Академический Документы

Профессиональный Документы

Культура Документы

EC 135 Training Manual

Загружено:

robbertmdАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EC 135 Training Manual

Загружено:

robbertmdАвторское право:

Доступные форматы

EC 135

Training Manual

Intro

Intro 1

July 2002 For training and information only

EC 135 -- Training Manual

EUROCOPTER DEUTSCHLAND GmbH

Helicopter Training Center

P.O. Box 1353

D--86603 Donauwrth

Phone: (0049) 906 71--4481

Fax: (0049) 90671--4499

EC 135

Training Manual

Intro

Intro 2

July 2002 For training and information only

Foreword

Welcome to the EUROCOPTEREC135 Training Course. This course

was designed to instruct pilots and maintenance personnel on the

EC 135 helicopter.

The training manual is comprised of 9 modules and takes into

consideration, to a certain extent, ATA 104 specifications. It correlates

to the sequence of the factory training you will receive.

Annotation to the Training Manual

This training manual is not a subject for revision service. It is the

manufacturers practice to improve continously its products and

therefore the right is reserved to make without notice alterations in

design or manufacture which may deemed necessary.

All rights reserved.

Reproduction or translation in whole or in part of the contents of this

publication without permission of EUROCOPTER is not authorized.

1. edition December 2000

1. revision June 2002

2. revision July 2002

Modules

00 General Information

01 Lifting System

02 Fuselage

03 Tail Unit

04 Flight Control

05 Landing Gear

06 Power Plant

07 Standard Equipment (not applicable for this

manual)

08 Optional Equipment (not applicable for this

manual)

09 Electrical System

10 Inspections

EC 135

Training Manual

Intro

Intro 3

July 2002 For training and information only

Abbreviations

A

A Ampere

a/c, acft Aircraft

AC Alternating current

AEO All Engines Operative

Ah Ampere hours

AR Auto

ARIS Anti resonance rotor isolation system

ATA Air Line Transport Association

B

B.A. Bleed air

BAT Battery

BIT Built in test

B.L. Buttock line

C

CAD Caution and advisory display

CAS Calibrated airspeed

Cat. Category

CCW Counter clock wise

CDS Cockpit Display System

CG Center of gravity

CPDS Central panel display system

CSAS Control stability augmention system

CT Continuous test

CTR Center

CW Clockwise

D

DC Direct current

DCU Data control unit

DG Directional Gyro

DISCH Discharge

E

EEC Electronic engine control (P&W)

EECU Electronic engine control unit (TM)

EFIS Electronic flight instrument system

e.g. For example

EGT Exchaust gas temperature

EHA Electronic hydraulic actuator

EC 135

Training Manual

Intro

Intro 4

July 2002 For training and information only

EMER Emergency

ENG Engine

EPU External power unit

EXT External; extinguisher

F

FADEC Full Authority Digital Engine Control

FCDM Flight control display module

FCDS Flight control display system

Fh Flight hours

FLIR Forward looking infra red

FLI First limit indication

FLI Flight manual

FMM Fuel metering module

FMS Flight manual supplement

FMU Fuel metering unit

FRP Fibre reinforced plastic

F.S. Fuselage station

ft Foot (feet)

G

GA Go around

GAL; gal Gallon

GEN Generator

GRP Glassfibre reinforced plastic

GS, gs Ground Speed

GSE Ground service equipment

H

h; hr Hours of time

hPa Hectopascal

HTG Heating

HTR sw Heater switch

HUMS Health and Usage Monitoring System

HV Height velocity

HY, HYD, HYDR Hydraulic

I

IAC--AR Interstate Aviation Commitee

--Aviation Register

IAS Indicated airspeed

IC Intercommunication

ICP Instrument control panel

ICS Intercommunication system

i.e. That is (id est)

IFR Instrument flight rules

IFCO In Flight Change Over

EC 135

Training Manual

Intro

Intro 5

July 2002 For training and information only

IGE In ground effect

IMC Instrumental meteorolocical conditions

Imp. Imperial

in. Inch

IND Indicator

INV Inverter

ISA International Standard Atmosphere

J

JAR Joint Airworthiness Requirements

K

KCAS Knots calibrated airspeed

kg Kilogram

KIAS Knots indicated airspeed

km Kilometer

kt Knot

KTAS Knots true airspeed

kW Kilowatt

L

L, l, LTR, ltr Liter

lb Pound

LBA Luftfahrt Bundesamt

LDG Landing

LDP Landing decicion point

LEP List of effective pages

LH Left hand

LOAP List of applicable publications

LRM Line replaceable module

LRU Line replaceable unit

LVDT Linear voltage differential transducer

M

m Meter

MAN Manual mode of operation

max Maximum

MC, mc Maximum continuous

MCP Maximum continuous power

MEL Minimum equipment list

MFD Multi function display

MGT Measured gas temperature

MHS Mechano--hydraulic servo actuator

MIL Military standard, military specification

min. Minimum

MISC Miscellaneous

MM Mast moment

EC 135

Training Manual

Intro

Intro 6

July 2002 For training and information only

mm Millimeter

MMC Metal matrix compose

MMEL Master minimum equipment list

MOD Modification

MSL Mean sea level

MTBF Mean time between failure

MTOW Maximum take-off weight

N

NACA

N

1

, n

1

, Ng, ng Gas generator speed

N

2

, n

2

, Np, np Power turbine speed

NAV Navigation (radio)

ND Navigation display

NMS Navigation management system

No., no. Number

NORM Normal mode of operation

NR, N

RO

Rotor speed

NVG Night vision goggles

O

OAT Outside air temperature

OEI One engine inoperative

OGE Out of ground effect

OPT Optional equipment

OVHT Overheat

P

PA Pascal

PA Pressure altitude

PAX Passanger

pb Push button

PEC Position error correction

PFD Primary flight display

PLA Power lever angle

P/N Part number

POR Point of regulation

R

RA Radio altimeter

RAI Registro Aeronautico Italiano

R/C Rate of climb

RCU Reconfiguration control unit

R/D Rate of decent

RD Reference datum

Rev. Revision

EC 135

Training Manual

Intro

Intro 7

July 2002 For training and information only

RH Right hand

RPM, rpm Revolutions per minute

S

s, sec. Seconds of time

SAR Search and rescue

SAS Stability augmention system

SB Service bulletin

SEL Selector

SEMA Smart electro-mecanical actuator

SGL Single

SHED Shedding

SHP Shaft horse power

SL Sea level

SMD Smart multifunction display

S/N Serial number

SOV Shut-off valve

SPAS Stick position augmention system

SPIFR Single pilot IFR

sq Square

SRU Shop repalcement unit

STA. Station

STBY Stand-by

std Standard

SW, sw Switch

SYS System

V

V

H

Maximum horizontal speed

VHF Very high frequency

VMC Visual meteorolocical conditions

VMO, V

MO

Maximum operating speed

VNE, V

NE

Never exceed speed

VOR VHF omnidirectional radio ranging

VRM Video and radar module

V

TOSS

Take-of safety speed

V

Y

Best rate-of -climb speed

W

W.L. Waterline

WXR Weather radar

X

XMSN Transmission

XPDR/XTR Transponder

EC 135

Training Manual

General

00 -- 1

July 2002 For training and information only

General Description

EC 135

Training Manual

General

00 -- 2

July 2002 For training and information only

Table of Contents

The Development of the EC 135 4 . . . . . . . . . . . . . . . . . . . . . . . . .

General Description of the EC 135 6 . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Concept 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

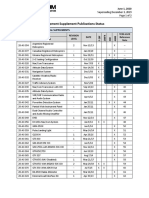

Documentation of the EC 135 12 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Planes 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cockpit Arrangement 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel with CPDS 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel with CDS 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triple Rotor RPM Indication 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Indicator 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dual TOT Indicator 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dual nN

1

Indicator T1 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dual N

1

Indicator P1 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Temperature and Pressure Indicator 30 . . . . . . . . . . . . . . . . .

