Академический Документы

Профессиональный Документы

Культура Документы

Compilation 2010-t-2

Загружено:

api-271252079Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Compilation 2010-t-2

Загружено:

api-271252079Авторское право:

Доступные форматы

STRUCTURAL GENERAL NOTES & SPECIFICATIONS

A. GENERAL NOTES

C. FORMWORKS

1. GENERAL NOTES AND TYPICAL STRUCTURAL DETAILS SHALL APPLY TO ALL DRAWINGS UNLESS

OTHERWISE SHOWN OR NOTED.

2. FEATURES OF CONSTRUCTION SHOWN ARE TYPICAL AND SHALL APPLY GENERALLY THROUGHOUT FOR

SIMILAR CONDITIONS. MODIFY TYPICAL DETAILS AS REQUIRED TO MEET SPECIAL CONDITIONS.

3. THE CONTRACTOR SHALL EXAMINE THE DRAWINGS AND SHALL NOTIFY THE ENGINEER/ARCHITECT OF

ANY DISCREPANCIES HE MAY FIND BEFORE PROCEEDING WITH THE WORK OR DURING CONSTRUCTION.

4. IT SHALL BE THE CONTRACTORS RESPONSIBILITY TO PROVIDE ADEQUATE SHORING AND BRACING OF

THE STRUCTURE FOR ALL LOADS THAT MAY BE IMPOSED DURING CONSTRUCTIONS.

5. ALL MATERIALS AND WORKMANSHIP SHALL CONFORM TO THE LATEST APPLICABLE STANDARDS OR

SPECIFICATIONS. ALL WORKS SHALL CONFORM WITH THE BEST PRACTICE PREVAILING IN THE VARIOUS

TRADES.

6. INSPECTION - ALL CONSTRUCTION AND WORKMANSHIP SHALL BE SUBJECT TO INSPECTION, EXAMINATION

AND TESTING BY THE ENGINEER/ARCHITECT. THE

ENGINEER/ARCHITECT SHALL HAVE THE RIGHT TO REJECT DEFECTIVE MATERIALS AND WORKMANSHIP

OR REQUIRE ITS CORRECTION.

7. UNLESS SPECIFICALLY DETAILED ELSEWHERE CONTRACTOR SHALL FOLLOW TYPICAL DETAILS AS

SHOWN IN THESE DRAWINGS.

8. THE CONTRACTOR WILL BE RESPONSIBLE FOR THE COORDINATION OF WORK AMONG THE VARIOUS

TRADES AS NECESSARY TO AVOID CONFLICTS AND TO INSURE INSTALLATION OF ALL WORK WITHIN THE

AVAILABLE SPACE.

9. DO NOT SCALE DRAWINGS, CALLED-OUT DIMENSIONS AND STANDARD CODE REQUIREMENTS SHALL

GOVERN OVER UNSCALED DRAWINGS. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE

SPECIFIED.

10. SPECIAL NOTE: DIMENSION INDICATED ON THE STRUCTURAL DRAWINGS SHALL BE COORDINATED WITH

THE ARCHITECTURAL DRAWINGS. ARCHITECTURAL DRAWINGS SHALL BE USED TO DEFINE DETAIL

CONFIGURATIONS, ELEVATIONS, OPENINGS, JOINTS, SLOPES, ETC.

11. THE CONTRACTOR IS GIVEN THE OPTION TO UTILIZE ALTERNATIVE METHODS OF DESIGN AND

ALTERNATIVE METHOD OF CONSTRUCTION AS DEEMED SUITABLE PROVIDED THAT SUCH OPTION IS IN

CONFORMANCE WITH THE DESIGN CONCEPT OF THE PROJECT AND IN COMPLIANCE WITH THE

INFORMATION GIVEN IN THE CONTRACT DOCUMENTS.

F. CONCRETE MASONRY WALL NOTES

1. FORMS SHALL BE PROVIDE FOR ALL CONCRETE INDICATED UNLESS SPECIFIES OTHERWISE. FORMS

SHALL BE SET TRUE TO LINE AND GRADE AND MAINTAINED SO AS TO INSURE COMPLETED WORK

WITHIN THE ALLOWABLE TOLERANCES SPECIFIED AND SHALL BE MORTAR TIGHT.

