Академический Документы

Профессиональный Документы

Культура Документы

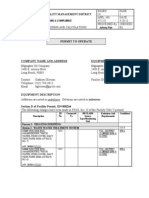

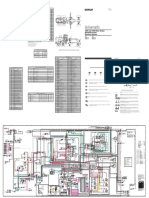

Castle Hotel BEMS Point Diagram Rev 2

Загружено:

Abraham JyothimonАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Castle Hotel BEMS Point Diagram Rev 2

Загружено:

Abraham JyothimonАвторское право:

Доступные форматы

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

A

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

k

W

L

o

a

d

I

t

e

m

7

DOL Extract Fan 4.0kW

2 Room temp. detector Room 1 A

Supply fan isolator [Field] 1 D

3

HV Cooling [C-G-EF-02]

[C-G-EF-02]

Supply fan starter [MCC] 3 D 5

2

Extract Fan

Supply fan isolator [Field] 1 D 2

2 3 4.0kW

HV Cooling [C-G-EF-01] [C-G-EF-01]

Supply fan starter [MCC] 3 D 5

6

DOL

LPG Gas Meter

Castle Hotel Field 1

Sprinkler zone alarm L3 - east

P 2

Sprinkler zone alarm L2 - centre Field

Sprinkler zone alarm L4 - east Field 1 D 2

[FM200 Systems]

[LPG Gas Detection System]

2 1.5 3

2 3 16

5

4

DOL 16

DOL

[Fire Alarm]

[FAN COIL UNITS]

FCU bus Interface unit (Ground)

1.5

FCU bus Interface unit (First & Second)

3 2

Pump isolator

Pump Starter

CCWS Motorised Valve

ChW Motorised Valve

Pump Starter

Pump isolator

1 D

Field 1

Sprinkler zone alarm L1 - east

Sprinkler zone alarm LG - east

[Sprinkler]

Fire Alarm Interface Unit, zone 3

Pump isolator

Pump Starter

Immersion temp. detector

[C-G-HWG-02]

2

Motorised Valve

Immersion temp. detector

[C-G-HWG-01]

[C-G-P-01]

Pump isolator

Immersion temp. detector

[C-G-HWG-03]

Pump Starter

D

2

2

2

Field 1 D 2

Field 1 D 2

MCC 1 D 2

Room C

4

2

2

D

3 D 5

1 D 2

4

2 D

Fire Alarm Interface Unit, zone 2 MCC 1

Common alarm Field 1

Sprinkler zone alarm L5 - east

C-G-P-03

C-G-P-05

C

-

G

-

M

C

C

-

0

1

2

D

D

0.75kW Shunt pump

C-G-P-02

1.5

1.1kW HWS pump

C-G-P-01

Shunt pump DOL 16 2 3 1.5

1.5 2 3

0.37kW

0.37kW Shunt pump

C-G-P-04

0.37kW 16 Shunt pump

Pump isolator Field 1

3 Pump Starter MCC 5 D

3 A

3 A

Pipe 1

[C-G-CWG-01]

Immersion temp. detector Pipe 1 2 A

Pipe 1

Field 1 2 D

MCC

Field

Pipe 1 2 A

MCC 3 5 D

2

Motorised Valve Pipe 1

MCC 3 5 D

3 A

Pipe 1 2 A

Field 1 2 D

MCC 3

2 A Pipe 1

5 D

Motorised Valve Pipe A 1

DOL

Pipe 1 A 3

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Castle Hotel, Ground Floor, Plant Room #1

1

3

16 DOL

D Field 1

3

C

2 Field 1 D

Room

Fire Alarm Interface Unit, zone 1 MCC 1

RE6309/D001369 Rev 0/2003 15910/1 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

A

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

k

W

L

o

a

d

I

t

e

m

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Castle Hotel, Ground Floor, Plant Room #1

8

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

2

Pump run monitoring Field 3 D 4

High level alarm Field 1 D

D 2

4

Common alarm Field 1

D Pump run monitoring Field 3

D 2

High level alarm Field 1 D 2

Common alarm Field 1

Field 1 D 2

Activate water feature 2 Field 1 D

D 2

Common alarm water feature 1 Field 1 D 2

Field 1

[Water Feature Courtyard]

Activate water feature 1 Field 1

Common Alarm

Security room alarm

Common alarm water feature 2

Sump Pump Station (C-S-P-05 A/B)

Sump Pump Station (C-S-P-06 A/B)

Lift Monitoring System

D 2

2

1 D 2

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

Field

Sewage Pumping Station 1 (SPS-01)

Common alarm Field 1

4

D 2

2 High level alarm Field 1 D

1 D 2

Pump run monitoring

Sewage Pumping Station 2 (SPS-02)

Common alarm Field

Field 3 D

4 Pump run monitoring Field 3 D

1 D 2

High level alarm Field

D 2

Sump Pump Station (C-S-P-01 A/B)