Cockpit Display System (CDS) 32 . . . . . . . . . . . . . . . . . . . . . . . . . .

CDS Operation 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDS Caution Display 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDS Advisory Display 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Select Switch / Scroll Button 40 . . . . . . . . . . . . . . . . . . . .

Torque Indication 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Power Indication 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outside Air Indication 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mast Moment Indication 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Quantity Indication 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Central Panel Display System (CPDS) 46 . . . . . . . . . . . . . . . . . . .

Function of the CPDS 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPDS Modes 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAUTION / FUEL -- Page 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Limit Page (FLI) P1/T1 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Limit Page (FLI) P2/T2 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page for Electrical and Engine Parameters (ELEC/VEH) 70 . .

FLIGHT REPORT Page 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM STATUS Page 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAUTION/BACKUP Page 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAUTION/FUEL FAIL Page 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPDS Switch Over Functions 84 . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Mode 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Derivative Mode with one VEMD Line off 86 . . . . . . . . . . . . . . . .

Derivative Mode with CAD off 88 . . . . . . . . . . . . . . . . . . . . . . . . . .

Derivative Mode with CAD and one VEMD Lane off 90 . . . . . . .

Derivative Mode with both VEMD Lines off 92 . . . . . . . . . . . . . . .

Maintenance Menu 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flight Report 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overlimit 98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Data 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Times 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Loading 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/C CONFIG Page 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPDS Software Versions Overview 108 . . . . . . . . . . . . . . . . . . . . .

H/C Serial Number Changes Overview 109 . . . . . . . . . . . . . . . . . .

Warning Unit 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Unit 116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overhead Console 118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pitot--Static System 122 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EC 135

Training Manual

General

00 -- 3

July 2002 For training and information only

Handling of the EC 135 124 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting 124 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jacking of the EC 135 126 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shoring 126 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weighing 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leveling 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Towing and Pushing 132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parking and Mooring 134 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EC 135

Training Manual

General

00 -- 4

July 2002 For training and information only

The Development of the EC 135

History

The first EUROCOPTER (ex. MBB, ex. BLKOW) helicopter with

glass fiber rotor blades was the single blade helicopter BO 102, a

captive trainer, operating for the first time in 1957. In 1961 the single

seater BO103 followed, the only helicopter to fly with one rotor blade.

In 1962/63, a new hingeless rotor system was created, and

successfully tried on an Alouette II, in Marignane, France.

From 1960 to 64 the high speed helicopter BO 46 was designed with

the Derschmitt rotor system.

In 1964 these helicopters were followed by the multi purpose 2 1/2 ton

twin engine helicopter BO 105.

TosubstitutetheBO105 after 20 years in duty, the BO108 was created

and flown on Okt. 15th, 1988 for the first time. Consultations with

potential customers -- operators of EUROCOPTER products and of

competing types -- showed that cabin volume should be increased and

visibility improved and that greater emphasis would have to be put on

mission flexibility (the cabin floor, for instance should be flat and

unobstructed to allow easy conversion from passengers to cargo

roles). In late 1992, the design was modified to provide

accommodation for max. six passengers, instead of the BO 108s

three, and two crew. The Aerospatiale developed Fenestron Anti

Torque systemwas adapted, and the EC135 as it is today took shape.

In the middle of 1996, the certification by the German (LBA) and the

American Airworthiness Authorities (FAA) was completed.

Engine Versions

The following engine versions are possible:

-- EC 135 P1

equipped with Pratt & Whitney PW 206 B engines.

-- EC 135 P2

equipped with Pratt & Whitney PW 206 B2 engines.

-- EC135 T1

equipped with Turbomeca ARRIUS 2B1, 2B1A, 2B1A_1

-- EC135 T2

equipped with Turbomeca ARRIUS 2B2 engines.

Both engine types are in the 450 KW class. The maximum take-off

weight for both standard versions is 2720 kg (upgrade to 2835 kg

MTOW is possible), with external load 2900 kg.

Cockpit Versions

Two major cockpit versions are possible:

-- CPDS (Central Panel Display System with multifunction

screens) together with analog flight instruments. As an

option, the CPDS can be combined with FCDS (Flight

Control Display System).

-- CDS (Cockpit Display System) with analog flight

instruments or EFIS (Electronic Flight Instrumentation

System)

u NOTE CDS Standard cockpit has been replaced by CPDS

cockpit.

EC 135

Training Manual

General

00 -- 5

July 2002 For training and information only

EC 135 Variants

EC135 P1

Pratt&Whitney Engine

206 B

EC135 T1

TURBOMECA Engine

ARRIUS 2B1, 2B1A, 2B1A_1

CDS CPDS CPDS+FCDS CDS CPDS CPDS+FCDS

EC135 T2

TURBOMECA Engine

ARRIUS 2B2

CPDS CPDS+FCDS

EC135 P2

Pratt&Whitney Engine

206 B2

CPDS+FCDS CPDS

Analog

Instruments

EFIS Analog

Instruments

EFIS

EC 135

Training Manual

General

00 -- 6

July 2002 For training and information only

General Description of the EC 135

General

The EC 135 is a light multi purpose twin engine helicopter in the 2.5t

class. There are five seats in the basic version, they can be extended

up to eight seats.

Engines

The EC135 T is powered by two engines Turbomeca ARRIUS 2B, the

EC135 P is powered by two engines Pratt & Whittney PW206 B. They

are equipped with a digital engine control system.

Transmission

The main transmission is a two-stage flat gearbox (produced by

Zahnradfabrik Friedrichshafen ZF), which is mounted by an

anti-resonance rotor isolation system (ARIS) on the transmission

deck.

Main Rotor

The helicopter is equipped with a four-bladed hingeless and

bearingless main rotor (BMR). The inboard flexbeam enables

movement of the blades in all axes. Blade pitch angles are controlled

through integrated glass/carbon fibre control cuffs.

The main rotor control linkage system is of conventional design. The

hydraulic system for the main rotor controls is designed as a duplex

system with tandem piston (both systems are active). In case of a

failure of one system, the remaining system has sufficient power to

ensure safe flight operation and a safe landing.

Tail Rotor System

The helicopter is equipped with a Fenestron tailrotor system. There

are 10 blades rotating in a housing integrated in the tail boom.

The Fenestron is controlled via a Flexball type cable, routed fromthe

pedals to the input control rod of the Fenestron.

Tail Boom

The tail boomcan be separated fromthe fuselage, and consists of tail

boom cone, the horizontal tail plane with end-plates, vertical fin with

integrated tail rotor, tail rotor gearbox and fairing.

EC 135

Training Manual

General

00 -- 7

July 2002 For training and information only

Dimensions

10.20m

12.16m

10.20m

5.87m

3.51m

2.65m

3.20m

3.35m

2.00m 1.56m

5

0.66m

3

EC 135

Training Manual

General

00 -- 8

July 2002 For training and information only

Fuselage

The primary structure consists mainly of sheet metal design. Cabin

frame, bottomshell, doors, engine cowling, nose access panel and the

entire tail boom are made of composite material.

The cabin is accessible through six doors: two hinged doors for the

front occupants, two sliding doors for the rear passengers, and two aft

clamshell doors for the rear compartment.

Fuel System

The fuel system comprises of two fuel tanks, a fuel supply system, a

refueling and grounding equipment and a monitoring system. The

main tank and the separated supply tank with overflowtothe maintank

are installed under the cabin floor.

Electrical System

The fully redundant electrical 28 V DC system is supplied by two

generators and the battery.

Landing Gear

The EC 135 has two cross tubes and two skids. The crosstubes are

constructed to be bent to absorb forces during touch down of the

helicopter.

Dimensions

Figure 2 and 3 shows the principal dimensions of the EC 135.

EC 135

Training Manual

General

00 -- 9

July 2002 For training and information only

Cabin Dimensions

4.11 m

2.32 m

0.97 m 1.79 m 1.22 m

1.50 m

1.05 m 0.74 m

0

.

8

9

m

1

.

2

3

m

1

.

1

5

m

1

.

