Академический Документы

Профессиональный Документы

Культура Документы

Sound Abs Barr

Загружено:

Rakesh0 оценок0% нашли этот документ полезным (0 голосов)

5 просмотров23 страницыsound absorbing barrier

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документsound absorbing barrier

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

5 просмотров23 страницыSound Abs Barr

Загружено:

Rakeshsound absorbing barrier

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 23

us United States

cz) Patent Application Publication co) Pub. No.: US 2013/0161126 Al

Wilson et al.

oy

0s)

03)

an

@2)

(86)

G0)

SOUND ABSORBENT BARRIER

irphy, Surrey (GB)

us

er Wilson, Berkshire (GB); Andrew

Assignee: ECHO BARRIER LIMITED,

Appl. No,

PCT Filed

PCT No.

$371 (ol),

(2),(4) Date: Feb, 28, 2013

Sep.

Cheam Surrey (GB)

137819,837

Sep.1,2011

PCTGB2011/001287

Forcign Application Priority Data

2010

(op)

10145597

2013

(43) Pub, Date Jun, 27, 2013

ication Classification

(1) Ince

OMB 184 2006.01)

@) v.

cee POdB 128409 (2013.01)

USPC 181/290

on ABSTRACT

A sound absorbeat barrier has a sound absorbent layer dis:

posed between a porous lst eover and a second cover The

barrier also hus a waterproof sound-permeable membrane

between the first cover and the sound absorbent layer. The

sound absorbent layer is thus protected from damage by the

frst and second covers and water ingress is provented by the

sound pemneable membrane. The second caver may be non-

ports fo reflect sound waves which have passed through the

Sound absorbent layer back through the sound absorbent

layer. Altomatively, the second eover may be porous to enable

absorption oF sous from Wo directions

US 2013/0161126 AI

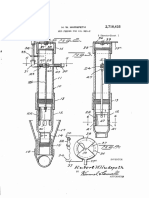

Jun. 27,2013 Sheet 1 of 17

Patent Application Publication

7

US 2013/0161126 AI

Jun. 27,2013 Sheet 2 of 17

Patent Application Publication

FIG. 2

Patent Application Publication Jun, 27,2013 Sheet 30f17 US 2013/0161126 Al

FIG. 3

Patent Application Publication Jun, 27,2013 Sheet 4 of 17

180

FIG. 4

\

US 2013/0161126 AI

30

170

130

120

ex

Lv

c—

Patent Application Publication Jun, 27,2013 Sheet Sof 17 US 2013/0161126 Al

+2120

US 2013/0161126 AI

Jun. 27,2013 Sheet 6 of 17

Patent Application Publication

9 Dla

Patent Application Publication Jun, 27,2013 Sheet 70f17 US 2013/0161126 Al

Patent Application Publication Jun, 27,2013 Sheet 8 of 17 US 2013/0161126 Al

30

40

Patent Application Publication Jun, 27,2013 Sheet 9 of 17 US 2013/0161126 Al

US 2013/0161126 AI

Jun. 27,2013 Sheet 13 of 17

Patent Application Publication

FIG. 13

Patent Application Publication Jun, 27,2013 Sheet 14 of 17 US 2013/0161126 A1

230

Patent Application Publication Jun, 27,2013 Sheet 1S of 17 US 2013/0161126 Al

Patent Application Publication Jun, 27,2013 Sheet 16 of 17 US 2013/0161126 Al

FIG. 16

Patent Application Publication Jun, 27,2013 Sheet 17 of 17 US 2013/0161126 Al

FIG. 17

US 2013/0161126 Al

SOUND ABSORBENT BARRIER

10001) The present invention relates to 9 flexible sound

absorbent hare. In particu, the preci ivention relates

to sound absorbent haner forthe aeoustie sreening ot con-

srtion sites and the like, The preseot invention is ely

applicable to other uses, for example at music concerts ot

sporting vents

{0002} Typical aoise harriers for such applications include

asolidmasshanierconsricted fom amtrial sich as ct

plod or arylic gins in ordeeo prevent the tassios

‘Of noise, These bari tend 0 rellet rar than absor®

Sound waves. Ths, theaveal level of noses ueneraly not

reduce. Infact, noise levels within the enclosure dened by

the barter may be inreasd by the presence of the barter.