Common alarm Field 1

2

Pump run monitoring Field 3 D

D 2

High level alarm Field 1

High level alarm Field 1 D

4

Sump Pump Station (C-S-P-02 A/B)

Common alarm Field 1 D

Sump Pump Station (C-S-P-03 A/B)

Common alarm Field 1

2

Pump run monitoring Field 3 D 4

D

D 2

High level alarm Field 1 D 2

4

Sump Pump Station (C-S-P-04 A/B)

Common alarm Field 1 D 2

Pump run monitoring Field 3

2

Pump run monitoring Field 3 D 4

High level alarm Field 1 D

RE6309/D001369 Rev 0/2003 15910/2 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

L

o

a

d

I

t

e

m

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

MCC 1 D

2

[C-G-SCS-01]

2

DOL 16 2 3 2.5

2

[C-G-AH2-01]

1

Supply fan isolator [AHU] 1 D

Monitoring system common alarm Field 1 D

1 A

Mixing damper 2 [AHU] 1 A

Mixing damper 3 [AHU] 1 A

Room hum detector Room 1 A 2

[AHU] 1 A

Duct LL temp detector [AHU] 1 A 2

2

Duct RA Hum detector [AHU] 1 A 2

2

D

1 A

1 A

1 A

1

1.1kW Supply fan

Supply fan SD 4 5.5 kW

[Coldroom Equipment]

2

1 P 2

Field

Field

1

A

Speciality Kitchen

Main Kitchen

Pre Filter DP switch [AHU] 1 D

Supply fan starter [MCC]

[AHU]

[C-G-SCS-01]

Duct SA temp. detector

Motorised Valve [AHU] 1

Motorised Valve 1

1

3

Room temp. detector Room

Mixing damper 1

Main Filter DP switch

[AHU]

Extract fan isolator

Filter DP switch [AHU]

Motorised Valve

3

3

2

[C-G-AH2-01]

[AHU]

Duct RA temp. detector [AHU]

Duct RA Air Quality Detector [AHU]

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

30 2 12

Castle Hotel, Speciality Restaurant Plant Room #2

3

2

D

2 Supply fan isolator [AHU] 1 D

2

3 D 5

A

3

D 2

A

3

5

2

5

3

P

Activate water feature MCC 1 D 2

Common alarm water feature 2

[Water Feature Entrance]

1

1

2

Supply fan starter [MCC]

Fridge condensing unit common alarm Field 1 D

[Water Meters]

C

-

G

-

M

C

C

-

0

2

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

D 2

Extract fan starter [MCC] 3 D

[AHU]

[AHU]

RE6309/D001369 Rev 0/2003 15910/3 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

A

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

k

W

L

o

a

d

I

t

e

m

3 1.5 0.2kW Heat Wheel

16

3 2.5 1.5kW Supply fan

1.1kW Extract fan 3

DOL 16 2

DOL 2

DOL 16 2

2

Main Filter DP switch [AHU] 1 D 2

Pre Filter DP switch [AHU] 1 D

2

Rotary wheel isolator [AHU] 1 D 2

Exract fan isolator [AHU] 1 D

5

Supply fan isolator [AHU] 1 D 2

Extract fan starter [MCC] 3 D

3

Supply fan starter [MCC] 3 D 5

Rotary wheel starter [MCC] 2 D

3

Motorised Valve [AHU] 1 A 3

Motorised Valve [AHU] 1 A

3

Motorises damper 2 [AHU] 1 D 3

Motorised damper 1 [AHU] 1 D

Duct IA Hum. detector [AHU] 1 A 2

Duct IA temp. detector [AHU] 1 A

Duct SA Hum. detector [AHU] 1 A 2

2

[C-3-PAH3-02]

Duct SA temp. detector [AHU] 1 A 2

DOL 16 2 3

2

2

[C-3-PAH3-03]

4

DOL 16 2 3 2.5 2.2kW

Heat Wheel 0.2kW

Supply fan

2.5 2.2kW Extract fan

2.5

[C-3-PAH3-02]

Supply fan

3.0kW Extract fan

5.5kW

[C-3-PAH3-01]

2.5

7.5kW Supply fan

2

Duct SA Hum. detector [AHU] 1 A 2

D

[C-3-PAH3-03]

Duct SA temp. detector [AHU] 1 A

Main Filter DP switch [AHU] 1 D

1 D

2

Rotary wheel isolator [AHU] 1 D

Pre Filter DP switch [AHU] 1

2 D

2

Exract fan isolator [AHU] 1 D 2

Supply fan isolator [AHU]

1 A

3

Extract fan starter [MCC] 3 D 5

Rotary wheel starter [MCC]

1 D

3

Motorised Valve [AHU] 1 A 3

Motorised Valve [AHU]

