Академический Документы

Профессиональный Документы

Культура Документы

Ethylene Propylene

Загружено:

Siva KumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ethylene Propylene

Загружено:

Siva KumarАвторское право:

Доступные форматы

10.5.

1 Ethylene

Properties

Ethylene (H

2

CCH

2

) is the largest volume

building block for many petrochemicals and end

products such as plastics, resins, fibres, etc. The

IUPAC (International Union of Pure and Applied

Chemistry) name is ethene.

Physical properties

Ethylene is a colourless, flammable gas with a

slight odour. Table 1 summarizes its physical,

thermodynamic and transport properties; additional

values are available in many references (Harrison and

Douslin, 1971; Starling, 1973; Bonscher et al., 1974;

Vargaftik, 1975; Douslin and Harrison, 1976; TRC,

Thermodynamics Research Center, 1986; Jacobsen,

1988).

Chemical properties

Ethylene is a very reactive intermediate and,

therefore, is involved in many chemical reactions. The

chemistry of ethylene is based mainly around its

double bond, which reacts readily to form saturated

hydrocarbons, their derivatives and polymers. It is a

planar molecule with a carbon-carbon bond distance

of 1.34 , which is shorter than the CC bond

(s bond) length of 1.53 found in ethane, a saturated

molecule.

In ethylene, the carbon is in its sp

2

-hybridized

state. Each carbon uses two of its sp

2

-hybridized

orbitals to form s bonds with two hydrogen atoms. The

remaining sp

2

orbitals one on each carbon overlap

to form a s bond connecting the two carbons. The two

unhybridized 2p orbitals one from each carbon

overlap to give a p molecular orbital. Therefore, the

double bond in ethylene is composed of a s

component and a p component.

Based on the orbital theory of molecules, 2p

orbitals overlap to give p and p

*

orbitals; in ethylene,

however, only the p orbital is occupied at normal

conditions. Electrons in the p bond are held less

tightly and more easily polarized than electrons in a s

bond. The carbon-carbon double bond (sp) energy

is 611 kJ/mol, which is less than twice the CC bond

(s) dissociation energy of 736 kJ/mol found in ethane.

The CH bond dissociation energy is 451 kJ/mol

and the approximate acidity as measured by the

dissociation constant K

a

is 10

45

. Ethylene reacts with

electrophilic reagents like strong acids (H

), halogens,

and oxidizing agents, but not with nucleophilic

reagents such as Grignard reagents and bases. For the

fundamental mechanisms of these reactions, consult

the following references (Sykes, 1975; Carey, 1987).

Some important reactions are discussed below. Other

reactions not included in the following overview are

primarily of academic interest and comprehensive

discussions are provided in various references (Miller,

1969; Kniel et al., 1980).

Polymerization

Polymerization is one of the main reactions of

ethylene, and polyethylene ranks as its major

polymer: nCH

2

CH

2

( CH

2

CH

2

)

n

. Very

high-purity ethylene (99.9%) is polymerized under

specific conditions of temperature and pressure in

the presence of an initiator or catalyst. This is an

exothermic reaction, and both homogeneous (radical

or cationic) and heterogeneous (solid catalyst)

initiators are used (Miller, 1969; Reichert and

Geiseler, 1983; Ulrich, 1988). The products range

551 VOLUME II / REFINING AND PETROCHEMICALS

10.5

Ethylene and propylene

H

H

H

H

C C

from a few hundred to a few million atomic mass

unit in molecular weight.

Four types of basic reaction systems are of

commercial importance in the production

of polyethylene:

High-pressure (60-350 MPa) free radical

polymerization using oxygen, peroxide or other

strong oxidizers as initiators at temperatures of up

to 350C. These produce Low-Density

PolyEthylene (LDPE), a highly branched polymer

with densities from 0.91 to 0.94 g/cm

3

.

Low-pressure (0.1-20 MPa) polymerization at

temperatures of 50 to 300C using heterogeneous

catalysts such as molybdenum oxide or chromium

oxide supported on inorganic carriers. These are

used to produce High-Density PolyEthylene

552 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

Property Value

Molecular weight, u 28.0536

Triple point

Temperature, C 169.164

Pressure, kPa 0.12252

Latent heat of fusion, kJ/mol 3.353

Normal freezing point

Temperature, C 169.15

Latent heat of fusion, kJ/mol 3.353

Normal boiling point

Temperature, C 103.71

Latent heat of vaporization, kJ/mol 13.548

Density of liquid

mol/l 20.27

d

4

104

0.566

Specific heat of liquid, J/molK 67.4

Viscosity of the liquid, mPas (=cP) 0.161

Surface tension of the liquid, mN/m (=dyn/cm) 16.4

Specific heat of ideal gas at 25C, J/molK 42.84

Critical point

Temperature, C 9.194

Pressure, kPa 5,040.8

Density, mol/l 7.635

Compressibility factor 0.2812

Gross heat of combustion at 25C, MJ/mol 1.411

Limits of flammability at atmospheric pressure and 25C

Lower limit in air, mol% 2.7

Upper limit in air, mol% 36.0

Auto ignition temperature in air at atmospheric pressure, C 490

Pitzers acentric factor 0.278

Dipole moment, D 0.0

Standard enthalpy of formation at 25C, kJ/mol 52.3

Standard Gibbs energy of formation at 25C for ideal gas at atmospheric pressure, kJ/mol 68.26

Solubility in water at 0C and 101 kPa, ml/ml H

2

O 0.226

Speed of sound at 0C and 409.681 kPa, m/s 224.979

Standard entropy of formation, J/molK 219.28

Standard heat capacity, J/molK 42.86

Table 1. Physical properties of ethylene

(HDPE), which is more linear in nature, with

densities of 0.94 to 0.97 g/cm

3

.

Low-pressure polymerization via ionic catalysts,

using Ziegler catalysts (aluminum alkyls and

titanium halides).

Low-pressure polymerization with Ziegler catalysts

supported on inorganic carriers.

A notable development in ethylene polymerization

is the simplified low-pressure LDPE process. The

pressure range is 0.7-2.1 MPa with temperatures less

than 100C. The reaction takes place in the gas phase

instead of the liquid phase as in the conventional

LDPE technology. These new technologies require

ultra-high-purity ethylene and many can use

metallocene catalysts (Bennett, 1999). The physical

properties of the polymers can be modified by

copolymerizing ethylene with other chemicals like

higher olefins, maleic anhydride, etc. Generally,

linearity provides strength, and branching provides

toughness to the polymer.

Oxidation

Oxidizing ethylene produces ethylene oxide:

CH

2

CH

2

0.5O

2

The reaction is carried out over a supported

metallic silver catalyst at 250-300C and 1-2 MPa.

To produce ethylene glycol, ethylene oxide is

further reacted with ethylene in the presence of excess

water and an acidic catalyst at low temperatures

(50-70C), followed by hydrolysis at relatively high

temperatures (140-230C) and moderate pressures

(2-4 MPa). At low water concentration, polyethylene

glycol is obtained.

Acetaldehyde can be obtained by the Wacker

process in which a homogeneous CuCl

2

/PdCl

2

system

is used for the oxidation:

CH

2

CH

2

0.5O

2

CH

3

CHO

The reaction is carried out in a bubble column at

120-130C and 0.3 MPa. Palladium chloride is

reduced to palladium during the reaction and then is

reoxidized by cupric chloride. Oxygen converts the

reduced cuprous chloride to cupric chloride.

Vinyl acetate is obtained by the vapour phase

oxidation of ethylene with acetic acid, which is

obtained by oxidation of acetaldehyde:

CH

2

CH

2

CH

3

COOH0.5O

2

CH

2

CHOCOCH

3

H

2

O

This process employs a palladium on carbon,

alumina or silica-alumina catalyst at 175-200C and

0.4 to 1.0 MPa.

Addition

Many addition reactions with ethylene are

important in the chemical industry.