{0003] _Attrmatively, nose bariers may include a sound

sbsorpton material t0 reduce the overall noise level. Typi-

cally sch barriers inelude rock woo! o fibre glass a the

Soundabsorbent. Although effective at sound absorption,

‘cautions mas be taken when handling these motels

they can be absorbed into the body by ination and can

inte the eyes skin and respiratory tract. Generally, this

{ype of sound absorption material encased between 160

solid layers of materia, for example PVC t prevent water

ingress and to prevent the escape of the sound absorbent

material However, by encasing the sound absorbent mistrial

in solid impenneable materials, the effectiveness ofthe ba

rier as a sound absorber is reduced because sound cannot

pone into the sound absorbent mater

{0008} Some acoustic barers are known which have an

Saproteted liver of acoustic absorbent material, However,

these soak up water fom the rain which eauses problems with

increased weal, leakage of water when the barers are

being trnsportedin vehicles o stored and wih the mtr

roting or going mou

10005} Some iid baries are known which nce thin

plastic ln a a skin over the absorbent material. However,

although the i is waterpoo it doesnot pass ar and here

Tore rellets a signiical proportion of te sound, reducing

the performance of the aduste absorbent materia,

{0006} Conventionally. sound ubsorben noise barriers are

folded ft for storage en transpor. Although thisredaces the

barser's size o 0 degre, such barr are sll unwieldy

‘overly flexible and difficult to manage

10007} Funke, conventional sound absorbent aries are

gery suspend fom suppoting site for example

Scaffolding or Heras fencing, by means of abi tes. Thus,

theirinsalation time-consuming and rirestie coopera.

tion oF atleast two persons. This ean bea siniiantdsad-

‘anlage, paricully ifthe barr are to be asl and

removed Within a shoe space o ine, fr example to sereen

the sound rom ray uiatenane card out overght

10008} According tothe present invention thereisprovided

alexible sound absorbent barrier comprising a ound-sbsor

bent layer disposed betwen fist porous sound-pemmeable

‘over and a second cover and a Waterpro sound permeable

textile membrane disposed betwesn the fist cover and the

sound absorbent ier

{0009} Withhis configuration the sound absorbent ayers

protected from damage bythe first and sosond covers and

‘voter ingress prevented Pathe, the porous first over and

Sound: permeahle membrane enable sound t penetrate othe

sound absorbent layer rater than ta he elected back othe

Jun. 27, 2013

{0010} Preferably, the sesond covers porous and sound

permcable. With this arangement, both sides ofthe sod

Sarier may provide sound absorption.

{0OIT]Alismatvey the secon eoveris non-porous. Cone

Sequel any sound which pases through the fst cover nd

the sound absorbent layer is reflected hack by the second

cover so that the soted passes though the sound absorbeat

layer foca second time. Thus the sound attenuation provided

by the Barer may be improved

{0012} Preferably, a second waterproof sound-permeable

textile membrane ix disposed between the second cover ad

te sound absorbent ayer. Ths, water ingress to the sound

absorbent later through the sacond cover aay be prevented

‘without significantly reducing the sound absorption charae-

testis ofthe barce

{0013} _ Preferably, the sound absorbent ayer comprises an

open cel foam

(0014) Preferably, the sound absorbeat layer comprises &

rofl surfice including a pura of ridges or protrusions,

{0015} Preferably, the sound absorbent barr is suc

ciently flexible for itt he roll-up.

[0016] Preferably. the sound absorbent barier further om

Pikes fastening cans o retin the sound absorbent baer in

roll-up state

(0017) ‘Thus, the size ofthe barrier may he ediced and its

strveturaliity may be increased when isnot in use. This

tis storage and transportation ofthe barrier. Further, asta

Javon ofthe baer may bemade easier since, onee hung fom

4 supposing stuctire twill aro wader is own Weight

‘whet the festening means is released

{0018} Preferably. he second covers formed fr PVC

{0019} A exible, non-porous third cover may be provide

Adjacent to the second cover. The thied cover may be formed

from PVC.