2. FORMS AND THEIR SUPPORTS SHALL BE DESIGNED SO AS NOT TO DAMAGE PREVIOUSLY PLACED

STRUCTURE.

3. NO CONSTRUCTION LOAD SHALL BE SUPPORTED ON, NOR ANY SHORING REMOVED FROM ANY PART

OF STRUCTURE UNDER CONSTRUCTION EXCEPT WHEN THAT PORTION OF THE STRUCTURE IN

COMBINATION WITH THE REMAINING FORMING AND SHORING SYSTEM HAS SUFFICIENT STRENGTH

TO

SUPPORT SAFELY ITS WEIGHT AND THE ADDITIONAL IMPOSED LOADS.

4. FORMS SHALL BE REMOVED IN SUCH MANNER AS NOT TO IMPAIR SAFETY AND SERVICE ABILITY OF

THE STRUCTURE.

5. SCHEDULE OF STRIPPING OF FORMS AND SHORES.

ITEM

TIME

24 HRS

14 DAYS

SCHEDULE OF MASONRY UNITS/REINFORCEMENTS

WALL THICKNESS

ASTM

GROUT TYPE

REINFORCEMENT

REMARKS

1. ALL NON-LOAD BEARING TYPE CONCRETE BLOCKS SHALL HAVE A UNIT WEIGHT NOT TO EXCEED 80

PCF.

2. ALL CMU CELLS CONTAINING REINFORCEMENTS SHALL ONLY BE SOLIDLY FILLED WITH GROUT. ALSO,

ALL CMU CELLS BELOW FINISHED GRADE SHALL BE SOLIDLY FILLED WITH GROUT.

3. UNLESS OTHERWISE NOTED, SOLID GROUT SHALL MEAN ALL CELLS (WITH OR WITHOUT REINFORCING)

BE GROUTED.

4. SPECIAL FIELD INSPECTION IS REQUIRED.

SCHEDULE OF STIFFENER COLUMNS & BEAMS

D. REINFORCING STEEL

ITEM THICKNESS

SIZE

MAIN

REINFORCEMENT

TIES

C. TO C.

DISTANCE

SCHEDULE OF REINFORCING BARS

B. REINFORCED CONCRETE NOTES

DIAMETER OF BARS

GRADE (fy)

ASTM

ASTM A615 / PNS49

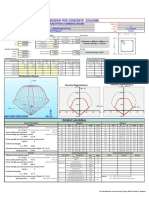

SCHEDULE OF STRUCTURAL CONCRETE 28-DAY

COMPRESSIVE STRENGTH AND TYPES

BUILDING

LOCATION

STRUCTURAL

ELEMENTS

28-DAY

COMPRESSIVE

STRENGTH

DENSITY MAX SLUMP

NOTE: tm = THICKNESS OF WALL

1. BARS SHALL BE CLEAN OF RUST, GREASE OR OTHER MATERIALS LIKELY TO IMPAIR BOND. ALL

REINFORCING BAR BENDS SHALL BE MADE COLD.

2. ALL GRADE 60 REINFORCING STEEL SHALL BE CLEARLY MARKED TO DIFFERENTIATE THEM FROM

GRADE 40 REINFORCEMENT STEEL IF CONCURRENTLY ON SITE.

3. IN GENERAL, BAR SPLICES SHALL BE MADE AT POINTS OF MINIMUM STRESS. SPLICES SHALL BE

SECURELY WIRED TOGETHER. STAGGER SPLICES AT LEAST 600 mm. WHENEVER POSSIBLE IN BEAMS

AND SLABS SPLICE TOP BARS AT MIDSPAN AND BOTTOM BARS NEAR SUPPORT. SPLICE OF

REINFORCEMENT SHALL BE MADE ONLY AS REQUIRED OR PERMITTED ON DESIGN DRAWINGS OR AS

ALLOWED BY THE ACI CODE OR AS AUTHORIZED BY THE ENGINEER.