2

6

m

EC 135

Training Manual

General

00 -- 10

July 2002 For training and information only

Maintenance Concept

General

Maintenance covers all scheduled and unscheduled maintenance

activities. It also applies to the on condition maintenance. It is based

on condition monitoring by visual checks/inspections and diagnostic

features such as chip detectors, filter bypass indicators, boroscope

access, failure code indications, built-in tests, warning lights etc.

Maintenance Levels

EC 135 maintenance is split into three maintenance levels:

-- Organizational Level (O)

-- Intermediate Level (I)

-- Depot Level (D)

Organizational Level

The organizational level covers tasks of the daily servicing,

maintenance checks, inspections for condition, exchange of

components (LRUs) and quick, simple repairs as specified in the

aircraft maintenance manual (AMM).

The work generally takes place at the operators site. After a on the job

training these checks can be carried out by pilots, mechanics and

operators.

Intermediate Level

The intermediate level covers repairs on/off helicopter, extended

periodical inspections as specified in the aircraft maintenance manual.

To fulfill these tasks, maintenance facility, qualified personel, test

equipment and special tools are required.

u NOTE The maintenance manual covers all tasks of

organizational level and intermediate level.

Depot Level (D)

Depot level covers major repair or overhaul at the manufacturer or at

authorized service stations under industrial premises.

More extensive tools/test equipment and specialized personnel are

necessary.

u NOTE Documentation and spares for depot level tasks

will be delivered to authorized customers only.

u NOTE Information about inspections and intervals are to

be found in chapter 10 of this training manual.

EC 135

Training Manual

General

00 -- 11

July 2002 For training and information only

Maintenance Concept

Maintenance

Scheduled

Unscheduled

On Condition

Organizational

Level (O)

Intermediate

Level (I)

Depot Level (D)

Daily servicing, maintenance checks

inspections for condition, exchange of LRUs. acc. to AMM -- Can be carried

out by a mechanic or by the pilot (i.e. main transmission servicing).

Repair on/off the helicopter extended

periodical inspections acc. to AMM -- maintenance facility, qualified personnel,

test equipment and special tools are required (i.e. main transmission change).

Major repair or overhaul at the manufacturer or at authorized service stations

acc. to special documentation. Tools/test equipment and specialized personnel

are neccessary (i.e. main transmission overhaul).

Manufacturer/authorized customers only

EC 135

Training Manual

General

00 -- 12

July 2002 For training and information only

Documentation of the EC 135

General

The documentation of the EC 135 consists of two main groups:

-- EC 135 helicopter documentation written by

EUROCOPTER

-- Other manufacturers documentations

Layout

The whole documentation library is prepared in general compliance

with Air Transport Association Specification 100 and ATA 2100. The

customized documentation is available for certain H/C serial numbers

or a group of H/C serial numbers. A part of the documentation library

is delivered on CD ROM.

Revision Reissue

Changes in the helicopter equipment, maintenance practices,

procedures etc. update and replace the manual content. To ensure

that the EC135 manuals continue to showthe latest information, twice

a year the CDROMis replaced by a reissue. The preceding issue then

becomes obsolete and must be discarded.

ATA Numbering

The numbering systemprovides a procedure for dividing material into

chapter section subject and page. The number is composed of three

elements, which have two numbers each. The chapter and section

element are established by ATA 2100. Subject and unit element

numbers are assigned by ECD.

Page Number Blocks

Page number blocks are used for the different sections of the

maintenance manual to logically place the activities in sequence as

follows: Procedures have either a brief subtopic or a combination of

subtopics i.e. Removal/Installation, Inspection/Test. If subtopics are

brief, then they are combined in one topic under Maintenance

Practices. If the subtopics become lengthy so that a combination

would require numerous pages, the topics are broken out into page

number blocks.

-- Pageblock 1--99 System Description

-- Pageblock 101--199 Troubleshooting

-- Pageblock 201--299 Maintenance Procedures

-- Pageblock 301--399 Servicing

-- Pageblock 401--499 Removal/Installation

-- Pageblock 501--599 Adjustment/Test

-- Pageblock 601--699 Inspection

-- Pageblock 701--799 Cleaning/Painting

-- Pageblock 801--899 Repair

-- Pageblock 901--999 Storage

u NOTE Element 1, element 2 and the pageblocks are set

by the ATA 2100 schematic. The following

elements can be defined by the aircraft

manufacturer as required.

EC 135

Training Manual

General

00 -- 13

July 2002 For training and information only

ATA Numbering

28 -- 10 -- 00

Chapter Section Subject/Unit

1. Element 2. Element 3. Element

EC 135

Training Manual

General

00 -- 14

July 2002 For training and information only

Mechanics Documentation

The mechanic has available (CD or hardcopy):

-- Systems Description Section (SDS)

-- Aircraft Maintenance Manual (AMM)

-- Master Servicing Manual (MSM)

-- Wiring Diagram Manual (WDM)

-- Illustrated Parts Catalog inclusive Tools Catalog (IPC)

Pilots Documentation

The pilot has four documents available (hardcopy):

-- The Flight Manual (FLM) according Helicopter Association

International, HAI

-- Log Book

-- Pilots Checklist (PCL)

-- Master Minimum Equipment List (MMEL)

u NOTE The Flight Manual, the Pilots Checklist and the

Log Book are hardcopies and must always be

present in the helicopter.

Operators Technical Control Documentation

The following documents are kept by the operators technical control:

-- Historical Record

-- LOAP (List of applicable publications, hardcopy)

-- Service Bulletins / Alert Bulletins, (hardcopy)

-- Service Informations / Alert Service Informations,

(hardcopy)

Other Manufacturers Documentation

The other manufacturers (engines, Avionics and optional equipment)

deliver their own documentation:

-- Engine Maintenance Manual

-- Engine Illustrated Parts Catalog

-- Engine Service Bulletins / Service Letters

-- Avionics Manuals

-- Special optional equipment (e.g. external hoist system)

u NOTE The valid manuals incl. the revision status are

published in the LOAP (list of applicable

publications).

EC 135

Training Manual

General

00 -- 15

July 2002 For training and information only

FLM

T1, CDS/CPDS

T2 CPDS

P1, CDS/CPDS

P2 CPDS

Log Book

MMEL

SDS

WDM

IPC + Tools

AMM

Historical

Record

SB/ASB

SI/ASI

LOAP

ECD Helicopter Documentation EC 135

Mechanic

Pilot

Operator

CD--ROM

PCL

T1, CDS/CPDS

T2 CPDS

P1, CDS/CPDS

P2 CPDS

MSM

EC 135

Training Manual

General

00 -- 16

July 2002 For training and information only

Reference Planes

General

The frame coordinates of the EC 135 are defined in accorance with

LN 65619 (Luftfahrtnorm). All dimensions are given in the metric

system (mm).

The reference planes are used to determine locations on and within

the helicopter.

Definitions

Locations on and within the helicopter can be determined in relation

to fuselage stations, buttock lines and waterlines, measured in

millimeters (mm) from known reference points. Fuselage stations,

buttock lines, and waterlines are planes perpendicular to each other.

Reference plane is the plane at the longitudinal centerline of the

helicopter perpendicular to the cabin floor.

Fuselage Stations

Fuselage stations (FS) are vertical planes perpendicular to, and

measured along, the longitudinal axis of the helicopter.

Station 0 is an imaginary vertical plane forward of the nose of the

helicopter, from which all horizontal distances are measured for

balance purposes (see also reference datum).

Buttock Lines (+/-- Y Coordinates, Lateral)

Buttock lines (BL) are vertical planes perpendicular to, and measured

to the left and right along the lateral axis of the helicopter.

Buttock line (0) is the plane at the longitudinal centerline of the

helicopter.

Waterline (+ Z Coordinates, Vertical)

Waterlines (WL) are horizontal planes perpendicular to, andmeasured

along, the vertical axis of the helicopter.

Waterplane (0) is a plane 1505 mm below the cabin floor at fuselage

station 2160 mm.