Halogenation-hydrohalogenation is used to produce

various halides of ethylene, such as ethylene

dichloride, which is further cracked to produce

vinyl chloride, the monomer required for the

production of polyvinyl chloride (PVC):

CH

2

CH

2

Cl

2

ClCH

2

CH

2

Cl

Vinyl chloride is obtained by the

dehydrochlorination of 1,2-dichloroethane in the gas

phase (500-600C and 2.5-3.5 MPa):

ClCH

2

CH

2

Cl

CH

2

CHClHCl

Oxychlorination of ethylene is carried out in a

fixed or fluidized bed at 220C, with a suitable solid

chloride catalyst:

2CH

2

CH

2

O

2

4HCl

2ClCH

2

CH

2

Cl2H

2

O

Trichloroethylene and tetrachloroethylene are

important organic solvents that are produced by the

further chlorination of 1,2-dichloroethylene in the gas

phase, with the simultaneous dehydrochlorination in

the presence of a suitable chloride catalyst.

Oligomerization is used to produce a-olefins and

linear primary alcohols. Hydration of ethylene

produces ethanol.

Ethylbenzene, the precursor of styrene, is produced

from benzene and ethylene. The ethylation of benzene

is carried out in several different ways. In the older

technologies, the reaction is conducted in the liquid

phase in the presence of a Friedel-Crafts catalyst

(AlCl

3

, BF

3

, FeCl

3

). The new processes all use zeolite

catalysts. ABB Lummus Global and UOP (Universal

Oil Products) commercialized a process for liquid

phase alkylation based on a zeolite catalyst (Horigome

et al., 1991). Badger and Mobil offer a similar process

and also have a vapour phase alkylation process using

zeolite catalysts (Lewis and Dwyer, 1977). A process

based on a catalytic distillation reactor also has been

commercialized using zeolites (Ercan et al., 1998).

Almost all ethylbenzene produced is used for the

manufacture of styrene, which is obtained by

dehydrogenation in the presence of a suitable catalyst

at 550-640C and relatively low pressures

(Lummus Crest, 1988).

Ethanol is manufactured from ethylene by direct

catalytic hydration over a H

3

PO

4

/SiO

2

catalyst at

process conditions of 300C and 7.0 MPa (diethyl

ether is formed as a by-product):

CH

2

CH

2

H

2

O

C

2

H

5

OH

Ethylene can also be reacted to form propylene via

the metathesis of butene and ethylene (see below). The

553 VOLUME II / REFINING AND PETROCHEMICALS

ETHYLENE AND PROPYLENE

O

CH

2

CH

2

butenes can be taken from steam cracker effluent or a

refinery Fluid Catalytic Cracking (FCC) unit. Ethylene

dimerization to butene can also be utilized, giving a

direct conversion route of ethylene to propylene. This

route is expected to become more prevalent as the

propylene demand grows and ethylene production

from ethane pyrolysis becomes more common.

Biological properties

Ethylene is slightly more potent as an anesthetic

than nitrous oxide, but the smell of ethylene causes

choking; therefore, it is no longer used as an anesthetic

agent. Diffusion through the alveolar membrane is

sufficiently rapid for equilibrium to be established

between the alveolar and the pulmonary capillary

blood with a single exposure. Ethylene is held in both

cells and plasma, in simple physical solution. The

lipoid stroma of the red blood cells absorbs ethylene,

but it does not combine with hemoglobin. It is

eliminated from the body unchanged primarily by

the lungs and most elimination is complete within

three minutes of administration.

Ethylene has been used in the controlled ripening

of various fruits and vegetables since the 1930s. It

causes the bleaching of green tissue, gives rise to foliar

abscission, suppresses certain types of dormancy, and

promotes cellular swelling. For further information on

this subject, consult references (Miller, 1969).

Manufacture via thermal cracking

Thermal cracking of hydrocarbons is the major

route for the industrial production of ethylene. The

chemistry and engineering of thermal cracking has

been reviewed by Kniel et al. (1980), Froment (1981),

Albright et al. (1983), Raseev (2003), and also in an

earlier review by Sundaram et al. (1994). In thermal

cracking, valuable by-products including propylene,

butadiene, and benzene are produced. Less valuable

methane and fuel oil are also produced in significant

quantities. An important parameter in the design of

commercial thermal cracking furnaces is the

selectivity to produce the desired products.

Mechanism, kinetics, conversion

The thermal cracking of hydrocarbons proceeds via

a free-radical mechanismas proposed by Rice (1931).

Since that discovery, many reaction schemes have been

proposed for various hydrocarbon feeds (Allara and

Edelson, 1975; Sundaram and Froment, 1978b; Allara

and Shaw, 1980; Dente and Ranzi, 1983; Willems and

Froment, 1988a, 1988b; Depeyre et al., 1989). Since

radicals are neutral species with a short life, their

concentrations under reaction conditions are extremely

small. Therefore, the integration of continuity equations

involving radical and molecular species requires special

integration algorithms (Gear, 1971). To overcome these

numerical difficulties, various approximate methods

have been introduced in the past, such as pseudo

steady-state approximation for radicals (Semenov, 1959;

Boudart, 1968), and the errors associated with such

techniques have been discussed by Sundaram and

Froment (1978a). With modern computing power, such

approximate methods are no longer required.

Thermal cracking is a complex reaction and

involves many thousands of chain reactions even for

simple ethane cracking (Sundaram and Froment,

1978b; Dente and Ranzi, 1983); however, the reactions

can be classified into several known groups (Table 2).

During initiation, two radicals are produced for

each paraffin molecule. For example:

C

2

H

6

2CH

3

Only a small fraction of reactant is involved in this

step. When naphthenes are involved, diradicals are

produced. For aromatics with side chains, H radicals

are produced. Typically, this is the rate-controlling step

under normal commercial operating conditions.

In propagation, many types of reactions are

involved, including hydrogen abstraction, methyl

abstraction, radical addition, radical decomposition

and radical isomerization.

In hydrogen abstraction, a hydrogen radical reacts

with a molecule (primarily a paraffin) and produces a

hydrogen molecule and a radical. In methyl

abstraction, a methyl radical reacts to produce a

radical and methane. Similar reactions with other

radicals (ethyl and propyl) can also occur.

In radical addition, some radicals like H, CH

3

,

etc., are added to olefins (or diolefins) to form heavier

radicals. Radical decomposition is one of the most

important types of reactions. In this case, a larger

radical decomposes to an olefin and a smaller radical.

Radicals usually decompose at the beta-position of the

radical centre where the CC bond is the weakest. In

the case of naphthenes and aromatics, this may not be

the case and a CH bond may be the weakest.

Finally, radical isomerization frequently occurs for

large radicals and explains to a large extent the

observed product distribution (i.e. many isomers).

Radical termination is the reverse of initiation.

In addition to radical reactions, molecular and

surface reactions also occur.

According to Laidler (1965), radicals are classified

as b and m radicals. b radicals (e.g. H, CH

3

) undergo

only addition reactions and do not decompose. m radicals

(e.g. C

4

H

9

) undergo mainly decomposition. Some

radicals, such as C

2

H

5

, can act as both b and m radicals.

The kinetics of thermal cracking is not simple and

involves a series of elementary reactions. The order of

554 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

the elementary reactions almost follows molecularity.

Energetically active small radicals, like H and C

2

H

3

,

may involve a third body collision. Based on the main

initiation, propagation, and termination reactions, one

can deduce the overall order of the reaction for the

decomposition of simple molecules like ethane

(Laidler, 1965).

Most paraffin decomposition follows a first order

rate-of-reaction, while olefin decomposition follows a

higher order rate-of-reaction. With the advent of

modern computers, kinetic models for thermal

cracking of hydrocarbons involving a few hundred to

a few thousand reactions and their mass and energy

balance equations can be solved in a few minutes. The

following references provide a detailed review on this

topic (Allara and Edelson, 1975; Sundaram and

Froment, 1978b; Dente et al., 1979; Allara and Shaw,

1980; Dente and Ranzi, 1983; Willems and Froment,

1988a, 1988b; Depeyre et al., 1989; Froment, 1992).