1 A

3

Motorises damper 2 [AHU] 1 D 3

Motorised damper 1 [AHU]

2

2

2

Duct IA Hum. detector [AHU] 1 A 2

Duct IA temp. detector [AHU]

1 A 2

[AHU] 1 A

3

3

3

3

2.5

1.5 DOL 16 2

SD 30 2

DOL 20 2

Duct SA temp. detector [AHU] 1 A 2

2 Duct SA Hum. detector [AHU] 1 A

[C-3-PAH3-01]

2

2

Main Filter DP switch [AHU] 1 D

Pre Filter DP switch [AHU] 1 D

Extract fan starter

5 Supply fan starter [MCC] 3 D

[MCC] 3 D 5

2 Extract fan isolator Field 1 D

A

2

Mixing damper 3 [AHU] 1 A 3

Supply fan isolator Field 1 D

3

3 Mixing damper 1 [AHU]

Mixing damper 2 [AHU] 1 A

1 A

2

Duct RA Air Quality Detector [AHU] 1 A 2

Duct LL temp detector [AHU] 1 A

Duct RA temp. detector SD 40 2

1

C

-

3

-

M

C

C

-

0

1

[AHU]

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Castle Hotel, Level 3, Plant Room #1

[C-3-AH2-01] [C-3-AH2-01]

7

Duct RA Hum detector

D 5

3

Motorised Valve [AHU] 1 A

Motorised Valve [AHU] 1

4

3

Supply fan starter [MCC] 3

RE6309/D001369 Rev 0/2003 15910/4 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

A

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

k

W

L

o

a

d

I

t

e

m

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Castle Hotel, Level 3, Plant Room #1

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

Rotary wheel isolator

Main Filter DP switch [AHU] 1 D 2

Pre Filter DP switch [AHU] 1 D 2

DOL 16 2 3

DOL 16 2 3

4

0.2kW Heat Wheel

2.5 2.2kW Extract fan

[AHU] 1 D

2

2

2

Supply fan isolator [AHU] 1 D

Exract fan isolator [AHU] 1 D

5

Extract fan starter [MCC] 3 D 5

Supply fan starter [MCC] 3 D

3

Motorised Valve [AHU] 1 A 3

Motorised Valve [AHU] 1 A

3

Motorises damper 2 [AHU] 1 D 3

Motorised damper 1 [AHU] 1 D

2

Duct IA Hum. detector [AHU] 1 A 2

Duct IA temp. detector [AHU] 1 A

Duct SA Hum. detector [AHU] 1 A 2

2.5

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

MCC 1 D

[Fire Alarm]

2 Fire Alarm Interface Unit, zone 2

3 Rotary wheel starter [MCC] 2 D

RE6309/D001369 Rev 0/2003 15910/5 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

K

w

L

o

a

d

I

t

e

m

1

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

1 A 3

Field 1 D 2

[AHU]

2

3

2

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

3

C-3-AH2-01

2.2kW Supply fan

[Fire Alarm]

[AHU] 1 D

2 Pre Filter DP switch [AHU] 1 D

Main Filter DP switch 2

5

Supply fan starter [MCC] 3 D

Extract fan starter [MCC] 3 D

5

Extract fan isolator

Motorised Valve

Supply fan isolator Field 1 D

1 A 3

3 Mixing damper 2 [AHU] 1 A

Duct LL temp detector [AHU] 1 A

Duct RA Air Quality Detector [AHU] 1

1

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

16

Castle Hotel, Level 3, Plant Room #2

2 6

1

A

C

-

3

-

M

C

C

-

0

2

DOL

2

2 2.5

C-3-AH2-02

Duct RA temp. detector

[AHU]

[AHU] 1

Motorised Valve [AHU] 1 A

Duct RA Hum detector

A

Mixing damper 1 [AHU] 1

2 Fire Alarm Interface Unit, zone 2 MCC 1 D

A 2

A

Mixing damper 3 [AHU]

RE6309/D001369 Rev 0/2003 15910/6 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

A

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

k

W

L

o

a

d

I

t

e

m

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

4.0 kW Extract fan

3 1.5 0.2 kW Heat Wheel

3 2.5 2.2 kW Extract fan

4

C

-

5

-

M

C

C

-

0

1

C-5-KEF-01

C-4-KEF-02

DOL 20 3 4

[C-5-PAH3-01]

[C-5-AH2-01]