4. BARS NOTED AS "CONT." SHALL HAVE A MINIMUM SPLICE LENGTH OF 42 BAR DIAMETERS BUT NOT

LESS THAN 600 mm UNLESS OTHERWISE NOTED.

5. REINFORCING SHALL BE SPLICED ONLY AS INDICATED ON THE DRAWINGS.

6. MINIMUM CONCRETE COVER FOR REINFORCING BARS SHALL BE.

ITEMS

G. STRUCTURAL STEEL

1. ALL STRUCTURAL MILL SECTIONS BUILT UP PLATE SECTIONS SHALL BE DESIGNED IN ACCORDANCE

WITH AISC'S LATEST "SPECIFICATION FOR THE DESIGN, FABRICATION AND ERECTION OF STRUCTURAL

STEEL FOR BUILDINGS".

2. DESIGN LOADS FOR BUILDINGS SHALL MEET THE REQUIRED STRUCTURAL DESIGN CRITERIA.

3. STEEL PLATES, SHAPED, BARS, AND METAL FABRICATIONS: ASTM A-36.

4. STRUCTURAL BOLTS AND NUTS:

ASTM A-325, 7/8 DIAMETER AND BELOW.

A-490 1" DIAMETER AND ABOVE.

5. ELECTRODES FOR WELDING: ASTM A233 E_70XX SERIES; COMPLY WITH AWS D1.1 CODE

REQUIREMENTS.

6. FLAME CUTTING AND WELDING SHALL BE DONE IN ACCORDANCE WITH LATEST "STANDARD CODE FOR

WELDING IN BUILDING CONSTRUCTION" OF THE AMERICAN WELDING SOCIETY.

COVER

75 mm

1. INFORM ARCHITECT/ENGINEERS OF OTHER MISCELLANEOUS CONCRETE STRUCTURAL ELEMENTS NOT

SHOWN ABOVE TO DETERMINE THEIR RESPECTIVE COMPRESSIVE STRENGTHS.

ITEM

AGGREGATE SIZE

2. ALL CONCRETE WORK SHALL CONFORM TO THE LATEST EDITION CODE OF THE AMERICAN CONCRETE

INSTITUTE (ACI 318-08).

3. LOCATION OF ALL CONSTRUCTION OR COLD JOINTS MUST BE APPROVED BY THE ENGINEER/ARCHITECT.

4. PIPE OR DUCTS EXCEEDING ONE THIRD THE SLAB OR WALL THICKNESS SHALL NOT BE PLACED IN

STRUCTURAL CONCRETE UNLESS SPECIFICALLY DETAILED. PIPES MAY PASS THROUGH STRUCTURAL

CONCRETE IN SLEEVES BUT SHALL NOT BE EMBEDDED THEREIN.

5. REINFORCING BARS, ANCHOR BOLTS, AND OTHER INSERTS SHALL BE SECURED IN PLACE BEFORE

POURING CONCRETE. BAR PLACEMENT AND SUPPORTS SHALL BE IN ACCORDANCE WITH THE

RECOMMENDED ACI PRACTICE.

6. ALL INSERTS, ANCHOR BOLTS, PLATES, ETC. TO BE EMBEDDED IN CONCRETE SHALL BE HOT DIP

GALVANIZED UNLESS NOTED OTHERWISE.

7. IN GENERAL, THE LATEST EDITION OF (MANUAL OF STANDARD PRACTICE FOR DETAILING CONCRETE

STRUCTURES) ACI 315, SHALL BE ADHERED TO, UNLESS SHOWN OTHERWISE.

8. USE OF ADMIXTURES IS PERMITTED TO PRODUCE PROPER SLUMP AND WORKABILITY BUT SUBJECT TO

THE ENGINEER'S APPROVAL ADDITION OF WATER TO CONCRETE AT JOBSITE IS NOT ALLOWED.

