Академический Документы

Профессиональный Документы

Культура Документы

Chemical Reaction Engineering 40 L CSTR Saponification

Загружено:

Mohamad Turmizi JaafarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chemical Reaction Engineering 40 L CSTR Saponification

Загружено:

Mohamad Turmizi JaafarАвторское право:

Доступные форматы

FACULTY OF CHEMICAL ENGINEERING

UiTM Terengganu, Bukit Besi Campus

Program : Diploma in Chemical Engineering

Course : Introduction To Chemical Reaction

Engineering

Course Code : CHE244

Lecturer : Marshahida bin Mat Yashim

Laboratory Report

Experiment Title

THE SAPONIFICATION REACTION OF ETHYL ACETATE, ET(AC) AND

SODIUM HYDROXIDE, NAOH

No Name Student ID No Signature

1. MOHAMAD TURMIZI BIN JAAFAR

2013450634

2. AMIRUL AIMAN BIN ZULFAKAR

2013419606

3. MUHAMMAD AZIZI BIN AB WAHAB

2013451738

4. NUR SYAFIQAH BINTI MOHD SAIDI

2013884596

5. NOR SYAZA MUNIERAH BINTI SALLEH

2013246812

Date of Experiment : 03.09.2014

Date of Submission : 23.09.2014

Received by:-

________________________

MARSHAHIDA BINTI MAT YASHIM

Date :

List of contents

THE SAPONIFICATION REACTION OF ETHYL ACETATE, ET(AC) AND SODIUM

HYDROXIDE, NAOH ........................................................................................................................... 1

1.0 INTRODUCTION ...................................................................................................................... 5

2.0 OBJECTIVE ............................................................................................................................... 7

3.0 APPARATUS ............................................................................................................................. 8

4.0 THEORY .................................................................................................................................. 11

5.0 PROCEDURE ........................................................................................................................... 13

7.0 DISCUSSION ........................................................................................................................... 18

8.0 CONCLUSION ......................................................................................................................... 19

Bibliography ......................................................................................................................................... 21

List of figures

Figure 1 : Cross-sectional diagram of Continuous stirred-tank reactor .................................................. 5

Figure 2 : Single Continuous Stirred Tank Reactors (CSTRs) ............................................................... 6

Figure 3 : Continuously Stirrer Tank Reactor (CSTR) in series ............................................................. 6

Figure 4 : 25 mL burette ......................................................................................................................... 8

Figure 5 : Stand with clamps .................................................................................................................. 8

Figure 6 : Conical Flask .......................................................................................................................... 9

Figure 7 : Continuous Stirred Tank Reactor 40L .................................................................................... 9

Figure 8 : 100 ML Beaker ..................................................................................................................... 10

Figure 9 : Calibration curve (Conversion vs. Conductivity) ................................................................. 16

Figure 10 : Graph of conversion against residence time ....................................................................... 16

List of tables

Table 1 : Calculations for back titration ................................................................................................ 12

Table 2 : Preparation calibration curve ................................................................................................. 15

Table 3 : Effect of residence time Continuous Stirred Tank Reactor ................................................... 15

TITLE : THE SAPONIFICATION REACTION OF ETHYL ACETATE, ET(AC) AND

SODIUM HYDROXIDE, NAOH

1.0 INTRODUCTION

Firstly, a common type of reactor is the mixing, or stirred reactor .The basic components

of this device will include a mixer or agitator mounted to a tank. One of the stirred reactors is

Continuous Stirred Tank Reactors (CSTR). The flow stirred tank reactor in series is a

common reactor type in environmental applications. The principle characteristic is that the

reactor is assumed to be instantaneously and perfectly mixed. Majority of industrial chemical

processes, a CSTR reactor is the equipment in which raw materials undergo a chemical

change to form desired product. The types of process this equipment is the continuous stirred

tank reactor which is this reactor is almost always operated at steady state. The CSTR reactor

used are most commonly used in industrial processing, primarily in homogeneous liquid-

phase flow reactions, where constant agitation is required. They may be used by themselves,

in series, or in a battery. It is referred to as the continuously stirred tank reactor (CSTR). It is

normally operated at steady state and is assumed to be perfectly mixed. The characteristic of

this equipment is run at steady state with continuous flow of reactants and products, the feed

assumes a uniform composition throughout the reactor, and exit stream has the same

composition as in the tank.