The kinetic parameters of typical reactions occurring

in thermal cracking are given in Table 2.

The terms conversion or severity are used to

measure the extent of cracking. Conversion (X) can be

easily measured for a single component feed:

component inletcomponent outlet

X

11111212111111111

component inlet

where inlet and outlet quantities are measured in

weight units.

When a mixture is cracked, one or more

components in the feed may also be formed as

products. For example, in the co-cracking of ethane

and propane, ethane is formed as a product of

propane cracking and propane is formed as a

product of ethane cracking. Therefore, the outlet

term in the above equation contains the contribution

of formation from other feed components and thus

does not represent a true conversion. For simple

mixtures, the product formation can be accounted

for and approximate true conversions can be

calculated (Sundaram and Fernandez-Baujin, 1988).

For liquid feeds like naphtha, it is impractical, if not

impossible, to calculate the true conversion. Based

on measured feed components, one can calculate a

weighted average conversion (

X) as proposed by van

Camp et al. (1985):

X

W

i

X

i

where X

i

is the conversion for the i

th

feed component

555 VOLUME II / REFINING AND PETROCHEMICALS

ETHYLENE AND PROPYLENE

Frequency factor* Activation energy

(thousands of t) (kJ/mol)

A) Initiation

C

2

H

6

2CH

3

4.010

16

366.1

B) Propagation

H-abstraction

C

2

H

6

H

C

2

H

5

H

2

1.010

11

40.6

Methyl abstraction

C

2

H

6

CH

3

C

2

H

5

CH

4

Radical addition

C

2

H

4

H

C

2

H

5

1.010

10

6.3

Radical decomposition

C

2

H

5

C

2

H

4

H 3.210

13

167.4

Radical isomerization

1-C

4

H

9

2-C

4

H

9

5.210

14

171.5

C) Termination

2C

2

H

5

n-C

4

H

10

4.010

8

0

D) Molecular reactions

C

2

H

4

C

4

H

6

cyC

6

H

10

3.010

7

125.5

E) Surface reactions

C

2

H

3

T

C

2

H

2

HT 2.010

9

131.8

Table 2. Examples of reactions occurring in thermal cracking

T= third body collision molecule

* For first order reactions the unit is s

1

and for second order reactions lmol

1

s

1

. These are typical values

and W

i

is the weighting factor (weight or mol fraction

usually).

Designers have employed other practical methods

such as a key component conversion (e.g. n-pentane),

kinetic severity factor (Zdonik and Green, 1970), or

molecular collision parameter (Lohr and Schwab,

1979) to represent severity. Alternatively, molecular

weight of the complete product distribution has been

used to define conversion for liquid feeds:

M

f

23223

1

M

e

X

1111

M

f

23223

1

24.5

In the equation, M

f

and M

e

are the molecular

weight of the feed and of the dry (steam-free) effluent

respectively. Instead of molecular weight, hydrogen

content in the C

5

product is also used:

Y1

X

1111

CY1

In the equation, Y=(H6)/(HF6), where HF is

feed hydrogen content in wt%, H is hydrogen content

in the C

5

product in wt%, and C is a constant for any

given feed.

Instead of conversion, some producers prefer to use

other identifications of severity, including coil outlet

temperature, propylene-to-methane ratio, propylene-

to-ethylene ratio, or cracking severity index (Ross and

Shu, 1979). Of course, all these definitions are

somewhat dependent on feed properties and most are

also dependent on the operating conditions.

When simple liquids like naphtha are cracked,

it may be possible to determine the feed

components by Gas Chromatography combined

with Mass Spectrometry (GC-MS; van Camp et

al., 1985); however, when gas oil is cracked,

complete analysis of the feed may not be possible.

Therefore, some simple definitions are used to

characterize the feed. When available, paraffins,

olefins, naphthenes, and aromatics (PONA)

content serves as a key property. When PONA is

not available, the Bureau of Mines Correlation

Index (BMCI) is used:

48,640

BMCI

1111

473.7g456.8

MABP

where MABP is the Molal Average Boiling Point

(expressed in K) and g is the specific gravity of the

feed.

Other properties like specific gravity, ASTM

distillation, viscosity, refractive index, Conradson

carbon, and bromine number are also used to

characterize the feed. Even nuclear magnetic

resonance spectroscopy has been used to characterize

heavy feedstocks.

Commercial furnaces

Thermal cracking of hydrocarbons is

accomplished in tubular reactors commonly known

as cracking furnaces, crackers, cracking heaters,

etc. Several engineering contractors, including

ABB Lummus Global, KBR, Linde, Stone and

Webster (a Shaw Group Company), and Technip

offer cracking furnace technology. Two cracking

furnaces may share a common stack, and the

height of the heater may vary from 30 to 50 m.

Before the 1960s, cracking tubes were arranged in

horizontal rows in a radiant chamber, leading to

low ethylene capacity (20,000 mta, metric tonnes

per annum). Modern designs use tubes arranged in

vertical rows, providing superior mechanical

performance and higher capacity. Today, the

capacity of a single cell furnace is well over

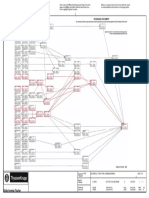

150,000 mta. Fig. 1 provides a sketch of a typical

furnace.

Reaction

The reaction proceeds in the pyrolysis coils of

the radiant section of the furnace. Since coke is

also formed during pyrolysis, steam is added as

diluent to the feed. The steam minimizes the side

reaction forming coke and also improves the

selectivity to olefins by lowering the hydrocarbon

partial pressure. The temperature of the

hydrocarbon and steam mixture entering the

radiant chamber (known as the crossover

temperature) is 500 to 700C. Lower temperatures

are used for heavy feeds like Atmospheric Gas Oil

(AGO) and Vacuum Gas Oils (VGOs) to minimize

coking in the convection section, and higher

temperatures are used for light gases like ethane

and propane, which are more refractory. Some

incipient cracking can start as low as 400C.

However, for light gases incipient conversion is

quite low. Depending upon the residence time in

the radiant coil and the required feed severity, the

coil outlet temperature is typically maintained

between 775 and 950C.

The combination of low residence time and low

hydrocarbon partial pressure produces high

selectivity to olefins at a constant feed conversion.

In the 1960s, the residence time was 0.5 to 0.8 s;

by the 1990s, the residence time was typically 0.1

to 0.2 s. Typical pyrolysis heater radiant coil

characteristics are given in Table 3. The typical

temperature, pressure, conversion, and residence

time profiles across the reactor for naphtha

cracking are illustrated in Fig. 2.

556 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

Cracking reactions are endothermic (1,800 to

2,800 kJ/kg of ethylene produced) with heat

supplied by firing fuel gas and/or fuel oil in

sidewall or floor burners. Sidewall burners usually

give uniform heat distribution, but the capacity of

each burner is limited (0.1-1 MW) and hence 40 to

200 burners are required in a single furnace. With

modern floor burners, also called hearth burners,

uniform heat flux distribution can be obtained for

coils as high as 13.1 m, which are used extensively

in newer designs. The capacity of these burners is

considerably large (1-4 MW) and thus only a few

burners are required. The selection of burners

depends on the type of fuel (gas and/or liquid), the

source of combustion air (ambient, preheated or

gas turbine exhaust), and the required NO

x

levels.

The reaction mixture exiting the furnace is

quickly cooled in quench coolers called Transfer

Line Exchangers (TLEs). In earlier designs, direct

quenching (spraying water or oil) was used for

most liquid feeds. Today, almost all designs employ

indirect quenching, which generates valuable

high-pressure steam. Direct quenching is used

only, in some designs, for very heavy feeds.

Single-stage or two-stage cooling is used to

achieve the desired degree of cooling in the TLE.

