Академический Документы

Профессиональный Документы

Культура Документы

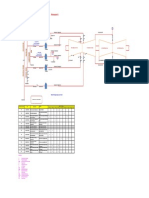

351 MW Operating Parameters For STG ROLLING

Загружено:

Rakesh Mishra0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров1 страницаOne of the guideline parameters for starting the GE9FA 351MW CCPP without DD

Оригинальное название

351 MW Operating Parameters for STG ROLLING

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документOne of the guideline parameters for starting the GE9FA 351MW CCPP without DD

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров1 страница351 MW Operating Parameters For STG ROLLING

Загружено:

Rakesh MishraOne of the guideline parameters for starting the GE9FA 351MW CCPP without DD

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

1:30 HRS GT SYNC @ 15 MW

2:00HRS

HP SHAFT TEMP 150DEG C

MS TEMP BEFORE ESV 390 DEG C

GT EXHAUST TEMP 390 DEG C WITH TEMP MATCHING ON

WE NEED EITHER HP SHAFT TEMP>260 DEGC OR HPMS TEMP BEFORE ESV< 365 DEG C ,HRH

TEMP 402 DEG C ,IP SHAFT TEMP 147 DEG C FOR X5,X6,X7 CRITERIA

2:45 HRS

HP SHAFT TEMP 148 DEG C

MS TEMP BEFORE ESV 380 DEG C

HRH TEMP 380 DEG C

IP SHAFT TEMP 146 DEG C

MS PR 45 KSC

GT EXHAUST TEMP 390 DEG C @ 15 MW LOAD

5:00 HRS

HP SHAFT TEMP 147 DEG C

MS TEMP BEFORE ESV 377 DEG C

HRH TEMP 373 DEG C

IP SHAFT TEMP 144 DEG C

GT EXHAUST TEMP 400 DEG C @ 20 MW LOAD

5:15 HRS FOR FULLFILLING X5 CRITERIA

HP SHAFT TEMP 146 DEG C

MS TEMP BEFORE ESV 366 DEG C

HRH TEMP 373 DEG C

IP SHAFT TEMP 144 DEG C

GT EXHAUST TEMP 400 DEG C @ 20 MW LOAD

MS PR 35 KSC, BY PASS OPENED

MS SATURATION TEMP 242 DEG C

5:22 STG ROLLING STARTED AND ON SOAKING SPEED @650 RPM FOR 30 MIN THEN GO TO FSNL

HPMS AND HRH TEMP LOWERED BY DESUPER HEATER STATION.

DURING SOAKING, SHAFT TEMP AND MS TEMP DIFF IS REDUCED AND SYNC AT 06:08 HRS

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Near Miss Reporting FormatДокумент1 страницаNear Miss Reporting FormatRakesh MishraОценок пока нет

- Reliability Test For The CCPPДокумент3 страницыReliability Test For The CCPPRakesh MishraОценок пока нет

- Equipment Changeover Practice ProposedДокумент2 страницыEquipment Changeover Practice ProposedRakesh MishraОценок пока нет

- Major Start Up ActivityДокумент2 страницыMajor Start Up ActivityRakesh MishraОценок пока нет

- SWAS Taking ActivityДокумент1 страницаSWAS Taking ActivityRakesh MishraОценок пока нет

- Optimisation Time For Startup and Shutdown Time of CCPPДокумент3 страницыOptimisation Time For Startup and Shutdown Time of CCPPRakesh MishraОценок пока нет

- Responsiblities of Technical CellДокумент3 страницыResponsiblities of Technical CellRakesh MishraОценок пока нет

- Optimisation Time For Startup and Shutdown Time of CCPPДокумент3 страницыOptimisation Time For Startup and Shutdown Time of CCPPRakesh MishraОценок пока нет

- X Criteria InstrumentlocationДокумент1 страницаX Criteria InstrumentlocationRakesh MishraОценок пока нет

- Fuse CutoutДокумент2 страницыFuse CutoutRakesh MishraОценок пока нет

- CAWTL - Monthly ReportДокумент5 страницCAWTL - Monthly ReportRakesh MishraОценок пока нет

- CWДокумент2 страницыCWRakesh MishraОценок пока нет

- LDP Micom Relays P441 & P442 For Distance ProtectionДокумент16 страницLDP Micom Relays P441 & P442 For Distance ProtectionRakesh MishraОценок пока нет