Figure 1 : Cross-sectional diagram of Continuous stirred-tank reactor

The CSTR can run as single reactor and also in series. The CSTR reactor is connected

in series so that the exit stream of one reactor is the feed stream for another reactor. There are

three reactor vessels connected in series by piping, each containing a propeller agitator driven

by a variable speed electric motor and the unit based on the simplest classic case of well

mixed, multi-staged process operation. The solution in each reactor is well stirred and the

concentration can be measured. These three reactors are to compare the measured responses

of the vessel concentrations to deliberate change at the inlet with a theoretical prediction.

Figure 2 : Single Continuous Stirred Tank Reactors (CSTRs)

The piping arrangement has been designed to include a dead time coil in the system. Feed

liquid to the first vessel is drawn from of the two sump tanks by a pump, via a flow meter and

control valve. The trace material concentration in each sump tank is made to be different. At

a selected instant, a sudden change from one feed to the other is made: either for continuous

period is known as the step function, or for a short interval is known as impulse function, and

the concentration or conductivity changer with time in each vessel is measured.

Figure 3 : Continuously Stirrer Tank Reactor (CSTR) in series

The advantages of CSTR are easily maintained, good temperature control, cheap to construct,

reactor has large heat capacity and interior of reactor is easily accessed. Meanwhile, the

disadvantages of using CSTR are lowest conversion per unit volume and also by-passing and

channelling possible with poor agitation.

2.0 OBJECTIVE

That shown the objective of this experiment:

i) To carry out a saponification reaction between NaOH and Et(Ac) in a CSTR.

ii) To determine the effect of residence time onto the reaction extent of conversion..

iii) To determine the reaction rate constant.

BURETTE

BASE

CLAMP

SCALE

LIQUID

HOLDER

3.0 APPARATUS

A.

B.

Figure 4 : 25 mL burette

Figure 5 : Stand with clamps

C.

Figure 6 : Conical Flask

D.

Figure 7 : Continuous Stirred Tank Reactor 40L

SCALE

E.

Figure 8 : 100 ML Beaker

4.0 THEORY

One of the organic chemical reactions known to ancient man was the preparation of soaps

through a reaction called saponification. Natural soaps are sodium or potassium salts of fatty

acids, originally made by boiling lard or other animal fat together with lye or potash

(potassium hydroxide). Hydrolysis of the fats and oils occurs, yielding glycerol and crude

soap. In the industrial manufacture of soap, tallow (fat from animals such as cattle and sheep)

or vegetable fat is heated with sodium hydroxide. Once the saponification reaction is

complete, sodium chloride is added to precipitate the soap. The water layer is drawn off the

top of the mixture and the glycerol is recovered using vacuum distillation.

The equation below shows the saponification process between sodium hydroxide and ethyl

acetate (irreversible reaction) to produce sodium acetate and by-product ethanol.

NaOH + C

2

H

5

O

2

CCH

3

CH

3

CO

2

Na + H

3

CCH

2

OH

Sodium Hydroxide Ethyl Acetate Sodium Acetate Ethanol

A. Preparation of Calibration Curve for Conversion vs. Conductivity

The reaction to be studied is the saponification reaction of ethyl acetate Et(Ac) and

sodium hydroxide (NaOH). Since this is a second order reaction, the rate of reaction

depends on both concentrations of Et (Ac) and NaOH. However, for analysis

purposes, the reaction will be carried out using equimolar feeds of Et (Ac) and NaOH

solutions with the same initial concentrations. This ensures that both concentrations

are similar throughout the reaction.

NaOH + Et (Ac) Na(Ac) + EtOH

It will calibrate the conductivity measurement of conversion values for the reaction

between 0.1 M ethyl acetate and 0.1 M sodium hydroxide that we will get from the

experiment.