7. ANY WELDING TO BE PERFOMED MUST HAVE PRIOR WRITTEN APPROVAL OF THE ENGINEER

8. WELDING OF REINFORCING STEEL IS NOT PERMITTED UNLESS OTHERWISE SHOWN ON THE

DRAWINGS. WELDING OF REINFORCING STEEL SHALL CONFORM TO AWS D1.4-79 " AWS STRUCTURAL

WELDING CODE - REINFORCING STEEL" OF THE AMERICAN WELDING SOCIETY. REINFORCING

STEEL WHICH IS WELDED SHALL CONFORM TO ASTM A 706. REINFORCING STEEL NOT CONFORMING

TO ASTM A 706 MAY BE USED IF MATERIAL PROPERTIES OF THE REINFORCING STEEL CONFORM TO

AWS D1.4-79.

9. WELDED WIRE FABRIC (WWF) SHALL CONFORM TO ASTM A 185. WELDED WIRE FABRIC IN SUSPENDED

SLABS SHALL HAVE FY 60 KSI. LAP 152 MM. MINIMUM OR ONE FULL MESH, WHICHEVER IS GREATER FOR

SLABS ON GRADE.

10. SHOW DRAWINGS: THE CONTRACTOR SHALL SUBMIT SHOP DRAWINGS FOR REINFORCING STEEL

PREPARED IN ACCORDANCE WITH ACI 315. INDICATE BENDING DIAGRAM, ASSEMBLY DIAGRAM,

SPLICING AND LAPS OF RODS AND SHAPES DIMENSIONS AND DETAILS FOR REINFORCING BARS.

11. ANCHOR BOLTS, DOWELS AND OTHER EMBEDDED ITEMS ARE TO BE SECURELY TIED IN PLACE

BEFORE CONCRETE IS POURED.

7. ALL BUTT WELDS SHALL BE FULL PENETRATION WELDS AND SHALL BE PROPERLY BACK-CHIPPED OR

GOUGED. BACK-UP PLATES SHALL BE PROVIDED AS REQUIRED.

8. SHOP PAINTING FOR STRUCTURAL STEEL SHALL BE RUST INHIBITIVE PRIMER WITH MINIMUM D.F.T. OF

2.0 MILS.

9. TOUCH-UP PAINTING: APPLY PAINT TO EXPOSED AREAS IN MANNER SATISFACTORY TO THE ENGINEER

WITH SAME MATERIAL AS SHOP PAINT.

10. COMPLY WITH AISC CODE AND SPECIFICATIONS FOR BEARING, ADEQUACY OF TEMPORARY

CONNECTIONS AND ALIGNMENT.

11. CONTRACTOR SHALL FURNISH COMPLETE ERECTION DRAWINGS FOR THE PROPER IDENTIFICATION

AND ASSEMBLY OF ALL BUILDING COMPONENTS. THESE DRAWINGS WILL SHOW ANCHOR BOLT

SETTING, PRIMARY, SECONDARY, AND ROOF FRAMING, AND NECESSARY INSTALLATION DETAILS.

SUBMIT SHOP DRAWINGS FOR APPROVAL BEFORE FABRICATION.

E. CONSTRUCTION JOINTS

1. ALL SURFACES OF CONSTRUCTION JOINTS SHALL BE ROUGHEN TO 6 MM AMPLITUDE.

2. ALL CONSTRUCTION JOINTS SHALL BE CLEANED TO REMOVE DUST, CHIPS, OR OTHER FOREIGN

MATTER PRIOR TO PLACING THE ADJACENT CONCRETE.

3. THE CONTRACTOR SHALL SUBMIT THE PROPOSED LOCATIONS OF CONSTRUCTION JOINTS TO THE

ENGINEER BEFORE STARTING CONSTRUCTION.

5CE-B: B6

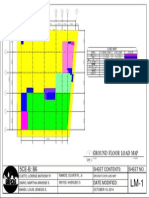

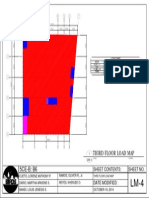

SHEET CONTENTS:

CUETO, LORENZ ANTHONY P.