Supply fan

12 10 11.0kW Supply fan

1

SD 63 2

2

DOL 16 2

3 4 3.0 kW DOL 20 2

DOL 16 2

2 Main Filter DP switch [AHU] 1 D

2

2

Pre Filter DP switch [AHU] 1 D 2

Rotary wheel isolator [AHU] 1 D

2

Exract fan isolator [AHU] 1 D 2

Supply fan isolator [AHU] 1 D

5

Extract fan starter [MCC] 3 D 5

Supply fan starter [MCC] 3 D

3

Rotary wheel starter [MCC] 2 D 3

Motorised Valve [AHU] 1 A

3

Motorised Valve [AHU] 1 A 3

Motorises damper 2 [AHU] 1 D

2

Motorised damper 1 [AHU] 1 D 3

Duct IA Hum. detector [AHU] 1 A

2

Duct IA temp. detector [AHU] 1 A 2

Duct SA Hum. detector [AHU] 1 A

2

[C-5-PAH3-01]

Duct SA temp. detector [AHU] 1 A 2

Main Filter DP switch [AHU] 1 D

5

Pre Filter DP switch [AHU] 1 D 2

Extract fan starter [MCC] 3 D

3

Supply fan starter [MCC] 3 D 5

Motorised Valve [AHU] 1 A

2

Motorised Valve [AHU] 1 A 3

Extract fan isolator [AHU] 1 D

3

Supply fan isolator [AHU] 1 D 2

Mixing damper 3 [AHU] 1 A

3

Mixing damper 2 [AHU] 1 A 3

Mixing damper 1 [AHU] 1 A

2

Room hum detector Room 1 A 2

Room temp. detector Room 1 A

2

Duct LL temp detector [AHU] 1 A 2

Duct RA Air Quality Detector [AHU] 1

2

Duct RA Hum detector [AHU] 1 A 2

[C-5-AH2-01]

Duct RA temp. detector [AHU] 1

A

A

Extract fan 16 2 3 2 0.55 kW DOL

2

[Fire Alarm]

Fire Alarm Interface Unit, zone 1 MCC 1 D

3

DOL 16 4

2

2

3 2.2 kW Extract fan

Electrostatic filter 1 kW 2

2 Extract fan isolator Field

D 5

1 D

C-5-KEF-01

D 2

2

C-4-KEF-02

Extract fan starter [MCC] 3

Electrostatic filter isolator

D 5

Field

Field

Extract fan isolator Field 1

D 2

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

12

Extract fan starter

Electrostatic Filter enable

D

1

1 Electrostatic filter alarm

[MCC] 3

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Castle Hotel, Level 5, Plant Room #1

Field 1 D 2

3

DOL 16

RE6309/D001369 Rev 0/2003 15910/7 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

A

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

L

o

a

d

I

t

e

m

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

D

Castle Hotel, Zone 1, Level 4, Plant Room #1

D

2

1

[AHU]

Main Filter DP switch

3

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

2 [AHU] 1 D

Fire Alarm Interface Unit, zone 1 MCC 1

1

[Fire Alarm]

[AHU]

3 D

Extract fan starter [MCC] 3

Supply fan isolator

D

Rotary wheel starter [MCC] 2 D

Exract fan isolator [AHU] D

Supply fan starter [MCC]

2

3

Motorised Valve [AHU] 1 A 3

2

DOL 16

Duct SA temp. detector [AHU] 1 A 2 3.0 kW

1

DOL 20

Duct IA Hum. detector

[C-4-PAH3-01]

[AHU] 1 A

[AHU] 1 A 2

Motorised Valve [AHU]

2

[AHU] 1 A 2

Duct SA Hum. detector

Duct IA temp. detector

D 2

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

2

2 Pre Filter DP switch [AHU] 1 D

Rotary wheel isolator

Extract fan

20

5

2

1 A

2.2 kW

3

5

1

3 Supply fan

3 Heat Wheel 0.2kW

4

2

2 3

C

-

4

-

M

C

C

-

0

1

DOL 16

RE6309/D001369 Rev 0/2003 15910/8 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

C

a

b

l

e

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

s

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

L

o

a

d

I

t

e

m

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

5

2

1

3

3

3 D

3 D

0.2kW 3

3.0 kW 3

4

1.5

2.5

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

D 2

D 2

D 2

D 2

D

[Fire Alarm]

2

C

-

4

-

M

C

C

-

0

2

2 Fire Alarm Interface Unit, zone 1 MCC

1

1

1

20 2 DOL

5

3

2

Extract fan

3 4.0 kW

1 A

Supply fan

Heat Wheel

20 2

16 2 DOL

Exract fan isolator [AHU] 1

1

[AHU]

Pre Filter DP switch [AHU]

Rotary wheel isolator [AHU]

Main Filter DP switch

[AHU]

Extract fan starter [MCC]

Supply fan starter [MCC]

Duct IA Hum. detector [AHU]

1 A

1 A

Duct SA Hum. detector 1 2

2 D

Motorised Valve [AHU] 1 A

A

[AHU]

Supply fan isolator 1 D

Motorised Valve [AHU]

Duct IA temp. detector [AHU]

Rotary wheel starter [MCC]

