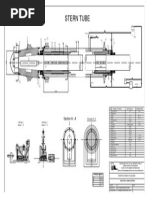

Stern Tube Boring

Загружено:

Medha Jog KatdareАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stern Tube Boring

Загружено:

Medha Jog KatdareАвторское право:

Доступные форматы

IN-SITU STERN TUBE BORING AND SHAFTLINE REPAIR BULK CARRIER

When an assessment showed that a bulker needed to have its tail shaft machined, new stern tube bearings, and a line

boring of the stern-tube housing during a short dry dock, was engaged to take on the repairs.

After discovering the leaking forward stern tube seal, inspection revealed that the tail shaft could not be machined in-

situ and needed to be removed and that both the fwd and aft stern tube bearings and stern-tube housing had been

badly damaged.

worked round the clock with multiple shifts to line bore the stern tube housing while machine shop repairs were

completed on the shaft and bearings by machinists ashore.

REPAIRS CONSISTED OF:

line bored the 6.5 meter long, 6! mm diameter stern tube housing from an original diameter of 65 mm to the

finished diameter in 5 hours.

"achining of tail shaft from a diameter of 5 mm to 5#$ mm within 5 days

"achining of forward and aft stern tube bearings within 6 days

%aser alignment check of machined stern tube bore with engine flywheel

&itting and load test of bearings and shaft

'reation of new technical drawings approved by "arine 'lass society

RESULTS:

A class approved repair inside of e(tremely tight timelines to the highest tolerances resulting in a successful sea trial and

)uick return to service for the owner.

JOB SPECS* +,%- 'A../0.

Stern Tube Length: 6.5" Origin! Stern Tube Di": 65mm Fin! Stern Tube Di": 6!mm Ti! #h$t Origin!

Di": 5mm Ti! #h$t $in! Di": 5#$mm

Вам также может понравиться

- Stern Tube Lubrication Systems ExplainedДокумент1 страницаStern Tube Lubrication Systems ExplainedAbdur RachmanОценок пока нет

- Steering Gear ManualДокумент187 страницSteering Gear ManualSavinda JanszОценок пока нет

- VTMH Am Brochure g1861 Designer-Manual eДокумент12 страницVTMH Am Brochure g1861 Designer-Manual eCleyton LeiteОценок пока нет

- Marine Propeller Shaft PowerДокумент26 страницMarine Propeller Shaft PowerJuniorJavier Olivo FarreraОценок пока нет

- Stern tube bearings and wear measurementДокумент3 страницыStern tube bearings and wear measurementaadarsh kumarОценок пока нет

- ZERO POLLUTION HIGH PERFORMANCE BEARING SYSTEMSДокумент12 страницZERO POLLUTION HIGH PERFORMANCE BEARING SYSTEMSAndrea NaranjoОценок пока нет

- Diesel Engine ConstructionДокумент53 страницыDiesel Engine ConstructionLasse HansenОценок пока нет

- Propeller Shafts (BV)Документ2 страницыPropeller Shafts (BV)João Henrique Volpini MattosОценок пока нет

- Stern Tube Diagram Parts ListДокумент1 страницаStern Tube Diagram Parts ListBagus Gelis Pratama Putra100% (1)

- Drive PerformanceДокумент47 страницDrive PerformanceEduardo VicelisОценок пока нет

- Crankshaft, crosshead and bearing constructionДокумент47 страницCrankshaft, crosshead and bearing constructionMeghanath Adkonkar0% (1)

- Report of Marine Diesel PracticumДокумент31 страницаReport of Marine Diesel PracticumPutu Widhi ApriliaОценок пока нет

- 8 Common Problems Found in Steering Gear System of ShipsДокумент5 страниц8 Common Problems Found in Steering Gear System of ShipsNorman prattОценок пока нет

- Mtu 16V 595 Te 70Документ1 страницаMtu 16V 595 Te 70Aytaç KesginОценок пока нет

- BearingsДокумент58 страницBearingsSarath RaghavОценок пока нет

- EHV Module IДокумент92 страницыEHV Module IArun ShobyОценок пока нет

- Van Der Velden® ATLANTIC Rudder: Choose To IntegrateДокумент2 страницыVan Der Velden® ATLANTIC Rudder: Choose To IntegrateKaliostro CeroОценок пока нет

- Sea-Water Lubricated Stern Tube BearingsДокумент5 страницSea-Water Lubricated Stern Tube BearingsfrancisОценок пока нет

- The Turnomat Valve RotatorДокумент5 страницThe Turnomat Valve RotatorBharatiyulam100% (1)

- Bow Thruster Installation InstructionsДокумент9 страницBow Thruster Installation InstructionsRovert AlonzoОценок пока нет

