Академический Документы

Профессиональный Документы

Культура Документы

Service Tip 1.5.2 Tightening Torques: © 2006 Kaeser Compressors, Inc. All Rights Reserved

Загружено:

Guillermo Andres Gomez RamirezИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Service Tip 1.5.2 Tightening Torques: © 2006 Kaeser Compressors, Inc. All Rights Reserved

Загружено:

Guillermo Andres Gomez RamirezАвторское право:

Доступные форматы

SERVICE TIP 1.5.

2

J une 20, 2006

Page 1 of 2

2006 Kaeser Compressors, Inc.

All Rights Reserved

Service Tip 1.5.2

Tightening Torques

Attention! Before beginning work on any machine:

Make sure the disconnect is off, locked, and tagged out in accordance

with OSHA

Check that there is no voltage on the machine

Check that the machine is not under pressure

Read and follow all safety instructions in the service manual.

Certain screws in compressors must be tightened to specific torques. A torque

wrench should be used in all the following cases:

Tapered fittings such as pulleys on motor and airend shafts

Radial fixing screws in couplings

Oil separator tank cover securing screws

The table on the following page lists the tightening torque of thread sizes and

tensile classes. The tensile class is generally stamped on the head of the screw.

SERVICE TIP 1.5.2

J une 20, 2006

Page 2 of 2

2006 Kaeser Compressors, Inc.

All Rights Reserved

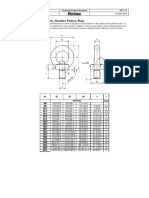

Tensioning Torque

Tensile Class 5.8 Tensile Class 8.8 Tensile Class 10.9

Thread

size

Nm Lbf-in Lbf-ft Nm Lbf-in Lbf-ft Nm Lbf-in Lbf-ft

M4 1.7 15.0 1.3 2.7 23.9 2 3.8 33.6 2.8

M5 3.4 30.1 2.5 5.5 48.7 4.1 8 70.8 5.9

M6 6 53.1 4.4 9.5 84.1 7 13 115.1 9.6

M8 14.5 128.3 10.7 23 203.6 17 32 283.2 23.6

M10 29 256.7 21.4 46 407.1 33.9 64 566.4 47.2

M12 50 442.5 36.9 80 708.1 59 110 522.2 81.1

M14 79 699.2 58.3 125 1106.3 92.2 180 816 132.8

M16 122 1079.8 90 195 1725.9 143.8 275 1272.7 202.8

M20 242 2141.9 178.5 385 3407.5 284 540 2513.6 398.3

Fine Thread

M8 X 1 17 150.5 12.5 25 221.3 18.4 36 318.6 26.6

M10 X 1.25 33 292.1 24.3 49 433.7 36.1 72 637.3 53.1

M12 X 1.25 59 522.2 43.5 87 770 64.2 128 1132.9 94.4

M16 X 1.5 140 1239.1 103.3 207 1832.1 152.7 304 2690.6 224.2

M20 X 1.5 292 2584.4 215.4 433 3832.4 319.4 617 5460.9 455.1

Вам также может понравиться

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingОт EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingРейтинг: 4.5 из 5 звезд4.5/5 (9)

- SUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFДокумент18 страницSUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFsekfsekmddde100% (4)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- Parts and Repair Manual: Delta MotorДокумент24 страницыParts and Repair Manual: Delta MotorErik LawrenceОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- S & SL Series Hydraulic Cylinders: Special FeaturesДокумент2 страницыS & SL Series Hydraulic Cylinders: Special FeaturesmachineCanОценок пока нет

- 8-2 Group 2 Tightening Torque PDFДокумент3 страницы8-2 Group 2 Tightening Torque PDFrodinei cesar gomes gomes100% (1)

- TORQMAXДокумент8 страницTORQMAXReddy SadhanaОценок пока нет

- 8-1. Disassembly and AssemblyДокумент175 страниц8-1. Disassembly and AssemblyDeyvi Cconocuyca HuallparimachiОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major Componentslevinton jose tobias genesОценок пока нет

- GROUP 2 TIGHTENING TORQUE SPECSДокумент3 страницыGROUP 2 TIGHTENING TORQUE SPECSSergey MovchanОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsHậu Minh100% (1)

- Schrader - Hydraulic Cylinders ISO 6020-1Документ9 страницSchrader - Hydraulic Cylinders ISO 6020-1alvaromviegas_191514Оценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsDenОценок пока нет

- 4-1. MaintenanceДокумент54 страницы4-1. Maintenancemargotsilva96Оценок пока нет

- Mazda 121 2 2Документ381 страницаMazda 121 2 2grumpyoldfart0175% (4)

- Group 2 Tightening TorqueДокумент3 страницыGroup 2 Tightening TorqueSergey MovchanОценок пока нет

- MAINTENANCE SCHEDULEДокумент47 страницMAINTENANCE SCHEDULEGetachew GechОценок пока нет

- Group 2 Tightening Torque: Major Components 1Документ3 страницыGroup 2 Tightening Torque: Major Components 1АлексейОценок пока нет

- Metric Bolt Torque Table: Thread EngagementДокумент2 страницыMetric Bolt Torque Table: Thread EngagementRathnam Ravi100% (3)

- Metric Bolt Torque TableДокумент1 страницаMetric Bolt Torque TableChittaranjan PradhanОценок пока нет

- Tightening Torque1Документ1 страницаTightening Torque1EngrMuhammadAzizОценок пока нет

- WEG W22 Terminal BoxДокумент1 страницаWEG W22 Terminal BoxTerry BaddeleyОценок пока нет

- ML An Af2 Aus Und Einbau enДокумент2 страницыML An Af2 Aus Und Einbau ensáng nguyễnОценок пока нет