B. Back Titration for Manual Conversion Determination

It is advisable to carry out manual conversion determination on experiment samples to

verify the conductivity measurement values. It is based on the principle of quenching

the sample with excess acid to stop any further reactions, then back titrating with a

base to determine the amount of unreacted acid.

NaOH + HCl NaCl + H

2

O

The calculations of back titration :

No. Quantities Formula Unit

1. Concentration of NaOH entering

the reactor, C

NaOH,0

C

NaOH,f

mol/L

2. Volume of unreacted quenching

HCL, V

2

(C

NaOH,s

/C

HCL,s

) x

V

1

mL

3. Volume of HCL reacted with

NaOH in sample, V

3

V

HCL,S

V

2

mL

4. Moles of HCL reacted with NaOH

in sample, n

1

(C

HCL,S

x V

3

) /

1000

mol

5. Moles of unreacted NaOH in

sample, n

2

n

1

mol

6. Concentration of unreacted NaOH

in the reactor, C

NaOH

n

2

/ V

s

x 1000 mol/L

7. Conversion of NaOH in the

reactor, X

[1 (C

NaOH

/

C

NaOH,0

)] x 100%

Table 1 : Calculations for back titration

C. Reaction Rate Constant

5.0 PROCEDURE

1. Preparation of Calibration Curve for Conversion vs. Conductivity

i) The solutions for the first method were prepared

- 1 L of sodium hydroxide, NaOH ( 0.1 M )

- 1 L of sodium acetate, Et (Ac) ( 0.1 M )

- 1 L of deionised water, H

2

O

ii) The conductivity and NaOH concentration had been determined for each

conversion values by mixing the solutions into 100 mL of deionised water :

- 0% conversion : 100 mL NaOH

- 25% conversion : 75 mL NaOH + 25 mL Et (Ac)

- 50% conversion : 50 mL NaOH + 50 mL Et (Ac)

- 75% conversion : 25 mL NaOH + 75 mL Et (Ac)

- 100% conversion : 100 mL Et (Ac)

2. Back Titration for Manual Conversion Determination

i) 0.1 M NaOH solution was filled in a burette.

ii) 10 mL of 0.25 M HCL was measured in a flask.

iii) 50 mL sample had been obtained from the experiment and had been added up to

the HCL in the flask immediately to quench the saponification reaction.

iv) A few drops of pH indicator were added into the mixture.

v) The mixture had been titrated with NaOH solution from the burette until the

mixture is neutralized and the amount of NaOH titrated was recorded.

3. Reaction Rate in the CSTR

i) The general start-up procedures as before were performed.

ii) Both pumps P1 and P2 were switched on simultaneously and valves V5 and V10

were opened to obtain the highest possible flow rate into the reactor.

iii) The reactor had been filled up with both the solution until it is just about to

overflow.

iv) The valves V5 and V10 were readjusted to give flow a rate of about 0.1 L/min.

Both flow rate were made at the same value and it had been recorded.

v) The stirrer M1 was switched on and the speed was set up about 200 rpm.

vi) The conductivity value was started to be monitored at Ql-401 until it does not

change over time. This is to ensure that the reactor has reached steady state.

vii) The steady state conductivity value was recorded and the concentration of NaOH

in the reactor was obtained and extent of conversion from the calibration curve.

viii) Sampling valve V12 was opened and a 50 mL sample was collected. Back

titration procedure was carried out to manually determine the concentration of

NaOH in the reactor and extent of conversion.

ix) The experiment was repeated (step 5 to 9) for different residence times by

adjusting the feed flow rates of NaOH and Et (Ac) to about 0.15, 0.20, 0.25, 0.30

L/min. Both flow rates were make sure to be the same.