[0020] Proferaby, the sound absorbent barter further com

Prikes mounting device for banging the sound sbsorbeat

bearer rom a supporting strate

{002t] Preferably, the mounting device comprises hook

rember

{0022] Preferably, the mounting device furer comprises a

Carriero which the hook member is slidably connected sh

thatthe book member i slidable relative othe sound absor

bent bauer in direction substontilly perpendicular to a

plane of the sound absorbent Barer. The mounting device

‘may include @ detent means 10 resist sliding of the hook

‘memberandor wo divide the sliding displacement of thehook

‘mombr inta discrete increments.

[0023] Preferably, the hook menber comprises a est hook

{or haoging the border from supporting srictire ad

second nok fr hanging the are fom te hook member

[0024] Preferably, te fst and second hook members are

different sizes andre arrange such that they may belied

ove diferent size fence posts.

{0025} Preferably, the porous inner covers formed fom a

exible plastic materi.

[0026] Preferably, the waterproof sound-permeable mem

brane is foe from Gore-Tex® or equivalent materi

{0027} A prefered embodiment of the presen invention

Will now be described with eeference to the accompanying

drawings in which

(0028). FIG. isa front view ofa sound absorbent barierin

cconlance with fist embodiment ofthe present iventio

US 2013/0161126 Al

10029] FIG. 2s front view ofthe sound absorbent barrier

‘of PIG. 1 with the fistening means and mounting devices

removed far catty:

[0030] FIG. 3isa part sectional view ofthe sound absorbent

barrier of FIG.

10031] FIG. 4isa sectional view ofthe mounting devie of

the sound sbsorbeat barrier of FIG. 1;

[0032] FIG. Sisa front view of due mounting device of FIG.

4, with the majority ofthe carrer of the mounting device

removed for earty:

10033] FIG. 6s. atop view of the mounting device of FIG.

4

10034] _ FIG. 7a sido view ofthe sound absorbomtbaioe

‘oTFIG. 1, showing the sound absorbent barrier na roll-up

state:

[1035] 1G, 8s side view ofthe sound absorbent basiee

‘ofFIG. 1 showing the sound absorbet Barer hangig oa

‘supporting structure,

10036] FIG. 9 s from view ofa sound absorbent layer

having aided profile;

0037] FIG. 10s. par seetional view ofthe sound absor-

Beat Liye o FIG. 9

10038) FIG. 11 isa prt sectional view of an altemative

Sound absorbent baer n accordance with second embod

ment ofthe invention:

10039] FIG. 12 isa part sections view of an altemative

sound absorbent bari in accordance with a hid embodie

ment ofthe invention:

[0040] FIG. 13isa fom viewofthesoundabsorbent barrier

ofFIG. 12;

10041) FIG. 14 sa sectional view ofan ltemative mount-

ing device of the sound absorbent barrier of FIG.

[0042] FIG. 15 isa sectional view ofa futher altemative

‘mounting device forthe sound absorbent basrier of FIG. 1

10043] FIG. 16 isa sectional view ofa further altemative

‘mounting device forthe sud absorbent barrier of FIG. 1

10048) FIG. 17 isa sectional view ofa farther atemative

mounting device of the sound absorbent barrier of FIG. 1,

shovving the mounting device in frst coafiguration

10045] FIG. 18isa sectional view ofthe mounting deviceof

EIG. 15 ina second eontiguration

10045] It should be noted that the figures are illustrated

schematically for simplicity and are not necessarily drawn 10

scale,

10047] FIG. 1 shows a sound absorbent barrier 10 of the

present invention illistrating the main components of the

barriee 10, The barr 10 has a screen body 20 for absorbing

noise and mowing devices 30 for mounting the barier 10

‘onto a supporting structure (not shown), such as fencing oF

scaffolding. The barrier 10 also includes festening means 32

for securing the bacrier ina rolled-up state when its novia

[0048] _Inthis example, the fastening means 32 comprises 2

two-piece plasticelip witha female part 34 attached toa strap

‘stone end of the barrier 10 and male part ¥6 attached 0 a

adjustable strap which is fixed tothe barrier 10 towards the

‘opposite end of the barrier 10, Other festening means are

possible, for example a hook an loop fastener, or a buckle,

‘ete. The straps of the fastening means 32 may’ also act as 3

handle for eanying the barrier wine itis roll-up. With this

‘arrangement, the barrier 10 can he kept sceurely rolled-p

shen not in use, thus reducing the space require for storage

and improving the ease of handling. This of particular use

Jun. 27, 2013

‘when the barrier 10s to be mounted 16 stactre to which

secs Limited, such as scalfolding

{0049} As shown in FIGS. 2 and 3, the screen body 20

comprises exible etangulr panel of sound sbsorbeat

‘aterial 40 encased between fit cover 80 and a second

cover 60, The scree bay 2055 ypically 2.080 mm i length

by 1.300 mm in width, allbough these dimensions can be

changed to sit diferent applications.