In the first stage, the process gas is cooled in a

double pipe exchanger or in a shell and tube

exchanger. In the second stage, a shell and tube

exchanger is used to generate additional steam and

sometimes to preheat the feed and dilution steam

mixture. The outlet gas temperature from the TLE

varies from 350 to 650C, depending upon the

feedstock and the design. If the reaction mixture is

not cooled quickly, olefin selectivity is reduced due

to the many side reactions taking place in this

557 VOLUME II / REFINING AND PETROCHEMICALS

ETHYLENE AND PROPYLENE

1

2

3

4

5

7

8

9

10

11

6

14

13

12 16

15

17

18

19

1- stack

2- induced draft fan

3- upper preheat coil

4- BFW preheat

5- SHP steam superheat coil

6- desuperheater BFW injection

7- lower mixed preheat coil

8- radiant coil

9- floor burner

10- wall burner

11- crossover manifold

12- primary TLE

13- SHP saturated steam line

14- steam drum

15- transfer line valve

16- secondary TLE

17- decoke valve

18- decoke bypass valve

19- decoke pot

BFW

convection

section

radiant

section

hydrocarbon feed

dilution

steam

SHP

steam

gaseous

fuel

BFW: Boiler Feed Water

SHP: Super High Pressure

Fig. 1. Typical heater configuration.

Number of coils 2-176

Coil length, m 9-80

Inside coil diameter, mm 30-200

Process gas outlet temperature, C 750-950

Clean coil metal temperature, C 900-1,080

Maximum metal temperature, C 1,040-1,150

Average heat absorption, kW/m

2

external area 50-120

Bulk residence time, s 0.1-0.6

Coil outlet pressure, kPa 150-275

Clean coil pressure drop, kPa 10-200

Ethylene capacity, mta 20,000-250,000

Table 3. Pyrolysis heater radiant coil characteristics

(single heater range)

zone. After the TLE, further cooling is achieved by

directly quenching the furnace effluent with

quench oil. The cooled furnace effluent then

proceeds to the recovery section for further

separation.

Thermal efficiency

Since only a percentage between 35 and 50% of

fired duty is absorbed in the radiant section, the

flue gas leaving the radiant chamber contains

considerable energy, which can be extracted

efficiently in the convection section of the furnace.

In the convection section, the feed is preheated

along with dilution steam to the desired crossover

temperature. Residual heat is recovered by

generating steam. The overall thermal efficiency of

modern furnaces exceeds 93%, and a value of 95%

is not uncommon. Modern heaters generate

super-high pressure steam (11 MPa) compared to

old generation heaters, which produced 4-6 MPa of

steam. Since the steam produced in the heaters is

used to drive turbines in the recovery section,

super-high pressure steam is preferred due to

higher efficiency.

The convection section is a series of cross flow

exchangers with flue gas on one side and process

fluids on the tube side. Since mainly gas-to-gas heat

transfer is involved, fin tubes are employed where

practical to improve the heat transfer rate. The

metallurgy of the tubes varies from carbon steel to

high temperature alloy depending on the service.

When high overall efficiency is desired, condensation

of acidic flue gases must be taken into account in the

selection of materials. Fouling of heat transfer surfaces

both inside and outside is unavoidable. Outside fouling

is cleaned by steam lancing and inside fouling is

usually cleaned by burning with air (and steam) or by

mechanical methods.

In new plant designs, cogeneration of electricity

and steam is economically attractive. Depending

upon the plant capacity, gas turbines (15 to 70

MW) are used to generate electric power. These

turbines usually burn fuel gas with over 200%

excess air. Therefore, the exhaust gas is not only

hot, but also rich in oxygen. Instead of directly

generating steam from the exhaust gas by using

waste heat boilers, the gas is fed to the cracking

heaters as a source of combustion oxygen.

Typically, the exhaust gas temperature is 400 to

590C with an oxygen content of 14 mol% or

more. Typical energy savings of 10 to 30% are

reported (Albano et al., 1991; Cooke and Parizot,

1991). Using hot combustion air requires special

ducting and hence the investment cost of the heater

is slightly higher.

To reduce fuel consumption, air preheat has

been used in some plants. Flue gas leaving the

furnace stack passes through an air preheater and

the preheated air is supplied to the burners. By

using mostly hearth burners, the ductwork and the

investment cost can be minimized with air preheat

and gas turbine exhaust. It is also possible to

operate with 100% wall fired furnaces, which has

been proven in commercial operation (Albano

et al., 1991). Economizers also have been used to

increase the thermal efficiency.

Environment

Stringent environmental laws require that the

emission of nitrogen oxides (NO

x

) and sulphur

oxides from furnaces be drastically reduced. In

many parts of the world, regulations require NO

x

levels of 70 vol ppm or lower on a wet basis.

Conventional burners usually produce 100 to 150

vol ppm of NO

x

. Many burner vendors now supply

low NO

x

and ultra-low NO

x

burners (40 ppm).

Since NO

x

production depends upon the flame

temperature and quantity of excess air, meeting the

required limits may not be possible through burner

design alone. Many new designs incorporate

558 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

c

o

n

v

e

r

s

i

o

n

(

%

)

conversion

t

e

m

p

e

r

a

t

u

r

e

(

C

)

r

e

s

i

d

e

n

c

e

t

i

m

e

(

s

)

residence time

max wall T

pressure

gas T

0

20

40

60

80

100

600

700

800

900

1,000

1,100

p

r

e

s

s

u

r

e

(

k

P

a

)

150

170

190

210

230

250

0

0.20

0.15

0.10

0.05

coil length (%)

0 20 40 60 80 100

Fig. 2. Conversion, pressure,

temperature and residence

time along the reactor

length for naphtha

cracking.

DeNO

x

units that employ catalytic methods to

reduce the NO

x

level. Platinum-containing

monolithic catalysts are used (Boer et al., 1990).

Each catalyst performs optimally for a specific

temperature range and most of them work properly

at around 400C. Both the American Institute of

Chemical Engineers (AIChE) and the European

Ethylene Producers Association hold regular

meetings and the proceedings contain the current

status of ethylene production and government

regulations. A recent handbook published by John

Zink Company (Baukal Jr., 2001) provides the

fundamentals of burner design and controlling

emissions in a fired heater.

Product distribution

In addition to ethylene, many by-products are

also formed. Typical product distributions for

various feeds from a typical short-residence-time

furnace are shown in Table 4. The product

distribution is strongly influenced by the residence

time, the hydrocarbon partial pressure, the

steam/oil ratio, and the coil outlet pressure.

Generally, the higher the hydrogen content of feed,

the higher the ethylene yield. Normal paraffins

produce more ethylene and propylene than

isoparaffins. Aromatics produce very little ethylene

and propylene. Hydrocracked Vacuum Gas Oil

(HVGO) behaves like naphtha in terms of olefin

production and behaves like vacuum gas oil in

terms of fouling characteristics. This feed is the

unconverted oil from a hydrocracker, rich in

hydrogen but containing polynuclear aromatics.

Natural Gas Liquids (NGLs), also known as field

condensates, are cracked in many plants and

behave almost like a mixture of naphtha and gas

oil. The product distribution is similar to that of

full range naphtha feed except for coking. Since

the end point of NGL is not well defined, the

fouling (or coking) in the convection section and in

the TLE is of concern.

Table 4 (in the eighth and ninth columns) shows

the effect on product distribution of varying

steam/oil ratio for a typical naphtha feed. Although

this table shows the severity as maximum, it is

theoretically possible to further increase the

severity and thus increase the ethylene yield.

Increasing the severity above these practical values

produces significantly more fuel oil and methane

with a severe reduction in propylene yield. The run

length of the heater is also significantly reduced.

Beyond a certain severity level, the ethylene yield

drops (after attaining a maximum); operating near

or beyond this point results in extremely severe

coking.

Kinetic models used for designs

Due to many free radical and molecular

reactions, simplified kinetics was used in the past.

This is no longer necessary with modern

computing power. Laidler (1965) has generalized

the reaction order for overall feed decomposition

based on simple reactions for alkanes. Many

researchers have correlated the overall

decomposition as an n

th

order reaction with most

paraffin molecules following the first order and

most olefin molecules following a higher order.