6.0 RESULT

Table 2 : Preparation calibration curve

Reactor volume : 40 L

Conc. of NaOH in feed vessel : 0.1 M

Conc. of Et(Ac) in feed vessel : 0.1 M

No Temperature

(C)

Flow rate

of NaOH

(mL/min)

Flow rate

of Et

(Ac)

(mL/min)

Total

flow rate

of

solutions,

F

0

(mL/min)

Residence

time,

(min)

Conductivity

(mS/cm)

Exit

concentration

of NaOH,

C

NaOH

(M)

Conversion,

X (%)

1. 27.0 100 100 200 200.00 3.30 0.002 96

2. 27.1 150 150 300 133.33 3.14 0.004 92

3. 27.3 200 200 400 100.00 3.00 0.005 90

4. 27.5 250 250 500 80.00 2.90 0.006 88

5. 27.7 300 300 600 66.67 2.78 0.008 84

Table 3 : Effect of residence time Continuous Stirred Tank Reactor

Conversion Solution

Mixtures

Concentration

of NaOH (M)

Conductivity

(mS/cm)

0.1 M

NaOH

0.1 M

Et(Ac)

H

2

O

0% 100 mL - 100 mL 0.0500 5.930

25% 75 mL 25 mL 100 mL 0.0375 2.160

50% 50 mL 50 mL 100 mL 0.0250 1.619

75% 25 mL 75 mL 100 mL 0.0125 0.757

100% - 100 mL 100 mL 0.0000 0.0900

Figure 9 : Calibration curve (Conversion vs. Conductivity)

Figure 10 : Graph of conversion against residence time

CALCULATION

NaOH + HCl NaCl + H

2

O

Sample calculations for flow rate = 0.10 L/min

Volume of sample, V

s

= 50 mL

Concentration of NaOH in the feed vessel, C

NaOH,f

= 0.1 M

Volume of HCl for quenching, V

HCl,s

= 10 mL

Concentration of HCl in standard solution, C

HCl,s

= 0.25 mol/L

Volume of NaOH titrated, V

1

= 24.0 mol/L

Concentration of NaOH used for titration, C

NaOH,s

= 0.1 mol/L

Concentration of NaOH entering the reactor, C

NaOH,0

= (1/2)(0.1)

= 0.05 mol/L

Volume of unreacted quenching HCl, V

2

= (C

NaOH,s

/C

HCl,s

) x V

1

= (0.1/0.25) x 24.0

= 9.6 mL

Volume of HCl reacted with NaOH in sample, V

3

= V

HCl,s

- V

2

= 10 9.6

= 0.4 mL

Moles of HCl reacted with NaOH in sample, n

1

= (C

HCl,s

x V

3

)/1000

= (0.25 x 0.4) / 1000

= 0.0001mol

Moles of unreacted NaOH in sample, n

2

= n

1

= 0.0001 mol

Concentration of unreacted NaOH in the reactor, C

NaOH

= n

2

/ V

s

x 1000

=

x 1000

= 0.002

Conversion of NaOH in the reactor, X = (1 -

) x 100%

= (1 -

) x 100%

= 92%

Residence time, = V

CSTR

/F

0

= 40 L/ (0.10 + 0.10) L/min

= 200 min

7.0 DISCUSSION

The experiment is conducted to determine the reaction rate and to determine the effect

of the residence time on the conversion in Plug Flow Reactor which related with it. The

CSTR model is used to predict the behaviour of chemical reactors, so that the key reactor

variables, which is the dimensions of the reactor, can be estimated.

The experiment is conducted by setting the flow rate of both solutions NaOH and

Et(Ac) into 0.10 L/min, 0.15 L/min, 0.20 L/min, 0.25 L/min and 0.30 L/min at each run of

experiment. From the experiment, the residence time is about to decrease when the flow rates

of the reactor become faster. Residence time is the removal time which is the average amount

of time that a particle spends in a particular system. Furthermore, residence time is measured

with the amount of substance which is present in the system.