- Tie Bolts or Tie RodsДокумент8 страницTie Bolts or Tie RodsAayush AgrawalОценок пока нет

- A Conceptual Design and Analysis Tool For AircraftsДокумент13 страницA Conceptual Design and Analysis Tool For AircraftsAltay TabancacıОценок пока нет

- SL00 383Документ5 страницSL00 383bekavacsОценок пока нет

- Crankshaft TerminologyДокумент16 страницCrankshaft TerminologySathistrnpcОценок пока нет

- VehicleDriveCalculation PDFДокумент1 страницаVehicleDriveCalculation PDFnithansaОценок пока нет

- M.a.N. 6L16-24 MK II Upgrades at Sefine Shipyard 2015Документ4 страницыM.a.N. 6L16-24 MK II Upgrades at Sefine Shipyard 2015techОценок пока нет

- Thrust BlockДокумент2 страницыThrust Blockkyaw yaОценок пока нет

- 513 613 L28 32H Compressed Air SystemДокумент9 страниц513 613 L28 32H Compressed Air SystemFlo MarineОценок пока нет

- Alley - Maclellan - Steering-Gear Marine - Eng - Jul - 01 - 1888Документ2 страницыAlley - Maclellan - Steering-Gear Marine - Eng - Jul - 01 - 1888John Smith100% (1)

- 2 Stroke Diesel Engine Components-1Документ72 страницы2 Stroke Diesel Engine Components-1EdemОценок пока нет

- Oros PistonДокумент6 страницOros Pistonbrigolmustihotmail.com100% (1)

- Crankpin Calibration ReportДокумент1 страницаCrankpin Calibration ReportDoss LawrenceОценок пока нет

- Ada462130 PDFДокумент149 страницAda462130 PDFmaxpattОценок пока нет

- The Virtual Shipyard: A Simulation Model of The Shipbuilding ProcessДокумент12 страницThe Virtual Shipyard: A Simulation Model of The Shipbuilding ProcessAdades Safede EfdОценок пока нет

- Steam Turbine Construction MaterialsДокумент14 страницSteam Turbine Construction MaterialsmarpelОценок пока нет

- Brochure 51 60DFДокумент8 страницBrochure 51 60DFSenol Seidali100% (1)

- Wartsila O Pumps Hamworthy Pump RoomДокумент8 страницWartsila O Pumps Hamworthy Pump Roomliao_marcoОценок пока нет

- HOUTTUIN Catalog GeneralДокумент12 страницHOUTTUIN Catalog GeneralRelu123Оценок пока нет

- Turbocharger Principles and Components for Marine EngineersДокумент14 страницTurbocharger Principles and Components for Marine EngineersDodi SuhendraОценок пока нет

- Aux EngineДокумент45 страницAux Enginetheva34Оценок пока нет

- 40MF Series End Suction Fire Pump & Package System BrochureДокумент4 страницы40MF Series End Suction Fire Pump & Package System BrochurearsushanОценок пока нет

- Man New Piston RingsДокумент3 страницыMan New Piston RingsMario AndrewОценок пока нет

- 516 616 L28 32H Cooling Water SystemДокумент13 страниц516 616 L28 32H Cooling Water SystemFlo MarineОценок пока нет

- A Study On Torque Rich Phenomena in Ship OperationДокумент11 страницA Study On Torque Rich Phenomena in Ship OperationAnonymous XtvvG80zuОценок пока нет

- Environmentally Friendly Marine Gensets Compliant with IMO RegulationsДокумент20 страницEnvironmentally Friendly Marine Gensets Compliant with IMO RegulationsAjinkya KhamkarОценок пока нет

- Cylinder LubricationДокумент8 страницCylinder LubricationVinay Kumar Neelam100% (1)

- IRON Pump - QV SeriesДокумент2 страницыIRON Pump - QV SeriesAbsar MamunОценок пока нет

- K90MC-C Project Guide for Two-stroke Marine EnginesДокумент279 страницK90MC-C Project Guide for Two-stroke Marine EnginesfaintaresОценок пока нет

- Checklist for FiFi installations and startup report optimizationДокумент2 страницыChecklist for FiFi installations and startup report optimizationTa Bon0% (1)

- Service Bulletin RTA-43.3 RT-flex-05Документ12 страницService Bulletin RTA-43.3 RT-flex-05Gaby CrisОценок пока нет

- Bedplate Foundation EngineДокумент11 страницBedplate Foundation EngineVinay Kumar NeelamОценок пока нет

- 6 Checking and Adjustment of Exhaust Cam LeadДокумент8 страниц6 Checking and Adjustment of Exhaust Cam LeadJomari Saligan100% (1)

- Refit Requirement - Fares1Документ35 страницRefit Requirement - Fares1boen jaymeОценок пока нет