Fig. 3 shows the first-order rate constant for

paraffins as a function of carbon number. In

general, isoparaffin rate constants are lower than

normal paraffin rate constants. Note that the rate

constants are somewhat dependent upon

conversion due to inhibition effects. That is, the

rate constant often decreases with increasing

conversion and the reaction order is not affected

significantly. This has been explained by

considering the formation of allyl radicals

(Buekens and Froment, 1968). To predict the

product distribution, yields are often correlated as

a function of conversion or other severity

parameters (Fernandez-Baujin and Solomon,

1975). Detailed kinetic models have also been used

(Ranzi et al., 1994; Tomlin et al., 1995).

Instead of radical reactions, models based on

molecular reactions have been proposed for the

cracking of simple alkanes and liquid feeds like

naphtha and gas oil (Hirato and Yosida, 1973;

Sundaram and Froment, 1977a, 1977b; Kumar and

Kunzru, 1985; Zou et al., 1993). However, the

validity of these models is limited and cannot be

extrapolated outside the range with confidence.

559 VOLUME II / REFINING AND PETROCHEMICALS

ETHYLENE AND PROPYLENE

r

a

t

e

c

o

n

s

t

a

n

t

(

s

1

)

a

t

8

0

0

C

0

10

20

30

carbon number

2 4 6 8 10

Z

D

Fig. 3. Overall first order reaction rate constants for paraffin

cracking. Z, Zdonik; D, Davis

(adapted from Froment, 1981).

560 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

Table 4. Product distribution obtained in a short residence time coil at 172 kPa

FEED C

2

H

6

C

3

H

8

n-C

4

H

10

i-C

4

H

10

Light

Full Full Full Light Hydrocracked

naphtha

range range range atmospheric vacuum

naphtha naphtha naphtha gas oil gas oil

Specific gravity 0.662 0.726 0.726 0.726 0.8191 0.852

ASTM, C

IBP

(Initial Boiling Point) 35.1 37.8 37.8 37.8 185.0 360.0

10 vol% 43.5 76.7 76.7 76.7 215.0 382.2

30 vol% 47.3 105.0 105.0 105.0 241.7 417.2

50 vol% 53.2 133.0 133.0 133.0 266.1 443.9

70 vol% 65.8 157.0 157.0 157.0 290.0 472.2

90 vol% 99.2 180.0 180.0 180.0 316.0 508.9

EBP

(End Boiling Point) 148.9 199.0 199.0 199.0 335.0 536.1

BMCI 3.5 12.0 12.0 12.0 23.3 15.6

Paraffins, wt% 100.00 100.00 100.00 100.00 89.60 73.80 73.80 73.80

Naphthenes, wt% 7.70 18.00 18.00 18.00

Aromatics, wt% 2.70 8.20 8.20 8.20

Iso/normal ratio 0.80 1.00 1.00 1.00

Molecular weight, u 30.0 44.0 58.0 58.0 81.0 108.0 108.0 108.0 205.0 425.0

Feed H

2

20.10 18.29 17.34 17.34 16.00 15.25 15.25 15.25 13.93 14.20

Steam/HC,wt/wt 0.30 0.30 0.40 0.40 0.50 0.50 0.50 0.75 0.75 0.75

Conversion 65% 95% 96% 95% Max Max Max Max Max Max

ethylene ethylene propylene ethylene ethylene ethylene

Yields, wt%

H

2

3.93 1.56 1.17 1.31 1.00 0.91 0.75 0.91 0.63 0.65

CH

4

3.82 25.30 21.70 23.80 18.00 15.70 12.60 15.30 11.20 12.60

C

2

H

2

0.43 0.64 0.78 0.90 0.95 0.78 0.43 0.95 0.47 0.33

C

2

H

4

53.00 39.04 39.20 15.50 34.30 30.80 25.50 32.20 26.50 29.00

C

2

H

6

35.00 3.94 3.02 0.55 3.80 3.30 4.30 2.80 3.40 3.70

C

3

H

4

0.06 0.53 1.15 3.55 1.02 1.00 0.56 1.15 0.80 0.95

C

3

H

6

0.89 11.34 15.34 19.30 14.10 14.00 17.00 14.40 13.40 13.10

C

3

H

8

0.17 5.00 0.16 0.33 0.35 0.28 0.45 0.22 0.25 0.24

C

4

H

6

1.19 4.50 4.08 2.70 4.45 4.70 4.50 4.90 5.00 5.00

C

4

H

8

0.18 0.80 1.69 16.15 3.70 3.80 6.50 3.81 3.70 3.40

C

4

H

10

0.22 0.09 4.00 5.00 0.20 0.20 0.80 0.20 0.10 0.07

C

5

0.27 1.61 1.38 1.40 2.10 2.93 4.95 3.10 2.75 1.90

C

6

-C

8

non aromatics 0.39 0.31 1.45 0.35 0.80 1.80 6.40 2.20 1.20 1.40

Benzene 0.37 2.74 2.48 4.03 6.40 6.70 4.00 5.95 6.90 7.30

Toluene 0.08 0.67 0.52 1.63 2.30 4.00 3.80 3.90 3.20 3.65

Xylene + ethyl

benzene 0.00 0.09 0.20 0.41 0.21 1.30 2.20 1.24 1.30 1.10

Styrene 0.00 0.51 0.23 0.42 0.75 0.82 0.65 0.75 0.79 0.65

C

9

-205C 0.00 0.93 0.87 0.86 1.40 1.82 2.16 1.72 2.96 2.90

Fuel oil 0.00 0.40 0.58 1.81 4.17 5.16 2.45 4.30 15.45 12.06

Total 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00

With the introduction of Gears algorithm for

integration of stiff differential equations, the

complete set of continuity equations describing the

evolution of radical and molecular species can be

solved even with a personal computer. There are

many articles dealing with kinetic models based on

free radical reactions (Rice 1931, 1933;

Trotman-Dickenson, 1965; Benson, 1968; Allara

and Edelson, 1975; Sundaram and Froment, 1978b;

Dente and Ranzi, 1983; Dean, 1985; Weast, 1987;

Hillewaert et al., 1988; Ranzi et al., 1994; Pant and

Kunzru, 1996). Some of them even used a

pseudo-steady state approximation for radical

concentrations that is not required. In fact, some

radicals will never reach steady state (Sundaram

and Froment, 1978b).

Run length

Coke is produced as a side product, which

deposits on the radiant coil walls. This limits the

heat transfer to the coils and increases the pressure

drop across the coil. The coke deposition not only

limits the heat transfer, but also reduces the olefin

selectivity. Periodically, the heater must be

decoked. Typical run lengths are 15 to 100 days

between decokings. Prediction of run length of a

commercial furnace is still an art, and various

mechanisms are postulated in literature

(Proceedings [...], 1991-2004). Often heater

maintenance and operation have a more significant

influence on the run length than any other single

variable in the unit. Coke also deposits in the TLE.

The mechanisms for coking in radiant coils and

TLEs appear to be different for different feeds.

From the beginning of 1960s, Lichtenstein

(1964) empirically correlated the coking factor of

the radiant coil to operating conditions.

Fernandez-Baujin and Solomon (1975) assumed

the mass transfer of coke precursors from the bulk

of the gas to the walls was controlling the rate of

deposition. Goossens et al. (1980), Dente and

Ranzi (1983), Plehiers et al. (1990), Kopinke et al.

(1993a, 1993b), and Wauters and Marin (2002)

developed kinetic models based on the chemical

reaction at the wall as a controlling step. Bench

scale data of Sundaram et al. (1981) and others

(Newsome and Leftin, 1980; Trimm and Turner,

1981; Lee et al., 2004) appear to indicate that a

chemical reaction controls. However, flow regimes

of bench scale reactors are so different from the

commercial furnaces that the scale-up of bench

scale results cannot be applied confidently to

commercial furnaces. For example, the coke

deposited on a controlled cylindrical specimen in a

Continuous Stirred Tank Reactor (CSTR) shows

that the deposition rate decreases with time and

attains a pseudo-steady state value (Sundaram et

al., 1981). Though this is achieved in a matter of

minutes in bench scale reactors, it takes a few days

in a commercial furnace.