[0050] In this example, the sound absorbent panel 40 is

formed from an opencell polyurethane foam, sbchas “Lame

hoo” although other types of sound absorption materia, or

Cxample a closed cel fom, sic as “Lamocell”, or equvae

ent ay be used. However, an open ell foan oft the

rctest sound absorption uate.

[0081] The frst cover $0 comprises a suitably durable yet

lightweight and flexible plastic sheet materi and is porous,

4 iL includes a plurality of apertures such tat sound waves

ray be more easly transmifedthrowgh the cover 80 and

‘edving the amount of sound which is reflected by the fst

over 80, Forexample, tay bes woven plastic shot with

loose, open weaveto provide porosity Ths, the ist cover 80

‘ay transmit the sound while forming a protective mesh over

{he sound absorbent panel 4. Preferably, te apetires othe

Jt cover 80 do not substantially exceed T mum in length or

width

{0082} ‘Thesecond cover 60s formes froma sutablethick-

ess of non-porous, exible and Waterpro shoct material

‘ich that i acts asa mass hair to prevent race the

‘eansmission ofsound nth example, the secondeover60is

formed from 900 gin® of PVC, altho a variety of ticks

esses oF material

preferably the second cover 60 is form! rom ne more than

1500 iar of PVC,

{0083} ‘The second cover 60 may also inchude one or more

Strips 62 of liahtefcetive material on its outer face, sich 28

Scotchlte to increase the visibility of the baer The

reflective sis 62 may be paced to target the headlights a

articular typeof vehicle. For example, a reflective stip 62

nay be placed a approximately 770 mm from the base ofthe

barer inorder to reflect the headlights of cars andor at

approximately 1300 mun rom te base ofthe Darin onder

to rolet the headlights of heavy goods vehicles.

[0054] The body 20 also comprises a waterpoot but a

permeable and. sound-pereable. membrane 70 sits

between the first cover 80 and the sound absorbent pane

Themembrane 7 enables the tansmissionof sound waves 0

{he sound absorbent pane] 40 yet prevents water ingress. This

‘may be of panicular benefit the sound absorbent panel 40s

Iydrophile sine water absorption may lessen the eectve-

ness ofthe panel 40 as. ascend absorber and case the batier

1010 become very heavy and cific to handle. The men

brane 70s formed fom asuitable thickness of watepmoo fair

axl sound permeable textile material. In ths example, the

‘embrane 1s formed fom between approximately 10/5

‘xd 100 gi of Gore-Tex o equivalent materi

{008} ‘The fist cover 8, sseond cover 60 and membrane

“Ware oversid and ited together sing thread 80. web-

bing 90 may also be positions! around the edges ofthe body

2040 further strengthen the barre 10. second ro of thread

100 may be stitched through the covers 0,60 and the mem

brane 7010 keep the panel 4 in a speci loaton, such as

aligned inthe entra the screen body 20, a show FIG

2

US 2013/0161126 Al

10086] The barrier 10 includes a number of eyelets 110

round the periphery of the screen 20. These eyeletsallow the

barrier 1010 be fixed to Fencing, scaffolding or other support-

ing structures, oto adjacent barriers 10, The barier 10 may

be fixed by hooks, cable tes, or other fixing mechanisms.

Preferably, the barrier 10 is fixed using mounting devices 30

as discussed below. Typically, the eyelets are 25 mm in diam=

‘ter. This size is sufficiently Inmge to aid the fxing of the

barrier 10 to the supporting structure, orto enable adjacent

barriers 10 to be more easily aligned and fixed together. The

barrier 10 may'have one or more rows of atleast two evelets

110 to enable the relative positon and overlap of adjacent

barriers 10 tobe adjusted,

[0057] FIGS, 4nd showa mounting device 30connected

to the screen body 20, The motinting device 30 comprises 2

‘carrier 120 and a hook member 130. The carrier 120 may be

formed from a plastic, or other suitable material, such as a

material or stool and has substantially U-shaped

ton to ft over the top edge ofthe burier 10, The

‘cartier 120 may be fixed othe body 20viaa fixing means 140,

Which is connected to the earvier 120 and may pass though

‘oncof the eyelets 10 of the barrier 10, The fixing means 140

may comprise 0 lip or a nut and bolt arrangement, for

‘example, With this arrangement, the mounting device 30 can,

be easily fixed to or removed from the sereen body 20 as

required.