When using the residence time equation, it is significant to made a variety of

assumptions. It is assumed that chemical degradation does not occur in the system in question

and that particles do not attach to surfaces that would hinder their flow. If chemical

degradation were to occur in a system, the substance that originally entered the system may

react with other existing compounds in the system, causing the residence time to be

significantly shorter since the substance would be chemically broken down and effectively be

removed from the system before it was able to naturally flow out of the system

Therefore, when the residence time decrease, it indicates that less molecules of

reactants are reacted with each other. Thus, the conversion of reactant into product is

decrease. From the result, it shows that when the flow rates was set into 0.30 L/min for both

reactants which is the highest flow rate in this experiment; the residence time of that reactants

in the CSTR is the shortest which is 66.67 min and give out the result for conversion of

84.0%.

Oppositely, when the flow rate for both reactants was set into 0.10 L/min which is the

lowest flow rate, the residence time of those reactants in the CSTR is the longest which is 200

min and the highest conversion of the reactants is 96.0 %. While for flow rates of 0.15 L/min,

0.20 L/min and 0.25L/min; the residence time are 133.33 min, 100.00 min and 80.00 min

respectively and the conversion of reactants are 92.0 %, 90.0 % and 88.0 % respectively.

8.0 CONCLUSION

The purpose of this experiment is to carry out saponification reaction between NaOH

and Et(Ac) in a CSTR which also required to determine the effect of residence time onto

the reaction extent of conversion and to determine the reaction rate constant. Continuous

stirred tank reactor is used in this experiment in order to achieve the purpose of this

experiment. After completing the experiment, we are able to collect the data and all the

purposes are achieved. From the results, it shows that each of the flow rates increase from

0.10 L/min to 0.30 L/min, the conversion of NaOH decrease from 96% to 84%. The

graph shows that conversion of NaOH versus residence time is plotted. It is directly

proportional. As the conversion decrease, the residence is decrease as well.

There are a few recommendations that can improve the experiment result. With these

recommendations, the result would be more better than before. This experiment is

considered succeed as all the purposes are achieved.

9.0 RECOMMENDATIONS

1. The device needs to be well maintenance in order to avoid it from malfunctioning

during the experiment period like the one we are having in our session.

2. To get a better result, only one person is needed to take care of the opening and

closing of the valve and other person take care of the pump. This is because some

valve needed to be opened or closed simultaneously.

3 Make sure the tank is filled with the correct solution and to the correct amount.

Different substance reacts differently and lack of substance can damage the apparatus.

4 Make sure general start-up procedure is done first in order to check the machine

functionality.

5 The burette should be rinsed with sodium hydroxide after rinsed using the distilled

water.

10.0 REFERENCES

Bibliography

A.James. 2014. [Online] 19 September, 2014. [Cited: 01 June, 2012.]

http://en.wikipedia.org/wiki/Saponification.

M.Rone. 1975. [Online] 18 July, 1975. [Cited: 7 May, 1975.]

http://www.sciencedirect.com/science/article/pii/0009250976850580.

Wojes, Rayan. 2014. A.Datum. [Online] 5 May, 2014. [Cited: 23 september, 2014.]

http://iitkgp.vlab.co.in/?sub=35&brch=107&sim=1175&cnt=1.

Вам также может понравиться

- CSTRДокумент19 страницCSTRAmir Al-AimanОценок пока нет

- Lab RPRT (CSTR)Документ21 страницаLab RPRT (CSTR)Black White80% (5)

- Lab CSTRДокумент24 страницыLab CSTRNurtasha Atikah50% (2)

- Experiment CSTR 40LДокумент18 страницExperiment CSTR 40LSaber Minato Azrul100% (2)

- Lab Report CSTR 40LДокумент26 страницLab Report CSTR 40LAnonymous NyvKBW33% (3)

- Continuous Stirred Tank Reactor (40 L)Документ16 страницContinuous Stirred Tank Reactor (40 L)Mohd Zhariff75% (4)

- CSTR 40LДокумент11 страницCSTR 40LSeiji Kyousei100% (1)

- Lab ManualДокумент24 страницыLab ManualAasia FarrukhОценок пока нет

- CSTR Lab Report .Документ18 страницCSTR Lab Report .Emily Swan50% (4)

- Batch ReactorДокумент4 страницыBatch ReactorFoo Xiao BingОценок пока нет

- CSTR in SeriesДокумент12 страницCSTR in Seriesmnizamarzuki0% (2)