Reference Datum (+ X Coordinates Longitudinal)

The reference datum (RD) is an imaginary vertical plane foreward of

the helicopter nose. The station is located is located 4000 mm in front

of the leveling point (center of double frame #4).

u NOTE The standard helicopter is well clear to the

reference planes in order to avoid negative

coordinates (X; Z) after exterior optional equipment

is mounted.

EC 135

Training Manual

General

00 -- 17

July 2002 For training and information only

Reference Planes

X 1099.32

Z 1505

X 4000

X 2160

Y+

Y--

Z

X

EC 135

Training Manual

General

00 -- 18

July 2002 For training and information only

Cockpit Arrangement

General

The EC 135 is provided with several units for monitoring, warning and

control purposes. These units are installed to certain control panels.

Control Panels

The control panels installed in the EC 135 are subdivided into:

-- Overhead Panel

-- Instrument Panel

-- Slanted Console

-- Center Console

EC 135

Training Manual

General

00 -- 19

July 2002 For training and information only

ND PFD NAV SOURCE EXT

DH

CRS

TST

BARO

POS

STD ND PFD NAV SOURCE EXT

DH

CRS

TST

BARO

POS

STD

Overhead Panel

Cockpit Arrangement (CPDS; FCDS)

Instrument Panel

Slant Console

Center Console

Center Post

Cyclic Stick

Collective Pitch

EC 135

Training Manual

General

00 -- 20

July 2002 For training and information only

Instrument Panel with CPDS

General

The instrument panel contains most of the displays and instruments

and some of the control units installed in the helicopter. The

configuration of the instrument panel varies according to operators

needs and the associated equipment.

System Components

The instrument panel consists of:

-- Center Console

-- RH section

-- LH section

Center Console

The center console of the instrument panel contains the CDS (Cockpit

Display System) in earlier versions or the CPDS(Central Panel Display

System) with analog back up instruments and the warning unit to

display system/engine conditions. A chronograph is also included. A

number of switches for engine and electrical system operation are

located on the center console, too.

RH Section

The RH section of the instrument panel contains the

instruments/displays for flight control and navigation. A number of

switches may be provided for controlling the radio/navigation system.

A nozzle is provided for regulating fresh air supply.

LH Section

The LHsection of the instrument panel is specified for the copilot. The

configuration of the LH section varies according to helicopter

equipment.

EC 135

Training Manual

General

00 -- 21

July 2002 For training and information only

Instrument Panel (CPDS, Analog Flight Instruments)

c

Switch Unit

Antiglare Device

Warning Unit

VEMD

LHSECTION

CENTERSECTION RH SECTION

CAD

Nozzle

Altitude Indicator

Vertical Speed

Indicator

Airspeed Indicator

Analog Clock

D-- HUMS

Triple Speed Indication

N

2

/N

RO

Artificial Horizon

HSI

EC 135

Training Manual

General

00 -- 22

July 2002 For training and information only

INTENTIONALLY LEFT BLANK

EC 135

Training Manual

General

00 -- 23

July 2002 For training and information only

ND

PFD NAV

SOURCE EXT

DH

CRS

T

S

T

BARO

POS

S

T

D

Instrument Panel (CPDS, FCDS)

Switch Unit

Antiglare Device Warning Unit

LHSECTION

CENTERSECTION RH SECTION

CPDS

Navigation Display

Nozzle

Analog Instruments

Primary Flight Display

ND

PFD NAV

SOURCE EXT

DH

CRS

T

S

T

BARO

POS

S

T

D

EC 135

Training Manual

General

00 -- 24

July 2002 For training and information only

Instrument Panel with CDS

General

All the instruments and indications to monitor the helicopter systems

are installed in the center section of the instrument panel.

Configuration

-- The following instruments, indicators and switches are

installed in the center section of the instrument panel:

-- Warning unit

-- Triple rotor RPM indicator (incl. N

2

indication for eng. 1/2)

-- Torque indicator

-- Dual TOT indicator

-- Dual nN

1

indicator (T1 engine only)

-- Dual N

1

indicator (P1 engine only)

-- Chronograph

-- Switch unit

-- Oil temperature and pressure indicator for engines and

main transmission (Different limit markers with the different

engines)

-- Cockpit Display System (CDS)

EC 135

Training Manual

General

00 -- 25

July 2002 For training and information only

Instrument Panel (CDS, P1, EFIS Cockpit)

SCROLL

DISPLAY

SELECT

SYSTEM II

MM

XFER LOW FREE LOW

BAT AMPS

GEN AMPS

DC VOLTS

LMT

SYSTEM I

PAGE

CAUTION

PAGE

VOLT

AMP

F

U

E

L

HOOK LOAD

Vne GROSS MASS

CDS

FAIL

BRIGHTNESS WEIGHT

(Vne)

2

OPT

1

P

F

M

T

CABLE

LENGTH

RAD ALT

LB KG LB KG

AUX SPLY 2

LB KG LB KG

MAIN SPLY 1

OAT

TQ

SYSTEM I MISC SYSTEM II

MASTER

CAUTION

c

Switch Unit

Antiglare Device

Warning Unit

Analog Instruments:

System/Engine

LHSECTION

CENTERSECTION RH SECTION

CDS

Switches

Nozzle

Altitude Indicator

Vertical Speed

Indicator

Airspeed Indicator

EFIS

PITCH

DAMPER

Oil Temperature/Pressure Indicators

EC 135

Training Manual

General

00 -- 26

July 2002 For training and information only

Triple Rotor RPM Indication

General

The triple rotor RPM indicator is part of the speed sensing system. It

is a 3--pointer instrument and indicates the RPM of the following:

-- Rotor RPM [ % ]

-- Power turbine speed engine 1 [ % ]

-- Power turbine speed engine 2 [ % ]

Operation

The system comprises of inductive pickups at the engines and at the

main transmission, each generating a voltage peak whenever the

appropriate interruptor passes.

Rotor RPM

The rotor RPM is indicated by the small pointer labelled R. The

indication range is 0 to 120 %.

Power Turbine Speed

The power turbine speed of engine 1 and engine 2 is indicated by

2 pointers, labelled 1 and 2. The indication range is 0 to 120 %.

Torque Indicator

General

The torque indicator indicates the torque, measured at each engine

output shaft. It is a 2--pointer instrument. The pointers are labelled 1

and 2.

The indication range is 0 to 140 %.

Dual TOT Indicator

General

The TOT indicator indicates the turbine outlet temperature at each

engine. It is a 2--pointer instrument. The pointers are labelled 1 and

2.

The indication range is 0 to 100 C x 10.

u NOTE The limit values might be different according to the

engine version installed.

EC 135

Training Manual

General

00 -- 27

July 2002 For training and information only

Engine Monitoring Instruments TM

Triple Rotor RPM Indicator

TOT Indicator

Torque Indicator

N

1

Indicator

EC 135

Training Manual

General

00 -- 28

July 2002 For training and information only

Dual nN1 Indicator T1

General

The Dual n N

1

indicator is part of the speed sensing system. It is a

2--pointer instrument and indicates the RPM of the following:

-- n gas producer RPM between the max. allowed (computed

by the FADEC) RPM and the present RPM for engine 1

and engine 2.

It is a 2--pointer instrument. The pointers are labelled 1 and 2. The

indication range is from -- 8 % to + 4 %.

Dual N1 Indicator P1

General

The Dual N

1

indicator is part of the speed sensing system. It is a

2--pointer instrument and indicates the RPM of the following:

-- Gas producer RPM for engine 1 and engine 2

It is a 2--pointer instrument. The pointers are labelled 1 and 2. The

indication range is from 0 % to + 120 %.

u NOTE The limit values might be different according to the

engine version installed.

EC 135

Training Manual

General

00 -- 29

July 2002 For training and information only

Engine Monitoring Instruments P1

N

1

Indicator

Torque Indicator

TOT Indicator

Triple Rotor RPM Indicator

EC 135

Training Manual

General

00 -- 30

July 2002 For training and information only

Oil Temperature and Pressure Indicator

General

The oil temperature and pressure indicator is an instrument cluster

indicating oil temperature and oil pressure for each engine and for the

main transmission on six individual indicators.