RAMOS, OLIVER R., Jr.

STRUCTURAL NOTES

DARIO, MARTHA ARKIENE S.

REYES, KHERJEE O.

DATE MODIFIED:

MANDI, LOUIE JENESIS S.

OCTOBER 1, 2014

SHEET NO.

T-2

Вам также может понравиться

- RCC95 Continuous Beams (Tables)Документ7 страницRCC95 Continuous Beams (Tables)Mohammad Twaha JaumbocusОценок пока нет

- Jain Ariditha-1Документ26 страницJain Ariditha-1preethiОценок пока нет

- Spreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)Документ10 страницSpreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)hala_azhariОценок пока нет

- Rate Book - 2011-NCP Building DPTДокумент244 страницыRate Book - 2011-NCP Building DPTthak_raj84Оценок пока нет

- Requirements for Engineers in RwandaДокумент1 страницаRequirements for Engineers in RwandaenatagoeОценок пока нет

- RCC14 Crack WidthДокумент2 страницыRCC14 Crack WidthMohammad Twaha JaumbocusОценок пока нет

- Design & Analysis of Mullion & Steel BracketsREV - 01Документ97 страницDesign & Analysis of Mullion & Steel BracketsREV - 01عزة الإسلامОценок пока нет

- Structural General NotesДокумент1 страницаStructural General Notesjuan camiloОценок пока нет

- R C C Design ServicesДокумент12 страницR C C Design ServicesPrayas SubediОценок пока нет

- Veran Structural Model2Документ1 страницаVeran Structural Model2mr. oneОценок пока нет

- Structural Design Plan Review Checklist for Beverly Hills Building ProjectДокумент14 страницStructural Design Plan Review Checklist for Beverly Hills Building ProjectOmer HayatОценок пока нет

- Fabrication Tolerances for Cold-Formed and Built-Up Structural MembersДокумент4 страницыFabrication Tolerances for Cold-Formed and Built-Up Structural MembersSyed Tauseef ShahОценок пока нет

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmДокумент1 страницаDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraОценок пока нет

- Allowable Load PlanДокумент6 страницAllowable Load Planmomin76Оценок пока нет

- Spreadsheets To BS 8110: Internal ColumnДокумент9 страницSpreadsheets To BS 8110: Internal ColumnKhac Hoang PhamОценок пока нет

- Mogadishu Hotel-Raft Foundation Layout - 1bДокумент1 страницаMogadishu Hotel-Raft Foundation Layout - 1bdanokrayОценок пока нет

- Nirmal Asangaon Plot 8-9-Dbr 260219Документ7 страницNirmal Asangaon Plot 8-9-Dbr 260219Titus PraveenОценок пока нет

- JJ Cruz + Associates S-02: Standard HooksДокумент1 страницаJJ Cruz + Associates S-02: Standard HooksCarlo GarciaОценок пока нет

- Sheet Size and Sewage Rising Main DetailsДокумент1 страницаSheet Size and Sewage Rising Main DetailsmohdnazirОценок пока нет

- PEB 2D Vs 3D ModelДокумент5 страницPEB 2D Vs 3D ModelGautam PaulОценок пока нет

- New Fulcrum Canopies - Structural Drawings - PermitДокумент6 страницNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezОценок пока нет

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMДокумент1 страницаH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraОценок пока нет

- RCC94 Two-Way Slabs (Tables)Документ4 страницыRCC94 Two-Way Slabs (Tables)Zayyan RomjonОценок пока нет

- References PDFДокумент42 страницыReferences PDFSalik Tramboo100% (1)

- Session 4 - Structural Design CriteriaДокумент34 страницыSession 4 - Structural Design CriteriaEdeline AnsayОценок пока нет

- Design Flexural Strength of Steel Beams GuideДокумент54 страницыDesign Flexural Strength of Steel Beams GuideFer Rivas NietoОценок пока нет