- Metric Bolt Torque TableДокумент1 страницаMetric Bolt Torque TableHari SankarОценок пока нет

- Seal Friction Parker SealsДокумент6 страницSeal Friction Parker SealsChristian MavarezОценок пока нет

- Megaflux Series: Engineering GuideДокумент24 страницыMegaflux Series: Engineering GuideErman GogenОценок пока нет

- Plant-2 Vibration Report (Dec-13)Документ5 страницPlant-2 Vibration Report (Dec-13)Chandra ShekarОценок пока нет

- 2006 Marathon RaceДокумент25 страниц2006 Marathon RacemvanoosterhouthotmaiОценок пока нет

- Harmonic CSF LW SpecsheetДокумент8 страницHarmonic CSF LW SpecsheetElectromateОценок пока нет

- MF CX330 Tier3 GBДокумент281 страницаMF CX330 Tier3 GBjose luis baldiviezo olmosОценок пока нет

- Fastenr GradesДокумент5 страницFastenr GradesVipul ShereОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsFábio Costa100% (1)

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsChristian VicenteОценок пока нет

- Group 2 Tightening Torque: 1. Major ComponentsДокумент3 страницыGroup 2 Tightening Torque: 1. Major ComponentsSaidi JalelОценок пока нет

- GROUP 2 TIGHTENING TORQUE SPECSДокумент3 страницыGROUP 2 TIGHTENING TORQUE SPECSSaidi JalelОценок пока нет

- Proof Load, Yield & Tensile Strength Chart MetricДокумент1 страницаProof Load, Yield & Tensile Strength Chart MetricAnonymous YWS7ndsiОценок пока нет

- XT250 2008 Service ManualДокумент282 страницыXT250 2008 Service Manualglorthron100% (2)

- Enticer ManualДокумент122 страницыEnticer Manualdhaze14Оценок пока нет

- SKF Shaft CouplingsДокумент24 страницыSKF Shaft CouplingsEmilio PortelaОценок пока нет

- Group 2 Tightening TorqueДокумент3 страницыGroup 2 Tightening TorquerolandseОценок пока нет

- Measurements, Sizes, Shafts, KeywaysДокумент91 страницаMeasurements, Sizes, Shafts, KeywaysVenkat DoraОценок пока нет

- 1ZFI209205-437-en_Installation instructions Tightening torqueДокумент5 страниц1ZFI209205-437-en_Installation instructions Tightening torquethomasvicson24Оценок пока нет

- Metric ThreadsДокумент35 страницMetric ThreadsmihaidelianОценок пока нет

- Manual TransmissionДокумент46 страницManual Transmissionjrrodrigueza2Оценок пока нет

- GPD 515 CДокумент26 страницGPD 515 CRoger MantillaОценок пока нет

- MaintenanceДокумент27 страницMaintenanceJuОценок пока нет

- Forged Eye Bolts, Metric, Shoulder Pattern, Plain: Page 1 of 2 REV-01 Date: August 9, 2012 M.Feb - SH.PДокумент2 страницыForged Eye Bolts, Metric, Shoulder Pattern, Plain: Page 1 of 2 REV-01 Date: August 9, 2012 M.Feb - SH.Pdonnyars1979Оценок пока нет

- Eg 00010 PDFДокумент7 страницEg 00010 PDFAnonymous EhdILsAwmsОценок пока нет

- Gas Pressure Regulator RMG 512: Operation and Maintenance, Spare PartsДокумент20 страницGas Pressure Regulator RMG 512: Operation and Maintenance, Spare PartsPop IonutОценок пока нет

- 1 634 TechnicalДокумент11 страниц1 634 Technicalmarsianin1_702850066Оценок пока нет

- Mechanical Bolt Torque TableДокумент7 страницMechanical Bolt Torque TablesitehabОценок пока нет

- 07Документ133 страницы07ROboii FavelaОценок пока нет

- 1521-Versys X300 Crash Bar PDFДокумент4 страницы1521-Versys X300 Crash Bar PDF孙振立Оценок пока нет

- Metric ThreadДокумент27 страницMetric Threadlucian lunaОценок пока нет

- 1.9L Parts BookДокумент33 страницы1.9L Parts Booklugarin1Оценок пока нет

- Kutna BrusilicaДокумент1 страницаKutna BrusilicaEnzo SovittiОценок пока нет

- 4 1. MaintenanceДокумент60 страниц4 1. MaintenancevolvoОценок пока нет

- Tyco Flange Tech DetailsДокумент0 страницTyco Flange Tech DetailsRajesh KanalaОценок пока нет

- RPS67.118.2 06/08 Version - A: Repair Parts Sheet RC-Cylinders 15-Ton Single-Acting 0-700 BarДокумент2 страницыRPS67.118.2 06/08 Version - A: Repair Parts Sheet RC-Cylinders 15-Ton Single-Acting 0-700 BarGuillermo Andres Gomez RamirezОценок пока нет

- Repair Parts Sheet: RC-101, RC-102, RC-104 RC-Duo Hydraulic CylindersДокумент2 страницыRepair Parts Sheet: RC-101, RC-102, RC-104 RC-Duo Hydraulic CylindersPedro Samuel Brito Lopes100% (1)

- Humidity Conversion Formulas B210973EN-F PDFДокумент17 страницHumidity Conversion Formulas B210973EN-F PDFGyana MatiОценок пока нет

- Manual SullairДокумент54 страницыManual Sullairandresito042150% (2)

- Aire KaeserДокумент4 страницыAire KaeserGuillermo Andres Gomez RamirezОценок пока нет

- NEMA Enclosure Types 11-05-2Документ9 страницNEMA Enclosure Types 11-05-2Duron SaavedraОценок пока нет