- Continuous Stirred Tank Reactor (CSTR)Документ6 страницContinuous Stirred Tank Reactor (CSTR)Elaine PuiОценок пока нет

- CSTRДокумент25 страницCSTRAinul Mardhiah Abdul Rahim100% (1)

- Lab CSTR in SeriesДокумент13 страницLab CSTR in SeriesKhairul Zakirin78% (9)

- Batch Reactor (Saponification) ExptДокумент3 страницыBatch Reactor (Saponification) ExptVijay Prasad0% (1)

- Continuous Stirred Tank Reactor CSTR in Series PDFДокумент15 страницContinuous Stirred Tank Reactor CSTR in Series PDFMuhamad Hafifi AjwadОценок пока нет

- CSTR 40LДокумент17 страницCSTR 40LMuhammad Affifudin100% (1)

- Lab Report CSTR in SeriesДокумент13 страницLab Report CSTR in SeriesNisha Sharif100% (1)

- Batch Reactor ExpДокумент12 страницBatch Reactor ExpJack AndreasОценок пока нет

- CHE506 - Lab Report On Continuous Stirre PDFДокумент29 страницCHE506 - Lab Report On Continuous Stirre PDFMuhammad AimanОценок пока нет

- Abstract For CSTR Lab ReportДокумент4 страницыAbstract For CSTR Lab ReportNabilah SyaheeraОценок пока нет

- Saponification Reaction of Sodium Hydroxide An Ethyl Acetate in A Continuous Stirred Tank Reactor CSTRДокумент21 страницаSaponification Reaction of Sodium Hydroxide An Ethyl Acetate in A Continuous Stirred Tank Reactor CSTRsyedmuhammadtarique100% (1)

- Experiment 6Документ20 страницExperiment 6Saniha Aysha AjithОценок пока нет

- Lab Report Dist 1 Batch DistillationДокумент20 страницLab Report Dist 1 Batch Distillationcsgo accountОценок пока нет

- Results and Discussion of CSTR in SeriesДокумент3 страницыResults and Discussion of CSTR in SeriesleenzalalОценок пока нет

- Report CSTRДокумент14 страницReport CSTRniraj_bairagiОценок пока нет

- Lab 10-Batch ReactorДокумент22 страницыLab 10-Batch Reactorniraj_bairagiОценок пока нет

- Lab Report Batch Reactor GGДокумент25 страницLab Report Batch Reactor GGFrost Orchid100% (1)

- Continuous Stirred Tank ReactorДокумент11 страницContinuous Stirred Tank ReactorFikrie Muhd100% (1)

- L9-Tubular Flow ReactorДокумент20 страницL9-Tubular Flow ReactorCik Tiem Ngagiman82% (11)

- Lab Report 7Документ39 страницLab Report 7Fatinnnnnn100% (2)

- CHE516 - Lab Report On Plug Flow Reactor PDFДокумент25 страницCHE516 - Lab Report On Plug Flow Reactor PDFCesarah Cabungcal100% (1)

- CSTR Lab ReportДокумент16 страницCSTR Lab Reportleenzalal100% (5)

- CSTR ReportДокумент21 страницаCSTR ReportJonathon Douglas100% (1)

- Liquid Liquid ExtractionДокумент12 страницLiquid Liquid Extractionshohan100% (1)

- CKB 20104 Reaction Engineering UniKL MICET Experiment 3a: Effect of Residence Time On The Reaction in A PFR Full Lab ReportДокумент20 страницCKB 20104 Reaction Engineering UniKL MICET Experiment 3a: Effect of Residence Time On The Reaction in A PFR Full Lab ReportSiti Hajar MohamedОценок пока нет

- Lab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFДокумент7 страницLab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFJaymacОценок пока нет

- LAB REPORT-Gas AbsorptionДокумент16 страницLAB REPORT-Gas Absorptionmizizasbonkure90100% (1)

- CSTR Lab ReportДокумент14 страницCSTR Lab ReportAmy Farhana33% (3)