- Engine Bearing Sizes - VW BeetleДокумент2 страницыEngine Bearing Sizes - VW BeetleDarius BooyensОценок пока нет

- 48 60Документ5 страниц48 60j1931ppОценок пока нет

- Docshare - Tips Stern Tube BoringДокумент2 страницыDocshare - Tips Stern Tube Boringfachrul rozziОценок пока нет

- Torre de Cucharas de Colada Continua Reemplazo de Rodamiento Y BujesДокумент12 страницTorre de Cucharas de Colada Continua Reemplazo de Rodamiento Y Bujesrcordero.tasОценок пока нет

- 'Replacement of Corroded and Perforated Cross Girders of BR - NO.449 DNДокумент11 страниц'Replacement of Corroded and Perforated Cross Girders of BR - NO.449 DNgopi bhupathiОценок пока нет

- Short Shut Down ReportДокумент4 страницыShort Shut Down ReportMuhammad Ahmed AltafОценок пока нет

- What Is Grease?Документ5 страницWhat Is Grease?Medha Jog KatdareОценок пока нет

- Material Used in Ship BuildingДокумент13 страницMaterial Used in Ship BuildingMedha Jog KatdareОценок пока нет

- Gear Oil: Function of A Gear LubricantДокумент2 страницыGear Oil: Function of A Gear LubricantMedha Jog KatdareОценок пока нет

- Housekeeping: Storage On DeckДокумент3 страницыHousekeeping: Storage On DeckMedha Jog KatdareОценок пока нет

- Ac and DC Solenoid ValvesДокумент3 страницыAc and DC Solenoid ValvesMedha Jog KatdareОценок пока нет

- Trouble Shooting SeperatorДокумент1 страницаTrouble Shooting SeperatorMedha Jog KatdareОценок пока нет

- Liquefied Gas Handling TerminologyДокумент9 страницLiquefied Gas Handling TerminologyMedha Jog KatdareОценок пока нет

- Engine LubricationДокумент4 страницыEngine LubricationMedha Jog KatdareОценок пока нет

- Ensuring Sat Performamce of Stern TubeДокумент6 страницEnsuring Sat Performamce of Stern TubeMedha Jog KatdareОценок пока нет

- Ac and DC Solenoid ValvesДокумент3 страницыAc and DC Solenoid ValvesMedha Jog KatdareОценок пока нет

- Purifier Maintenance & Emergency ProceduresДокумент27 страницPurifier Maintenance & Emergency ProceduresMedha Jog KatdareОценок пока нет

- Classification of PumpsДокумент22 страницыClassification of PumpsMedha Jog KatdareОценок пока нет

- Ocean Pollution and CleaningДокумент8 страницOcean Pollution and CleaningMedha Jog KatdareОценок пока нет

- Horizontal Shaft Dismantling GuideДокумент2 страницыHorizontal Shaft Dismantling GuideMedha Jog KatdareОценок пока нет

- Trouble Shooting SeperatorДокумент1 страницаTrouble Shooting SeperatorMedha Jog KatdareОценок пока нет

- Difference Between Safety Valve and Relief ValveДокумент3 страницыDifference Between Safety Valve and Relief ValveMedha Jog KatdareОценок пока нет

- Cargo Pumping SystemДокумент24 страницыCargo Pumping SystemMedha Jog Katdare100% (1)

- Cargo Tank Venting ArrangementsДокумент3 страницыCargo Tank Venting ArrangementsMedha Jog KatdareОценок пока нет

- Risk AssessmentДокумент18 страницRisk AssessmentMedha Jog KatdareОценок пока нет

- Machine Safety 0 0Документ32 страницыMachine Safety 0 0Adam RossОценок пока нет

- Scavenge FireДокумент4 страницыScavenge FireMedha Jog KatdareОценок пока нет

- Scavenge FireДокумент4 страницыScavenge FireMedha Jog KatdareОценок пока нет

- Scavenge FireДокумент4 страницыScavenge FireMedha Jog KatdareОценок пока нет

- Lobe PumpДокумент15 страницLobe PumpMedha Jog KatdareОценок пока нет

- CorroisonДокумент3 страницыCorroisonMedha Jog KatdareОценок пока нет

- Impressed Current Cathodic Protection (ICCP) SystemsДокумент4 страницыImpressed Current Cathodic Protection (ICCP) SystemsMedha Jog KatdareОценок пока нет

- Formulae and Definitions in MathematicsДокумент71 страницаFormulae and Definitions in MathematicsMedha Jog Katdare100% (1)

- Dynamics of RotationДокумент32 страницыDynamics of RotationMedha Jog KatdareОценок пока нет