Initial coke deposition is affected by surface

conditions and is commonly known as catalytic

coke. The steady rate of coking following the

initial catalytic coking is known as thermal coking.

However, the influence of surface conditions on

thermal coking is not yet clear.

Many inhibitors and additives tend to reduce

the coking rate in bench scale units, but no

significant influence has been found in

commercial units. In order to take advantage of

any small benefits, many producers use some sort

of inhibitors mostly sulphur compounds to

suppress coking. Dimethyl disulphide (DMDS) or

other refinery gas containing H

2

S in the range of

typically 50 to 300 ppm is used. These

compounds are used to crack gaseous feedstocks

and sulphur-deficient liquid feedstocks. Usually,

naphtha and gas oil contain more than 100 ppm

sulphur, so sulphur is rarely added for these feeds.

Sulphur addition, at least in ethane cracking,

reduces CO formation and therefore reduces the

load on methanators in the recovery section.

Sulphur is often injected continuously with

hydrocarbon feed, although some producers prefer

to pretreat the reactor with sulphur (usually

higher than 300 ppm) for a few hours before

injecting hydrocarbon feed, and do not use

sulphur during operation. The beneficial effect of

sulphur pretreatment is still subjective. Though

steam acts as a diluent, it also suppresses coke

formation (Lee et al., 2004).

In many instances, the tube metal temperature

controls the run length, although it is not

uncommon that the pressure drop across the coil

which is equally important for gas cracking

limits the run length. Two-pass and single-pass

coils are very sensitive to fireside control (excess

air) and run length can be limited by the pressure

drop across the coil (or critical flow Venturi

pressure ratio used for distributing the flow),

instead of the tube metal temperature limit.

TLE coking is different from radiant coil

cracking. Fernandez-Baujin and Solomon (1975)

claim that condensation of coke precursors

contained in the fuel oil accounts for TLE fouling.

Mass transfer of precursors to the film is assumed

to be the controlling factor. In contrast, Chen and

Vogel (1973) and Dente et al. (1983, 1990) assume

that the chemical reaction is the controlling

mechanism and have proposed a polymerization

561 VOLUME II / REFINING AND PETROCHEMICALS

ETHYLENE AND PROPYLENE

mechanism similar to the Ziegler-Natta

mechanism. Both models work well within the data

range. Based on commercial experience for

hydrocracked vacuum gas-oil feed (Sundaram and

Fernandez-Baujin, 1990), it appears that more than

polymerization, condensation occurs in a TLE. By

way of example, the typical TLE outlet gas

temperatures as a function of time on-stream are

shown in Fig. 4 for various feeds.

TLE fouling for gaseous feedstocks is different

from that for liquid feedstocks. With gas cracking

(especially with ethane), coke deposits on the TLE

inlet tubesheet, but does not significantly build up

inside the tubes. With time, enough coke builds up

that the tubes are partially or fully blocked,

reducing the heat transfer surface and giving rise to

higher outlet temperatures and high-pressure drop.

This can be minimized with large diameter tubes

an advantage with double pipe exchangers, linear

exchangers, and quick quench exchangers.

Generally, only a small temperature rise is

observed from start- to end-of-run.

During the radiant coil decoking, the TLE is

also partially decoked (at least for ethane cracking,

where most of the coke is deposited on the inlet

tubesheet). For complete decoking, the furnace is

usually cooled down and the TLEs are opened and

hydrojetted with high-pressure water. In some

cases, the coke in the TLEs can also be burned off

and hence no mechanical cleaning is required

(BASF, 1980; Sliwka, 1981). The radiant coil is

always cleaned by burning off the coke with steam

and air. Usually, all coils in a given heater are

decoked simultaneously and the effluent during

decoking is sent to a decoking pot or to a firebox

for burning.

The inside of the convection tubes rarely foul,

but occasionally the unsaturated molecules in the

liquid feeds will polymerize and stick to the walls,

thus reducing the heat transfer. This soft coke is

normally removed by mechanical means. In some

cases, the coke can also be burned off with air and

steam. Normally, the outside surface of the

convection section fouls due to dust and particles

in the flue gas. Periodically (6 to 36 months), the

outside surface is cleaned by steam or air lancing.

With liquid fuel firing, the surface may require

more frequent cleaning.

Coke suppression technologies

Several companies are engaged in finding an

additive or modifying the radiant coil surface to

suppress coke deposition (Tong et al., 1994;

Brown et al., 1997; Redmond and Bergeron,

1999; Magnan et al., 2002). In place of sulphur,

or sometimes in addition to sulphur, coke

suppressing additives are added to the

hydrocarbon/dilution steam mixture before

entering the coil. It is claimed that these

additives reduce the CO formation and prolong

the run length by a factor of two to four. Some

additives have been used successfully in

commercial gas cracking furnaces. The

effectiveness of these additives in liquid cracking

has yet to be proven. The cost of these chemicals

needs to be evaluated considering the benefits of

longer run lengths. Instead of adding a chemical,

some vendors have modified the radiant coil

surface by a suitable coating. This reduces the

catalytic coking, which is predominant at

start-of-run, and also reduces the adherence of

gas phase coke, a dominant factor after a few

562 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

300

350

400

450

500

550

600

650

0 50 40 30 20 10 60

T

L

E

o

u

t

l

e

t

t

e

m

p

e

r

a

t

u

r

e

(

C

)

time on-stream (days)

HVGO, high severity

full range naphtha, high severity

naphtha, moderate severity

n-butane

ethane

steam

Fig. 4. Typical TLE

(Transfer Line

Exchanger) outlet

temperatures as a function

of time on-stream for

various feedstocks.

days of operation. Bench scale experiments show

as high as a ten-fold reduction in coking rate;

however, commercial tests show only a two-fold

increase in run length for shorter residence time

gas cracking heaters. Currently, the coating is

expensive and the life of the coating is not yet

fully established. Often these coatings or surface

treatments can enhance the tube life. This topic

has been discussed at many ethylene producers

conferences (Proceedings [...], 1991-2004;

Health [...], 2001-2004).

Metallurgy and mechanical engineering issues

Thermal cracking is a matured technology

and hence recent improvements often come in the

way of improved coil metallurgy. This subject

cannot be addressed completely in this review.

However, this is a significant discussion item in

most conferences (Proceedings [...], 1991-2004;

Health [...], 2001-2004). The producers expect a

long tube life. The radiant coils are usually made

of high strength materials withstanding

temperatures up to 1,150C for several years of

operation. Often the failure mode is carburization

of the radiant coils. In some cases, creep and

bulging also contribute. Modern furnaces use the

so-called micro alloys with nickel (30 wt%),

chromium (25 wt%) and the balance iron and a

few additives (Si, C, W, Mn). These are

proprietary alloys. Both wrought alloys and cast

alloys with smooth surfaces have been used in

commercial operation. For a detailed discussion

on related items, one should consult the

proceedings published annually in the

Proceedings [...], 1991-2004 and Health [...],

2001-2004 cited earlier. To improve the heat

transfer characteristics, fin tubes (Albano et al.,

1988; Barker and Jones, 2000) and elliptical

tubes (Heynderickx and Froment, 1996) have

been used and some are in the commercial

operation for more than 15 years.

Feed impurities

While industrial furnaces can accept a wide

range of feedstocks, the feedstocks are rarely free

of contaminants. Some contaminants present in

trace quantities (ppb to ppm range) can damage the

furnace, resulting in plant shutdown. The

contaminants impact the pyrolysis heater or the

recovery section, or both. Most of the impurities

reduce run length; some to an extent that the run

length is reduced from days to hours. Again, these

are discussed in the various conference

proceedings cited earlier (Proceedings [...],

1991-2004; Health [...], 2001-2004). Mercury in

the feed notably affects the brazed aluminum

exchangers in the recovery section, and arsenic and

mercury affect the hydrogenation reactors

(McPhaul and Reid, 1995). Sodium often reduces

the radiant coil run length and increases CO and

CO

2

formation. Chlorides cause corrosion of the

tubes. Some heavy molecules, which are present in

the feed in ppm range, can cause severe coking in

the convection section and in the TLE. Some

contaminants (oxygenates) affect only the

achievable olefin purity (ethylene or propylene).