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Castle Hotel, Zone 1, Level 4, Plantroom #2

[C-4-PAH3-02]

Duct SA temp. detector [AHU] DOL 1 A 2

RE6309/D001369 Rev 0/2003 15910/9 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

k

W

L

o

a

d

I

t

e

m

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

5. Cable sizes are in mm2. CPC sizes shall be as BS7671 (IEE Regulations)

[C-4-PAH3-03]

C

-

4

-

M

C

C

-

0

3

5.5 kW

16 2 Duct SA temp. detector 0.2kW [AHU] 1.5

Duct SA Hum. detector [AHU] 1 A

Duct IA temp. detector [AHU] 1 A

1 A

1 A

3 3.0 kW

2

2 DOL 16 2 2.5

Motorised Valve [AHU] 1 A 3

Supply fan starter [MCC] 3 D

Rotary wheel starter [MCC] 2 D

Exract fan isolator [AHU] 1 D

[AHU] 1 D

Rotary wheel isolator [AHU] 1 D

Pre Filter DP switch [AHU] 1 D

Main Filter DP switch

[Fire Alarm]

Fire Alarm Interface Unit, zone 1 MCC 1 D 2

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Castle Hotel, Zone 1 , Level 4, Plant Room 1

2

2

2

2

5

3

2 [AHU]

D

3. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

5

Supply fan isolator [AHU] 1 D 2

Extract fan starter [MCC] 3

Supply fan

DOL 2 3 Heat Wheel

SD 30 7 2 6

Extract fan

Motorised Valve [AHU] 1 A 3

1

Duct IA Hum. detector

RE6309/D001369 Rev 0/2003 15910/10 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

3

Activate water feature

Common alarm water feature

MCC 1 D 2

MCC

1 A

1 D

Return immersion detector spa 2 Field 1 A

1 D 2

1 D 2

3

Return immersion detector spa 1 Field 1 A 3

Common alarm spa 1

Common alarm spa 2

MCC

MCC

MCC

1

LTHW motorised Valve Field 1 A 3

Common alarm pool D 2

Return immersion detector pool Field

3

Chilled water motorised Valve Field 1 A 3

LTHW motorised Valve Field 1 A

A 3

Chilled water motorised Valve Field 1 A 3

Chilled water motorised Valve

LTHW motorised Valve Field 1

Field 1 A 3

2

C

-

G

-

M

C

C

-

0

3

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

Castle Hotel; Pool Plant Room

RE6309/D001369 Rev 0/2003 15910/11 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

L

o

a

d

I

t

e

m

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter, I = isolator

3 Cable Type :1 = Xlpe/Swa/LSF, 2 = PVC/PVC, 3 = PVC single conductors in conduit

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

[C-4-PAH2-01]

Duct SA temp. detector [AHU] 1 A 2

Room temp. detector Room 1 A

C

-

4

-

M

C

C

-

0

4

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

LEVEL 4 PLANTROOM 4

2

3

Motorised Valve [AHU] 1 A 3

Motorised damper 1 [AHU] 1 A

5

Supply fan isolator [AHU] 1 D 2

Supply fan starter [MCC] 3 D

2

Main Filter DP switch [AHU] 1 D 2

Pre Filter DP switch [AHU] 1 D

[C-4-PAH2-02]

Duct SA temp. detector [AHU] 1 A 2

Room temp. detector Room 1 A 2

Motorised damper 1 [AHU] 1 A

Motorised Valve [AHU] 1 A

[AHU] 1 D

Supply fan starter [MCC] 3 D

Main Filter DP switch [AHU] 1 D

Pre Filter DP switch [AHU]

[C-4-PAH2-01]

1

DOL 20 2 3 4 4.0kW Supply fan

[C-4-PAH2-02]

2

DOL 20 2 3 4 4.0 Kw Supply fan

2

2

5

2

3

3

Extract fan starter [MCC] 3 D

[C-4-KEF-01]

1 D

Supply fan isolator

Electrostatic filter alarm Field 1 D

5

Electrostatic Filter enable Field 1 D 2

Electrostatic filter isolator Field 1 D

2

Extract fan isolator Field 1 D 2

Extract fan isolator Field 1 D

2

[C-4-KEF-02]

Extract fan starter [MCC] 3 D

[C-4-KEF-01]

3

DOL 16 2 3 2.5 2.2 kW Extract fan

DOL 16 4 1.5 3

2

5

1 kW Electrostatic filter

[C-4-KEF-02]

4

DOL 16 2 3 1.5 0.55 kW Extract fan

Fire Alarm Interface Unit, zone 1 MCC 1 D 2

[Fire Alarm]