- Ship-Shore Safety Check List For TankersДокумент6 страницShip-Shore Safety Check List For TankersMedha Jog Katdare67% (3)

- Censorship Is Always Self Defeating and Therefore FutileДокумент2 страницыCensorship Is Always Self Defeating and Therefore Futileqwert2526Оценок пока нет

- Influencing Decisions: Analyzing Persuasion TacticsДокумент10 страницInfluencing Decisions: Analyzing Persuasion TacticsCarl Mariel BurdeosОценок пока нет

- 1) Anuj Garg Vs Hotel Association of India: Article 15Документ26 страниц1) Anuj Garg Vs Hotel Association of India: Article 15UriahОценок пока нет

- The Rocky Mountain WestДокумент202 страницыThe Rocky Mountain WestYered Canchola100% (1)

- 2016-2017 Course CatalogДокумент128 страниц2016-2017 Course CatalogFernando Igor AlvarezОценок пока нет

- Godbolt RulingДокумент84 страницыGodbolt RulingAnthony WarrenОценок пока нет

- Narrative On Parents OrientationДокумент2 страницыNarrative On Parents Orientationydieh donaОценок пока нет

- Square Pharma Valuation ExcelДокумент43 страницыSquare Pharma Valuation ExcelFaraz SjОценок пока нет

- Unit Test: VocabularyДокумент2 страницыUnit Test: VocabularyTrang PhạmОценок пока нет

- Tayug Rural Bank v. CBPДокумент2 страницыTayug Rural Bank v. CBPGracia SullanoОценок пока нет

- Codex Magica Texe MarrsДокумент588 страницCodex Magica Texe MarrsAndrew D WadeОценок пока нет

- MGT420Документ3 страницыMGT420Ummu Sarafilza ZamriОценок пока нет

- Ncaa Financial Report Fy19 AlcornДокумент79 страницNcaa Financial Report Fy19 AlcornMatt BrownОценок пока нет

- Madhuri Economics of Banking Semester 1 ProjectДокумент35 страницMadhuri Economics of Banking Semester 1 ProjectAnaniya TiwariОценок пока нет

- The Left, The Right, and The State (Read in "Fullscreen")Документ570 страницThe Left, The Right, and The State (Read in "Fullscreen")Ludwig von Mises Institute100% (68)

- RIZAL Childhood ScriptДокумент3 страницыRIZAL Childhood ScriptCarla Pauline Venturina Guinid100% (2)

- 79.1 Enrico vs. Heirs of Sps. Medinaceli DigestДокумент2 страницы79.1 Enrico vs. Heirs of Sps. Medinaceli DigestEstel Tabumfama100% (1)

- Vas Ifrs Event enДокумент2 страницыVas Ifrs Event enDexie Cabañelez ManahanОценок пока нет

- Aristotle Model of CommunicationДокумент4 страницыAristotle Model of CommunicationSem BulagaОценок пока нет

- Architecture FirmДокумент23 страницыArchitecture Firmdolar buhaОценок пока нет

- Handout On Reed 1 Initium Fidei: An Introduction To Doing Catholic Theology Lesson 4 Naming GraceДокумент8 страницHandout On Reed 1 Initium Fidei: An Introduction To Doing Catholic Theology Lesson 4 Naming GraceLEILA GRACE MALACAОценок пока нет

- Mediocrity-The Unwated SinДокумент3 страницыMediocrity-The Unwated SinJay PatelОценок пока нет

- Pendekatan (CTL) Dan Implementasinya Dalam Rencana Pembelajaran PAI MIДокумент20 страницPendekatan (CTL) Dan Implementasinya Dalam Rencana Pembelajaran PAI MIAfandi HusinОценок пока нет

- A Bibliography of China-Africa RelationsДокумент233 страницыA Bibliography of China-Africa RelationsDavid Shinn100% (1)

- Exploratory EssayДокумент9 страницExploratory Essayapi-237899225Оценок пока нет

- High-Performance Work Practices: Labor UnionДокумент2 страницыHigh-Performance Work Practices: Labor UnionGabriella LomanorekОценок пока нет

- NS500 Basic Spec 2014-1015Документ58 страницNS500 Basic Spec 2014-1015Adrian Valentin SibiceanuОценок пока нет

- Asset To LiabДокумент25 страницAsset To LiabHavanaОценок пока нет

- Penyebaran Fahaman Bertentangan Akidah Islam Di Media Sosial Dari Perspektif Undang-Undang Dan Syariah Di MalaysiaДокумент12 страницPenyebaran Fahaman Bertentangan Akidah Islam Di Media Sosial Dari Perspektif Undang-Undang Dan Syariah Di Malaysia2023225596Оценок пока нет

- Usui MemorialДокумент6 страницUsui MemorialstephenspwОценок пока нет