Nitrogen oxides in cracked gas effluents or feeds

can produce explosive mixtures in the chilling train

(Halle, 1994).

Decoking

The heater requires periodic decoking to

remove the coke laydown in the radiant coils, TLE,

and/or convection section. This is normally

accomplished in 12 to 48 hours by controlled

burning of the coke with a steam/air mixture in

different proportions from start to end. The initial

concentration of oxygen is kept low to control coke

burn and avoid temperature overshoot, as steam/air

decoking is an exothermic reaction. In other cases,

only steam is used for decoke, which gasifies the

coke. This reaction is endothermic and slow

compared to steam/air decoke. Some proprietary

procedures use an air only step for decoking the

TLE; when decoking cannot burn off the coke

layer, it must be mechanically cleaned.

In order to avoid contact between decoking air

and hydrocarbons, all designers and producers

adopt rigorous safety standards. These include

using interlocks to prevent unintended operations.

For example, when the heater is on decoke mode,

the interlock prevents the feed hydrocarbon valves

from opening to eliminate the contact of

hydrocarbons with air.

Recovery and purification

For gaseous and light naphtha feeds, the

pyrolysis gas leaves the TLE at 300 to 400C and

for heavy liquid feeds (i.e. gas oil), at 550 to

650C. The lowest temperature is at the beginning

of an operating cycle, when the exchangers are

clean. In order to minimize any further cracking

for liquid feeds, the temperature must be reduced

quickly. This is achieved by direct quench using

quench oil. For naphtha-based plants, quenching is

typically performed before reaching the oil quench

tower. In gas-oil plants, quenching is done

immediately after the TLE, resulting in two-phase

flow in the transferline. For gaseous feeds,

pyrolysis gas from the TLE is cooled by direct

563 VOLUME II / REFINING AND PETROCHEMICALS

ETHYLENE AND PROPYLENE

quench in the water column before being routed to

the compressor. Pyrolysis gas from liquid feeds is

cooled first by direct quench in an oil quench

column followed by a water quench column.

For all feeds, the effluent is separated into

desired products by compression in conjunction

with condensation and fractionation at lower

temperatures.

Fig. 5 represents a typical flow diagram of an

ethylene plant for a naphtha feedstock. The

quenched effluent enters the gasoline

fractionator, where the pyrolysis gas and heavy

fuel oil cuts are separated. The function of the

fractionator is to separate the pyrolysis gasoline

and pyrolysis fuel oil components and to cool the

cracked gas. The circulating quench oil is cooled

to 185C by generating dilution or low-pressure

steam. The bottom temperature of the

fractionator must be carefully controlled, since

the quench oil is unstable at high temperatures.

High residence time in combination with high

temperature results in polymerization that can

deposit in the system and also cause higher

viscosity. When light feeds are cracked, the fuel

oil content is low and therefore high

concentrations of unstable material are present.

When gas oil is cracked, though the fuel oil

content is high, it is mainly unconverted feed.

Hence the concentration of unstable material is

low and a higher bottom temperature can be

tolerated.

Due to the small temperature difference

between the hot quench oil and the steam

generators, and the large amount of heat to be

removed from the pyrolysis gas, the quench oil

flow has to be large and is typically in the range

of 15 to 25 times the flow of feedstock to the

heaters. Due to the presence of coke particles in

the quench oil, specially designed pumps are

used. The dilution steam generator is one of the

largest multiple-shell exchangers in the plant. In

addition, spare pumps and exchangers are

needed due to severe fouling (Picciotti, 1977a,

1977b, 1977c).

564 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

g

a

s

o

l

i

n

e

f

r

a

c

t

i

o

n

a

t

o

r

ethylene

fractionator

propylene

fractionator

d

e

e

t

h

a

n

i

z

e

r

d

e

p

r

o

p

a

n

i

z

e

r

d

e

b

u

t

a

n

i

z

e

r

d

e

m

e

t

h

a

n

i

z

e

r

dryer

a

c

e

t

y

l

e

n

e

c

o

n

v

e

r

t

e

r

m

e

t

h

y

l

a

c

e

t

y

l

e

n

e

a

n

d

p

r

o

p

a

d

i

e

n

e

c

o

n

v

e

r

t

e

r

f

u

e

l

o

i

l

s

t

r

i

p

p

e

r

p

r

o

c

e

s

s

w

a

t

e

r

s

t

r

i

p

p

e

r

c

a

u

s

t

i

c

a

n

d

w

a

t

e

r

w

a

s

h

t

o

w

e

r

c

o

n

d

e

n

s

a

t

e

s

t

r

i

p

p

e

r

water

steam

charge gas

compressor

1

st

- 3

rd

stages

charge gas

compressor

4

th

and 5

th

stages

q

u

e

n

c

h

t

o

w

e

r

p

y

r

o

l

y

s

i

s

h

e

a

t

e

r

fresh feed

fuel gas hydrogen methane ethane ethylene C

3

LPG

propylene

gasoline

C

4

product

fuel oil

Fig. 5. Schematic flow diagram of an ethylene plant using naphtha feedstock.

The quench tower in essence operates as a

partial condenser for the gasoline fractionator,

condensing practically all of the steam and the

heavy pyrolysis gasoline components. Separation

of the water phase from the gasoline phase occurs

in a quench water drum. Hot quench water is used

as a process heat source for the recovery section.

A portion of the gasoline phase is refluxed for the

gasoline fractionator, while the remainder is sent to

the gasoline stripper for stabilization. This gasoline

has a Research Octane Number (RON) of 95 to 99,

and is usually blended with other gasoline

products.

The pyrolysis gas leaving the quench tower is

compressed to 3.5 MPa in a four- or five-stage

centrifugal compressor. The number of stages is

determined by the maximum temperature

permissible for the fouling tendency of the

pyrolysis gas. The compressor typically consists of

three compressor casings driven by a single

extraction/condensing turbine. For large plants, two

turbines can be used. Water and hydrocarbons are

separated from the pyrolysis gas between stages,

and recycled.

Acid gases (CO

2

and H

2

S) are removed after

the third or fourth compression stage. This is an

optimum location since the gas volume has been

reduced significantly and the acid gases have not

contaminated any final products. When the

sulphur content of the feed is low, as in some

naphtha feeds, scrubbing with a dilute caustic

soda solution (typically 4 to 12% free caustic) is

cost-effective. Relatively weak solutions are

preferred to avoid the precipitation of sodium

salts and to minimize the formation of sodium

complexes and yellow oil. The pyrolysis gas

leaving the scrubber contains less than 1 ppm

acid gases and is further treated by a water wash

to remove any caustic carryover. A detailed

analysis is given by Raab (1976). Plants designed

to process high sulphur content feeds (i.e. higher

than 500 ppm) may contain a regenerative acid

gas removal system upstream of the caustic

scrubber. These systems employ

monoethanolamine, diethanolamine, or Alkazid

as solvents with a standard absorber-desorber

design. Depending upon the plant location, acid

gases are either sent to a fired heater or treated in

a Claus unit for conversion of hydrogen sulphide

to elemental sulphur. Coke suppression additives,

discussed earlier, somewhat decrease the CO

2

formation and can be economically attractive.

After acid gas removal, the pyrolysis gas from

the last stage of compression is cooled by

propylene refrigerant and sent to the charge gas

dryers. Molecular sieve dryers completely

remove water from the pyrolysis gas. Typically,

there are two dryers with one in normal

operation, while the other is being regenerated.

The dryers are designed for 24 to 48 hours

between successive regenerations. High-pressure

methane, heated with steam at 225C, is the

preferred regeneration medium. The pyrolysis

gas is partially condensed at essentially constant

pressure over the stages of the cascade

refrigeration system to about 165C, where

only the hydrogen remains in the vapour state.