[0058] The hook member 130 js formed from a suitable

thickness of deformable material, sich as stel, plastic, oF

‘composite material, such that the hook member 130 will,

‘deform if tralden on or driven over, rather than breaking oF

snapping, Further, the Nexibility ofthe barrier 10 allows the

‘mounting device 30 to move thus reducing the likelibood of

‘damage tothe mounting device 30 This prevents the mount-

Jing device 30 from presenting a sharp edgeby which a worker

ray be injured, or equipment may be damaged and prevents

damage to the barier 10 itself. The hook member 130)

lnchides top section 150 and at least one side ann section

160 projecting downwards from the top section 180,

[0089] The top section 150 of the hook member 130 is

supported within an aperture 170 of the easier 120 such that

the hook member 180 is slidable relative tothe eater 120 in

4 direction substantially perpendicular to the plane of the

screen 20, With this artangement, the distance between the

fide arm section 160 ofthe book member 130 and the carrier

120 may be varied to accommodate various sizes of support-

ing structure. The relative movement of the carrer 120 and

the hook member 130 isilustated in FIG. 6, shich shows the

hook member in fist position Pl and w second position P2

[0060] As analtematve to the single-sided hook arrange-

meat, the hook member 130 may be double-sided, ie. it may

have two side arm sections 160, as shown in FIG. 4, This

allows the barrier 10 to be installed on either side of the

supporting structure A.

[0061] The cartier 120 and the hook member 130 may be

fied with a detent means (aot shown) to resist the sliding

slisplacement othe hook member andor divide the dsplace-

‘ment ofthe hook meanber 130 ino discrete increments, This

‘vill enable the mounting device 30 to clamp the supporting

Structure A thus fixing the barier 10 more securely.

[0062] | Withreference PIGS. 7and 8, method ofinstall-

ing the barier 10 wil be describe.

10063] |The barrier 10 is held by a user and caried to the

desire location whilst ina roll-up state, as show in FIG.