RE6309/D001369 Rev 0/2003 15910/12 BEMS Point Schedule + MCC Load Diagram

D

e

v

i

c

e

L

o

c

a

t

i

o

n

N

r

o

f

P

o

i

n

t

s

A

n

a

l

o

u

g

e

o

r

D

i

g

i

t

a

l

C

o

n

t

r

o

l

C

a

b

l

e

C

o

r

e

s

C

o

m

p

a

r

t

m

e

n

t

#

S

t

a

r

t

i

n

g

G

e

a

r

T

y

p

e

S

t

a

r

t

i

n

g

G

e

a

r

R

a

t

i

n

g

A

C

a

b

l

e

T

y

p

e

C

a

b

l

e

C

o

r

e

s

C

a

b

l

e

S

i

z

e

L

o

a

d

I

t

e

m

P

o

w

e

r

k

W

L

o

a

d

I

t

e

m

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type : 1 Xlpe/Swa/Pvc

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Town Hotel, Level 2, Plant Room #3

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

RE6332/D001240 Rev 0/2002 15910/13 BEMS Point Schedule + MCC Load Diagram

Вам также может понравиться

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1От EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Рейтинг: 3.5 из 5 звезд3.5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Com 069 Agk 2030 EdДокумент14 страницCom 069 Agk 2030 EdSimamora Samuel HansenОценок пока нет

- Air ConditionerДокумент74 страницыAir Conditionermuzaaj100% (1)

- D2016-036 Volume 3 of 3Документ135 страницD2016-036 Volume 3 of 3Tej Vir SinghОценок пока нет

- Diagrama D6HДокумент2 страницыDiagrama D6HPepe Alonzo71% (7)

- Salon Tipi 3 Faz ServisДокумент79 страницSalon Tipi 3 Faz ServisaydintarakОценок пока нет

- TT2 P&ID 2015.01.20 AllДокумент36 страницTT2 P&ID 2015.01.20 AllCARLOS OLIVEROS100% (1)

- Ei 734-031-0029R01 PDFДокумент14 страницEi 734-031-0029R01 PDFOscar RochaОценок пока нет

- Wiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Документ13 страницWiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Dinu Muralidharan MОценок пока нет

- G93 123keДокумент3 страницыG93 123kejclevox100% (1)

- Esquma Eléctrico SencilloДокумент2 страницыEsquma Eléctrico SencilloJorge100% (3)

- Service: ManualДокумент54 страницыService: ManualElseven AkifОценок пока нет

- Multi Zone Outdoors Service ManualДокумент56 страницMulti Zone Outdoors Service Manualcmorley505775% (4)

- Basis of Engine ControlДокумент10 страницBasis of Engine ControlmihajlovichenkelОценок пока нет

- Renr1297renr1297 Sis (1) EngineДокумент2 страницыRenr1297renr1297 Sis (1) EngineAmber SmithОценок пока нет

- Reliability Based MaintenanceДокумент35 страницReliability Based MaintenanceManoj PaneriОценок пока нет

- Plano Electrico Del MotorДокумент2 страницыPlano Electrico Del MotorSINTRONONIREYNA0% (1)

- Cable Schedule For MCC To PLC&RIO Panel-RДокумент22 страницыCable Schedule For MCC To PLC&RIO Panel-RJagadeesan ShanmugamОценок пока нет

- ABB Battery ChargerДокумент56 страницABB Battery ChargercentralautomacaoОценок пока нет

- Supplier Documents - Petrobras (01 June 2012)Документ8 страницSupplier Documents - Petrobras (01 June 2012)Rapha SuzartОценок пока нет

- Opel Corsa DiagnosticoДокумент4 страницыOpel Corsa DiagnosticoVitor Roberto MoreiraОценок пока нет

- Cat - Dcs.sis - Controller 3412 XДокумент2 страницыCat - Dcs.sis - Controller 3412 XKariem R Noweer67% (3)

- Cooling Load EstimationДокумент69 страницCooling Load EstimationkarimОценок пока нет

- Hướng Dẫn Lắp Đặt Máy Treo Tường Cục Bộ FujitsuДокумент18 страницHướng Dẫn Lắp Đặt Máy Treo Tường Cục Bộ FujitsuDoan Tien Do100% (1)

- Edgington Oil Id 800264 An 471225 Eng EvalДокумент14 страницEdgington Oil Id 800264 An 471225 Eng Evalapi-242947664Оценок пока нет

- 01 General Master Index For TenderДокумент12 страниц01 General Master Index For TenderSubhojit AdhikaryОценок пока нет

- (BizhubPRESS C8000) ICP List Ver.1.1 (En) GДокумент6 страниц(BizhubPRESS C8000) ICP List Ver.1.1 (En) GEledu Mdq100% (1)

- KR - MV IDU - R410A - 5060Hz - MFL61741606 - 0CVP0-03A (110503)Документ388 страницKR - MV IDU - R410A - 5060Hz - MFL61741606 - 0CVP0-03A (110503)eselcosacОценок пока нет