The stage condensates (only one is shown

in Fig. 5) are fed to the appropriate trays of the

demethanizer. Hydrogen (95 mol%) is withdrawn

from the lowest temperature stage separator. The

demethanizer is designed for complete separation

of methane from ethylene and heavier

components, and operates at nearly 0.7 MPa for

ABB Lummus Globals low-pressure

demethanizer scheme. Condensing propylene

refrigerant supplies heat to the reboilers and

vaporizing refrigerant condenses the reflux.

The demethanizer overhead consists of methane

(95 mol%) with some minor impurities

of hydrogen, carbon monoxide, and traces

of ethylene. Brazed aluminum plate-fin exchangers

are used for the multi-pass cryogenic heat transfer

services and are installed in a cylindrical or

rectangular carbon steel container, commonly

known as a cold box. This unit is filled with

perlite or rockwool for insulation.

The demethanizer bottoms, consisting of

ethylene and heavier components, are sent to the

deethanizer a conventional tray-type fractionator

operating at a pressure of 2.4 to 2.8 MPa. An

overhead stream containing C

2

hydrocarbons and a

bottoms product of C

3

and heavier hydrocarbons

are produced. Since acetylene is not usually

recovered, the deethanizer overhead is heated to

20-100C and hydrogen is added. The mixture is

passed over a fixed bed of palladium catalyst for

acetylene hydrogenation. Due to the exothermicity

of acetylene hydrogenation, multiple beds with

intermediate cooling are preferred. The acetylene

hydrogenation reactor effluent contains less than

1 ppm of acetylene, but does contain traces of

methane and hydrogen. This is known as back-end

acetylene hydrogenation and is preferred to

front-end hydrogenation particularly in the case

of older catalysts with higher carbon-monoxide

(CO) sensitivity due to higher selectivity and

precise control as hydrogen is varied with

acetylene concentration; temperature is varied

depending on catalyst activity.

565 VOLUME II / REFINING AND PETROCHEMICALS

ETHYLENE AND PROPYLENE

Front-end acetylene hydrogenation is also

utilized in the ethylene flow scheme. This approach

requires a catalyst less sensitive to CO, and the

reactor is located upstream of the demethanizer.

For this design, typically a deethanizer or

depropanizer tower is located upstream of the

demethanizer to remove heavy fractions before

acetylene hydrogenation. The hydrogenation

catalyst is usually more sensitive to significant

variation in CO concentration, which is

experienced when cracking heaters are brought

on-line after decoke operation.

During acetylene hydrogenation, there is a net

gain of ethylene since, under normal conditions,

more acetylene is hydrogenated to ethylene than

ethylene is hydrogenated to ethane. The catalyst is

deactivated over time due to coke and green oil

(a polymer formed due to side reactions)

production and is therefore regenerated periodically

(six to twelve months). The kinetics of this reaction

has been discussed by Lam (1988) and Cider and

Schoon (1991). For some catalysts, a trace amount

of CO is used to control the selectivity of

hydrogenation; however, the new generation of

catalysts does not require CO addition.

Acetylene can be recovered by using an

absorption process with multiple towers. In the

first tower, acetylene is absorbed in acetone,

dimethyl formamide or methyl pyrrolidone (Lorber

et al., 1971; Stork et al., 1974). In the second

tower, absorbed ethylene and ethane are rejected.

In the third tower, acetylene is desorbed. Since

acetylene decomposition can result at certain

conditions of temperature, pressure and

composition, the design of this unit is critical for

safety reasons.

After acetylene hydrogenation/removal, the

dried gas enters an ethylene-ethane separator (i.e.

ethylene fractionator). This column contains 80 to

150 trays, and a reflux ratio of 2.5 to 4.0 is typical

depending upon feed composition. A pasteurizing

section is usually provided at the top of the

fractionator for removal of residual hydrogen,

carbon monoxide, and methane to achieve very

high purity ethylene (99.95%). Propylene

refrigerant is typically used as condensing and

reboiling medium. Condensing refrigerant vapour

supplies heat to the reboiler, while the refrigerant

boiling under low-pressure generates the cooling

required in the overhead condenser. An open heat

pump can be used with the integration of the

ethylene-ethane fractionator into the ethylene

refrigeration system. The ethane withdrawn from

the tower bottom is recycled to the heaters and

cracked to extinction.

The condensate stripper bottoms and the

deethanizer bottoms are processed in the

depropanizer for a sharp separation of C

3

hydrocarbons and C

4

and heavier hydrocarbons.

The reboiler may be fouled by rubber-like

polymers and require periodic mechanical

cleaning. To minimize this problem, two types of

designs are used. In the first design, the bottoms

temperature is set low, which results in an

operating pressure requiring propylene

refrigerant instead of cooling water for the

condensation of the overhead product. In the two

tower system design, cooling water is used as the

condensing medium for the high pressure tower

and propylene refrigerant for the low pressure

tower. This concept results in better overall

energy efficiency, but involves higher capital

investment.

The depropanizer bottoms are further

processed in the debutanizer for separation of C

4

product from light pyrolysis gasoline. The

debutanizer operates at a moderate pressure of

0.4 to 0.5 MPa and is a conventional fractionator

with steam-heated reboilers and water-cooled

condensers.

The overhead of the depropanizer is sent to the

propylene fractionator. The methyl acetylene (MA)

and propadiene (PD) are usually hydrogenated

before entering the tower. A MAPD converter is

similar to an acetylene converter, but operates at a

lower temperature and in the liquid phase. Due to

recent advances in catalysis, the hydrogenation is

performed at low temperatures (50-90C) in trickle

bed reactors (Stanley and Venner, 1991). Methyl

acetylene and propadiene are only rarely recovered.

Catalytic distillation technology has been used to

saturate MAPD in recent designs (Gildert et al.,

1995).

Due to the low relative volatility, fractionation

of propylene and propane is even more difficult

than the fractionation of ethylene and ethane. The

propylene fractionator operates at a pressure of

1.8 to 2.0 MPa, with nearly 160 trays required for a

high purity propylene product. Often a two-tower

design is employed when polymer grade (high

purity 99.9%) is required. A pasteurization

section may also be used when high purity is

required. The bottoms product contains mainly

propane, which can be recycled to the cracking

heaters or used as fuel.

A typical specific energy consumption curve

for various feedstocks processed at high severity is

shown in Fig. 6. The energy consumption for a

naphtha-based plant has been reduced from 8,100

kcal/kg C

2

H

4

in the 1960s to nearly 5,000 kcal/kg

566 ENCYCLOPAEDIA OF HYDROCARBONS

BULK PRODUCTS AND PRODUCTION LINES IN THE PETROCHEMICAL INDUSTRY

in 2003. This reduction was made possible by

improvements in cracking coil technology and

recovery section design.

The energy consumption values do not include

the Olefins Conversion Technology (OCT) unit.

When OCT is integrated with an ethylene plant,

the specific energy drops by up to 10% with

similar investment cost.

Recent improvements

Some recent improvements not only reduce the

energy consumption, but also increase the capacity

of an existing plant. These approaches are

discussed below.

Large capacity cracking heaters. With large

capacity ethylene plants, it is possible to consider

high capacity heaters and still keep economical

spare heater capacity. All technology suppliers

are currently proposing large capacity heaters, in

the range of 150,000-250,000 mta of ethylene

production. New computer tools, utilizing

Computational Fluid Dynamics (CFD)

techniques, have allowed designers and

developers to better understand the aerodynamics

of the firebox side of large capacity heaters

(Platvoet et al., 2003).

Quench oil viscosity control. Increasing the

bottoms temperature of the gasoline fractionator

increases the bottoms liquids viscosity;

therefore, flux oil is often added to reduce the

viscosity. Effluents from ethane cracking can be

used as a viscosity control stripping medium,

allowing a temperature of 195-230C in the

gasoline fractionator bottom (depending on type

of feed mix). This reduces the quench oil

pumping power, eliminates the flux oil addition

(Stanley and Venner, 1991), and improves energy

efficiency.

Feed saturation. When gas feeds like ethane

and propane are cracked, dilution steam can be