7. The hook member 190 of each mounting device 30 oF the

Jun. 27, 2013

buarier 10 is placed over the supporting siete AI the

barrier 10s o beng inside the strctre A, for example

inside the boundary fence of conseuction site, the hook

members 130 ofthe mounting devies 40 should be located

Gthe ease ofa single-sided hook rangement or extended

(athe ease of a double-sided hook arangement) onthe side

ofthe baer 10 conespondig tothe send eave 60.Con-

‘orc, fhe barrier 105 be hung outside the sopping

Strut A, for example on the extemal side of scalolsing,

{he hook members 130 shouldbe located or extended onthe

side the barrier 10 comexponding tthe fist cover 50 This

sures that he fist over 80 faves the soure of the noi

{0058} Once positioned over the supporting stirs A

cach hook member 130 can then be aljsted sch that it

lamp the sipporting sic A. The fastening mans 328

then released sch that the barter 10 unfurl in dietion B

tuner its own weight to the position shown in FIG. 8

{0065} "Similarly, funherbaners LO canbe istalles onthe

supponing sructure A sh that adjacent bares 10 overlap

to provide a continases layer of noise protection. Adjacat

‘atiers canbe fixe to one another ether by aligning the

cysts 110 and employing sfavening device such a a cable

tie through the eyelets 10, ory oer means such a Vler>

ean

[0066] Once the barr 10 is installed atthe desire Toea-

‘ion with the fist cover 80 fcing the soise sour, sound

‘waves passthrough the eepiormeshor be fist cover and

‘ue absorbed by the sound absorbent pael 40 wich disse

ates a proportion ofthe energy ofthe indent sound waves

2s heat A proportion of the remaining sound waves are

reflected bythe second cover 6 beck into the sound abso

bent pane, ths enhancing th noise absorption

{0067} If greater noise atemuation i equired or insane

in close proximity to @ pariculary loud source of mois,

_nuliplelavers of barrens 10 an be hung fom the sopping

structs A In order todo 20, the hook members 130 of

Second, or further, barier 10 may be extended 10a greater

dlgre than those ofthe fit baer 10 so that they my slso

fitoverthe supporting stcture A. Alteratvely. ia double-

sided hook arrangement is employed further barr may Be

installed onthe reverse side othe fence or seffolding

{0068} With reference 9 FIGS, 9 and 10, a altmative

Sound absorbent layer 4 i shown, Rater than presenting a

fat surface tothe noise source the sound absorbent layer 40

nay have a profiled suefice, For example, the sound absor

tetlayer 40 may havea plurality of ridges 180 or protrusions

extending aerost the wih othe panel 40 inorder t increase

the surlace ara ofthe sound absorber 40 ano change the

abscebig characteristics Such ridges 180 also clita the

any roling of the barr 10, The ridges 180 may have a

‘eure asshownby the ridges 182 alongthe mide of

TIG. 10, oran treular roi, fr example beng formed as

plurality of egg box-shaped protons, oras shown by the

ridges 184 the top and bortom of FIG. 10

{0069} "FIG. 11 shows a second embodiment of sound bar-

ee 1. As with previously desribed barrier 10, the soreen

body 20'of he soi harser 17 compiaes a Nexble panclo

soundabsorbent material eneasedbereenafisteaver 0

dnd second cover 60

{0070 Inthis configuration, both te fist over $0 andthe

second cover 60” comprise suitably durable ye lightweight

tnd exible plastic sheet material whichis porbus ie. it

Jncludess phimlity of aperture. A wateqnoot hat

able and sound-permeable membrane 70" situated on each

US 2013/0161126 Al

side of the sound absorbent panel 401. Thus, the frst and

second covers 80" and 60 form a sound-permeable protective

mesh over the sound absorbent panel 40” and the membranes

70), while the membranes 70° prevent water ingsess. This

‘configuration enables both face’ ofthe sound barrier 107 to

‘absorb sound elletively

0071)

‘The harrier 10 may also include an impermeable

ng the top or other edges ofthe barrier to

Iherproofing and a surlace for printing.

FIGS. 12 and 13 show a third embodiment of sound

Tn this example, the sereen body’ 20" shown in

(0072)

bareioe 10"

FIG. 11 may be attache to a exible, waterproof non-porous

layer 65, for example a PVC layer, whieh is hung From @

supporting stricture (aot shown) using eyelets 110. The non-

porous layer 68 aes asa mass layer, ie it restricts the trans-

‘mission of sound through the barrier 10", With the addition of

the non-porous layer mass layer 6, sound which bas passed

through the sereen20'is reflected back through the sergen 20°

by the non-porous layer 68, Thus, the arrangement may pro-

vide improved sound absorption in addition to reduces sound

transmission. The non-porous layer 65 and the sereen may be

‘coextensive with the sercen 20 and both bung frm the sup=

Porting structure using, as shown in FIG. 12. Alternatively, as

shown in FIG. 13, the non-porous layer may be hung from a

supporting structure andthe sereen 20' attached to the non-

porous layer 68 using known technigues, such as Velero®,

ties, poppers, andior clips (not shown). With the later

‘arrangement, the non-porous layer 65 can be sized to fit the

requirements ofa given installation,

10073] Iwill be appreciated that the mounting device 30

‘wih Hooks 130, and the Listening means 32 for securing the

barriers 10 in a rolled upstate are features which could be

applied (ogether or separately) to different types of barriers,

sich as sound absorbing barriers which do not include @

‘waterproof sound permeable layer, or bartiers used for other

purposes such as visual screening

10074] FIG. 14 shows an alternative configuration of

‘motining device 230 connected to the sereen body 20. The

‘mounting device 230 is substantially the same as mounting

device 130, However, instead of fixing the book member by

means of a carrier, the fixing means 240 of the mounting

‘device 230 secures thehook member 235 directly othe eyelet

210 f the barrier 10, Alternatively, the fixing means fixes the

hook member 238 toa hole through the barrier 10, ifno eyelet

provided. In ether case, the hook member 238 isnot slid-

able relative to the harrier asin the first embodiment, but is

slidably fixed relative to the barrier.