- Liquid Diffusion CoefficientДокумент7 страницLiquid Diffusion CoefficientFoo He Xuan67% (3)

- Chemical Engineering Laboratory Ii: /DT Term Is Zero SinceДокумент9 страницChemical Engineering Laboratory Ii: /DT Term Is Zero SinceKayathre Raveendran100% (1)

- Introduction For Batch Reactor ExperimentДокумент5 страницIntroduction For Batch Reactor ExperimentSaints Burner Christopher25% (4)

- Exp. 8 Diffusion of Sodium Chloride in WaterДокумент6 страницExp. 8 Diffusion of Sodium Chloride in WaterElaine Pui33% (3)

- Report Distillation ColumnДокумент20 страницReport Distillation ColumnAzam Najmi33% (3)

- Tubular Flow Reactor ReportДокумент19 страницTubular Flow Reactor ReportN Afiqah Razak100% (1)

- PFR Lab ReportДокумент21 страницаPFR Lab ReportValentinoDullSatin100% (1)

- Stirred Tank Reactors in SeriesДокумент25 страницStirred Tank Reactors in SeriesChristopher Emeka Ominyi100% (1)

- Lab6-Tubular Flow ReactorДокумент11 страницLab6-Tubular Flow ReactorNurtasha Atikah100% (1)

- Experiment 6 CSTRДокумент9 страницExperiment 6 CSTRRicky JayОценок пока нет

- CHE504 - Lab Report On Distillation ColuДокумент27 страницCHE504 - Lab Report On Distillation ColuMuhammad Irfan MalikОценок пока нет

- Reaction Rate and Rate Constant of The Hydrolysis of Ethyl Acetate With Sodium HydroxideДокумент5 страницReaction Rate and Rate Constant of The Hydrolysis of Ethyl Acetate With Sodium HydroxideAmyОценок пока нет

- Plug FlowДокумент17 страницPlug FlowNurshahirahSapianОценок пока нет

- Effect of Temperature On Batch Saponification ReactionДокумент14 страницEffect of Temperature On Batch Saponification ReactionSyafiqah Yahya100% (5)

- Batch Reactor PDFДокумент29 страницBatch Reactor PDFSaranya KannanОценок пока нет

- Reaction Lab Exp#1Документ13 страницReaction Lab Exp#1Muataman KhОценок пока нет

- Group 4 - Report Experiment 2Документ26 страницGroup 4 - Report Experiment 2Farzanah AgeОценок пока нет

- Module 04 Continuous Stirred Tank Reactor (CSTR)Документ6 страницModule 04 Continuous Stirred Tank Reactor (CSTR)Farah -HОценок пока нет

- Stirred Tank in Series ReportДокумент20 страницStirred Tank in Series ReportEmonbeifo EfosasereОценок пока нет

- Stirred Tank in Series ReportДокумент20 страницStirred Tank in Series ReportEmonbeifo EfosasereОценок пока нет

- CSTR 40 LДокумент28 страницCSTR 40 LCik Tiem Ngagiman50% (2)

- Science 7 Q1 Week 6Документ15 страницScience 7 Q1 Week 6JOHN MAYKALE FARRALESОценок пока нет

- Scientific Notation Unit TestДокумент3 страницыScientific Notation Unit TestMohamed AbdisamedОценок пока нет

- Resume BLK PDFДокумент3 страницыResume BLK PDFTonyОценок пока нет

- Estimations in Numbers and Measurement: Multiple-Choice QuestionsДокумент5 страницEstimations in Numbers and Measurement: Multiple-Choice QuestionsJason Lam LamОценок пока нет

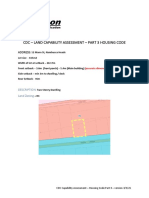

- CDC - Land Capability Assessment - Part 3 Housing Code: AddressДокумент5 страницCDC - Land Capability Assessment - Part 3 Housing Code: AddressDanny NguyenОценок пока нет

- Final Fantasy IvaliceДокумент156 страницFinal Fantasy IvaliceLuca De LongisОценок пока нет