- Peb Steel Structures Tolerance Table As Per Aisc: Builtup/ Hotroll BeamsДокумент2 страницыPeb Steel Structures Tolerance Table As Per Aisc: Builtup/ Hotroll BeamsSamsuОценок пока нет

- Structural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingДокумент56 страницStructural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingErwin ObenzaОценок пока нет

- LMW Engineering Group, LLC.: Revision Comment No. DateДокумент16 страницLMW Engineering Group, LLC.: Revision Comment No. DatenelsonОценок пока нет

- Analysis and Design of High-Rise Building (G+30) Using Staad - ProДокумент5 страницAnalysis and Design of High-Rise Building (G+30) Using Staad - ProআকাশআহসানОценок пока нет

- Case & Uzun: Mount Pisgah Christian School New Upper School BuildingДокумент20 страницCase & Uzun: Mount Pisgah Christian School New Upper School Buildingervikas34Оценок пока нет

- One Way Slab Design: Ref: Nilson-13Th Edition-418 Page ExampleДокумент4 страницыOne Way Slab Design: Ref: Nilson-13Th Edition-418 Page Examplerasedul islamОценок пока нет

- Eurocode - Load Combinations For Steel Structures - R1Документ26 страницEurocode - Load Combinations For Steel Structures - R1anil97232Оценок пока нет

- Design Recommendations For Steel Deck Floor SlabsДокумент32 страницыDesign Recommendations For Steel Deck Floor SlabsYannick PrattОценок пока нет

- Section Section Section: FC Sefc, LLCДокумент1 страницаSection Section Section: FC Sefc, LLCeliu100Оценок пока нет

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationДокумент6 страницNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezОценок пока нет

- Technical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisДокумент6 страницTechnical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisAdnan NajemОценок пока нет

- 2.analysis and Design of Inclined Columns - CompressДокумент77 страниц2.analysis and Design of Inclined Columns - Compressyigit erkoc100% (1)

- Multi Deck 146Документ36 страницMulti Deck 146bondar1100% (1)

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmДокумент1 страницаDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraОценок пока нет

- Software ArcelorMittal CTICM Columns Calculator A3C Version 2.20Документ1 страницаSoftware ArcelorMittal CTICM Columns Calculator A3C Version 2.20bosnia76Оценок пока нет

- LC Primary Load Case NameДокумент8 страницLC Primary Load Case Nametrishia arcillaОценок пока нет

- 2013 07 27 Manapakkam House Vamsi WD 03 04 Terrace Floor PlanДокумент1 страница2013 07 27 Manapakkam House Vamsi WD 03 04 Terrace Floor PlanJuly RaviОценок пока нет

- Structural - LaneДокумент37 страницStructural - LaneAngel Lisette Lao100% (1)

- Thumb Rules For Designing A Column Layout WWW Uniquecivil CoДокумент9 страницThumb Rules For Designing A Column Layout WWW Uniquecivil CoRam KrishnaОценок пока нет

- S 1 Structural NotesДокумент1 страницаS 1 Structural NotesJBFPОценок пока нет

- Spreadsheets To BS 8110Документ11 страницSpreadsheets To BS 8110NitinShepurОценок пока нет

- Foundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Документ1 страницаFoundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Godino ChristianОценок пока нет

- FF GG HH II JJ EE: Key PlanДокумент1 страницаFF GG HH II JJ EE: Key PlanPraveen Varma VОценок пока нет

- Composite Slab Design 01of02Документ4 страницыComposite Slab Design 01of02EJ Dela CruzОценок пока нет

- Spreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Документ4 страницыSpreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3hala_azhariОценок пока нет

- Material Properties C28-35 & C32-40 (EC2)Документ4 страницыMaterial Properties C28-35 & C32-40 (EC2)a96lhfОценок пока нет

- Sonar Structural TrainingДокумент14 страницSonar Structural TrainingGiridhari ChandrabansiОценок пока нет

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreДокумент1 страницаLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenОценок пока нет

- General Specifications: I. Clearing and EarthworksДокумент4 страницыGeneral Specifications: I. Clearing and EarthworksFroilan AngbengcoОценок пока нет