10075] As shown in FIG. 14, one of the side arm seetions

260may be bent, fabricated, or moulded such that itis angled

back towards the barrier 10 to suspend the barrier 10 more

securely.

10076] FIG. 15 shows a furher alternative configuration of

‘mounting device 330. The mounting device 330 comprises &

hook member 338, which includes rounded, frst se arm

section 360 Tor placing ver the lop ofa supporting structure

‘Nanda second side arm section 365, atthe end of which is a

barrier hook section 380 facing inwardly, i. toward the frst

side arm section 360. The hook section 380 is passed through

the eyelet 310 of te bavier 10, or simpy through olen the

barrier 10; to suspendithebarriec 10 fromthe mounting device

330.

10077] _Altemtively, as shown in FIG. 16, the barter hook

section 380 ofthe mounting device 3M may be configu to

Jace outwardly, ie- away from the fist side arm section 360.

Jun. 27, 2013

‘With this configuration, the barrier 10 may be easily placed

‘over, or removed om, the harrier hook section 380" while the

‘mounting device 330" remains in place over the supporting

structure A.

[0078] FIGS. 17 and 18 show a further configuration of

‘mounting device 480, The mounting device 430 comprises a

resilient and substantially S-shaped hook member 435 having

fist and second hook sections 460, 465, The dimensions of

the frst and second hook sections 460, 465 may be diferent

and selected such that they clip over diferent diameter fence

tubes B and C. For example, inthe UK constuction industry

the fence tubes rypeally used are approximately 40 mm and

135 mm in diameter, respectively. Tas, if fist hook section

46a a diameter of slighty ess than 40 mm and the second

hook section 465 has a diameter of slightly less than 3§ mim,

the slightly resilient hook member 435 will beheld in tension

and will grip t the fence post Bor

[0079] The open ends 490, 49S of each hook section 460,

465 may be narower than the diameter ofthe respective tbe

BorC, asshovin in FIGS, 17 and 18, to providea more secure

clipping of the hook member 435 to ne fence tube B oF C.

[0080] In use, one or more hook members 438 are

vera fence tube B or C, using ether first or second hook

scction 460,465, The selection of first or second hook section

4460, 465 will depend on the diameter of fence tube from

the barrier 10 is to be suspended. The sereen 20 is then

hooked over the hook section which isnot clipped over the

ence tube. By way of example, FIG. 18 shows the first hook

soction 460 clipped over fence tube Band the sereen 20 hung

Irom the second hook section 465

[0081] Thus, the present invention provides a sound absor=

‘bent barrier tht is highly flexible and waterproof without

compromising the seoustic absorption properties af the

absorbent material. The flexibility allows the barrier to be

‘conformed to suit the supporting structure, typically fencing

or scaffolding, and to be rolled or folded for transport or

storage,

1. exible sound absorbent barrier comprising:

sound absorbent layer disposed between a first porous

Sounw-permeable cover anda second cover; and

‘waterproof sound-permeable textile membrane disposed

‘between the fist cover and the sound absorbent layer.

2. Alexible sound absorbent barrier acoording to claim 1,

‘wherein the second cover is porous and sound-permeable

3. flexible sound absorbent barrier according to claim 1,

‘wherein the second cover is non-porous

4.A flexible sound absorbent barrier according to claim 1,

wherein a second waterproof sound-permeable textile mem

brane is disposed between the second cover and the sound

sahsorbent ler.

5. A flexible sound absorbent barrier as claimed in claim 1,

wherein the sound absorbeat layer comprises aa open cell

foam:

6. flexible sound absorbent harrier as claimed in claim

‘wherein the sound absorbent layer comprises profiled sur

{ice including a purity of ridges or protrusions,

7.A flexible sound absorbeat hartier as claimed in claim I

‘wherein the sound absorbent barriers sufficiently exible for

ito be rolled,

8.A flexible sound absorbent barrier as claimed inclaim 7,

wherein the sound absorhent barrier further comprises fas.

‘ening means to retain the sound absorbent barrier in arolled-

upstate

US 2013/0161126 Al

9. flexible sound absorbeat barrie ax claimed inclim 3,

wherein the second cover i formed from PV

10.A flexible sound absorbent barieraecording claim 2,

wherein a exible, non-porous tind cover is provided adjan

‘cent 10 the second caver,

11. A flexible sound absorbent harrier according wo elim

10, wherein the third cover is formed from PVC.