-- The temperature indicators are calibrated in C

-- The pressure indicators are calibrated in bar

According to the engine type installed (TMor PW) the indicators have

different scaling and different limit markers.

The indicator illumination is adjusted with the aid of instrument

illumination potentiometer INSTR in the overhead panel.

More detailed description is given in the associated chapters.

EC 135

Training Manual

General

00 -- 31

July 2002 For training and information only

Oil Temperature-- and Pressure Indicator

Turbomeca

Pratt&Whitney

EC 135

Training Manual

General

00 -- 32

July 2002 For training and information only

Cockpit Display System (CDS)

Introduction

The Cockpit Display System (CDS) provides indication of aircraft

status information such as caution and advisory messages to the crew

accomplished by operating data and indication of special operation

modes. It consists of a self contained unit installed inthe center section

of the instrument panel.

Various switches facilitate operation of the device and allow control of

the indications. The brightness is automatically controlled with the aid

of a sensor.

An indication light flashes as soon as the CDS discovers an internal

malfunction.

The CDS is capable of identifying the type of engine installed

according to the wiring of the connectors.

The casing of the CDS is cooled by the cabin ventilation systemor the

air-conditioning system, if installed.

Associated Controls and Indicators

In order to provide proper function and handling, the following controls

and indicators beside the CDS are available:

-- MASTER CAUTION indication light

The MASTER CAUTION indication light is installed in the center part

of the instrument panel RH of the warning unit.

-- Switch CDS/AUDIO RESET

The switch CDS/AUDIORES is installed in the grip of the cyclic control

stick and enables the pilot and copilot (if dual pilot controls are

installed) to acknowledge the CAUTION indications.

-- Test Switch TEST/CDS

The test switch TEST/CDSis installed inthe overheadpanel. It triggers

the testing of the CDS indications.

-- CDS OVTP indication light

The CDS OVTP indication light is installed in the center part of the

instrument panel below the CDS on the left side. The light comes on

if the internal temperature is higher than 63 C.

Power Supply

In order to guarantee continuous operation even in the event of failure

of one of the essential busbars, the CDS is supplied by both

ESSENTIAL busbars via the circuit breakers located in the overhead

panel.

-- CDS/SYS 1

-- CDS/SYS 2

Data Storage

An CDS integrated memory has two functions which are as follows:

-- Storage of all of the CAUTION indications having occurred

within the penultimate minute

-- Storage of the failures reported to the CDS by the engine

control units along with their respective failure codes.

EC 135

Training Manual

General

00 -- 33

July 2002 For training and information only

CDS -- General Arrangement

Master

Caution

ESSENTIAL I

CB CDS/SYS1 CB CDS/SYS2

Aircraft Data

Engine Data

ESSENTIAL II

CDS

AUDIO

RES

CDS

OVTP

EC 135

Training Manual

General

00 -- 34

July 2002 For training and information only

Configuration

The CDS provides the crew with information while at the same time

indicating the present state of various systems of the helicopter.

The CDS performs the following tasks:

-- CAUTION indication

-- Advisory indication

-- Indication of engine parameter (engine cycle counter),

FADEC--MEM--codes and malfunction indications

-- Indication of helicopters power supply voltage and current

-- Outside air temperature indication

-- Mast moment bargraph with limit warning light*

-- Fuel system indication

-- Calculation and indication of V

ne

velocity **

-- Radar altimeter indication

-- Indication of length of rescue winch cable*

-- Indication of load attached to external cargo hook*

-- Engine operating hours counter

* Only available when the resp. systems are installed in the helicopter.

** The key V

ne

is installed in early CDS versions only. Current versions

are provided with a key FUNCTION.

The CDS is divided into several panels to enhance overall view. Each

of these panels serve assigned functions.

The basic brightness of the indications is controlled through the keys

BRIGHTNESS.

Colors of Indications

-- Amber

The upper display whichis theprimary display is split into four sections.

In the upper part CAUTIONS are displayed separately for SYST I/II

and MISC. The color of the cautions is amber.

-- Green

The lower part of the upper display shows the ADVISORIES The color

of the advisories is green.

-- White

The color in the lower display which is the secondary display in general

is white.

Exceptions are made with the mast moment indication which is green

-- yellow -- red and fuel lowindications in the fuel display which are red.

EC 135

Training Manual

General

00 -- 35

July 2002 For training and information only

CDS -- Displays and Controls

Caution Display

SYST I, MISC, SYST II

Advisory Display

Page Light

Mast Moment Indication

VOLT/AMP Key

Scroll Buttons

Display Select Switch

CDS FAIL Indication

BRIGHTNESS Keys

WEIGHT Key

Opt 1/2 Display

FUEL SYSTEM Display

OAT Indication

Electrical System Display

TORQUE Display

Engine Parameter Display

Default Values:

N

1

for TM, TOT for P&W

CAUTION PAGE Button

Brightness Sensor

EC 135

Training Manual

General

00 -- 36

July 2002 For training and information only

CDS Operation

Power Supply and Self Test

The CDS is activated by setting the battery master switch BAT MSTR

in ON position. This causes the CDS self test to be carried out. The

CDS checks also the presence of the following engine cautions for

SYS I and SYS II:

ENG FAIL ENG FAIL

ENG OIL P ENG OIL P

FUEL PRESS FUEL PRESS

HYD PRESS HYD PRESS

XMSN OIL P XMSN OIL P

GEN DISCON GEN DISCON

If the cautions have been successfully detected INP PASSED comes

on on the advisory display below the message CDS PASSED and

engine configuration (early CDS versions only). If a caution is missing,

INP FAIL appears in the center column of the caution display, followed

by the missing caution to the left/right.

The pilot has to acknowledge the messages by pushing the

CDS/AUDIO RES button on the stick grip. Subsequent to the

acknowledgement the CDSstarts normal operation. If the self test was

not successful CDS FAIL will appear on the display.

The indication light CDS FAIL comes on only when the CDS self test

is faulty.

Mast Moment Failure

If there is a failure of the mast moment system detected, the caution

MMFAILEDcomes up in the MISCfield (depends on the part number).

Continuity Test

Continuity tests of the connecting cables between some sensors and

the CDS are made during CDS power -- ON self test. A failure is

indicated by displaying the respective detector name with an

additional ...CT on the caution panel. If a ...CT -- caution is indicated,

the monitoring circuit of the corresponding system must be assumed

to be unable to activate the real system caution in case of system

failure.

CDS Test Switch

The CDS test switch, located on the test switch panel of the overhead

console provides test function of the display screens and lamps of the

CDS. Activation of the test switch causes the screens and lamps of the

CDS and the indication CDS OVTP to illuminate.

EC 135

Training Manual

General

00 -- 37

July 2002 For training and information only

CDS Self Test

ENG FAIL

ENG OIL P

FUEL PRESS

HYD PRESS

XMSN OIL P

GEN DISCON

ENG FAIL

ENG OIL P

FUEL PRESS

HYD PRESS

XMSN OIL P

GEN DISCON

CDS PASSED

(Engine config.)*

INP PASSED

SYSTEM I MISC SYSTEM II

CDS PASSED

(Engine config.)

SYSTEM I MISC SYSTEM II

INP FAIL

CDS FAIL

SYSTEM I MISC SYSTEM II

HYD PRESS

All Parameters Available, Self Test Passed Signal HYD PRESS Missing

Self Test Not Passed.

* Early CDS versions only

EC 135

Training Manual

General

00 -- 38

July 2002 For training and information only

CDS Caution Display

General

The cautions are displayed in the CAUTION display, separately for

system 1, system 2 and miscellaneous.

New cautions emerging on the screen are accompanied by flashing

lines above and below the caution. Cautions, displayed before, are

extinguished from the display but stored in the background.

Each new caution indication causes the MASTER CAUTION light to

come on (The master caution light is located right beside the warning

panel).