- BT General NotesДокумент14 страницBT General NotesRufina Patricia MendozaОценок пока нет

- d8834-Ga-tk101 10-Sheet Tank Ga's (Signed)Документ7 страницd8834-Ga-tk101 10-Sheet Tank Ga's (Signed)Santheep KumarОценок пока нет

- General Notes & SpecificationsДокумент6 страницGeneral Notes & SpecificationsDon Santos100% (1)

- General NotesДокумент4 страницыGeneral Noteszamree BMОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Compilation 2010-s-6Документ1 страницаCompilation 2010-s-6api-271252079Оценок пока нет

- Compilation 2010-s-11Документ1 страницаCompilation 2010-s-11api-271252079Оценок пока нет

- Compilation 2010-s-10Документ1 страницаCompilation 2010-s-10api-271252079Оценок пока нет

- Compilation 2010-t-1Документ1 страницаCompilation 2010-t-1api-271252079Оценок пока нет

- Compilation 2010-s-9Документ1 страницаCompilation 2010-s-9api-271252079Оценок пока нет

- Compilation 2010-s-4Документ1 страницаCompilation 2010-s-4api-271252079Оценок пока нет

- Compilation 2010-s-7Документ1 страницаCompilation 2010-s-7api-271252079Оценок пока нет

- Compilation 2010-s-8Документ1 страницаCompilation 2010-s-8api-271252079Оценок пока нет

- Compilation 2010-s-5Документ1 страницаCompilation 2010-s-5api-271252079Оценок пока нет

- Compilation 2010-c-1Документ1 страницаCompilation 2010-c-1api-271252079Оценок пока нет

- Compilation 2010-s-3Документ1 страницаCompilation 2010-s-3api-271252079Оценок пока нет

- Compilation 2010-s-2Документ1 страницаCompilation 2010-s-2api-271252079Оценок пока нет

- Compilation 2010-s-1Документ1 страницаCompilation 2010-s-1api-271252079Оценок пока нет

- Compilation 2010-c-5Документ1 страницаCompilation 2010-c-5api-271252079Оценок пока нет

- Compilation 2010-c-3Документ1 страницаCompilation 2010-c-3api-271252079Оценок пока нет

- Compilation 2010-c-4Документ1 страницаCompilation 2010-c-4api-271252079Оценок пока нет

- Compilation 2010-c-2Документ1 страницаCompilation 2010-c-2api-271252079Оценок пока нет

- Compilation 2010-A-3Документ1 страницаCompilation 2010-A-3api-271252079Оценок пока нет

- Compilation 2010-A-10Документ1 страницаCompilation 2010-A-10api-271252079Оценок пока нет

- Compilation 2010-A-7Документ1 страницаCompilation 2010-A-7api-271252079Оценок пока нет

- Compilation 2010-A-8Документ1 страницаCompilation 2010-A-8api-271252079Оценок пока нет

- Compilation 2010-A-9Документ1 страницаCompilation 2010-A-9api-271252079Оценок пока нет

- Compilation 2010-A-4Документ1 страницаCompilation 2010-A-4api-271252079Оценок пока нет

- Compilation 2010-A-6Документ1 страницаCompilation 2010-A-6api-271252079Оценок пока нет

- Compilation 2010-A-2Документ1 страницаCompilation 2010-A-2api-271252079Оценок пока нет

- Compilation 2010-A-5Документ1 страницаCompilation 2010-A-5api-271252079Оценок пока нет

- Compilation 2010-A-1Документ1 страницаCompilation 2010-A-1api-271252079Оценок пока нет

- Design CriteriaДокумент5 страницDesign Criteriaapi-271252079Оценок пока нет

- P0562-Battery Voltage LowДокумент7 страницP0562-Battery Voltage Lowguillermoal539100% (1)

- Direct Stiffness Method for Truss AnalysisДокумент28 страницDirect Stiffness Method for Truss Analysisgilberthufana446877Оценок пока нет

- CV Software Engineer Sarika DhingraДокумент2 страницыCV Software Engineer Sarika DhingravirenderbishnoiОценок пока нет