12. A flexible sound absorbent hartir as claimed in elim

1, wherein the sound absorbent barter Further comprises @

mounting device for hanging the sound absorbent barrier

rom a supporting siructure

13. flexible souad absorbeat bartir as claimed in elim

12, wherein the mounting device comprises a hook member

14. flexible sound absorbeat barier as claimed in claim

13, wherein the mounting device further comprises a carrier

to which thehook member is slidably connected such thatthe

hook member is slidable relative to the sound absorbent bar

Fier in adireetion substantially perpendicular a plane ofthe

sound absorbent barrie.

15. A flexible sound absorbeat harrier as claimed in elim

14, wherein the mounting deviee comprises detent means to

resist sliding ofthe hook member.

Jun. 27, 2013

16. flexible sound absorbent barter as eaimed in chi

14, wherein the mounting device comprises detent means 10

divide the sliding displacement of the hook member into

‘serte increments

17. flexible sound absorbent barier according to claim

13, wherein the hook member comprises a frst hook for

hanging the barrier from a supporting structure anda second

book for hanging the barrie from the hook member

18, flexible sound absorbent barier according to claim

17, wherein the first and second hook members ae different

19. A sound absorbent barrier as claimed in claim 1

‘wherein the first cover is formed froma flexible plastie mate-

Fil.

20, A sound absorbent barrier as claimed in claim 1,

‘wherein the waterproof sound-permeable membrane is

ormed from Gore-Tex or equivalent material

21. (canceled)

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Fountain Pen PatentДокумент3 страницыFountain Pen PatentRakeshОценок пока нет

- Cooler Warm SeasonДокумент13 страницCooler Warm SeasonRakeshОценок пока нет

- Rechargable Cigrett LighterДокумент6 страницRechargable Cigrett LighterRakeshОценок пока нет

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LДокумент4 страницыSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshОценок пока нет

- Pen HolderДокумент8 страницPen HolderRakeshОценок пока нет

- Dynamic KeysДокумент46 страницDynamic KeysRakeshОценок пока нет

- Ornamenting A PaperДокумент2 страницыOrnamenting A PaperRakeshОценок пока нет

- Process For Surface Sizing PaperДокумент7 страницProcess For Surface Sizing PaperRakeshОценок пока нет

- Testing-Paper and Method of Making SameДокумент2 страницыTesting-Paper and Method of Making SameRakeshОценок пока нет

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterДокумент3 страницыLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshОценок пока нет

- Cigar Holding ApparatusДокумент1 страницаCigar Holding ApparatusRakeshОценок пока нет

- Hybrid Topcoat Formulations For PaperДокумент11 страницHybrid Topcoat Formulations For PaperRakeshОценок пока нет

- Froth Flotation Deinking Process For PaperДокумент16 страницFroth Flotation Deinking Process For PaperRakeshОценок пока нет

- Comb FilterДокумент5 страницComb FilterRakeshОценок пока нет

- KniДокумент5 страницKniRakeshОценок пока нет

- Toothbrush HolderДокумент7 страницToothbrush HolderRakeshОценок пока нет

- PencilДокумент1 страницаPencilRakeshОценок пока нет

- Solar PlantДокумент12 страницSolar PlantRakeshОценок пока нет

- Vernier DesignДокумент9 страницVernier DesignRakeshОценок пока нет

- CalДокумент48 страницCalRakeshОценок пока нет

- MicДокумент7 страницMicRakeshОценок пока нет

- Sol LampДокумент6 страницSol LampRakeshОценок пока нет

- Solar PlantДокумент12 страницSolar PlantRakeshОценок пока нет

- Pocket Lighter Patent from 1936 Describes Zippo DesignДокумент3 страницыPocket Lighter Patent from 1936 Describes Zippo DesignRakeshОценок пока нет

- Buddhism VolДокумент36 страницBuddhism VolRakesh100% (1)

- Sol ShieldДокумент9 страницSol ShieldRakeshОценок пока нет

- Sol StovДокумент11 страницSol StovRakeshОценок пока нет

- Solar HarnДокумент11 страницSolar HarnRakeshОценок пока нет

- Interconnected Solar CellsДокумент13 страницInterconnected Solar CellsRakeshОценок пока нет