- ElectriSCAN Sample ReportДокумент22 страницыElectriSCAN Sample ReportAnonymous Wu6FDjbОценок пока нет

- BOP - DCS IO List Rev 2.5 (08.04.2014)Документ535 страницBOP - DCS IO List Rev 2.5 (08.04.2014)prateek0291Оценок пока нет

- A320 Air PDFДокумент1 страницаA320 Air PDFStephanie Johnson100% (1)

- BOP - DCS IO List Rev 2.4 (27.01.2014)Документ566 страницBOP - DCS IO List Rev 2.4 (27.01.2014)vinospaceshuttleОценок пока нет

- 2 of 25 - NIT For PGR at NFL Vijaipur - Tech NITДокумент72 страницы2 of 25 - NIT For PGR at NFL Vijaipur - Tech NITsudhirkumar99Оценок пока нет

- Pin-Out of Socket 3 Patch Area in C16+Ef21 M2 Back Plane S5011Документ3 страницыPin-Out of Socket 3 Patch Area in C16+Ef21 M2 Back Plane S5011amanurrahmanОценок пока нет

- O & M Manual + As-Built PDFДокумент379 страницO & M Manual + As-Built PDFthaslim007Оценок пока нет

- Accu FcuДокумент2 страницыAccu FcuKuzin09Оценок пока нет

- Calculation For Technical Water Supply System PDFДокумент9 страницCalculation For Technical Water Supply System PDFVõ Duy GiaОценок пока нет

- 120H and 135H Motor GraderДокумент2 страницы120H and 135H Motor GraderMarvin Melendez Vanegas100% (4)

- Exc Cat #20 312Документ2 страницыExc Cat #20 312Washington Santamaria100% (1)

- Hvac CalculationДокумент7 страницHvac CalculationPrasanna kumar subudhiОценок пока нет

- SC21CL LBP Compressor R404A/R507 220-240V 50Hz: CompressorsДокумент2 страницыSC21CL LBP Compressor R404A/R507 220-240V 50Hz: CompressorsMichel Uribe AОценок пока нет

- China TV Chassis 3Y11Документ29 страницChina TV Chassis 3Y11dl1476Оценок пока нет

- Electronics Soalan Measurement MySkills Akhir 2011Документ14 страницElectronics Soalan Measurement MySkills Akhir 2011Afdzam AzuraОценок пока нет

- Pump CalculationДокумент20 страницPump Calculationcoolsummer1112143100% (1)

- Ea 682808 001 R05Документ7 страницEa 682808 001 R05anbarasusivaprakasam100% (1)

- Dwa 125RДокумент35 страницDwa 125RGuillermo HernandezОценок пока нет

- DTC P0505 Idle Control System Malfunction: Circuit DescriptionДокумент3 страницыDTC P0505 Idle Control System Malfunction: Circuit DescriptionRC VilledaОценок пока нет

- MKV HMI HardwareДокумент20 страницMKV HMI HardwarehassanaagibОценок пока нет

- Reference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELДокумент5 страницReference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELarunОценок пока нет

- Z Guaman Course-Engine-C9-Caterpillar-Systems-Controls-Components - 2 PDFДокумент71 страницаZ Guaman Course-Engine-C9-Caterpillar-Systems-Controls-Components - 2 PDFfelipe choque100% (1)

- Fujitsu ASYB18LDC - AOYS18LDCДокумент19 страницFujitsu ASYB18LDC - AOYS18LDCPablos Augoustis100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisОт EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Digital Signal Processing Using the ARM Cortex M4От EverandDigital Signal Processing Using the ARM Cortex M4Рейтинг: 1 из 5 звезд1/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IОт EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IОценок пока нет

- GDL Louvre CalculatorДокумент1 страницаGDL Louvre CalculatorAbraham JyothimonОценок пока нет

- (Dewa-98%) Anova-Safety and Secuirty ScoreДокумент6 страниц(Dewa-98%) Anova-Safety and Secuirty ScoreAbraham JyothimonОценок пока нет

- Notes On Work System Concepts1Документ12 страницNotes On Work System Concepts1Abraham JyothimonОценок пока нет

- Survey Works Rev 1Документ12 страницSurvey Works Rev 1Abraham JyothimonОценок пока нет

- Selton's Horse (Posterior Lottery Model)Документ3 страницыSelton's Horse (Posterior Lottery Model)Abraham JyothimonОценок пока нет

- Examples Done On Orthogonal ProjectionДокумент79 страницExamples Done On Orthogonal ProjectionAbraham JyothimonОценок пока нет

- Upper & Lower Contour SetsДокумент12 страницUpper & Lower Contour SetsAbraham JyothimonОценок пока нет