- DIN EN 10213 - 2008 - Fundidos em AçoДокумент29 страницDIN EN 10213 - 2008 - Fundidos em AçoLeonardo MartinsОценок пока нет

- Hollow Metallic and Dielectric Wave-Guides For Long Distance Optical Transmission and LasersДокумент28 страницHollow Metallic and Dielectric Wave-Guides For Long Distance Optical Transmission and LasersClaudia Lopez ZubietaОценок пока нет

- Squeeze Cementing TechniquesДокумент22 страницыSqueeze Cementing TechniquesDoni KurniawanОценок пока нет

- DB2 WebSphere BestPracticeДокумент53 страницыDB2 WebSphere BestPracticeSpeedyKazamaОценок пока нет

- Astm-A707 CS As LTS PDFДокумент5 страницAstm-A707 CS As LTS PDFGoutam Kumar DebОценок пока нет

- Microwave Engineering - E-H Plane TeeДокумент6 страницMicrowave Engineering - E-H Plane TeeJoker FОценок пока нет

- Solar Desalination PlantДокумент28 страницSolar Desalination PlantAnonymous TETH310% (1)

- Thermit Australia Product Catalogue 2012Документ20 страницThermit Australia Product Catalogue 2012Rey Luis TehОценок пока нет

- Sustainable Transport Development in Nepal: Challenges and StrategiesДокумент18 страницSustainable Transport Development in Nepal: Challenges and StrategiesRamesh PokharelОценок пока нет

- Monopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariДокумент52 страницыMonopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariKristamRajuОценок пока нет

- LAP Register To WLCДокумент12 страницLAP Register To WLCAditya NugrahaОценок пока нет

- Thiourea PDFДокумент43 страницыThiourea PDFMohamad EshraОценок пока нет

- NHA 2430 Design Analysis Reporting FEAДокумент7 страницNHA 2430 Design Analysis Reporting FEAASIM RIAZОценок пока нет

- p6 ReportДокумент19 страницp6 ReportAnonymous yrcU1kОценок пока нет

- Ci-2001 Ab OmДокумент30 страницCi-2001 Ab OmEnrique FlowersОценок пока нет

- Hardness Vs TextureДокумент5 страницHardness Vs TextureShofa R HaqОценок пока нет

- Adf Interview Questions and AnsewrsДокумент85 страницAdf Interview Questions and Ansewrsleninbabus100% (2)

- Making Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyДокумент2 страницыMaking Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyCương Phạm NgọcОценок пока нет

- MWD Log Quality & StandardsДокумент168 страницMWD Log Quality & StandardsHamed Sadeghi100% (1)

- 02 - MEE10603 - Fourier Series and Power Computations in Nonsinusoidally Driven CircuitsДокумент33 страницы02 - MEE10603 - Fourier Series and Power Computations in Nonsinusoidally Driven CircuitsMohammad HayazieОценок пока нет

- Vol 4 Div G ODS Part 1 of 2-Pages-18-55Документ38 страницVol 4 Div G ODS Part 1 of 2-Pages-18-55debapriyoОценок пока нет

- Ficha Tecnica Komatsu 400 - 7Документ52 страницыFicha Tecnica Komatsu 400 - 7bariciado1Оценок пока нет

- Nabll Mix DesignДокумент29 страницNabll Mix DesignPIDCL WITH SUBUDHIОценок пока нет

- Thermal Arc 161 STL 201 Ts Inverter Welder SM PDFДокумент96 страницThermal Arc 161 STL 201 Ts Inverter Welder SM PDFduyОценок пока нет

- IEEE Modeling of Generator Controls For Coordinating Generator Relays Draft 4.0Документ65 страницIEEE Modeling of Generator Controls For Coordinating Generator Relays Draft 4.0Alex PAОценок пока нет

- 1 GPM V1 vacuum dehydrator removes water down to 20 PPMДокумент3 страницы1 GPM V1 vacuum dehydrator removes water down to 20 PPMLuis100% (1)