- Day 02 ESP Basic Design and Operational FactorsДокумент113 страницDay 02 ESP Basic Design and Operational FactorsMustafa Abdel-WahabОценок пока нет

- 11 Simple Part D Vol 2 EM PDFДокумент19 страниц11 Simple Part D Vol 2 EM PDFNaveen 18Оценок пока нет

- The Correlation of Social Anxiety Towards The Behaviour of Grade 12 Students in SJDM Cornerstone College Inc.Документ47 страницThe Correlation of Social Anxiety Towards The Behaviour of Grade 12 Students in SJDM Cornerstone College Inc.Mark The PainterОценок пока нет

- Introduction Computational Ingineering MatlabДокумент439 страницIntroduction Computational Ingineering MatlabJose CapablancaОценок пока нет

- Nygård 2019Документ9 страницNygård 2019Wágner B SilvaОценок пока нет

- OSH Quiz Tutorial Openbook TestДокумент12 страницOSH Quiz Tutorial Openbook TestFunny tinny08Оценок пока нет

- Sociology As A Branch of KnowledgeДокумент19 страницSociology As A Branch of KnowledgeRaju AhmmedОценок пока нет

- Liquefaction Potential Based On Swedish Weight Sounding Test in Langaleso Village Sigy RegencyДокумент8 страницLiquefaction Potential Based On Swedish Weight Sounding Test in Langaleso Village Sigy RegencyInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- 0 BibliografíaДокумент3 страницы0 BibliografíaDaniel Espinosa RodriguezОценок пока нет

- I. Desired Learning Outcomes: Laboratory Activity 9 Test For ProteinsДокумент3 страницыI. Desired Learning Outcomes: Laboratory Activity 9 Test For ProteinsErika Joille PatayonОценок пока нет

- Faculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreДокумент21 страницаFaculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreNatasha YusofОценок пока нет

- Cholinoceptor AntagonistДокумент21 страницаCholinoceptor Antagonistraafat mohammedОценок пока нет

- Morph Elegant Powerpoint TemplateДокумент6 страницMorph Elegant Powerpoint TemplateAl FaritsiОценок пока нет

- A Detailed Lesson Plan in Science 6 DateДокумент6 страницA Detailed Lesson Plan in Science 6 DateRhoma P. TadejaОценок пока нет

- Real Analysis: Jos e Mar Ia CuetoДокумент14 страницReal Analysis: Jos e Mar Ia CuetoFor ThingsОценок пока нет

- Quarter 3 - Module 1 Writing and Composition: Department of Education Republic of The PhilippinesДокумент28 страницQuarter 3 - Module 1 Writing and Composition: Department of Education Republic of The PhilippinesEditha FernandezОценок пока нет

- Markov Clustering AlgorithmДокумент53 страницыMarkov Clustering AlgorithmAaryan GuptaОценок пока нет

- Civil Engineering Laws and Ethics in The PhilippinesДокумент16 страницCivil Engineering Laws and Ethics in The PhilippinesMonde Nuylan90% (48)

- CAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanДокумент7 страницCAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanShai Ra CapillanОценок пока нет

- Types of Academic Text: 1. Understanding The Importance of GenreДокумент9 страницTypes of Academic Text: 1. Understanding The Importance of GenreThelma LanadoОценок пока нет

- Jmse 10 01965 v3Документ26 страницJmse 10 01965 v3waa123sОценок пока нет

- Essentialism vs. Social Constructionism in The Study of Human Sexuality (1998) - DeLamater & Hyde PDFДокумент10 страницEssentialism vs. Social Constructionism in The Study of Human Sexuality (1998) - DeLamater & Hyde PDFKhoa LeОценок пока нет

- Science-9 q4 Mod5 Heat and WorkДокумент20 страницScience-9 q4 Mod5 Heat and WorkEden Cabarrubias86% (7)

- Industrial Accidents in Cement Industries of Nepal: Submitted ToДокумент58 страницIndustrial Accidents in Cement Industries of Nepal: Submitted ToSushma Karn100% (1)