- Sizing of Generators: Abraham Jyothimon, MSC, B.E Senior Electrical Engineer B.K GulfДокумент6 страницSizing of Generators: Abraham Jyothimon, MSC, B.E Senior Electrical Engineer B.K GulfAbraham JyothimonОценок пока нет

- Adaptaflex - Price ListДокумент42 страницыAdaptaflex - Price ListAbraham Jyothimon100% (1)

- Elec - HV LV SwitchroomsДокумент1 страницаElec - HV LV SwitchroomsAbraham JyothimonОценок пока нет

- Well FoundationДокумент12 страницWell FoundationNivedita Godara C-920Оценок пока нет

- Culvert ManualДокумент124 страницыCulvert Manualpelika_sueОценок пока нет

- 3 Stage and 5 Stage ARMДокумент4 страницы3 Stage and 5 Stage ARMRaj HakaniОценок пока нет

- Cài đặt phần mềm Nessus trên backtrackДокумент8 страницCài đặt phần mềm Nessus trên backtrackthanglxОценок пока нет

- New Text DocumentДокумент2 страницыNew Text DocumentNaj Kriztopher NoicnamaracОценок пока нет

- Art Socs ReportДокумент24 страницыArt Socs ReportTracyAnne JavierОценок пока нет

- GPRS Data ProtocolДокумент25 страницGPRS Data ProtocolDaniel VitorinoОценок пока нет

- 1-Introduction To Soil Mechanics (Introduction)Документ57 страниц1-Introduction To Soil Mechanics (Introduction)Farhat Iqbal Malik100% (1)

- GRI 8450-3 Data SheetДокумент4 страницыGRI 8450-3 Data SheetJMAC SupplyОценок пока нет

- Lecture Rearing House and Rearing Appliances of Mulberry Silkworm, Methods of Disinfection and HygieneДокумент13 страницLecture Rearing House and Rearing Appliances of Mulberry Silkworm, Methods of Disinfection and HygieneVIVEK SUTARОценок пока нет

- ACreferencias BibliográficasДокумент3 страницыACreferencias BibliográficasSenialsell Lains GuillenОценок пока нет

- As 2192-2002 Sterilizers - Steam - Downward-DisplacementДокумент8 страницAs 2192-2002 Sterilizers - Steam - Downward-DisplacementSAI Global - APACОценок пока нет

- Activity AnthropometricsДокумент1 страницаActivity AnthropometricsRechaina GwenОценок пока нет

- Rawl Bolts and CapacityДокумент2 страницыRawl Bolts and Capacitykevinisonline0% (1)

- Beumer HD Gurtbecherwerk GBДокумент8 страницBeumer HD Gurtbecherwerk GBrimarima2barОценок пока нет

- Chapter 1Документ7 страницChapter 1ErraОценок пока нет

- Daftar Harga Bahan Bangunan & Upah Kerja: Pemerintah Kabupaten Pasuruan Dinas Cipta KaryaДокумент274 страницыDaftar Harga Bahan Bangunan & Upah Kerja: Pemerintah Kabupaten Pasuruan Dinas Cipta KaryaHilda Isfanovi100% (6)

- Bo ConceptsДокумент12 страницBo ConceptsshaanviОценок пока нет

- Two Way SlabДокумент9 страницTwo Way SlabMehul Paþel100% (1)

- Oracle REST Data ServicesДокумент38 страницOracle REST Data ServicesMuhammad Sohail100% (1)

- Vidhan BhavanДокумент10 страницVidhan Bhavanaastha545Оценок пока нет

- Manual HLB 860 EnglishДокумент14 страницManual HLB 860 EnglishAlexandra UrruelaОценок пока нет

- KSB AmamixДокумент84 страницыKSB AmamixRicardo BarrosОценок пока нет

- Other Art Forms: Industrial Art (Raw Materials Forming SignificantДокумент10 страницOther Art Forms: Industrial Art (Raw Materials Forming Significantjohn mark dionidoОценок пока нет

- CFM M MUX - Tech DescriptionДокумент63 страницыCFM M MUX - Tech DescriptionFrankJoeОценок пока нет

- Free Download VOLVO PROSIS Part & Repair 2015 PatchДокумент4 страницыFree Download VOLVO PROSIS Part & Repair 2015 PatchEngematsu KomatsuОценок пока нет

- Technical Drawing StandardsДокумент20 страницTechnical Drawing StandardsGeorge Maliaris57% (14)

- PC-ITP-001 - Backfilling and ExcavationДокумент2 страницыPC-ITP-001 - Backfilling and ExcavationHusam zayedОценок пока нет

- Metalcraft Structural Technical Manual Feb 2011Документ51 страницаMetalcraft Structural Technical Manual Feb 2011John TaylorОценок пока нет

- Interoperability of Juniper and Cisco DevicesДокумент11 страницInteroperability of Juniper and Cisco DevicesvasanthmeОценок пока нет