The cautions must be acknowledged by pressing the CDS/AUDIO

RES button which is located on the cyclic stick.

After pressing the CDS/AUDIO RES button the master caution light

goes off and the CDS changes to the prioritized display mode. That

means, that all active cautions are displayed in sequence of priority.

If there are more acknowledged cautions than can be displayed on the

screen simultaneously, the PAGE light illuminates and the additional

cautions can be called up from the second page by pressing the

CAUTION PAGE button. If the CAUTION PAGE button has not been

pressed for 10 seconds, the top priority cautions are displayed.

u NOTE The following two listings show all possible

cautions/advisories at the time this manual has

been printed.

The caution configuration in the individual

helicopter depends on the helicopter serial

number, CDS configuration and optional

equipment installed.

The cautions will be explained in the respective

chapters.

EC 135

Training Manual

General

00 -- 39

July 2002 For training and information only

Priority of Cautions

SYS I/II MISC

1 ENG FAIL CDS PWR

2 ENG OIL P XMSN CHIP

3 ENG CHIP TRGB CHIP

4 FADEC FAIL XMSN OIL T

5 FUEL PRESS ROTOR BRAKE

6 FUEL FILT AUTOPILOT

7 ENG O FILT

8 ENG IDLE DOORS

9 TRAINING TRIM

10 TRAIN IDLE GYRO

11 AUTOPILOT ACTUATION

12 ENG MANUAL F PUMP AFT

13 TWIST GRIP F PUMP FWD

14 F VALVE F QTY FAIL

15 F VALVE CL F QTY DEGR

16 FADEC MINR (only PW) HTG OVTEMP

17 DEGRADE (only TM) EPU DOOR

18 REDUND (only TM) BAT DISCON

19 PRIME PUMP EXT POWER

20 HYD PRESS SHED EMER

21 XMSN OIL P DG

22 OVSP HOR BAT

23 GEN OVHT AP REDUCED

24 GEN DISCON ADC

25 INVERTER FLOATS ARM

26 FIRE EXT DECOUPLE

27 FIRE E TST AVAD FAIL

28 BUSTIE OPN P/R SAS

29 STARTER YAW SAS

30 ENG CHIP CT XMSN CHP CT

31 ENG OF CT

32 F FILT CT XMSN OT CT

33 INP FAIL TRGB CHP CT

34 INP PASSED MM FAIL

35 PITCH DAMP

36 CDS TEMP

37 ALT ALERT

38 MSG

39 AUX VALVE

EC 135

Training Manual

General

00 -- 40

July 2002 For training and information only

CDS Advisory Display

General

The section below the caution display contains the advisory display

which keeps the pilot informed about operatingconditions of additional

equipment which is not essential for the flight.

Matrix of Advisory Combination

Basic Opt.

Equipm.

DPIFR 1

Opt.

Equipm.

DPIFR 2

2.

Priority*

BLEED AIR

Bleed air heating active

X X X

LDG LIGHT

Standard and/or

optional landing light on

X X X

P/S--HTR--P

Heating of the pitot pilot

side is active

X X

P/S--HTR--CP

Heating of the pitot

copiltot side is active

X

LDG L RETR

Search and landing

light retracts at rest

X

LDG L EXTD

Search and landing

light extended

X

HOOK UNLD

Load is < 5 kg

X X

AIR COND

Air condition system

active

X X

AUX XFER

Aux. fuel valve is in-

open position

X X

CA CUT ARM

Cable cut circuit test is

passed

X

IR

Infra red light is active

X X

IFCO

The IR filter is active

X X X

* 2. priority means: If all advisories are ON, the advisories of the

2. priority will not be displayed.

Display Select Switch / Scroll Button

General

The display select switch has six selectable positions which provide

information and date about several engine parameters, failure codes,

operation parameters etc.

The informations can be displayed by selecting a certain switch

position and pressing the scroll buttons to scroll in the menu.

Selectable Parameters

The following table describes the possible parameters in dependency

on the chosen display select switch position.

EC 135

Training Manual

General

00 -- 41

July 2002 For training and information only

Display Select and Scroll Switch

SCROLL

DISPLAY

SELECT

2

OPT

1

P

F

M

T

Display Select Switch

Scroll Buttons

1

EC 135

Training Manual

General

00 -- 42

July 2002 For training and information only

Posi--

tion

Parameter Description

P

PARAMS

(Normal flight position)

Real timeFADECparameters canbesequentially selectedby means of thescroll buttons. They aredis-

playedontheengineparameter display. Thedisplay default uponpower is N1(TM) andTOT(PW)

Thepossibleparameters arelistedbelow.

N1 Gas generator turbine RPM [%]

N2 Power turbine RPM [%]

TQT Torque trim values of both engines [%] (TM only)

QMAT Torque trim values of both engines [%] (P&W only)

EGT Exhaust gas temperature [C] (TM only)

TOT Turbine outlet Temperature [C] (P&W only)

T1 Air temperature measured at the compressor air inlet and provided to the engine control unit. [C]

CLP Collective pitch resp. Linear--Voltage--Differential--Transducer--Position (LVDT) [%]

P0 Air pressure measured in both FADEC boxes [hPa]

N2T Power turbine reference speed trim value [%]

N1C N

1

Cycle counter

N2C N

2

Cycle counter

MEM CODES Numerical Failure Codes

F

FAIL MSG

The Fail Message provides abbreviated messages for active failure codes. They are displayed on the

advisory display. When viewing the FADECfailure messages and no fail code exists, a blank is displayed

continuously. The indication scrolls automatically for 3 seconds each when more than one exists. All of

the malfunction codes are stored. They are deleted with the next engine start when the N

1

RPMexceeds

20 %.

EC 135

Training Manual

General

00 -- 43

July 2002 For training and information only

Posi--

tion

Parameter Description

M MEM CODE

Stored failure codes can be selected by means of the scroll buttons and are displayed on the engine

parameter display by means of numerical failure codes. These codes correspond to the abbreviated

messages under FAIL MSG and are described in the respective maintenance manual. Mast moment

exceedance MMEXC is displayed in the advisory display.

T OTh

The Operating Time counter provides automatic timer function to continuously keep and indicate the

engine operating time. The time is displayed on the engine parameter display.

The counter starts when the resp. ENG FAIL CAUTION disappears and the collective lever position is

above 10%.

It stops when the collective lever position is below 10% and ENG FAIL CAUTION is active.

OPT1

Enables the operator to select between VNE and RAD ALT indication on the upper option line by

means of the scroll buttons.

VNE* The V

NE

depends on gross mass, pressure altitude and OAT. The present V

NE

is calculated and per-

manently updated by the CDS. By pushing the WEIGHT button the pilot can choose between the

symbols > or <.

> means that the gross mass is equal or greater than 2300 kg (standard presetting).

< means that the gross mass is lower than 2300 kg.

RAD ALT * A four digit display indicates the radar altitude from 0 to 2500 ft and a RAD ALT light will come on if

the radar altimeter is active.

OPT2

Enables the operator to select between HOOK LOAD and CABLE LENGTH indication on the lower

option line by means of the scroll buttons.

HOOK

LOAD *

A four digit display indicates the loading of the external cargo hook. In addition the illuminated HOOK

LOAD sign comes on.

CABLE

LENGTH *

The display indicates the length of the lowered cable. If the rescue hoist is active the illuminated

CABLE LENGTH sign comes on and the moving mode of the hoist (lowering or retracting) is

indicated.

*Only when the respective system is installed.

EC 135

Training Manual

General

00 -- 44

July 2002 For training and information only

Torque Indication

The torque is permanently displayed on the torque display in %.

Electrical Power Indication

The aircrafts electrical voltages and currents can be shown on the

electrical system display. The VOLT/AMP button enables the crew to

select between DC VOLTS, GEN AMPS or BAT AMPS. The default

setting is DC VOLTS.

Outside Air Indication

Outside air temperature is permanently displayed in C. The value is

also internally used for V

NE

calculation.

Mast Moment Indication

The EC135 is equipped with a hingeless and bearingless rotor system

and therefore high bending moments occur at the rotormast,

particularly during close ground operation. The bending of the

rotorshaft is monitored by a mast moment measuring system.

The mast moment indication consists of a bargraph and a limit light.

The bargraph is a three-color indication, indicating the mast moment

linear from 0 to 100% in green, yellow and finally red.

The LIMIT light remains on until a cold start of the CDS occurs.

If the input signal from the mast moment measuring system is out of

specified values, the caution MM FAIL will be displayed.

Fuel Quantity Indication

The CDSdisplays the fuel masses and fuel systemstatus of the supply

tank 1, supply tank 2, main tank and (if installed) auxiliary tank. Each

of the tank displays contain a bargraph display and a numeric text

display.

The supply 1 and supply 2 displays contain a LOW indication which

illuminates when the resp. tanks content is below a specified value.

The FREE advisory indication comes on when the free volume of the

main tank is greater than the current volume of the auxiliary tank.

The XFERadvisory indication comes on when fuel is being transferred

into the main tank (transfer valve OPEN).

EC 135

Training Manual

General

00 -- 45

July 2002 For training and information only

Outside Air Temperature, Mast Moment and Fuel System Indication

Outside Air

Temperature Display

Mast Moment Display

incl.

Limit Light

Fuel Display incl.

Low Level Warning

incl.

FREE and XFER

Advisory

EC 135

Training Manual

General

00 -- 46

July 2002 For training and information only

Central Panel Display System (CPDS)

General

The Central Panel Display System is an electronic indicating system

and presents various parameters of the onboard systems on three

screens.

CAD (Caution and Advisory Display)

The CAD displays cautions, advisory messages and fuel system

indications. If the VEMD fails, the CAD can take over and display

selected parameters from it.

The display instrument of the CAD consists of a color screen,

integrated in the left-hand side of the center section of the instrument

panel.

VEMD (Vehicle and Engine Monitoring Display)

The VEMD displays engine and dynamic system parameters. In

addition, it can present data relating to onboard systems (e.g. aircraft

electrical system, autopilot) and to optional equipment (e.g. cargo

hook).

If the CAD fails, the VEMD displays selected CAUTIONs. The duplex

configuration of the VEMD provides redundancy so that two

processing modules are each individually capable of taking over all

tasks.

Both the VEMDscreens are installed in the in the right-hand side of the

center section of the instrument panel.

Test Switch

The test switch triggers the CPDS to display the test page with the

complete color spectrum and the software version.

Circuit Breakers

The CADand the VEMDare supplied with voltage, each via two circuit

breakers, from the ESSENTIAL busbars 1 and 2. The circuit breakers

are arranged in the overhead panel.

CDS/AUDIO RES Switch

The CDS/AUDIO RES switch is used by the pilot and copilot to

acknowledge displayed cautions. It has the same function as the

SELECT key on the CAD.

The switch is installed in the grip of the pilots cyclic stick and, if dual

controls are installed, one is also installed in the copilots cyclic stick

grip.

Voltage Adjusting Element

An adjusting element for each voltage indication of the VEMD is

integrated in the sensor units, mounted to frame 1 in the forward part

of the helicopter. Hereby the voltage drop in the VEMD indication can

be corrected.

Maintenance Connector

Two maintenance connectors are mounted to the rear part of the

slanted console.

CPDS OVHT Caution

The CPDSoverheat caution is triggered by a temperature switch in the

instrument panel between 51 and 55 C.

EC 135

Training Manual

General

00 -- 47

July 2002 For training and information only

CPDS -- Locations

ENGI

ENGII

O

F

F

M

A

X

CDS

AUDIO

RES

CAD

Maintenance

Connectors

Switch

CDS AUDIO RES

Stick Grip

Circuit Breakers

Test Switch

VEMD

Voltage Adjusting Element

integrated into Sensor Units

at Frame 1

EC 135

Training Manual

General

00 -- 48

July 2002 For training and information only

Color Code Ranges and their Meaning

The range of colors used for displays on the screens of the CPDS

covers five different colors in addition to black and white. Each

individual color has a specific significance.

Black Background, Text on colored background

White Scales, Display arrows (pointers), numbers, etc.

Yellow Limits, Defect symbols

Red Limits, Defect symbols

Amber Cautions

Green Advisories

Cyan Tech. Units, Selections, Demarcations etc.

Blue Fuel quantity level

CAD Operation

The CAD is operated by the following keys in the front panel:

Key Function

OFF Switches CAD on/off

SCROLL Selects different screen pages (e.g. second page with

cautions)

SELECT Acknowledges new cautions

BRT + Increases brightness of screen

BRT -- Decreases brightness of screen

VEMD Operation

The VEMDis operated by the following keys located on the front panel

of the display monitor:

Key Function

OFF 1 Switches upper screen and processing module 1 on/

off

OFF 2 Switches lower screen and processing module 2 on/off

SCROLL Cycles to next page, depending on operating mode

and status

RESET Initiates return to normal screen display or to

previously displayed page (depending on the

operating mode)

SELECT Selects a particular data field

+ / -- Input of values to data field

ENTER Acknowledges selection of a data field or a data entry

to a data field

BRT + Increases brightness of screen by continuous

adjustment

BRT -- Decreases brightness of screen by continuous

adjustment

EC 135

Training Manual

General

00 -- 49

July 2002 For training and information only

CPDS

0

2

4

6

8

10

12

14

16

CAD VEMD

EC 135

Training Manual

General

00 -- 50

July 2002 For training and information only

Function of the CPDS

Overall System

The CAD and VEMD are each powered by two independent power

supplies and their respective circuits are each protected by two circuit

breakers. As both are connected to ESSENTIAL busbars 1 and 2, their

operational integrity is ensured if one of the busbars should fail.

Status of the CPDS

With the CPDS GROUNDand FLIGHT status are distinguished on the

bases of the following parameters:

GROUND Status:

-- n

1

RPM engine 1 and engine 2 < 50 %

-- XMSN oil pressure < 1bar

FLIGHT Status:

-- n

1

RPM engine 1 or engine 2 > 50 %

-- XMSN oil pressure > 1bar

-- Angle of collective lever CLP

> 28.5% (Turbomeca) or > 17% (Pratt&Whitney).

Switch-on Sequence (Power up)

The CPDS is activated as soon as the aircraft electrical system is

energized on the ground. An internal self-test and an external self-test

are run to establish the functional integrity of the CPDS:

While the internal self-test is running, the message TEST IN

PROGRESS will be displayed on the CAD/VEMD and the soft-- and

hardware is checked.

After the internal self test is passed, the external self test is performed.

While the presence of the followingparameters is verified themessage

EXTERNAL SELF TEST IN PROGRESS will be displayed on the

CAD/VEMD.

SYS I MISC SYS II

ENG CHIP XMSN CHIP ENG CHIP

ENG FUEL FILT TRGB CHIP ENG FUEL FILT

FUEL OIL FILT XMSN OIL TEMP FUEL OIL FILT

XMSN OIL FILT

During the external test, the wiring of certain sensors is checked with

a continuity test (CT). If a failure occurs, the respective sensor is

displayed on the CAD as a caution with CT as a supplement.

EC 135

Training Manual

General

00 -- 51

July 2002 For training and information only

Functional Schematic CPDS

VEMDSYS II

CADSYS II

VEMD

P1 P1

ESS BUS I

VEMDSYS I

CADSYS I

ESS BUS II

AUDIO

GONG

Master

Caution

TEMP

Air Cond.

ARINC 429

WARNING

UNIT

TEST CDS/

WARN UNIT

CDS/

AUDIO RES

CPDS OVHT

MAINT.

CONN

ARINC 429

FADEC

2 1

FCDM

Sensors

APM

HUMS

Pelican

Rack

CAD

VOLTAGE

ADJUSTMENT

VOLTAGE

ADJUSTMENT

EC 135

Training Manual

General

00 -- 52

July 2002 For training and information only

After the external self-test the functional integrity of the peripheral

assemblies is tested. After the test has run, the following cautions will

be displayed on the CAD:

SYS I MISC SYS II

ENG FAIL+ F PUMP AFT** ENG FAIL+

ENG OIL P+ F PUMP FWD** ENG OIL P+

FADEC FAIL* EPU DOOR FADEC FAIL*

FUEL PRESS+ BAT DISCON FUEL PRESS

HYD PRESS+ EXT POWER HYD PRESS

XMSN OIL P+ XMSN OIL P

GEN DISCON+ GEN DISCON

INVERTER*** INVERTER***

PITOT HTR PITOT HTR

* only when the FADEC is switched off

** only when the fuel pumps are off or running dry

*** only if the respective system is installed

+ only these cautions trigger the INP FAIL, if they are not active during

the test.

If an error occurs during the test, INP FAIL will appear at the bottom

edge of column MISCand ayellowbar above andbelowtherespective

caution will flash. The corresponding caution will appear on the CAD.

After 8 seconds, the ACK NEEDED prompt is displayed on the upper

VEMD screen.

In case of a malfunction the respective caution will flash with a yellow

bow, above and below. This message has to be acknowledged by the

CDS/Audio Reset or the select button.

Test Pattern

If the switch TEST CDS/WARN UNIT or TEST CDS/WU is set to

position CDS, a test pattern appears with Cyclic Redundant Code

(CRC), part number and configuration file number.

Cyclic Redundant Code

Check sum for the configuration file deviations (manufacturer only).

Part Number

Last two digits of the part number identify the software version.

Example:

B19030GB05 corresponds to software version V2001A

Configuration File

All software versions are delivered with a basic configuration file.

Necessary changes (e.g. after installation of optional equipment)

might require the upload of a customized configuration file delivered

by EUROCOPTER.

Example:

Software version V2001A,

Basic configuration file L316M30S0001

Customized configuration files L316M30SXXXX

u NOTE The CPDS description shows the latest standards.

Major changes with part numbers and serial

numbers are shown in an overview page at the end

of the CPDS description.

EC 135

Training Manual

General

00 -- 53

July 2002 For training and information only

Test Pattern (Example Software Version V2001A)

(1)

(8)

(1)

(7)

(8) (1) (8) (1)

(1)

(4) (3) (5)

(2) (6)

(1) (8)

(8)

B19030GB05

(8)

4E2F60A6

(8)

(1) (1)

L316M30S0001

(8)

Cyclic Redundant Code

Part Number

Configuration File Number

1 white

2 yellow

3 cyan

4 green

5 magenta

6 red

7 blue

8 black

EC 135

Training Manual

General

00 -- 54

July 2002 For training and information only

INTENTIONALLY LEFT BLANK

EC 135

Training Manual

General

00 -- 55

July 2002 For training and information only

CPDS--Architcture for N1(nN1), TOT, TQ

ENGINE 1 ENGINE 2

N

1

Sensor

N

1

Sensor

FADEC 1 FADEC 2

CAD

VEMD

Module 1

VEMD

Module 2

CROSSTALK

Analog

Signals

N

1

Analog N

1

Analog

N

1

/TOT/TQ

Digital

RS 422

N

1

/TOT/TQ

Digital

RS 422

N

1

Duplex

TQ

nN

1

(only TM)

TOT (only PW)

Analog

Signals

TQ

nN

1

(only TM)

TOT (only PW)

TOT Matching

Resistor (only TM)

TOT Matching

Resistor (only TM)

(Upper

Screen)

(Lower

Screen)

EC 135

Training Manual

General

00 -- 56

July 2002 For training and information only

CPDS Modes

General

The following modes are available:

Flight Mode

-- CAU/Fuel (Caution and Fuel Page)

-- FLI (First Limit Indicator)

-- ELEC/VEH (Engine and Electrical Parameters)

-- Flight Report

-- System Status

-- Caution Fuel Fail

-- CAU Backup

Ground Mode (Engines Shut Down)

In addition

-- Maintenance Menu

-- Configuration (AC Config Page)

CAUTION / FUEL -- Page

The CAUTION / FUEL page is displayed automatically on the CAD.

The fuel quantity parameters are displayed only on the CAD and are

no longer available if the CAD fails. The units of measurement on this

page can be changed in the configuration mode (A/C CONFIGpage).

The cautions inform the crew of defects in onboard systems. They

appear in yellow characters in the three columns of the upper half of

the CAD. The columns are divided as follows:

-- Left column: messages relating to eng. 1 and system 1

-- Center column: messages relating to non-redundant

systems

-- Right column: messages relating to eng. 2 and system 2

Cautions are listed in the order of their appearance (i.e. oldest caution

at the top). If there is not enough room on the page to display all the

cautions, e.g., 1 of 2 will appear at the top of the center column to

indicate the presence of a second page with cautions. This page can

be accessed with the SCROLL key, but there will be an automatic

return to page 1 after 15 seconds.

When a new caution appears, all the acknowledged cautions on

display will disappear, and a yellowbar will flash above and belowthe

new caution. At the same time, the MASTER CAUTION caption next

to the warning unit will illuminate.

The crew have to acknowledge the caution(s) by operating the

CDS/AUDIORES switch on the cyclic stick or the SELECT key on the

CAD. If the CAD has failed, the SELECT key on the VEMD must be

pressed. This leads to all cautions being displayed normally in the

order of their appearance. Also, the MASTER CAUTION caption will

extinguish and is free for the next error message (caution).

EC 135

Training Manual

General

00 -- 57

July 2002 For training and information only

CAD -- CAUTION/FUEL Page

CAUTION/ADVISORY Half Page

Fuel Indication

1OF2

0 32

EC 135

Training Manual

General

00 -- 58

July 2002 For training and information only

CPDS Cautions

The following CPDS cautions can be displayed on the CAD or VEMD.

No. SYS I/II MISC

1. FLI DEGR P DAMPER

2. FLI FAIL NMS

3. ENG FAIL XMSN CHIP

4. ENG OIL P TRGB CHIP

5. ENG CHIP XMSN OIL T

6. FADEC FAIL ROTOR BRK

7. FUEL PRESS TRGB CHP CT

8. FUEL FILT XMSN CHP CT

9. ENG O FILT DOORS

10. ENG IDLE F PUMP AFT

11. TRAINING F PUMP FWD

12. TRAIN IDLE F QTY FAIL

13. ENG MANUAL F QTY DEGR

14. TWIST GRIP ACTUATOR

15. FUEL VALVE EPU DOOR

16. FADEC MINR (only PW) BAT DISCON

17. DEGRADE (only TM) EXT POWER

18. REDUND (only TM) SHED EMER

19. PRIME PUMP DG

20. HYD PRESS GYRO

21. XMSN OIL P AUTOPILOT

22. OVSP DECOUPLE

23. GEN OVHT TRIM

24. GEN DISCON ACTUATION

25. INVERTER P/R SAS

26. FIRE EXT YAW SAS

27. FIRE E TST HTG OVTEMP

28. BUSTIE OPN T1 MISCMP (TM only)

29. STARTER P0 MISCMP (TM only)

30. ENG CHP CT P PITOT

31. ENG OF CT CAU DEGR

32. F FILT CT CAD FAN

33. PITOT HTR VEMD FAN

34. F VALVE CL CPDS OVHT

35. ENG EXCEED

(only T2, P2)

HOR BAT

36. CA CUT ARM

37. AUX VALVE

38. RNAV

39. OWS FAIL

40. MSG

41. CAT A (P2 only)

42. FUEL

43. XMSN OIL T CT

EC 135

Training Manual

General

00 -- 59

July 2002 For training and information only

u NOTE Cautions with the letters CT at the end indicate

negative continuity test of the respective caution

circuit only.

u NOTE If the CAD and one VEMD screen fail only a

degraded Caution list is available on the remaining

screen (see respective FLM).

Advisories

The advisories appear in green characters below the cautions in the

MISC column and provide the crew with information about the

operational status and optional equipment.